Patents

Literature

53 results about "Material requirements planning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

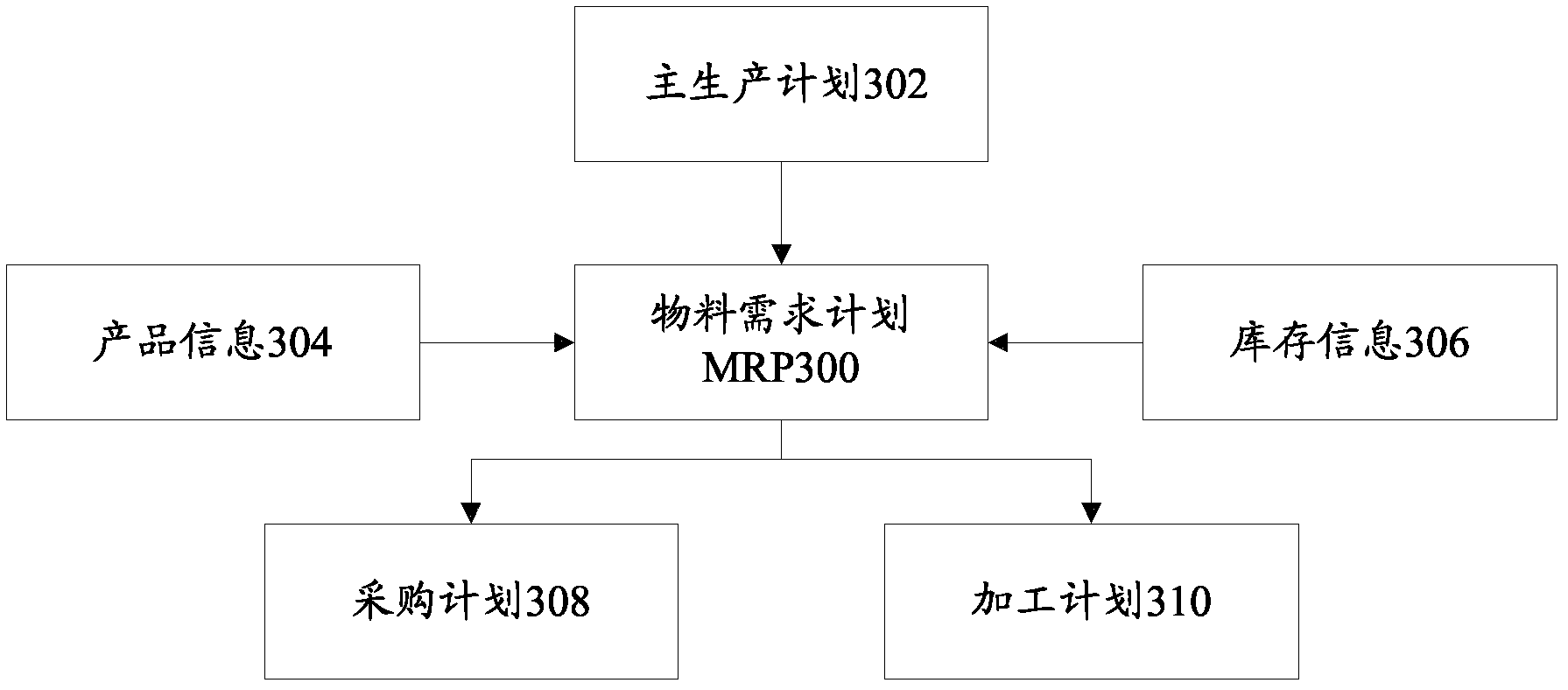

Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

Method to provide common support for multiple types of solvers for matching assets with demand in microelectronics manufacturing

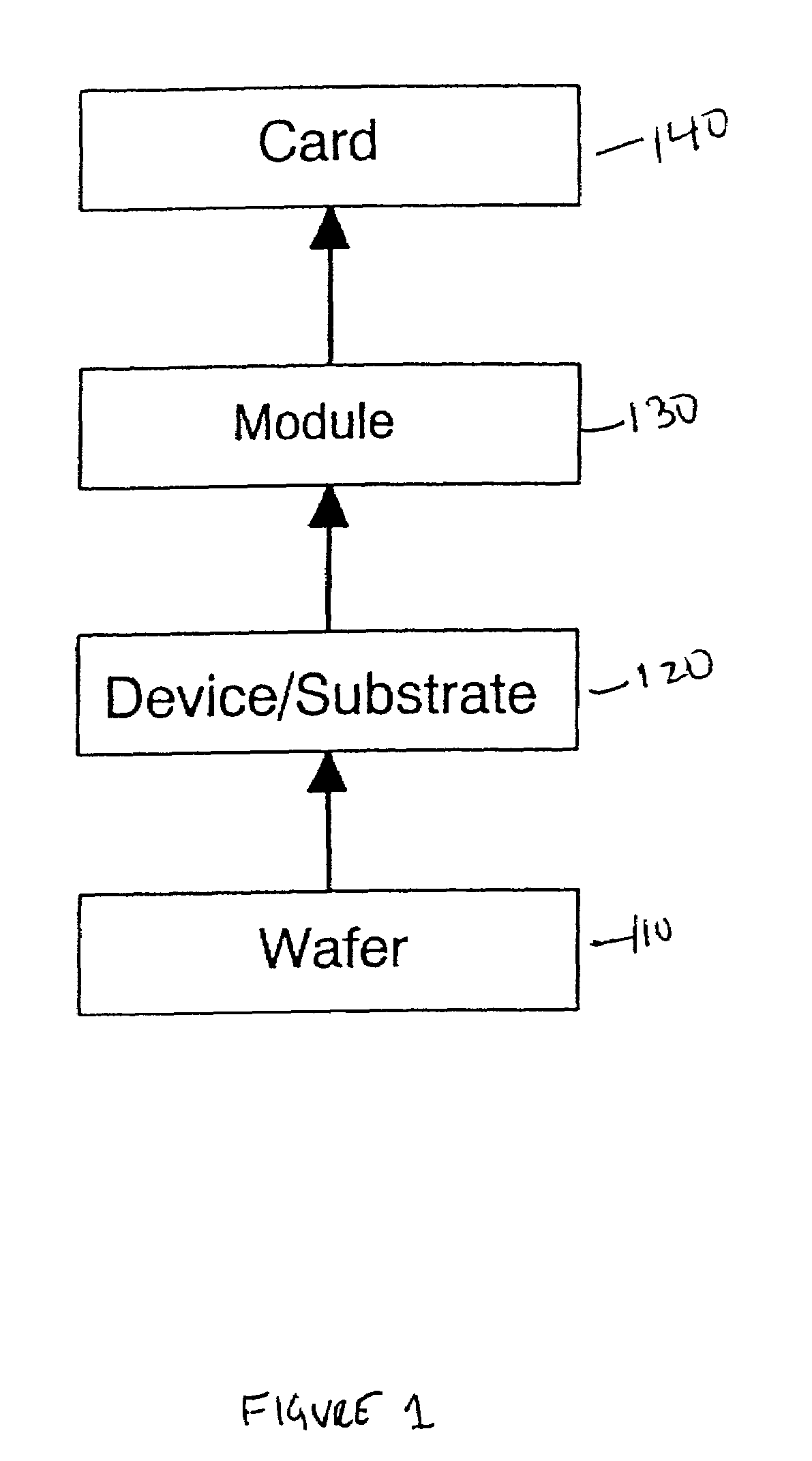

InactiveUS6041267ATotal factory controlSpecial data processing applicationsWorking environmentMaterial requirements planning

