System and method for automatically arranging production plan

A technology of production planning and scheduling, applied in the direction of calculation, instrumentation, data processing applications, etc., can solve problems affecting order delivery, conflicts, etc., and achieve the effect of improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

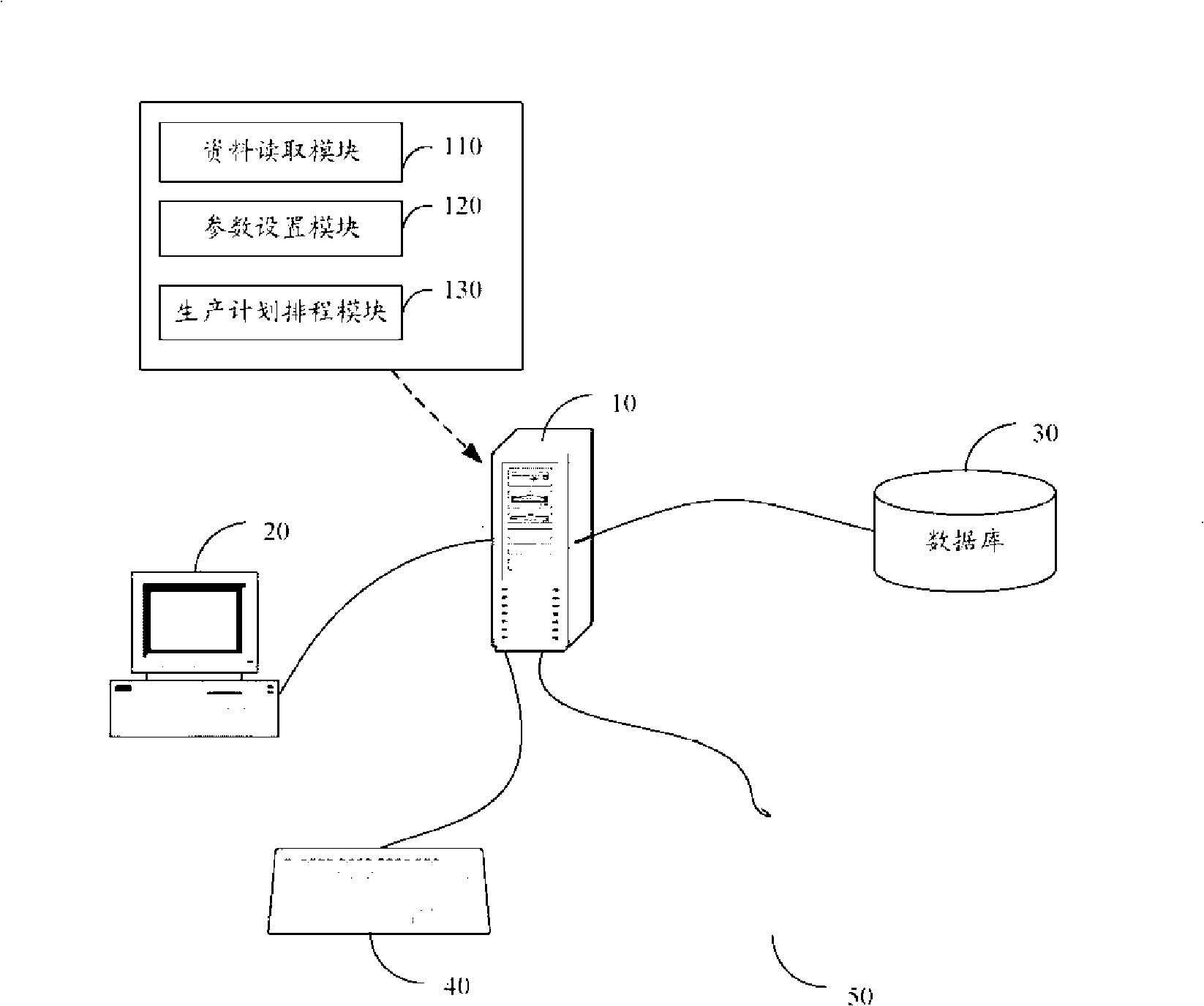

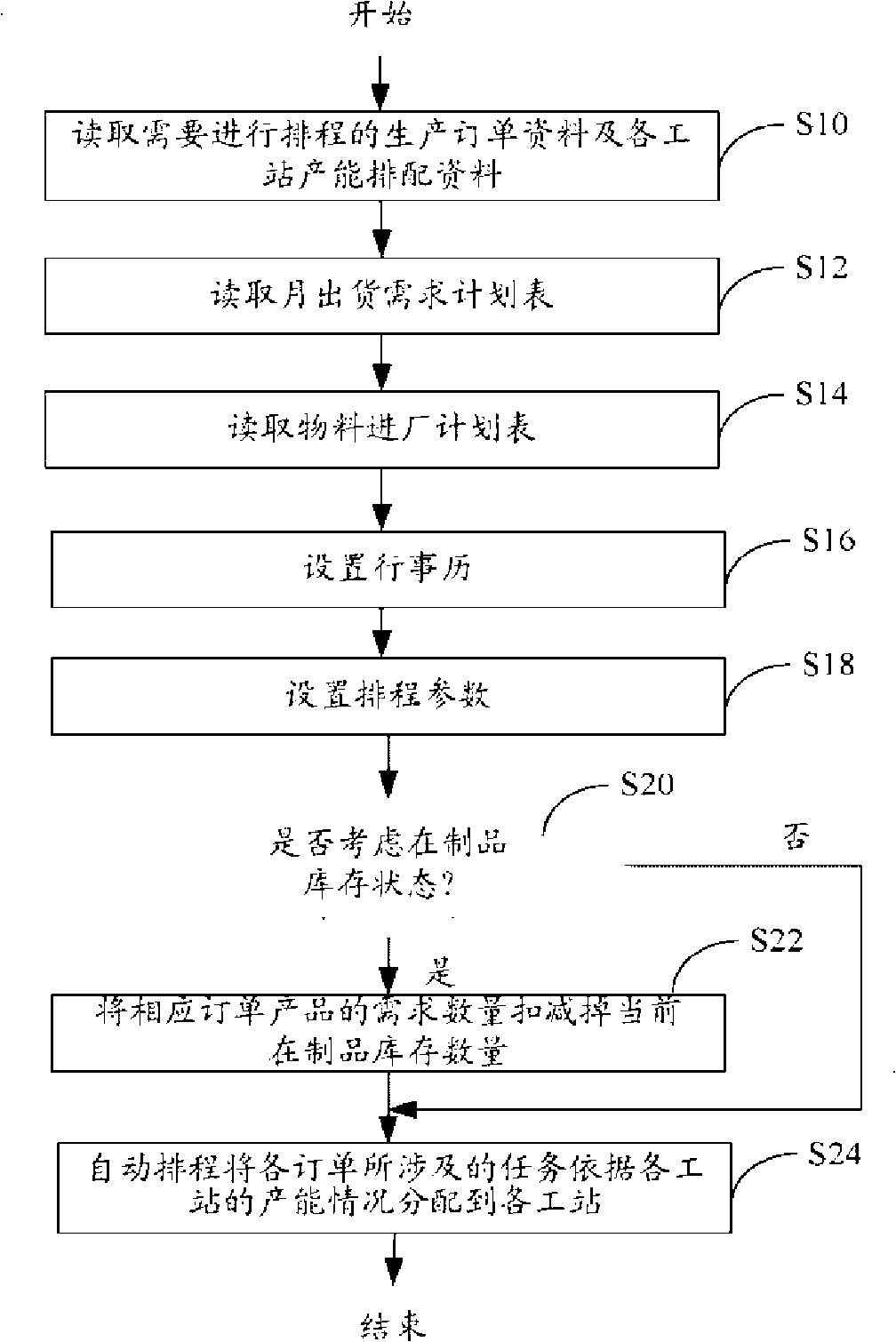

[0012] figure 1 It is a hardware architecture diagram of a preferred embodiment of the production planning automatic scheduling system of the present invention. The system mainly includes a host 10 and a database 30 connected to the host 10 .

[0013] The database 30 stores information such as order data, work in process (WIP) that has already been put into production, production capacity allocation of each station on the production line, monthly shipment demand schedule, and material incoming schedule. Among them, the order information includes the delivery date of each order, the customer, the type of goods ordered, the quantity required by the order, the tasks involved in completing an order (feeding, cutting, adhesive bonding, ... assembly, warehousing), various Information such as the workstations that the task needs to pass through, the order in which the tasks pass through the workstations, etc. Capacity refers to the quantity of products that a production equipment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com