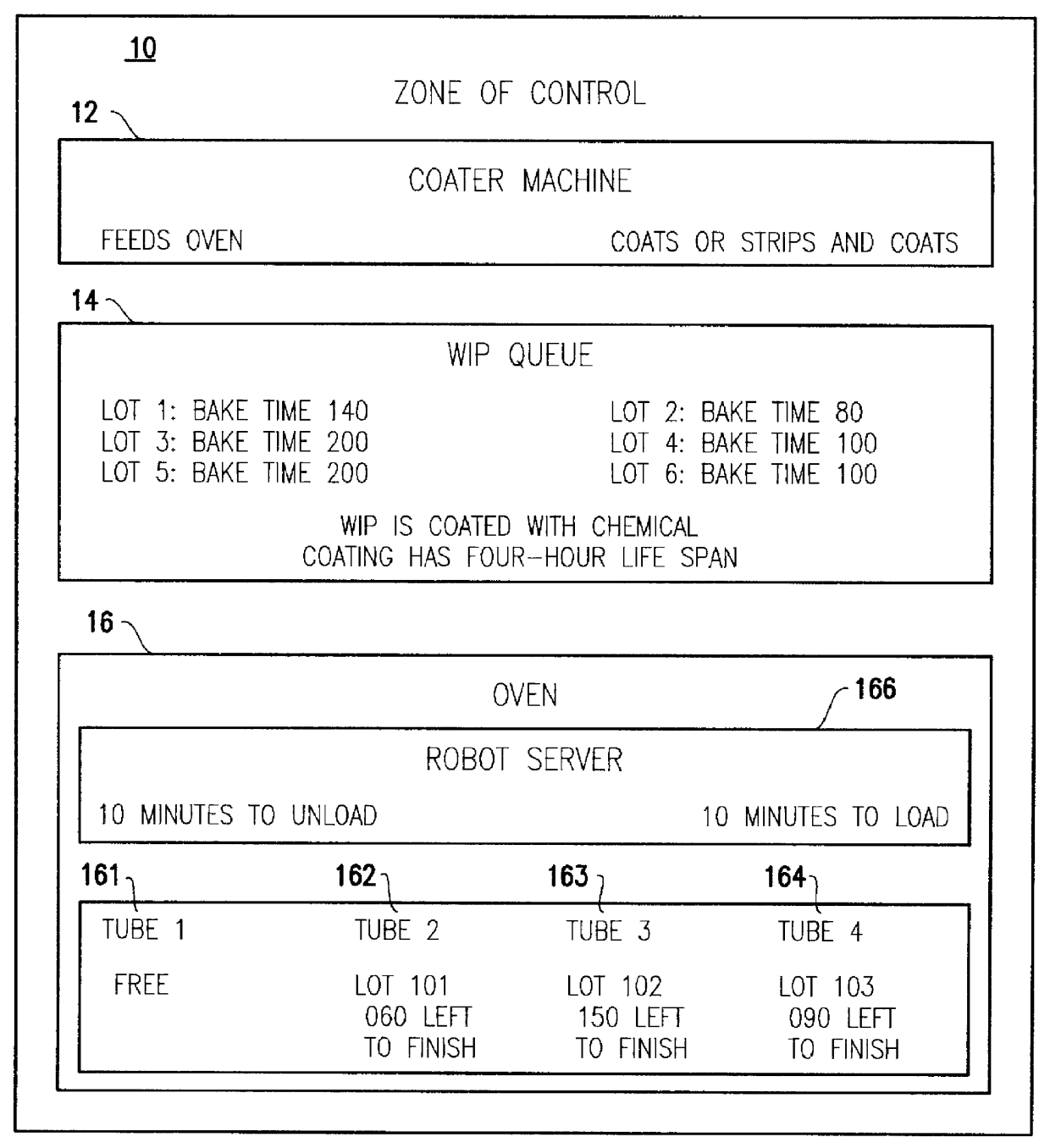

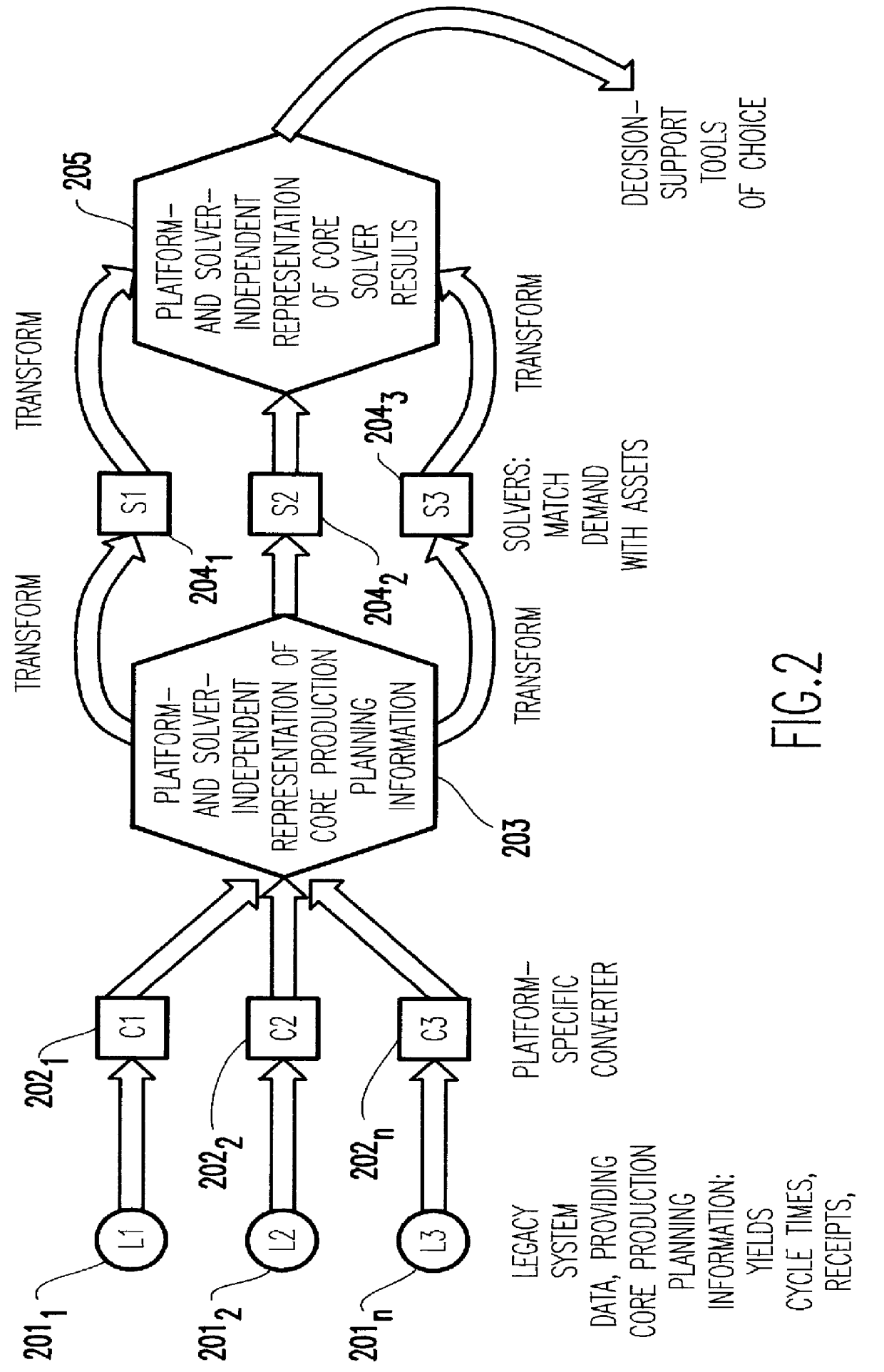

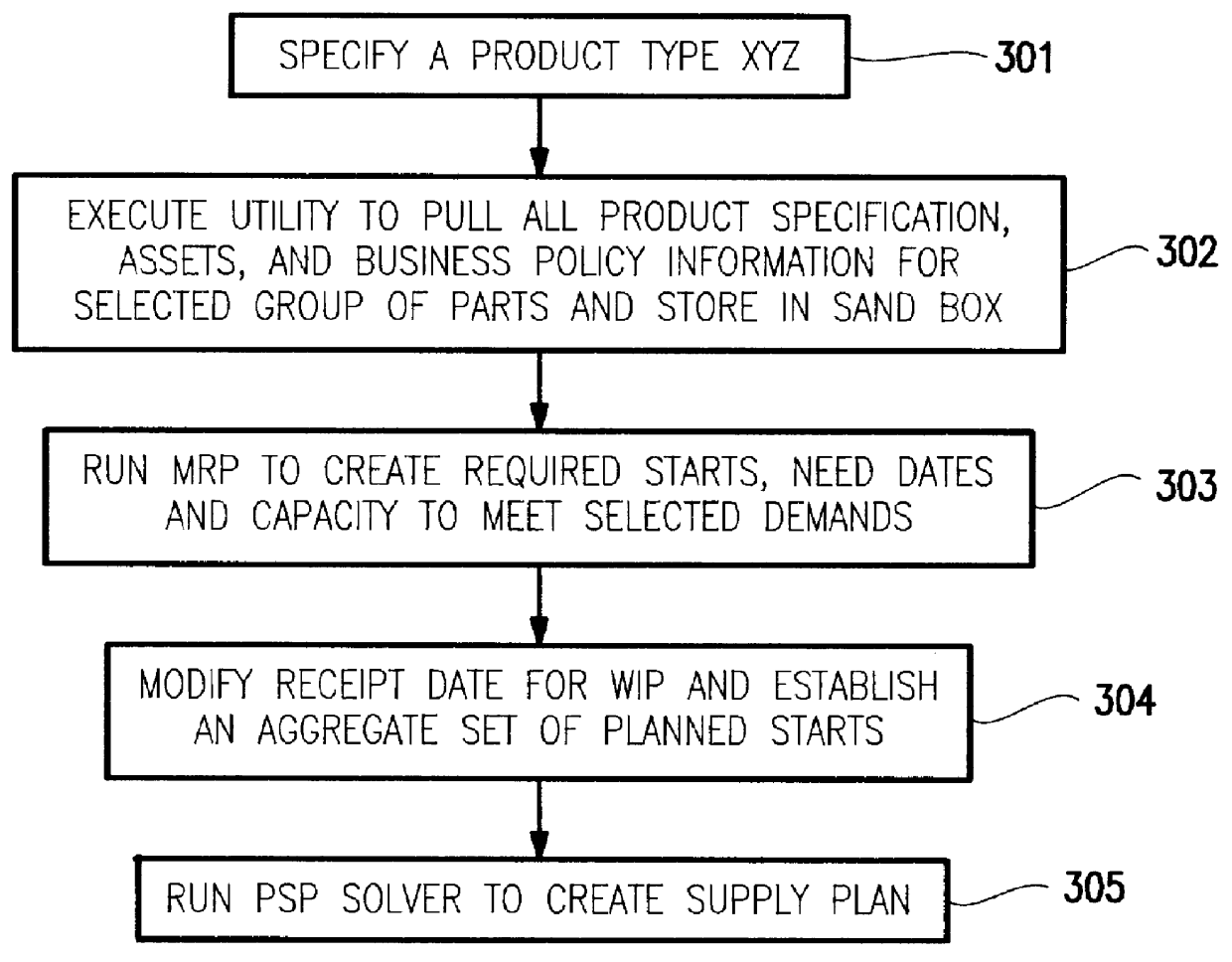

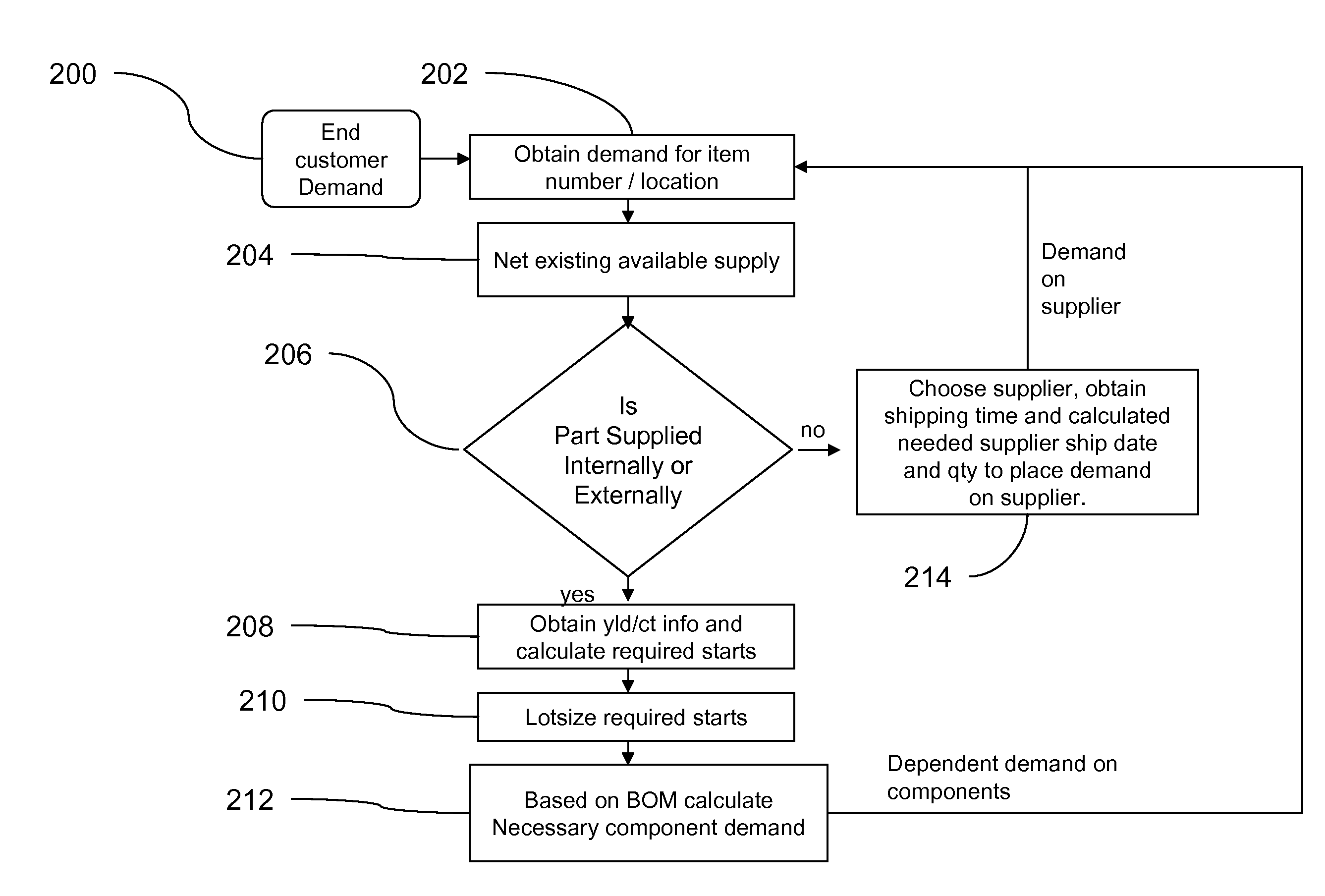

A computer implemented decision support tool serves as a vehicle to enable a user to execute within a common work environment, from common production information files, and at the discretion of the user one of three types of matching between existing assets and demands across multiple manufacturing facilities within boundaries established by manufacturing specifications and process flows and business policies. The tool provides an environment which permits the user to easily gain the advantages of a synergistic relationship between the three types of matching. The tool directly supports three types of matching: (1) material requirements planning (MRP) type of matching, (2) best can do (BCD) type of matching, and (3) projected supply planning (PSP) type of matching.

Owner:IBM CORP

Method for allocating limited component supply and capacity to optimize production scheduling

ActiveUS7197469B2Efficient rateTechnology managementMultiprogramming arrangementsMaterial requirements planningLimited component

Owner:RAKUTEN GRP INC

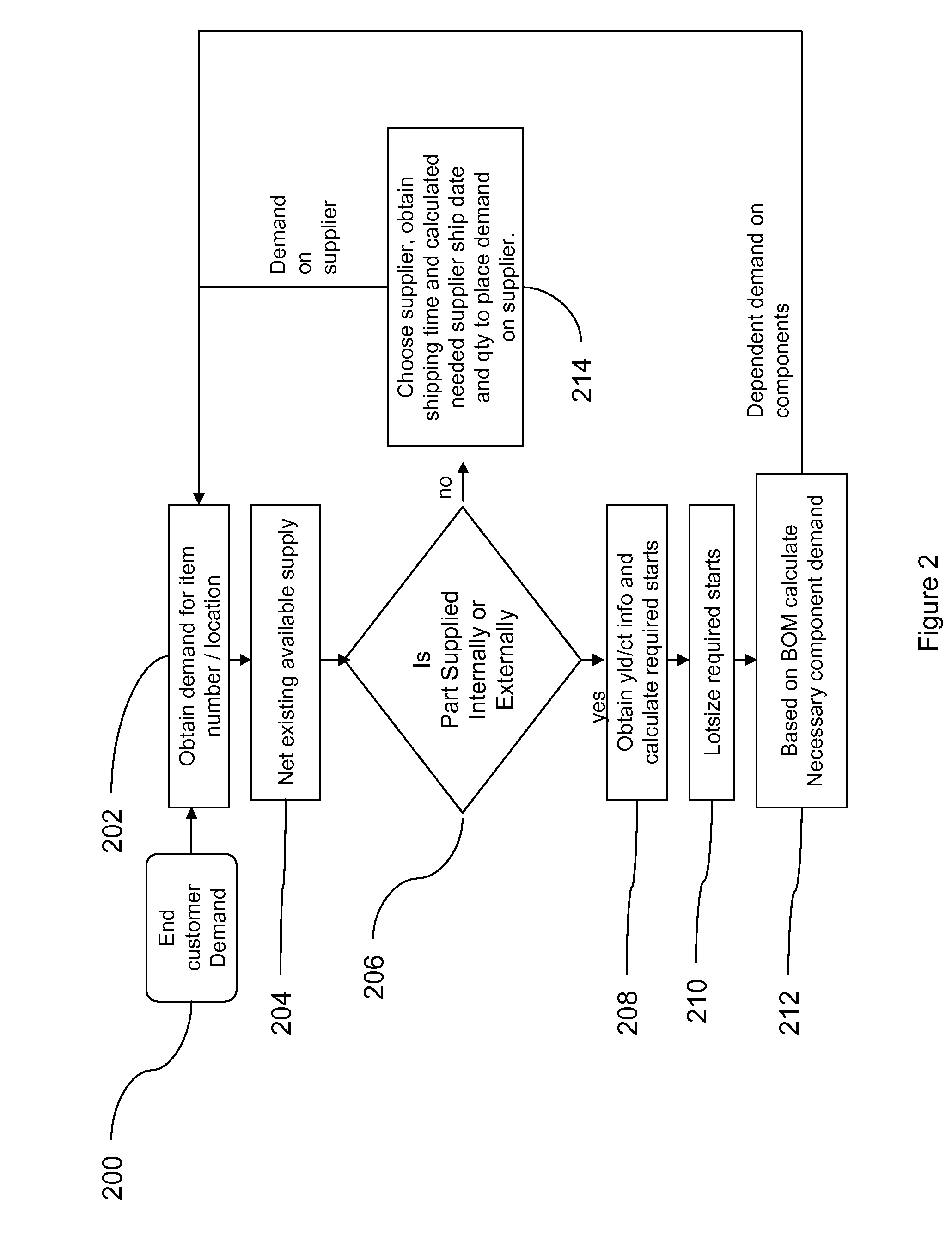

Method for allocating limited component supply and capacity to optimize production scheduling

ActiveUS20020198757A1Technology managementResourcesProduction planningMaterial requirements planning

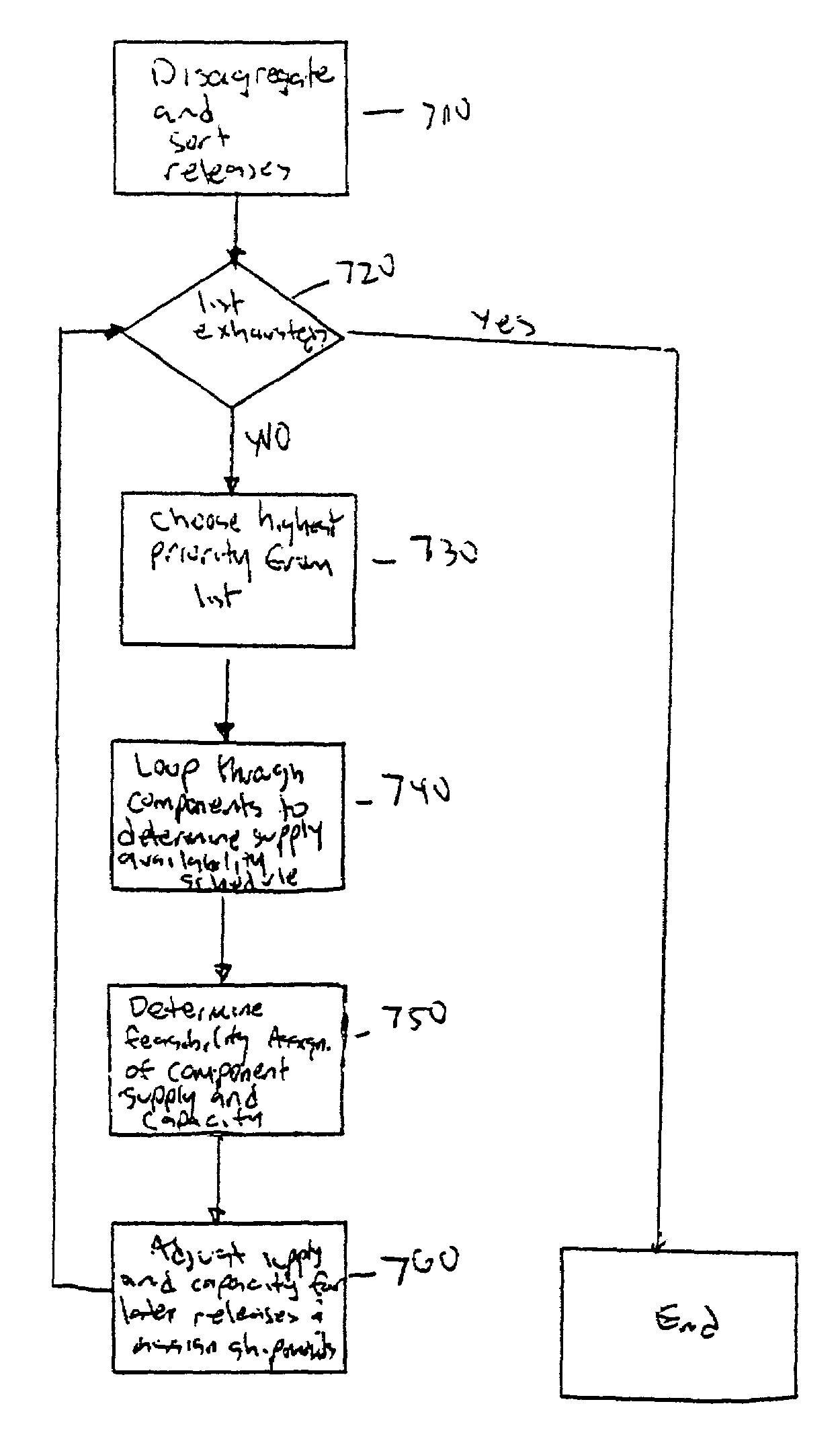

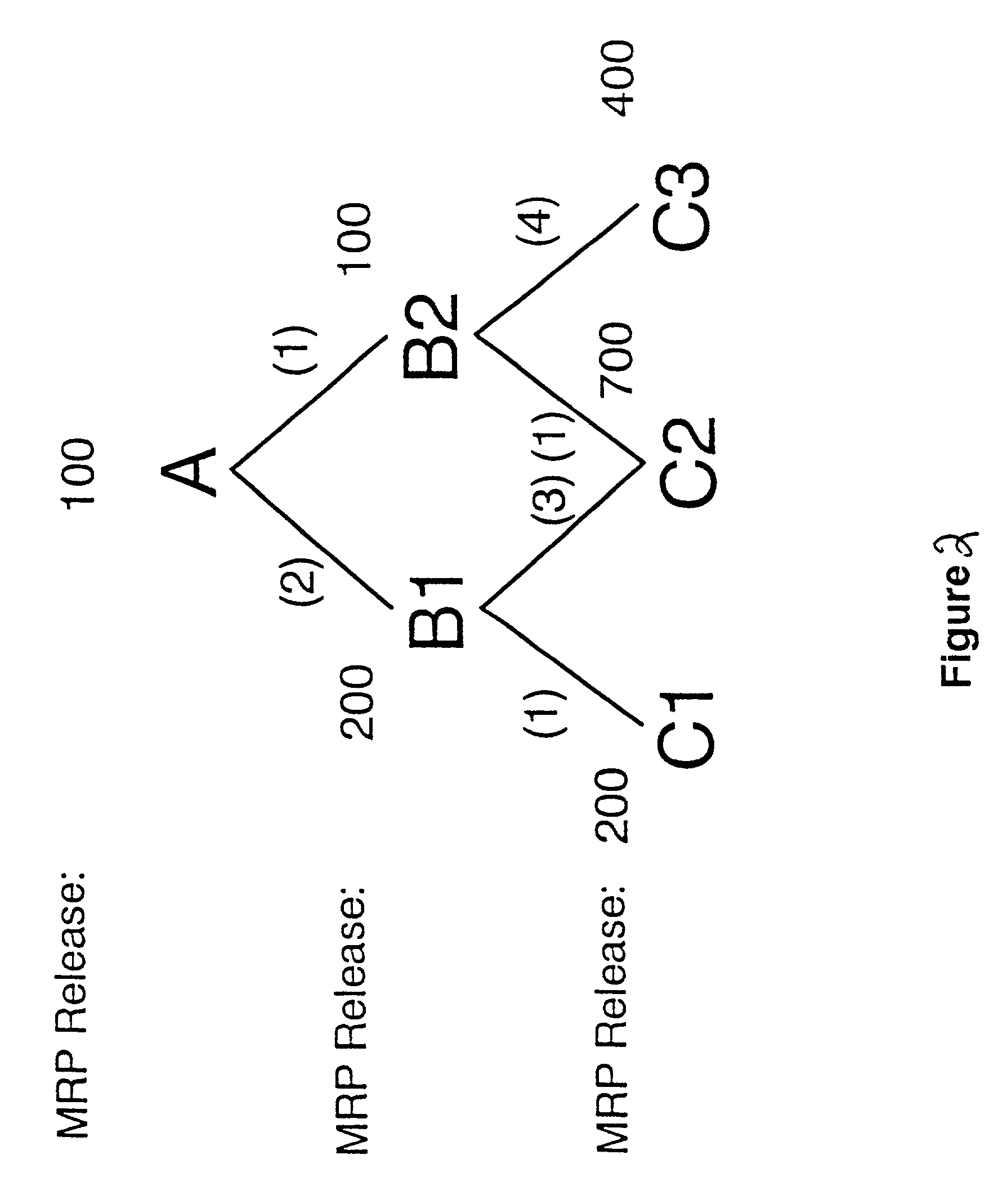

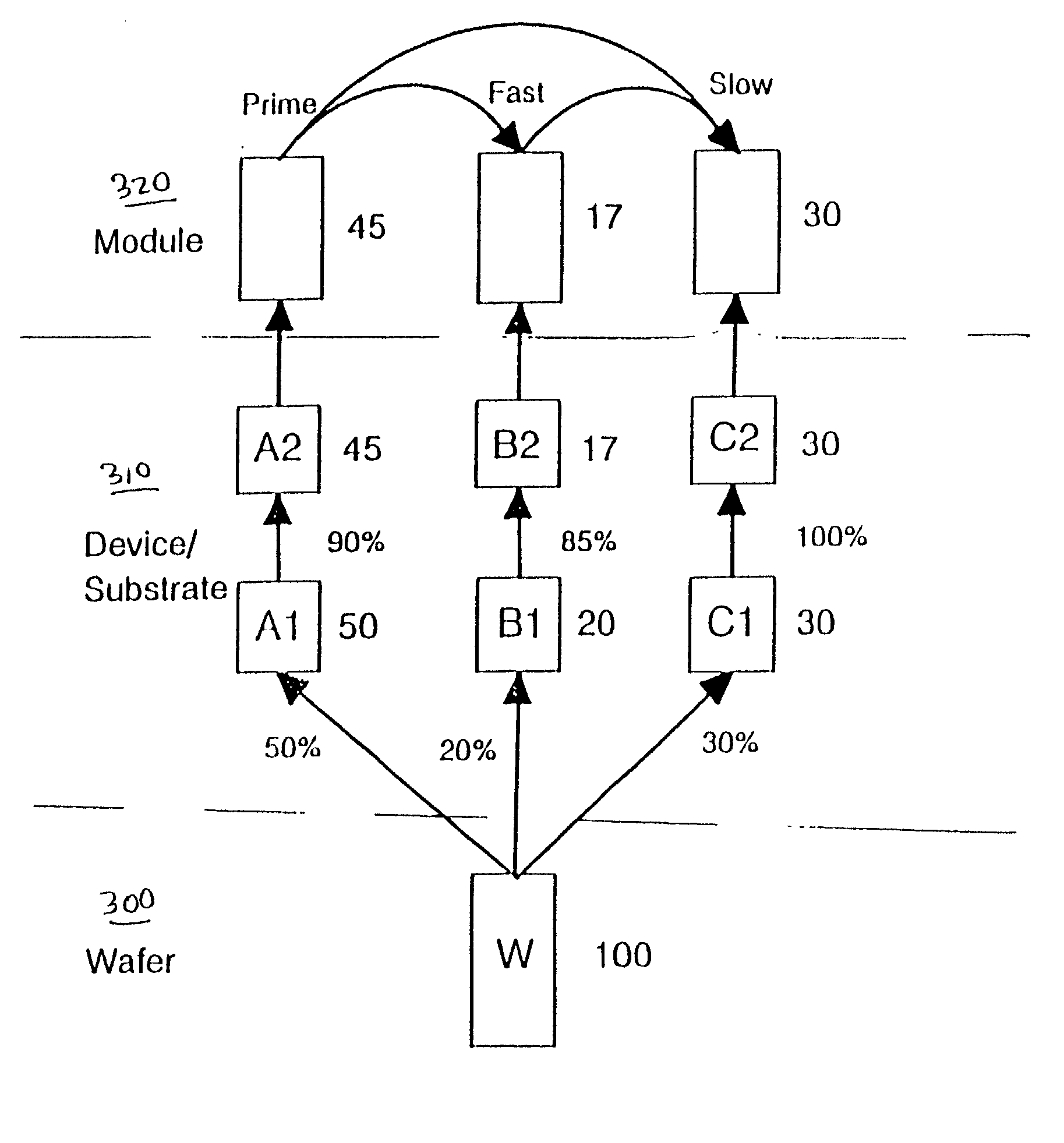

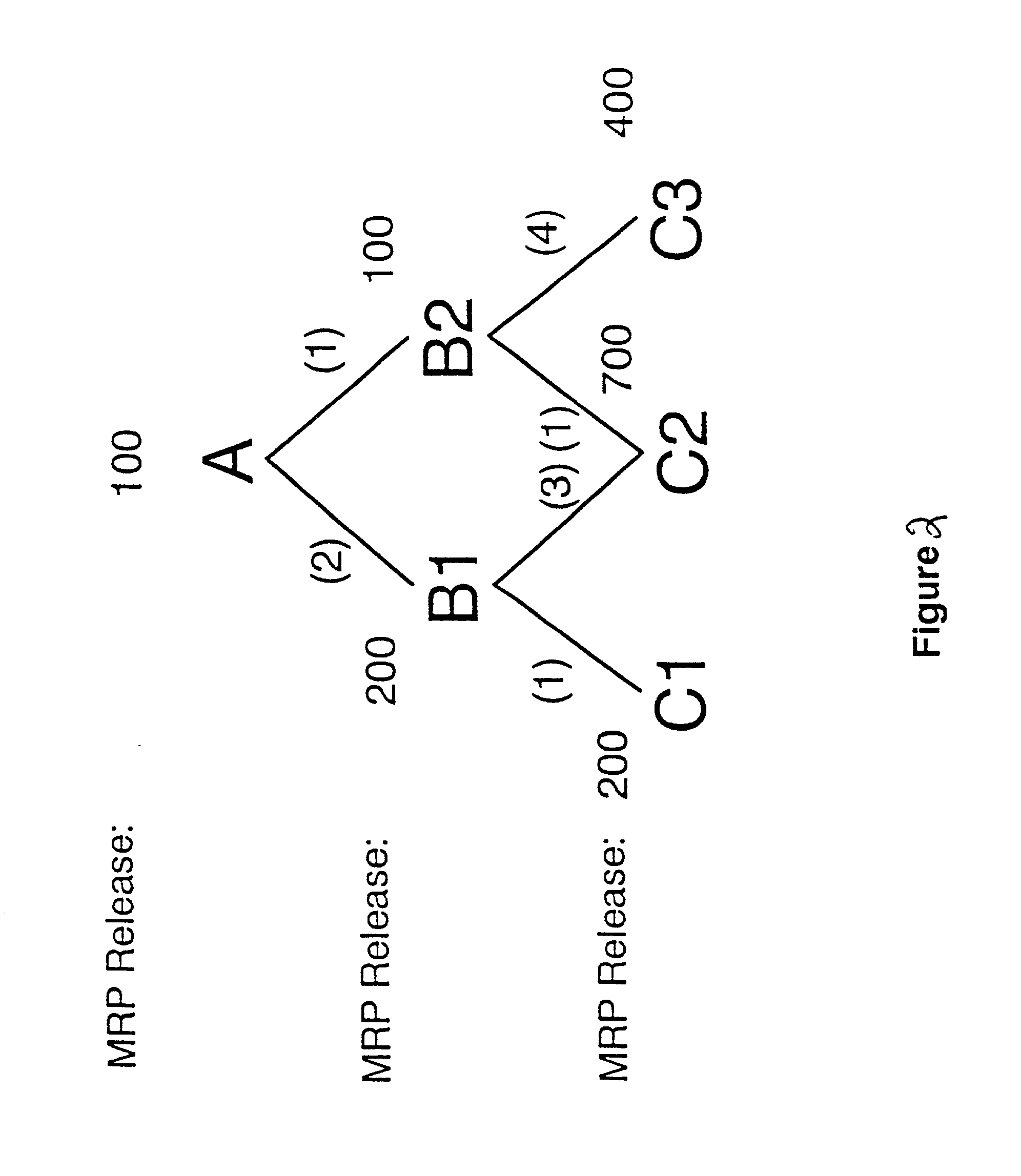

A method and system for resource rationing which employs decision rules for the optimal allocation of supply and capacity over time that satisfy two key requirements (a) being consistent with accepted operational objectives (e.g. low inventory, short lead times, prioritized allocation of supply and capacity) and (b) allowing for the timely computation of a feasible production schedule. The method and system is generally characterized in that it is able to divide each of the priority ranked scheduled releases (Material Requirements Planning (MRP)) into "N" separate and smaller sized scheduled releases where the priority of each of the "N" releases may be equal to the priority of the original release. The "N" separate and smaller sized scheduled releases are sorted according to priority and then used to determine an optimal supply schedule for allocating resources including component supply and assembly capacity.

Owner:RAKUTEN GRP INC

Method and apparatus for material requirements planning

InactiveUS6625616B1Fast data processingAvoid necessary capital expenditureHand manipulated computer devicesDigital data processing detailsNetwork connectionData access

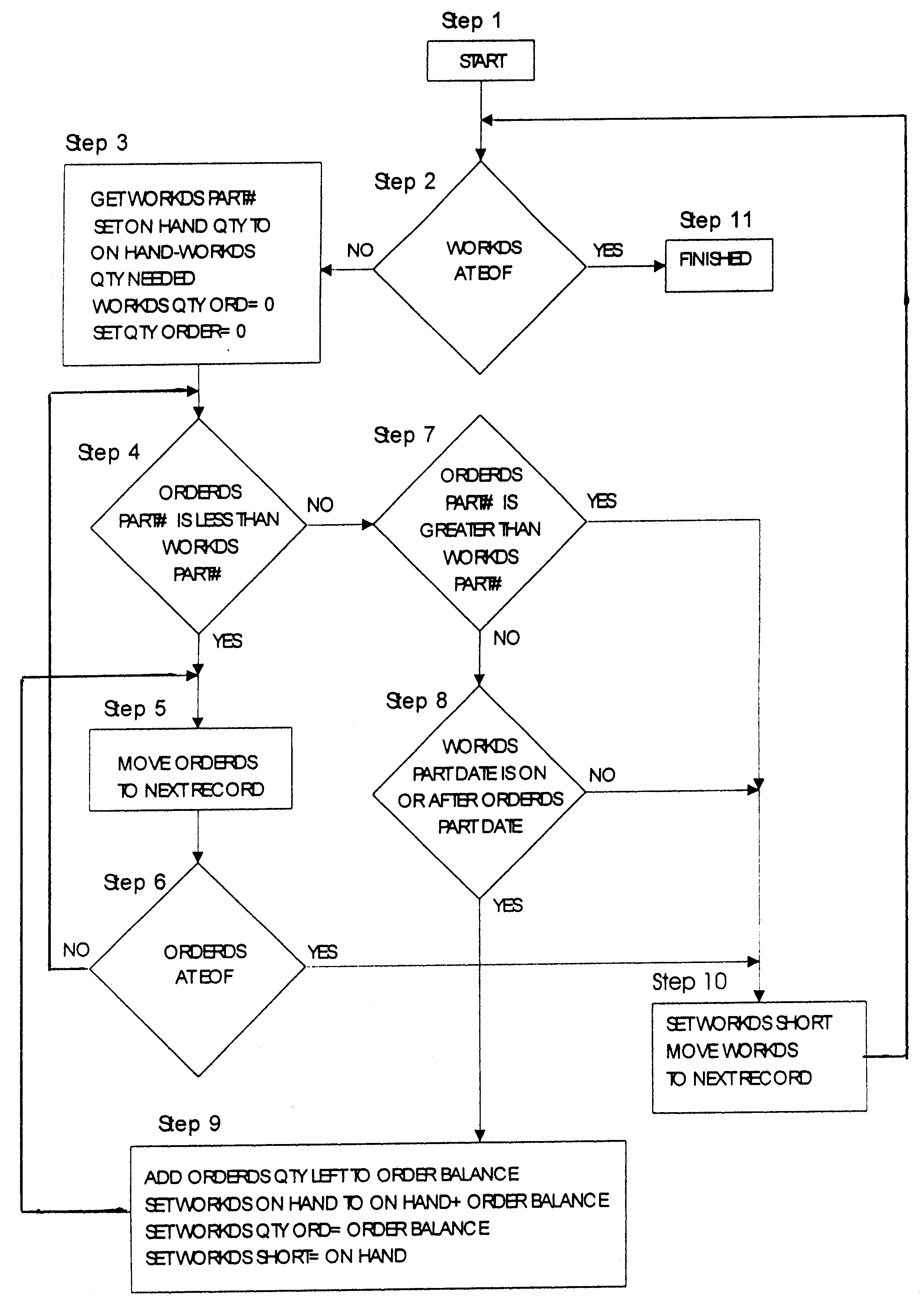

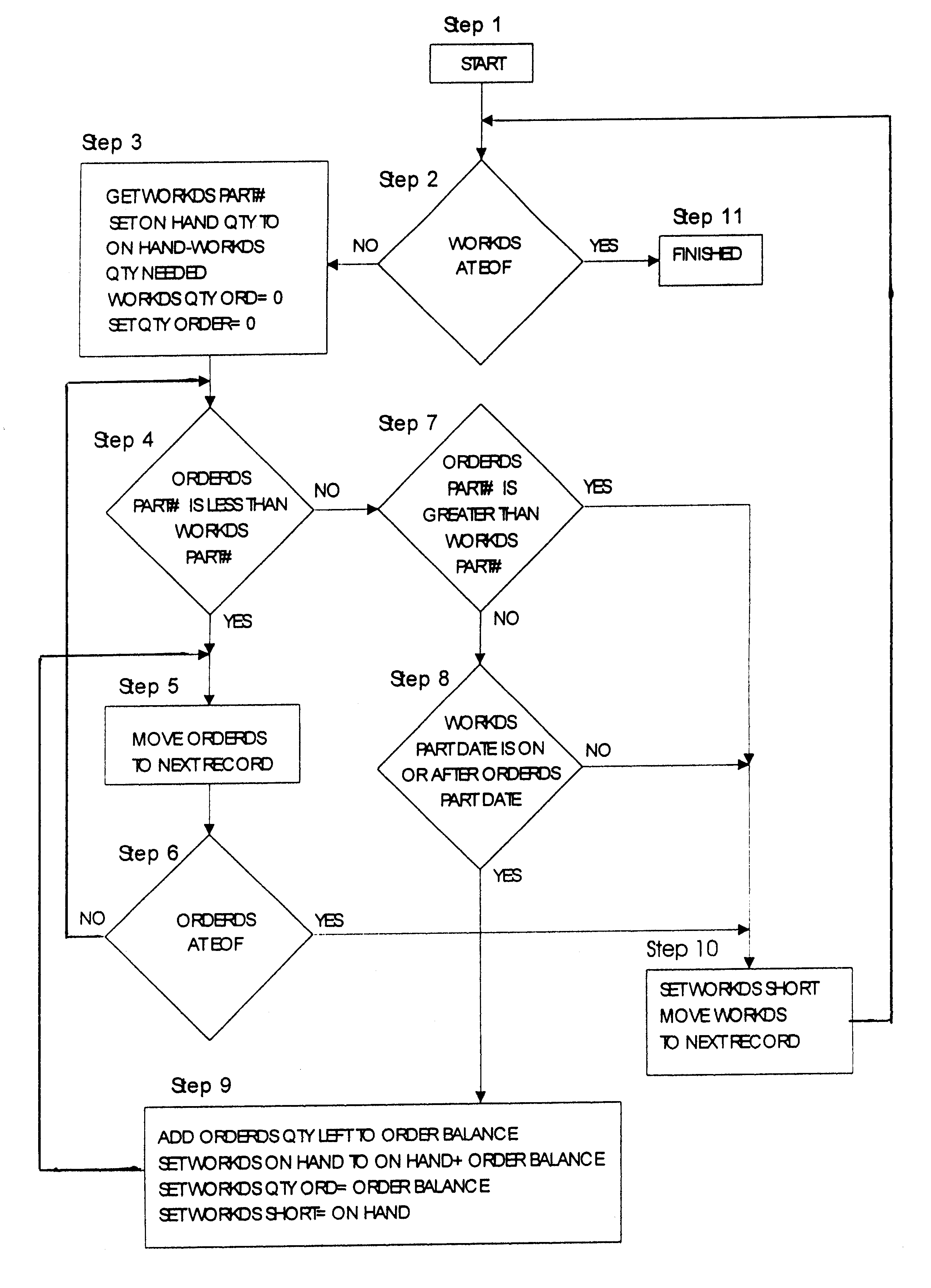

A method and apparatus for materials requirements planning that implements a client / server computer network with an algorithm which enables receiving and preserving input data from the client in a stateless protocol in the server, the input data from a client is preprocessed to determine the MPR state, and stored for each client in the server in a separate side container using stateless protocols. A side container containing a client's data is accessed by distinct SQL and VB code routines to perform specific reports, modification of a required materials order and / or adjustment of material availability for use dates. The preprocessing arranges the input data into record sets of all scheduled material requirements, all currently available and required materials and all unfulfilled ordered materials. The preprocessing is executed via SQL, and the processing is executed via executable code into a temporary record set that is placed into a storage container. The apparatus consists of a server side processor having a network connection and provided with software to supply network server functions, server side general purpose programming functions, and database functions using SQL code. A client side processor connected to the network and provided with software to enable login to the server side processor via the network, and to supply software functions including data access reports and / or modification in order to be able to control server access.

Owner:MRPONLINE COM

Method for planning enterprise resources

InactiveCN101833711AEasy to shareImprove work efficiencyResourcesInformation sharingProgram planning

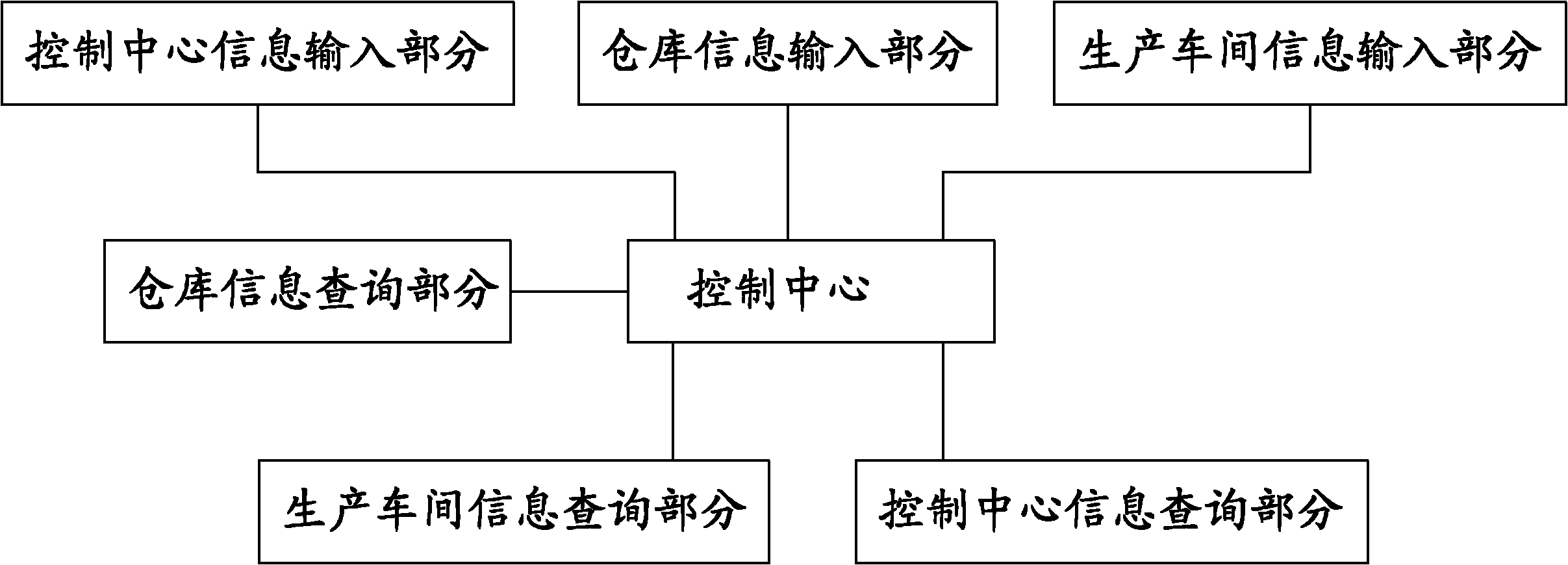

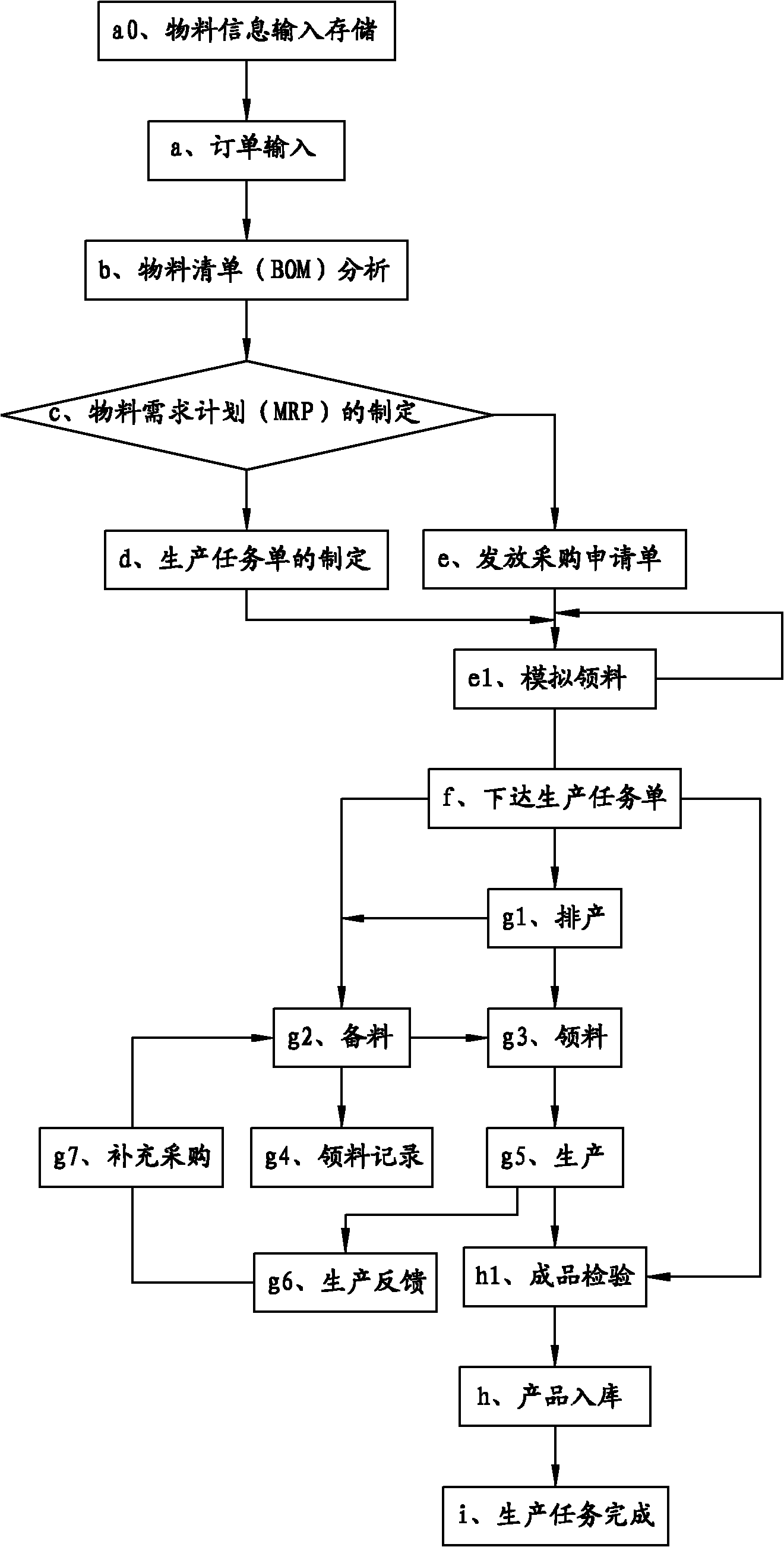

The invention provides a method for planning enterprise resources, belongs to the technical field of enterprise resource management, and solves the problems of complicated production dispatching and high error rate when the conventional enterprise performs production planning by using enterprise resource planning (ERP) software. The method for planning the enterprise resources implemented through an enterprise resource planning system which comprises an information inquiring part, an information input part and a control center with a database, wherein the information inquiring part and the information input part are both connected with the control center. The method for planning the enterprise resources comprise the following steps of: a, inputting an order; b, configuring a material list; c, making a material requirement plan; d, making a production task order; e, issuing a purchasing application form; f, releasing the production task order; g, producing; h, putting products in a storage and recording; and I, finishing the production task. The method for planning the enterprises has the advantages of convenient information sharing, low work load, high working efficiency and high accuracy.

Owner:ZHEJIANG VALOGIN TECH

Adaptive material requirement plan (MRP) calculation method

InactiveCN105389653AIncrease flexibilityAvoid restrictionsResourcesLogisticsBill of materialsOrder form

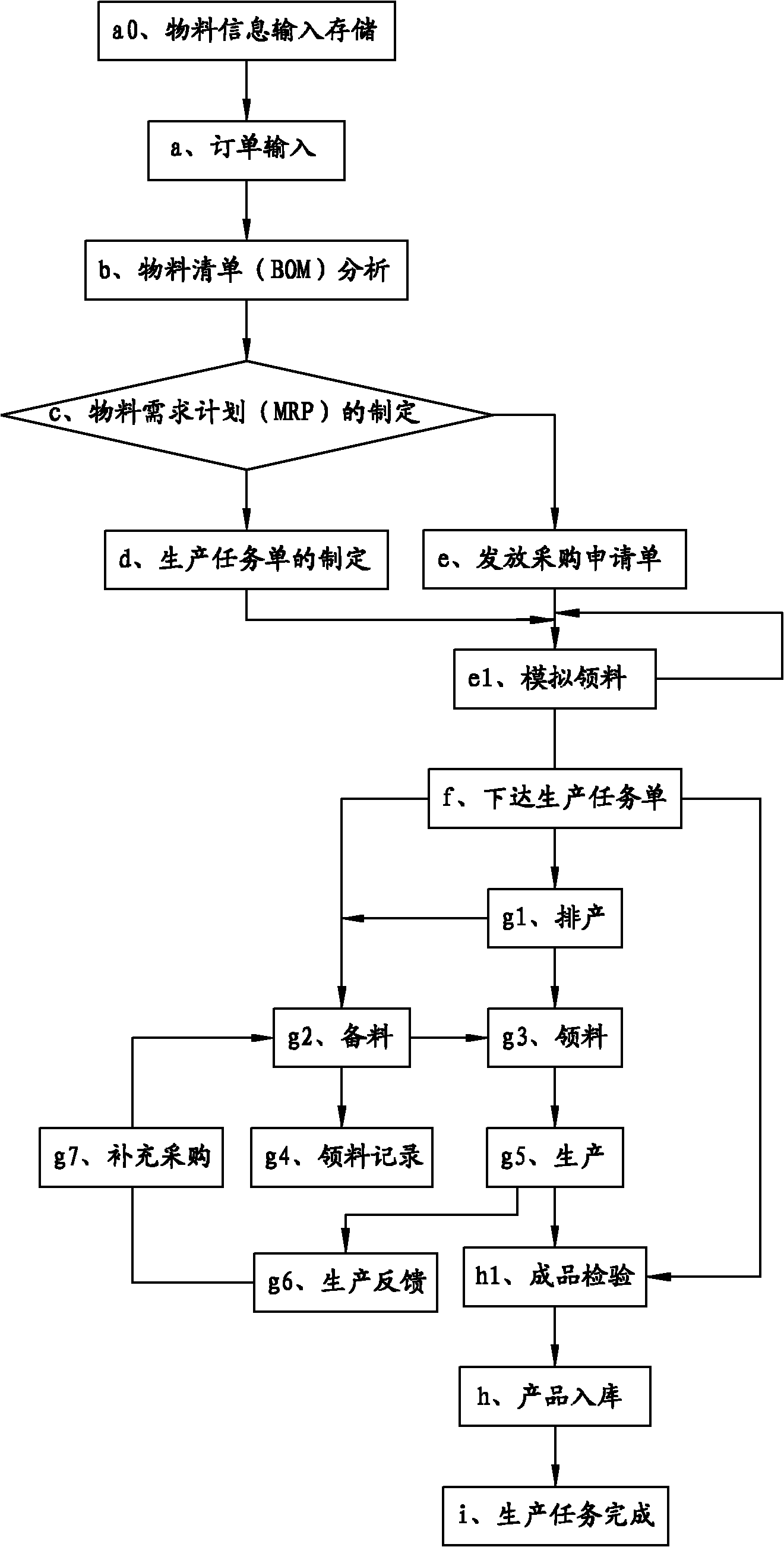

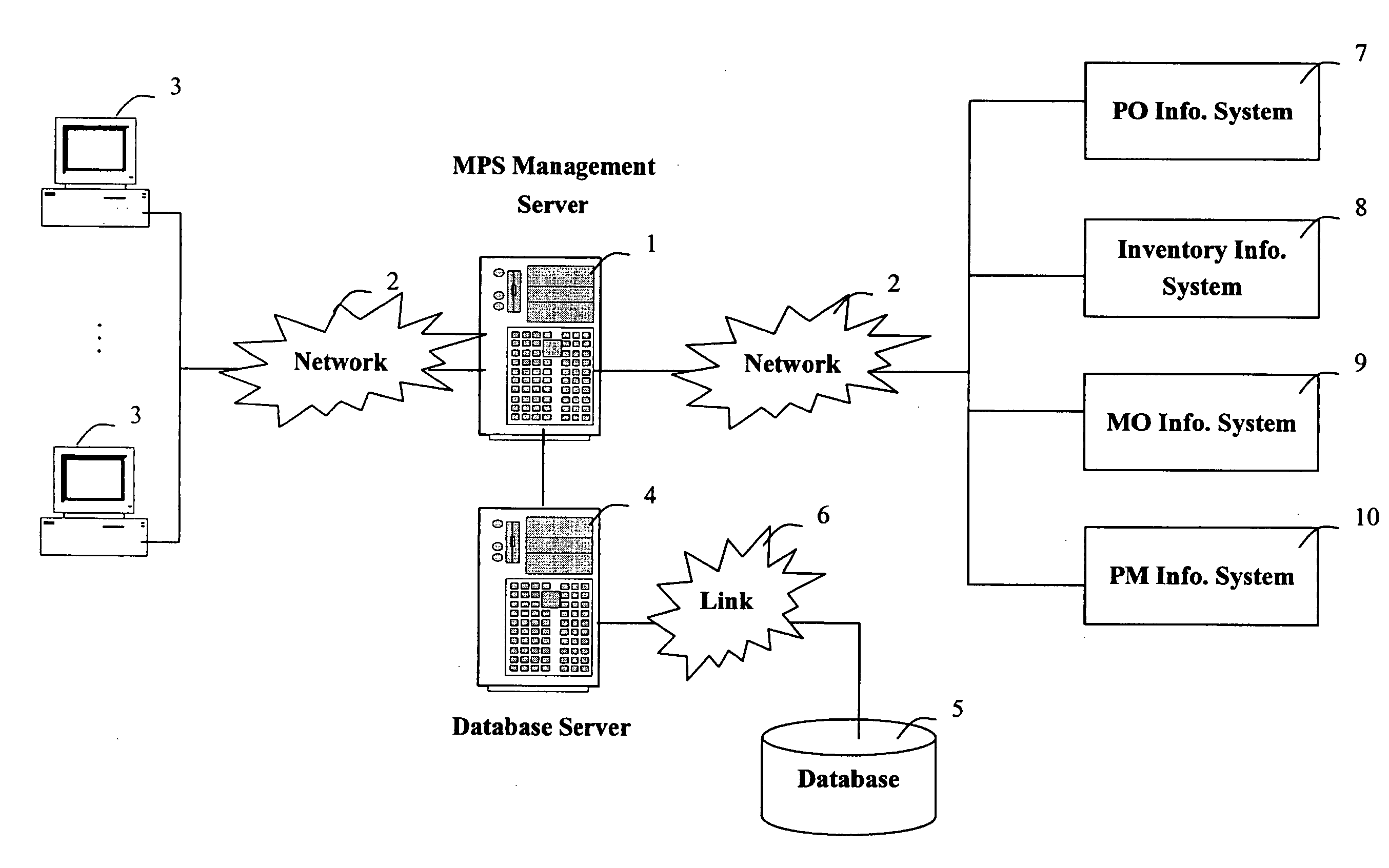

The invention discloses an adaptive material requirement plan (MRP) calculation method. The method comprises steps: a material list is acquired; lowlevel codes of all materials in the material list are calculated; sales orders in need of calculation are selected; according to conditions that the lowlevel codes and the material codes are ranked from low to high and the MRP type is equal to a requirement type, traverse calculation is carried out on MRP table records, and a production or procurement plan on the materials is generated; and automatic delivery date adjustment is carried out on all orders which participate in MRP calculation and need to automatically adjust the delivery dates. Delivery date adjustment can be automatically carried out on orders, whose delivery dates can not be met, and the generated plans, the process comprises steps in which the delivery dates of the sales orders are properly adjusted automatically, and the plan starting dates and the plan ending dates for a production order and a procurement order related to the sales order can be automatically adjusted, system flexibility is improved, and management by a manager is facilitated.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Production capability simulating system and method

InactiveUS20040117227A1ResourcesSpecial data processing applicationsProduction scheduleData retrieval

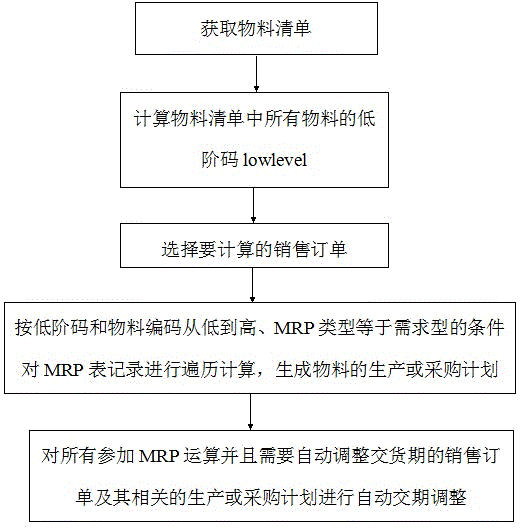

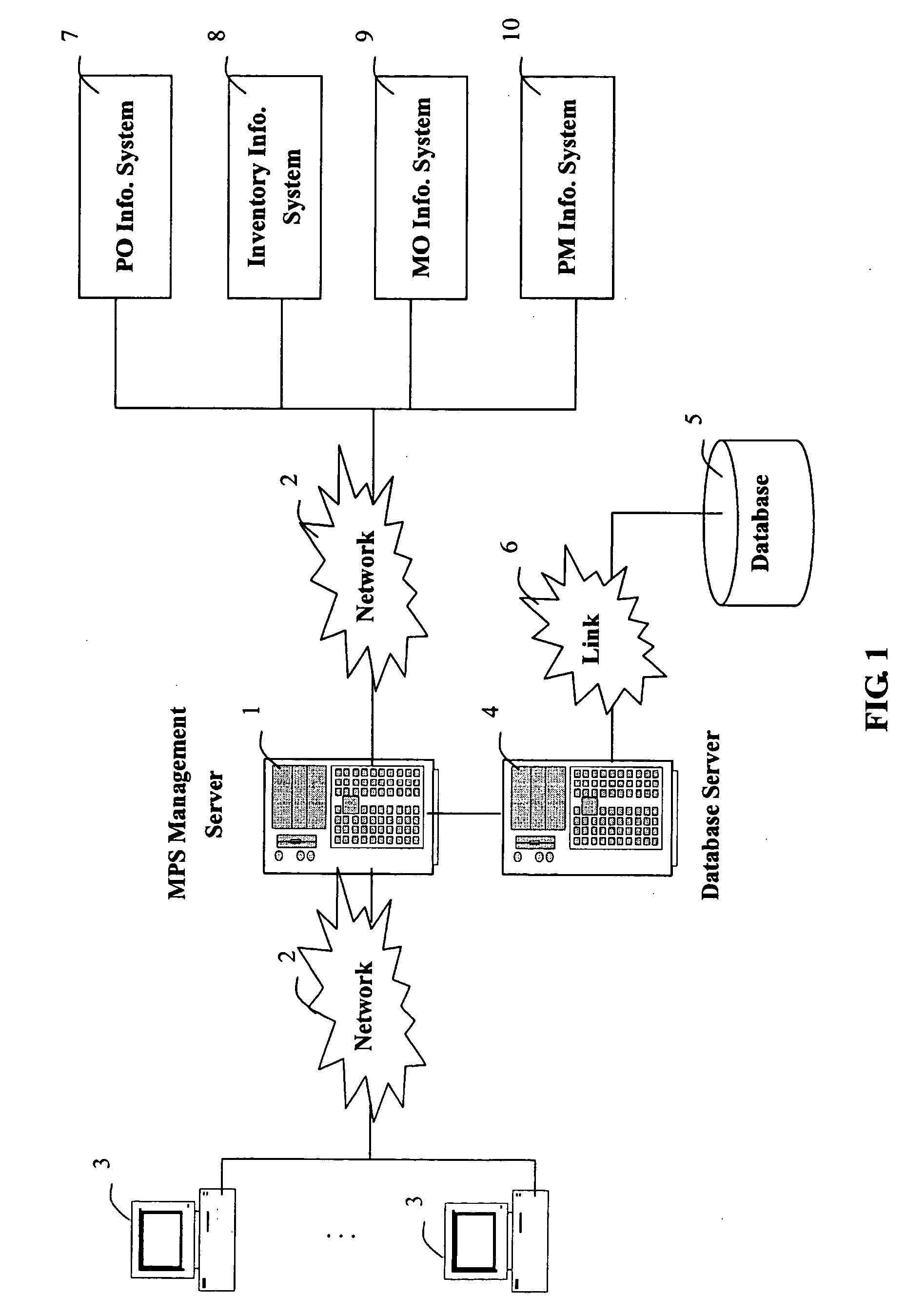

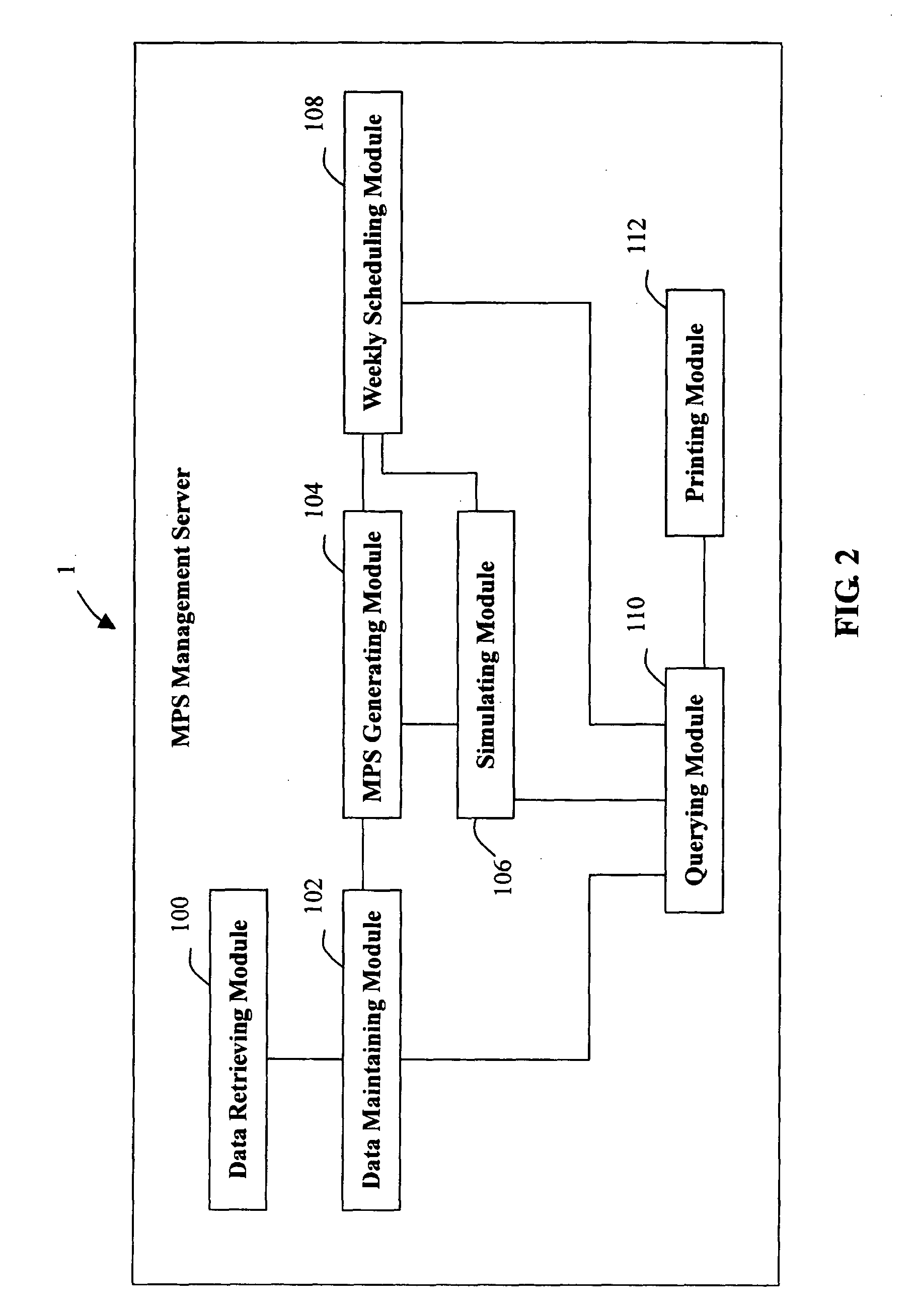

A system and method for simulating production capability is provided. The production capability simulating system can simulate rough-cut capacity planning (RCCP) and material requirements planning (MRP) of a manufacturing enterprise, and make main production schedule (MPS) accordingly. The system includes a plurality of client computers (3), an MPS management server (1), a database server (4) and a communication network (2) interconnecting the plurality of client computers, the database server, and the MPS management server. The MPS management server obtains data from external information systems by use of a data retrieving module (100), and generates an original MPS based on the obtained data for simulating the RCCP and the MRP. The original MPS is amended to be an optimized MPS according to the simulating results. Employing the present production capability simulating system, users can amend MPS in time by simulating RCCP and MRP and arrange production schedules efficiently.

Owner:HON HAI PRECISION IND CO LTD

System and method for implementing sales forecasting in catering industry

InactiveCN107292672AAchieve forecastSpecial data processing applicationsMarketingPredictive methodsInformation mining

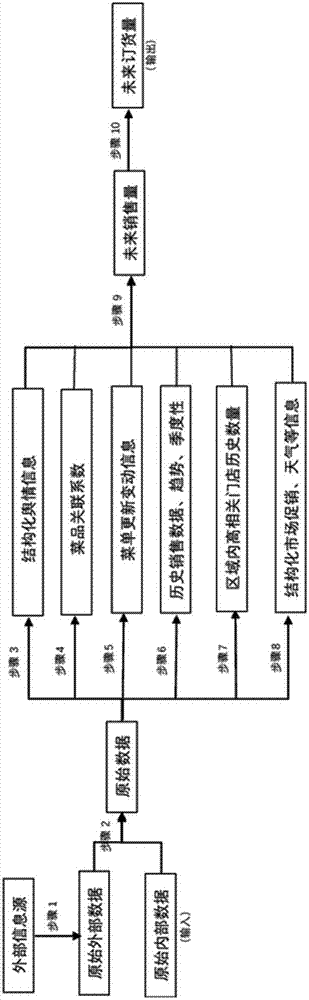

The invention discloses a system and a method for implementing sales forecasting in the catering industry. Acquisition and information mining are performed on external data such as online review platform data, geographic position information data, weather information, market information and the like and internal data such as pos data, store information, dish information, company market activity information and the like by adopting a crawler technology, an image recognition technology, a text analysis technology and a deep learning algorithm, a fused forecasting model is established, week-by-week dish sales data within future three months is given, and a future order plan is given in combination with dish BOM (Bill of Material), store inventory, total warehouse inventory, safety inventory MRP (Material Requirements Planning) and the like. Compared with other exiting forecasting method, the MAPE (Mean Absolute Percentage Error) can be improved from 30-40% to 10-15%.

Owner:上海数道信息科技有限公司

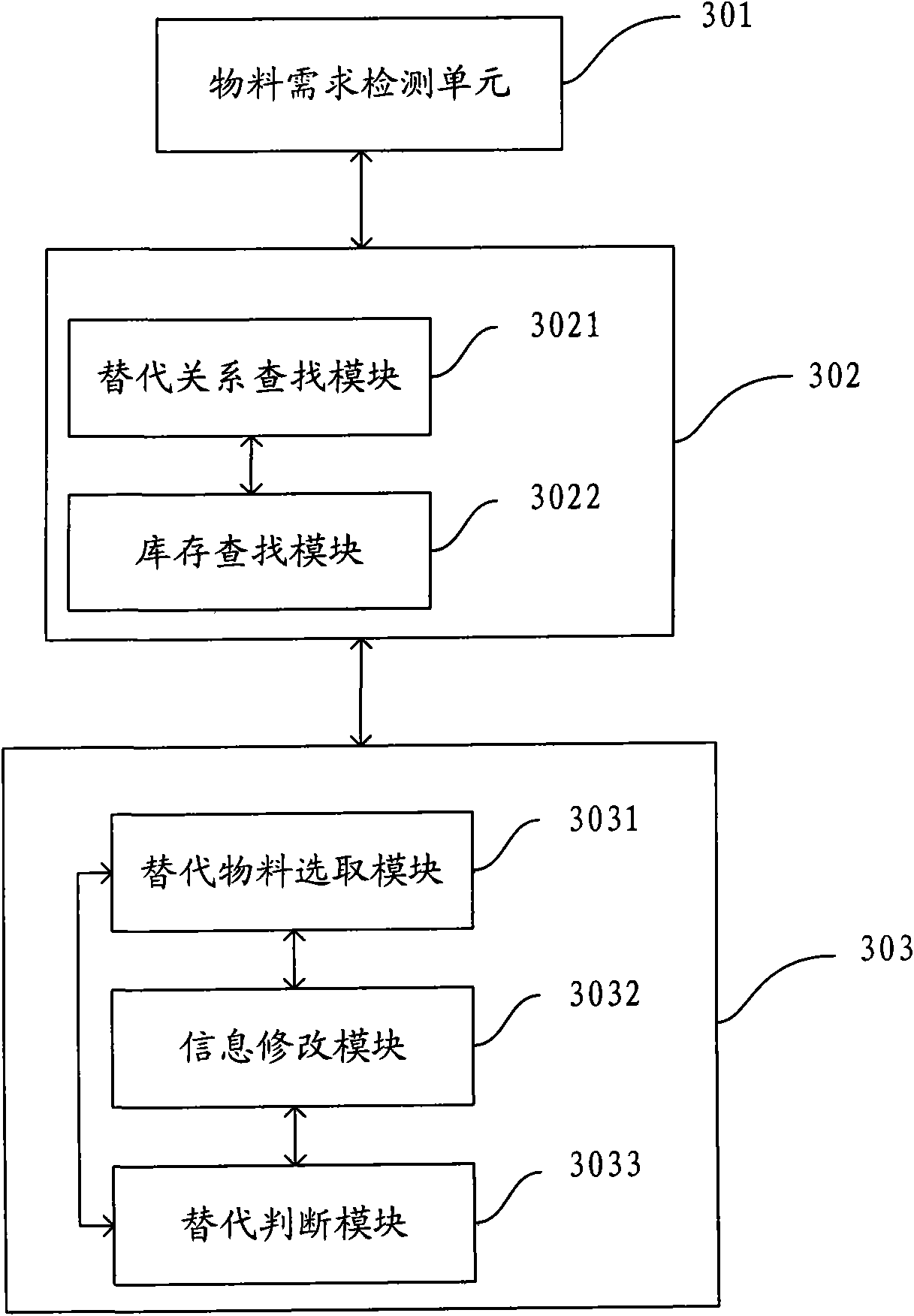

Material information modifying method and material information modifying device in material demand plan system

InactiveCN101650802AShort processing timeImprove efficiencyLogisticsBill of materialsMaterial requirements planning

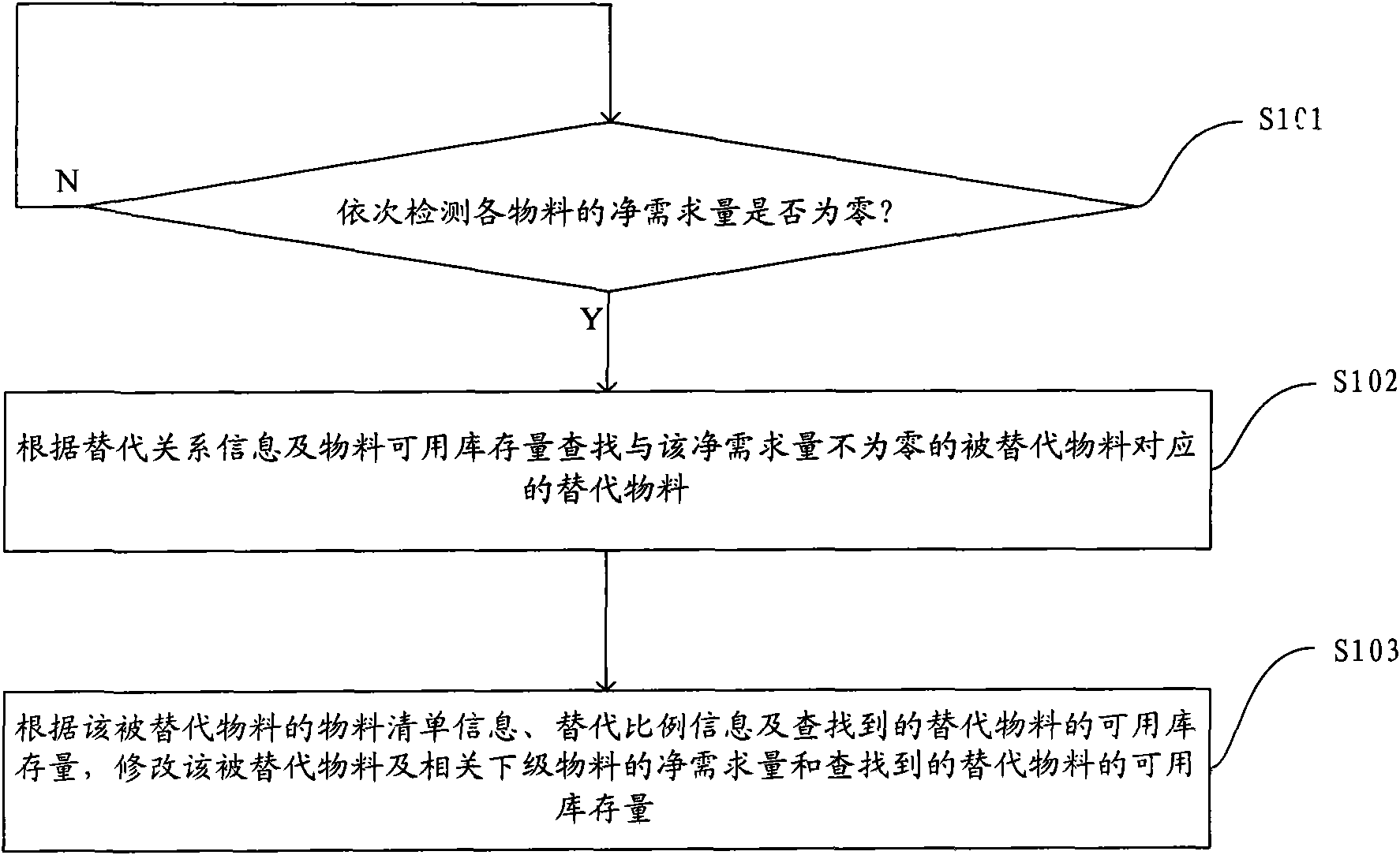

The invention is applicable to the field of resource management, which provides a material information modifying method, a material information modifying device and resource management equipment in amaterial demand plan system. The material modifying method comprises the following steps: sequentially detecting the net demand of all materials; when detecting that the net demand of any material isnot zero, searching a substitute material corresponding to a substituted material, the net demand of which is not zero, according to substitute relationship information and the usable material storagerate; and modifying the net demand of the substituted material and a relevant interior material and the searched usable storage rate of the substitute material according to a bill of material information of the substituted material, substitution ratio information and the searched usable storage rate of the substitute material. In the embodiment of the invention, the provided material informationmodifying method has the advantages of short processing time, high efficiency, high accuracy and thorough substitution.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

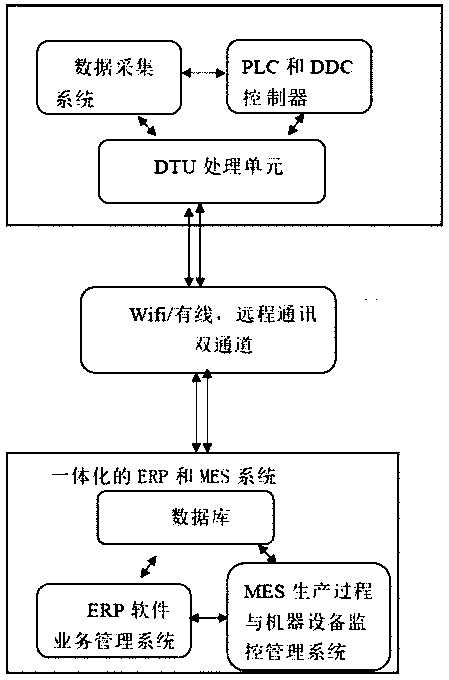

Intelligent processing equipment with integrated ERP and MES system

PendingCN111144671ACalculate lossData synchronizationOffice automationResourcesData transformationControl system

The invention discloses intelligent processing equipment with a built-in integrated ERP and MES system. The PLC and the DDC controller have a remote communication function. After data conversion is carried out through a DTU processing unit and the DDC controller, butt joint with data in a far-end integrated ERP and MES system is carried out, data sharing and real-time data access of the control system and the far-end integrated ERP and MES system are achieved, and the functions of instruction sending, receiving and executing are achieved through the PLC; remote monitoring of the packaging machine and the processing machine is achieved through remote control, and the artificial intelligence-like production scheduling operation capacity of automatic production scheduling, automatic scheduling and automatic material requirement plan arrangement of the machine equipment is monitored; the integrated ERP and MES systems are accurately associated with various data in real time; therefore, a plurality of packaging machines and processing machines not only can automatically cooperate with one another and synchronize data, but also can actively participate in productivity calculation, production scheduling plan arrangement and material demand plan operation, and the equipment has the capability of replacing most of the traditional manual work of PMC planners and dispatchers.

Owner:精效新软新技术(北京)有限公司

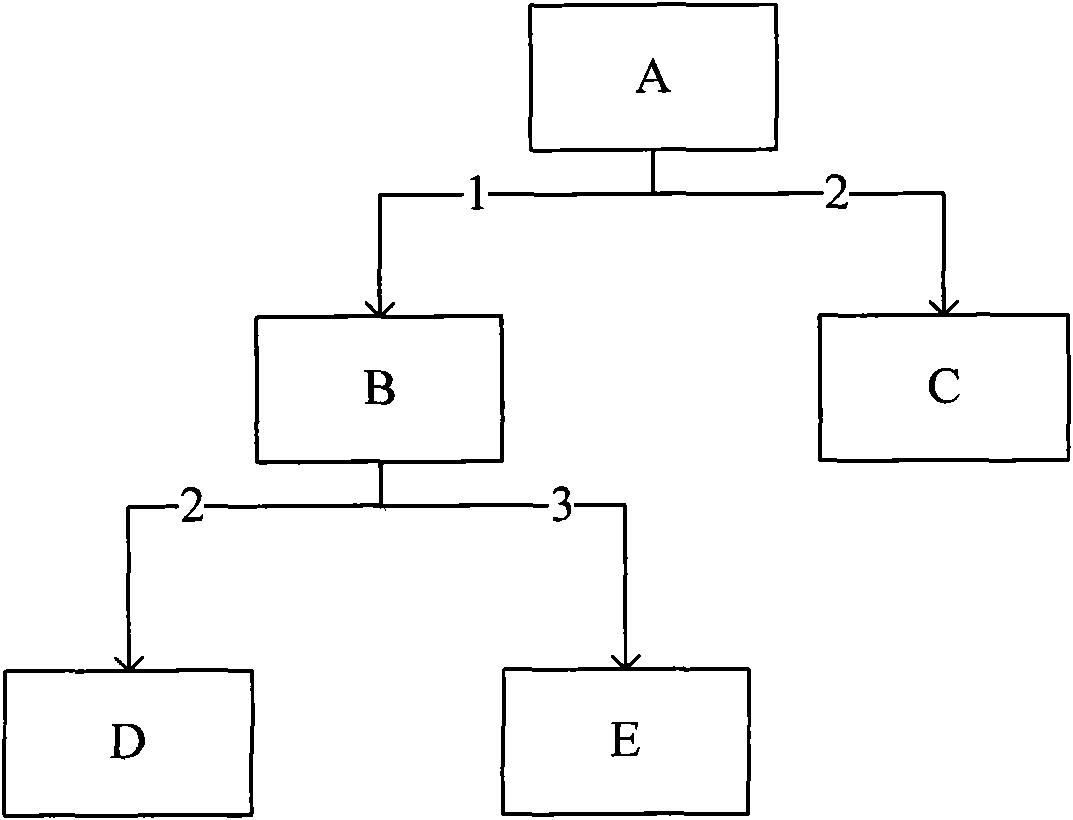

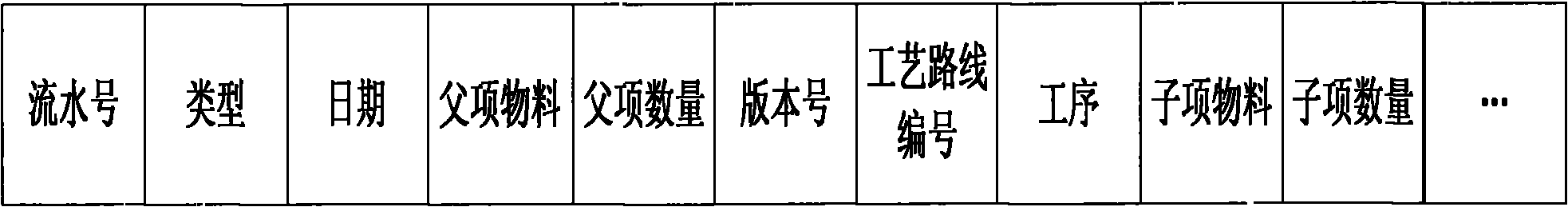

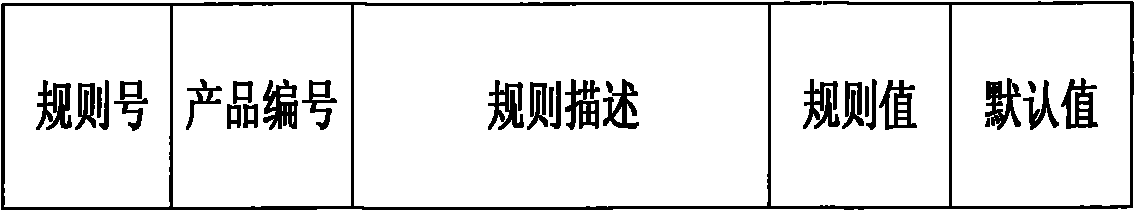

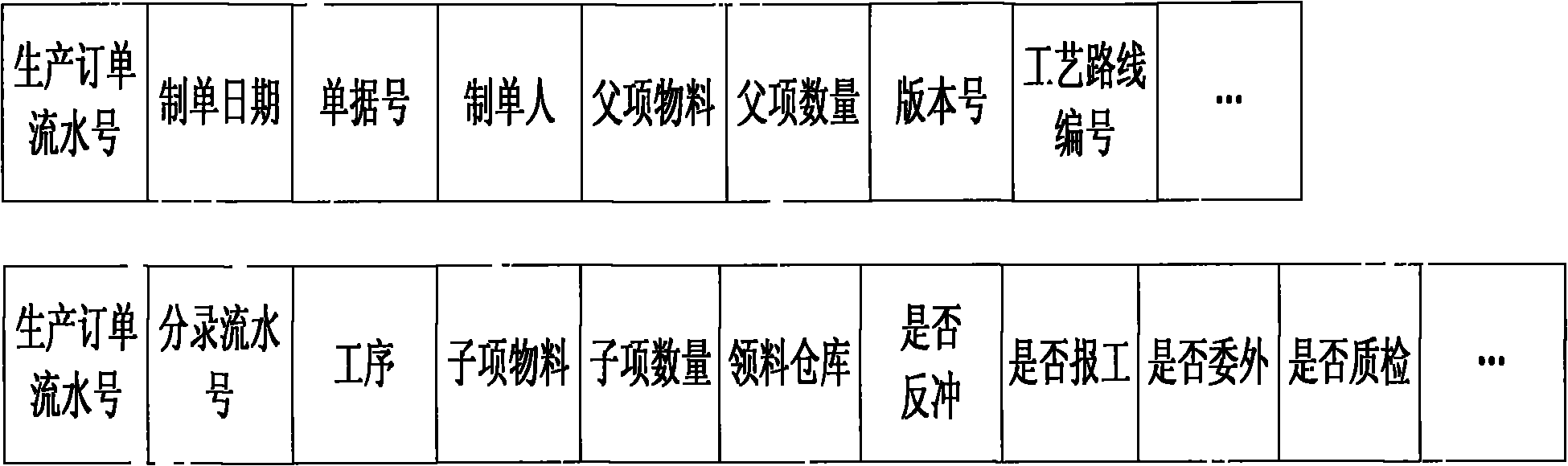

Method for synchronizing data between BOMs by utilizing implicit BOM model

The invention provides a method for synchronizing data between BOMs by utilizing an implicit BOM model, in particular to a realization method for synchronizing data between BOMs and production order process information by utilizing an implicit BOM model in the field of erp management software, which realizes the data synchronization among manufacturing BOM, process BOM and production order process information through the restriction of a synchronization rule. The synchronization rule is defined by users according to the actual needs in the use process, and a production order automatically forms the table information of the production order according to the defined rule and the process route information of products; conversely, a system forms a new-edition process BOM according to the new production order table information to be used for next scheduling, and the system presets up the synchronization rule of the manufacturing BOM and the process BOM, the synchronization rule of the process BOM and the production order and the data update rule of the process BOM; the change of the manufacturing BOM is predominant, and the rules are utilized to automatically form the implicit process BOM; and simultaneously, the synchronization rule of the process BOM and the production order process information is established so as to realize the synchronization of the data among the manufacturing BOM, the process BOM and the production order process information, so that the purchasing plan and the production plan are more accurate after the calculation of the MRP.

Owner:INSPUR COMMON SOFTWARE

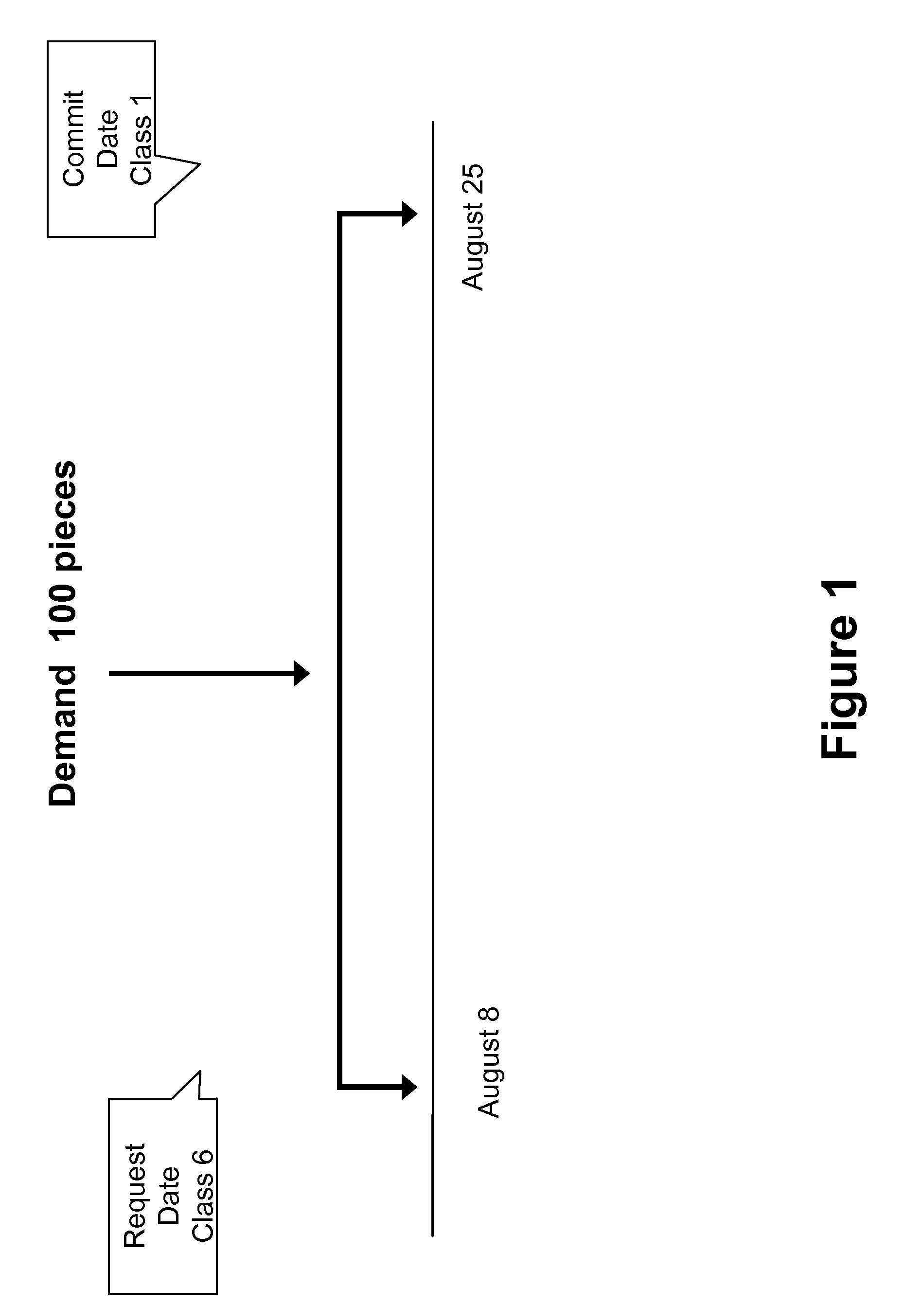

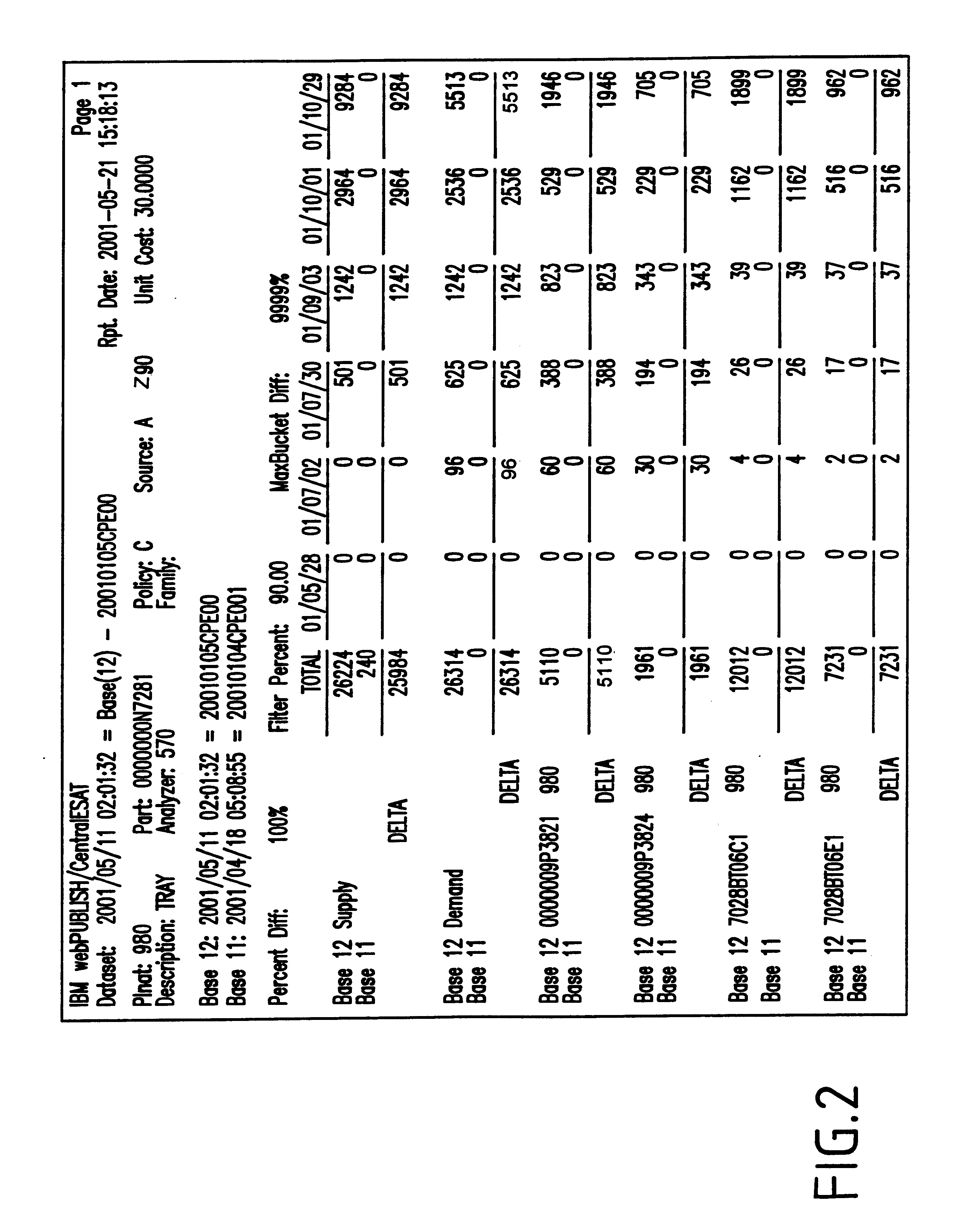

A method for calculating a materials requirements plan for demands containing multiple demand dates and priorities

InactiveUS20070239304A1Special data processing applicationsProgram planningMaterial requirements planning

Owner:IBM CORP

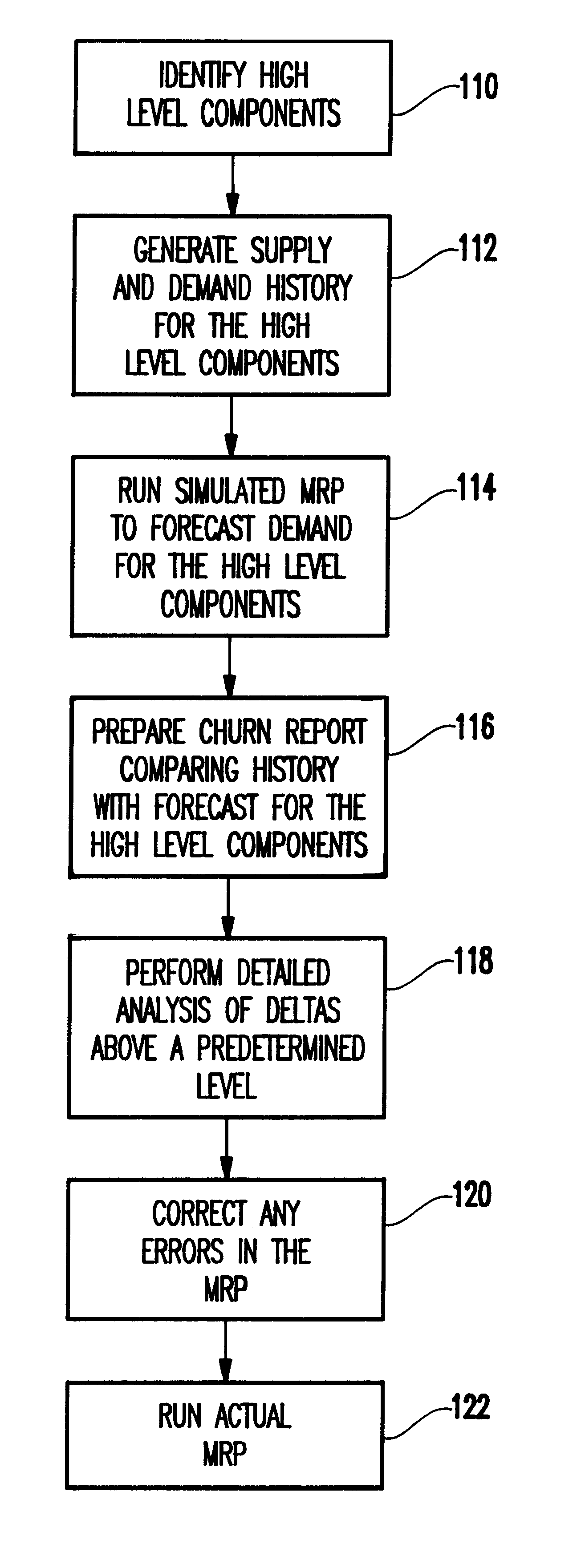

Materials requirements planning simulation analysis

A method and structure for using a materials requirements planning (MRP) tool is disclosed. The invention runs a simulation using a MRP tool for at least one preselected component to produce simulated order levels for a preselected component. The invention then identifies deviations of the simulated order levels from the historical order levels for the preselected component. Next, the invention analyzes the MRP tool to determine whether the deviations are appropriate or are errors. The invention corrects the MRP tool to correct for errors and runs the MRP tool after correcting.

Owner:IBM CORP

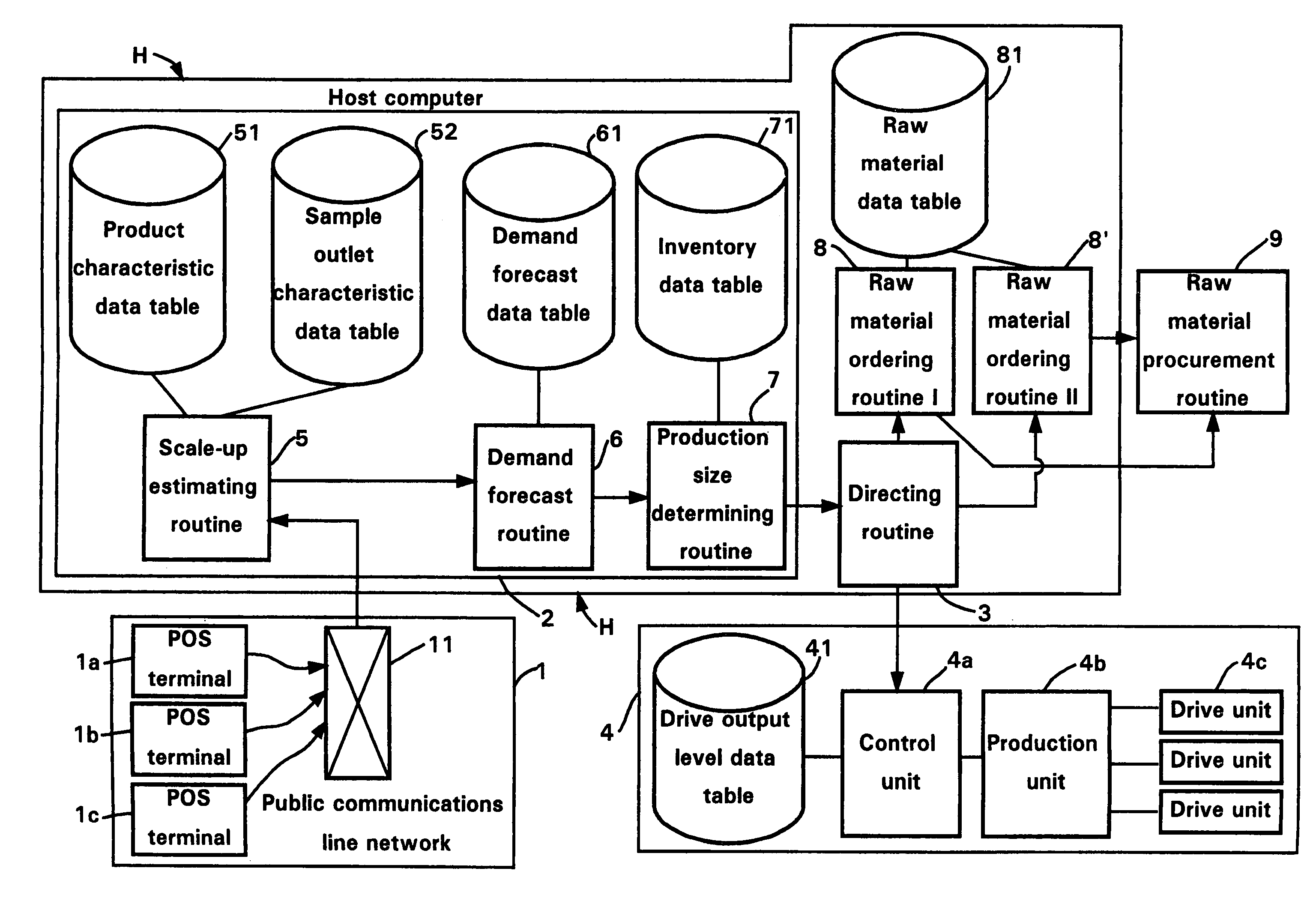

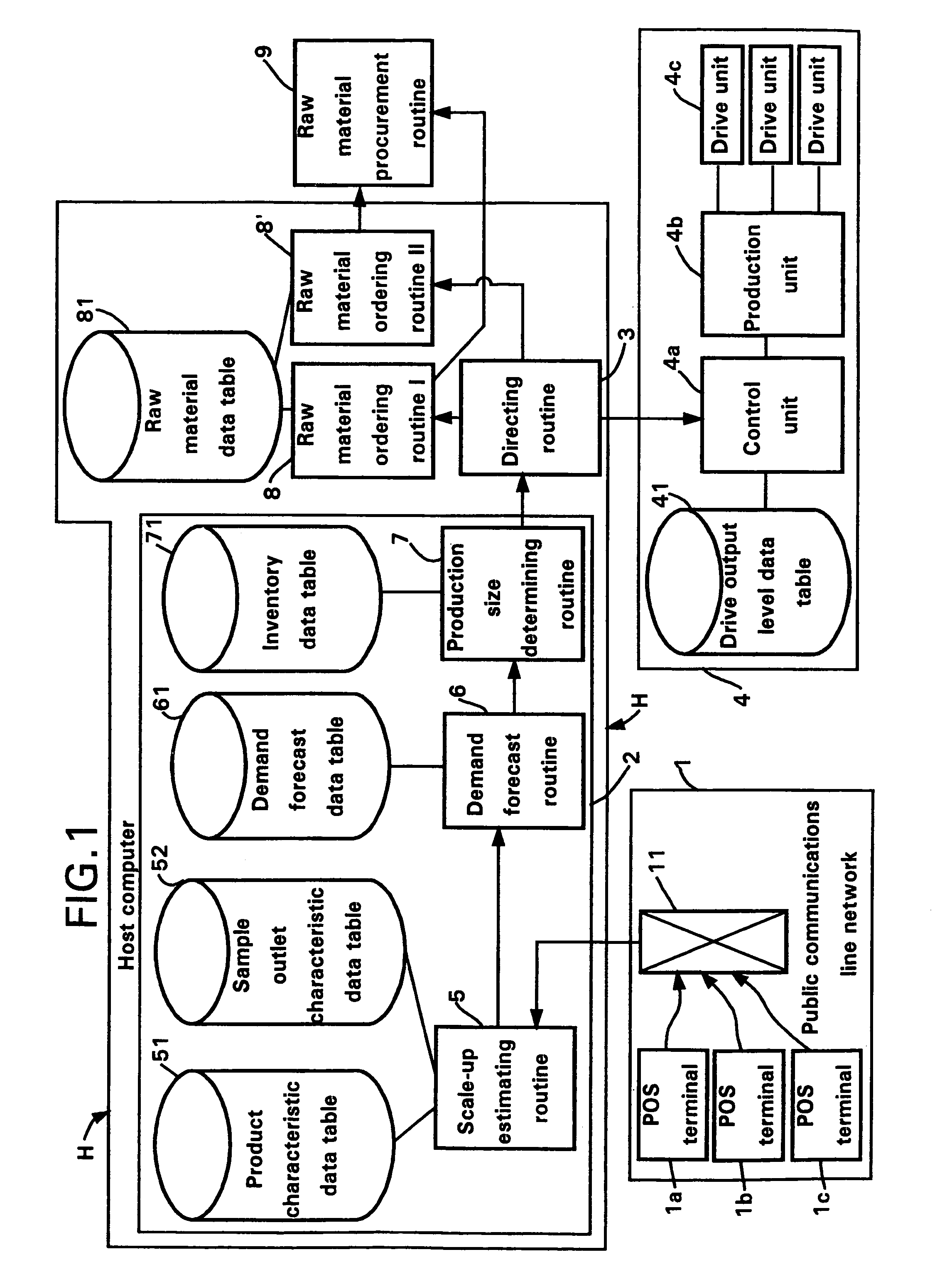

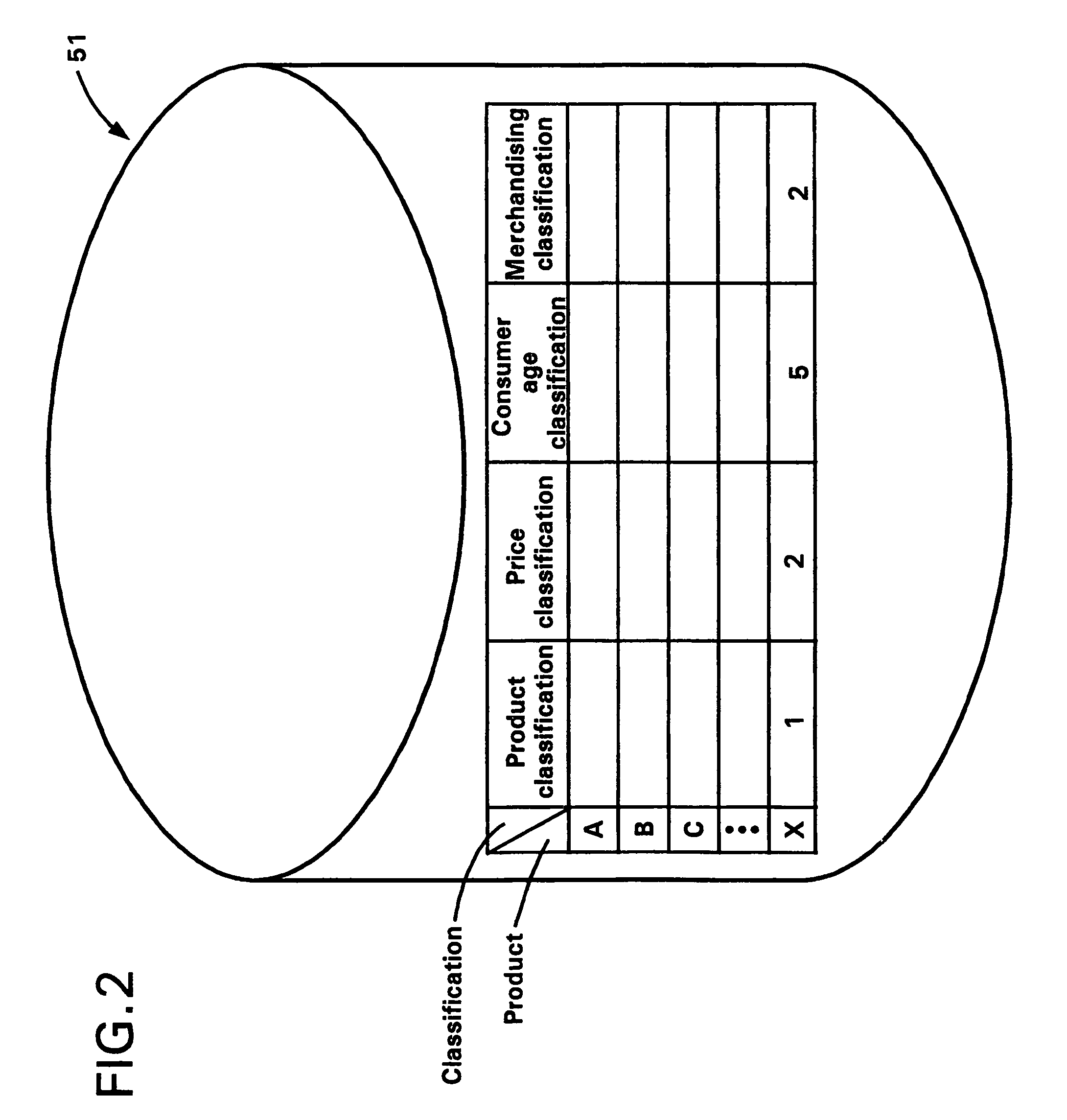

Flexible production and material resource planning system using sales information directly acquired from POS terminals

InactiveUS7197481B1Rapid responseReduce riskAnimal feeding devicesResourcesMaterial requirements planningMaterial resources

This invention relates to a production system for retail goods which is intended for timely collection of accurate sales information from retail outlets and flexible production of goods in accordance with the same information, and includes sales information collecting units for collecting sales information at a plurality of sales outlets, a production size determining unit for determining a production quantity to be produced in the future for a plurality of goods based on the sales information received from the plurality of sales information collecting units, and a production unit for flexibly manufacturing the plurality of goods based on the sales information which is collected at the plurality of sales information collecting units. After the production size determining unit determines the production quantity, output data indicative of the production quantity determined by the production size determining unit is transmitted to the production unit so that the production unit manufactures the production quantity of the plurality of goods.

Owner:KANEBO TRINITY HLDG +1

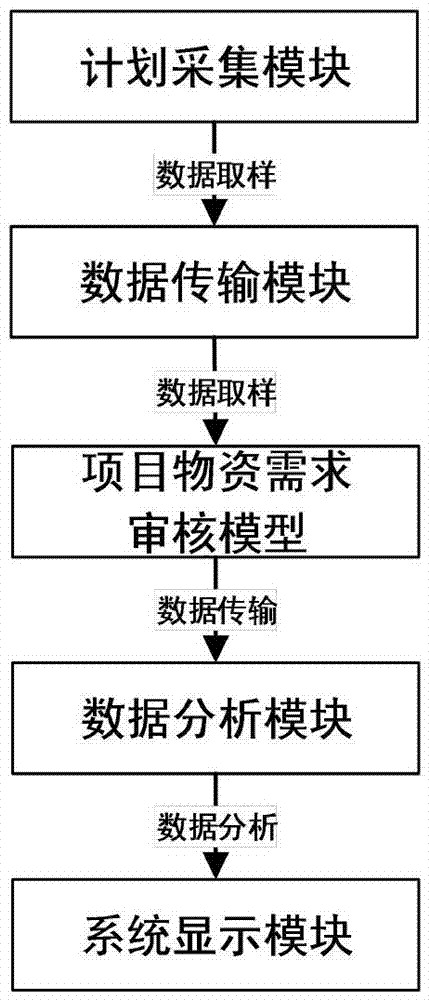

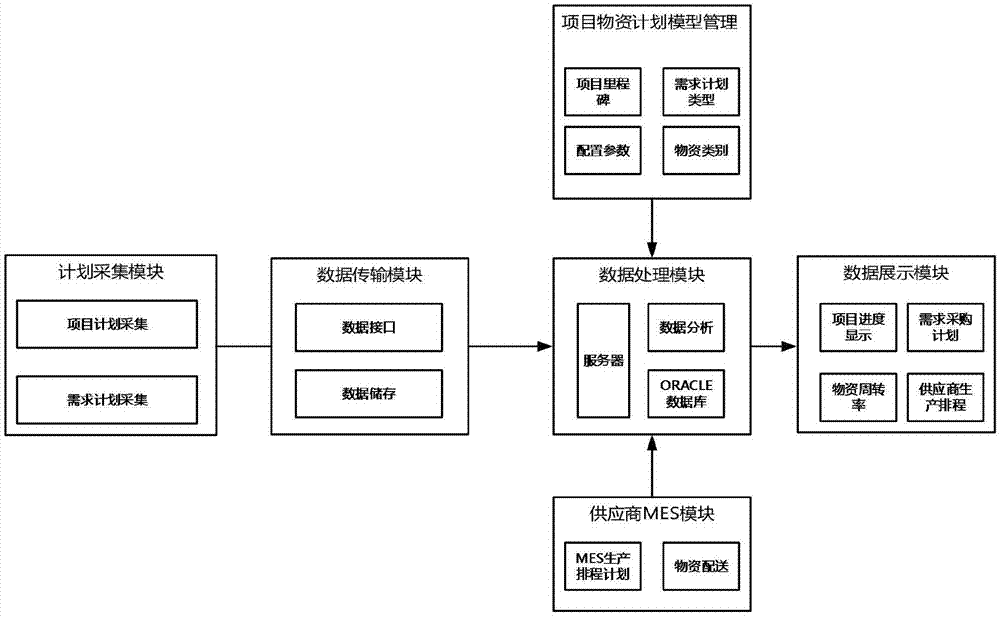

Typical configuration model and system for auditing material requirement plan of power project

InactiveCN105447624ATimely and accurate supplyImplement advance reservesResourcesProgram planningMaterial requirements planning

The invention provides a typical configuration model and a system for auditing the material requirement plan of a power project. The model and the system are characterized by comprising a plan collection module, a data transmission module, a project material requirement auditing model, a data analysis module, and a system display module, wherein the above modules are connected in turn. Due to the adoption of the above technical scheme of the invention, a material information storage bi-directional interaction mechanism during the prior-period management stage of an engineering project is realized, so that the material advanced storage of the engineering project is realized. Meanwhile, the rolling update for different stages of the project is realized, so that the storage information accuracy of materials is ensured. Therefore, a foundation is provided for the prediction and the analysis of material requirements. Moreover, the material plan declaration timeliness ratio and the material plan execution accuracy are improved. The successful development of the project and the timely and accurate supply of materials are effectively ensured.

Owner:LOGISTICS SERVICE CENT OF YUNNAN POWER GRID +1

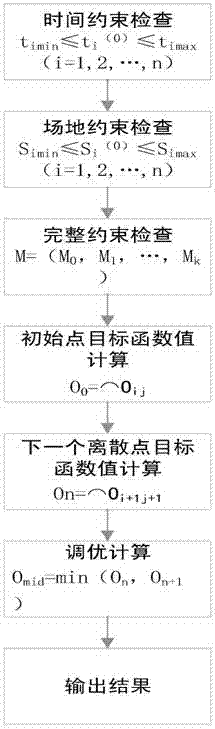

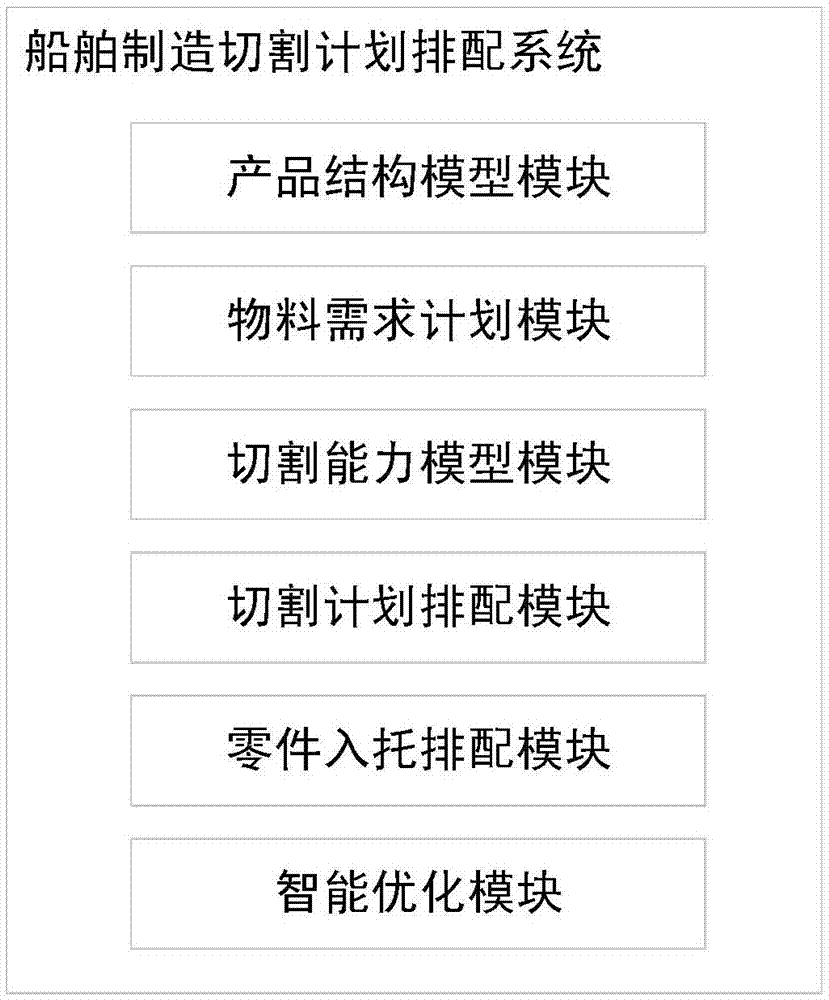

Shipbuilding cutting scheduling device

InactiveCN106897786AIncrease productivityForecastingManufacturing computing systemsMaterial requirements planningTime cost

The invention relates to shipbuilding cutting and arranging equipment, relates to the field of shipbuilding, specifically belongs to the field of part manufacturing, and proposes a shipbuilding cutting and arranging system. In the present invention, the cutting operation is realized in units of ship segmented products through the mutual cooperation of the product structure model module, material demand planning module, cutting capacity model module, cutting plan arrangement module, parts pallet arrangement module and intelligent optimization module. The plan, part placement details and material demand plan are consistent and optimized to achieve on-time, complete and punctual supply of materials in the product assembly process, taking into account the optimization of capital, time, site, personnel and other costs generated in the process, and improving Production efficiency of shipbuilding cutting and arrangement.

Owner:北京中船信息科技有限公司

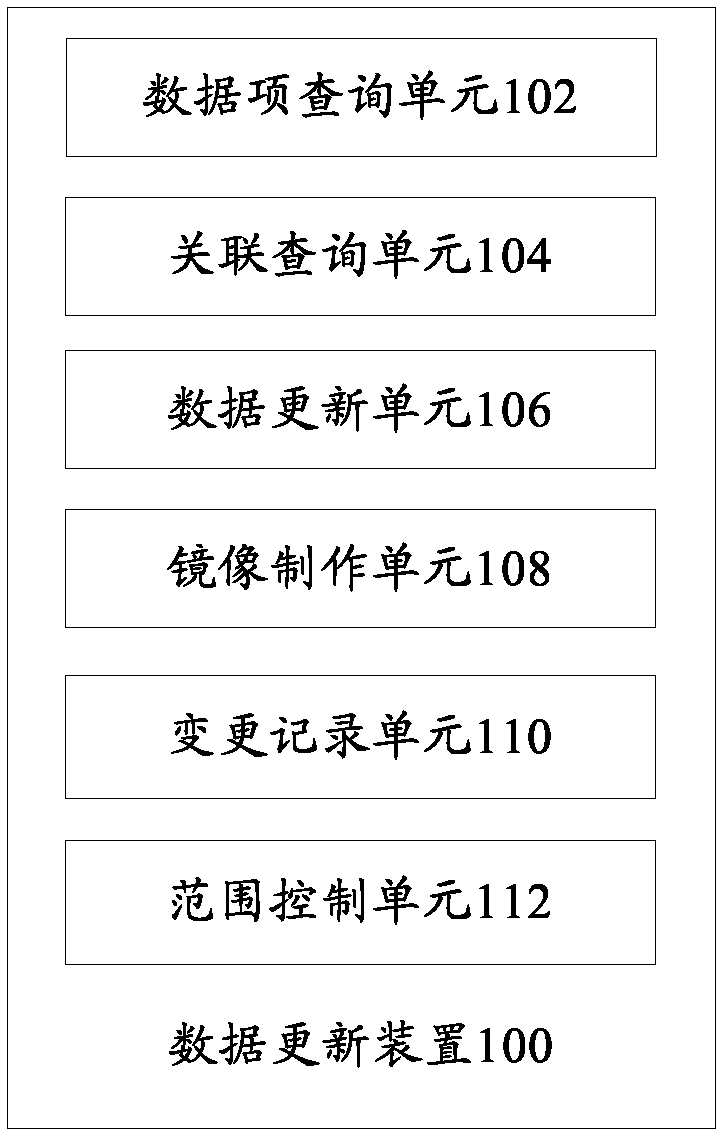

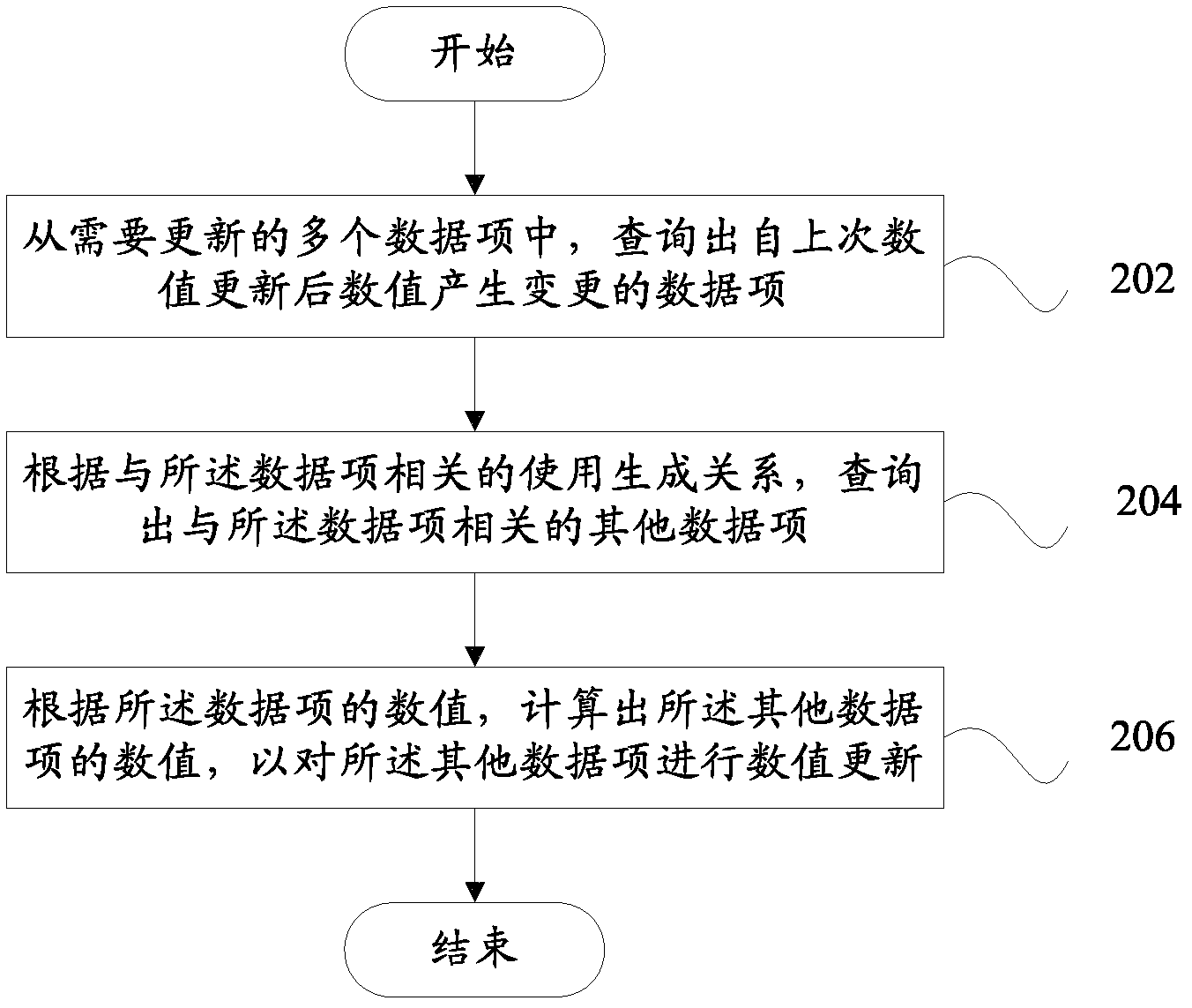

Data updating device and data updating method

InactiveCN102354316AShorten the timeSave resourcesSpecial data processing applicationsProgram planningMaterial requirements planning

The invention provides a data updating device and a data updating method. The data updating device comprises a data item query unit, an associated query unit and a data updating unit, wherein the data item query unit is used for querying data items (subjected to numerical value changes after last numerical value updating) from a plurality of data items required to be updated; the associated query unit is used for querying other data items relevant to the data items according to an application generation relation relevant to the data items; and the data updating unit is used for computing the numerical values of the other data items according to the numerical values of the data items so as to carry out numerical value updating on the other items. By using the device and method disclosed by the invention, only the data items subjected to numerical value changes are subjected to numerical value updating, thereby ensuring the speediness and high efficiency of the data updating. The technical scheme of the invention is suitable to be applied to the operations of material requirements planning.

Owner:YONYOU NETWORK TECH CO LTD

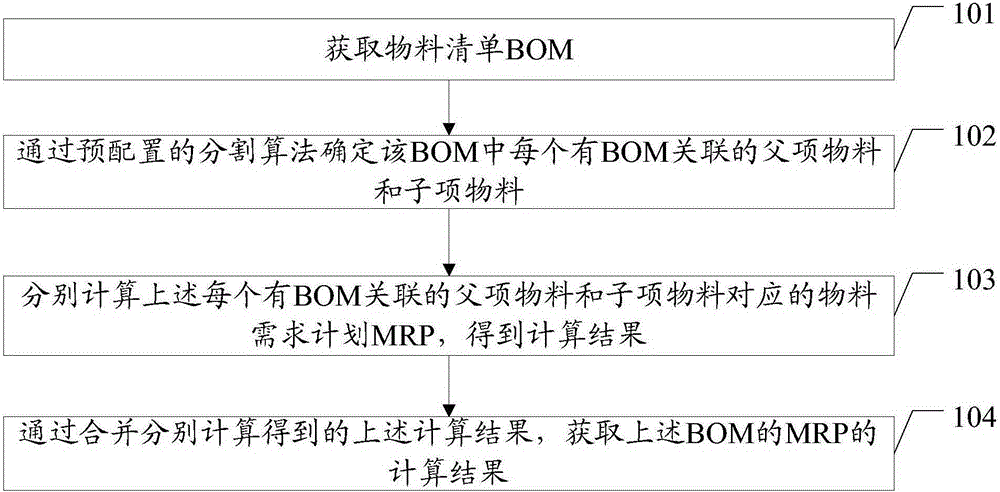

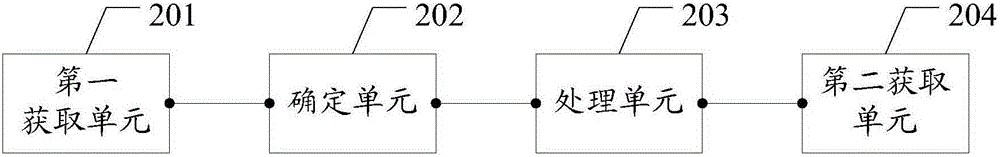

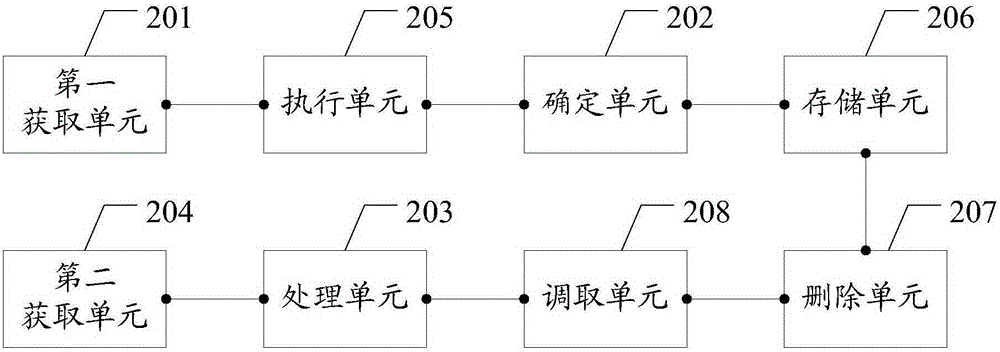

Method and device for calculating material requirement planning (MRP)

InactiveCN105205636AReduce the frequency of blockagesReduce resource consumptionLogisticsBill of materialsProgram planning

The embodiment of the invention discloses a method and device for calculating material requirement planning (MRP). By means of the method and device, materials can be segmented, a multi-process is used for performing distributed computing, blocking frequency of a database is reduced, and performance losses are reduced. The method includes the steps that a bill of materials (BOM) is obtained; parent item materials and subitem materials associated with the BOM in the BOM are determined through a pre-configured segmentation algorithm; the MRP corresponding to the parent item materials and the subitem materials associated with the BOM is calculated, and computing results are obtained; the computing results obtained respectively are combined, and a computing result of MRP of the BOM is obtained.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

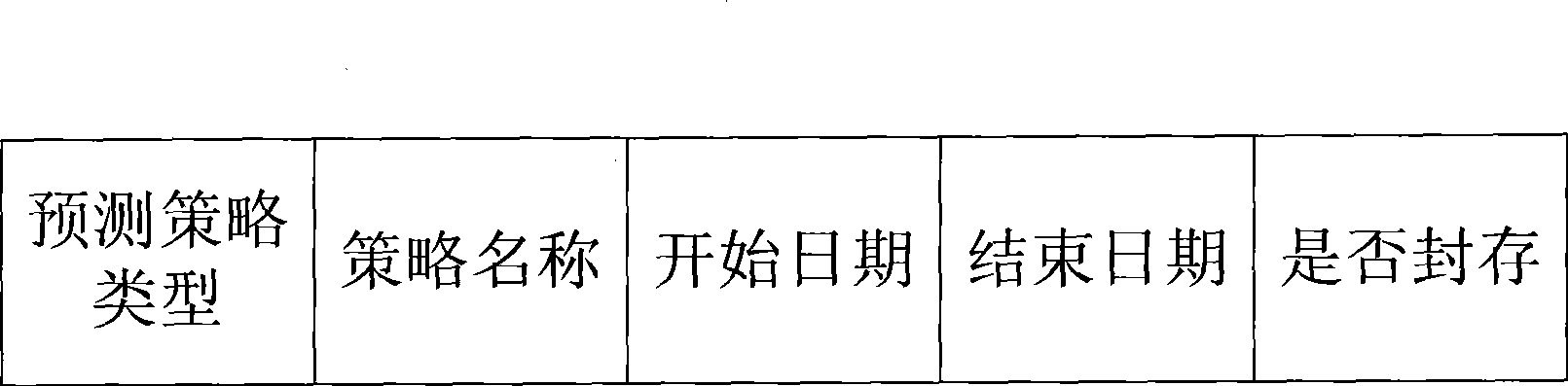

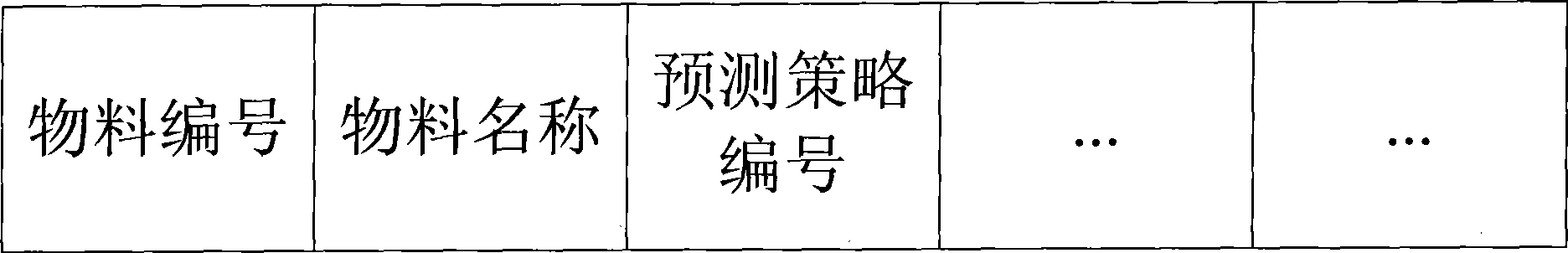

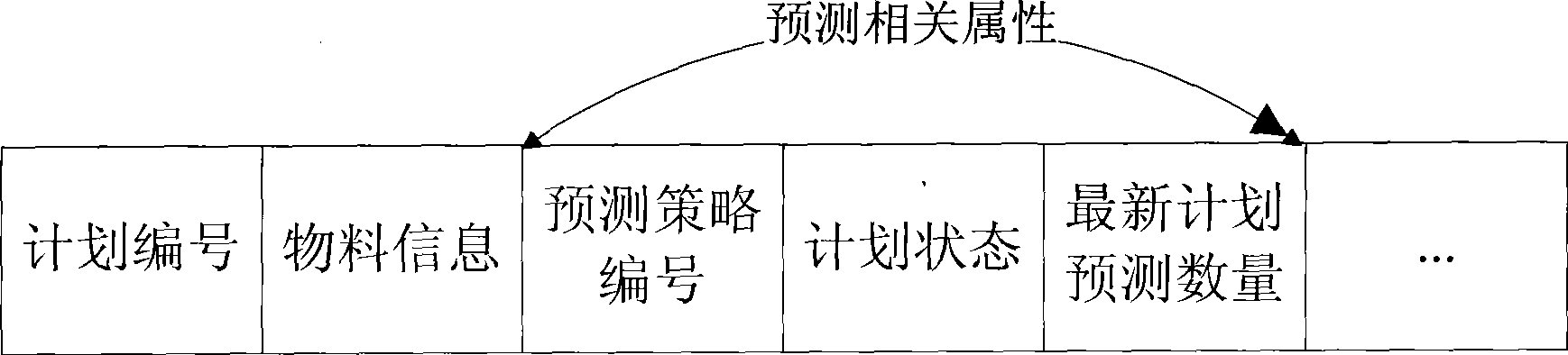

Method for rolling computation of material requirement in production management process

InactiveCN101510277AImprove turnover rateThe calculation result is accurateLogisticsManagement processMaterial requirements planning

The invention provides a rolling calculation method of material requirement in a production management process. According to the material requirement schedule of a product, a predicated type is set, the rolling calculation is carried out gradually on the basis that the ordering date is from far to near so as to lead the predicted value to be gradually close to the actual demand value, therefore, the method is used for guiding the purchase and production of enterprises. The detailed steps are as follows: A. a predicated strategy model formed by a predicated strategy number, a strategy name, a starting data, an ending data and attributes of sealing up or not is established; B. a material catalog model formed by a predicated strategy number and other attributes of the material is established; C. a production schedule model formed by a predicated strategy number, schedule states and other attributes of the production schedule is established; and D. an algorithm which is carried out by the material requirement schedule according to the predicated strategy is realized. The invention has the beneficial effects that the result is accurately calculated according to the material requirement schedule; the purchase and production requirements with accurate step-by-step prediction and reasonable product of the enterprise plan are met; and the inventory is reduced, and the turnover rate of funds is improved.

Owner:INSPUR COMMON SOFTWARE

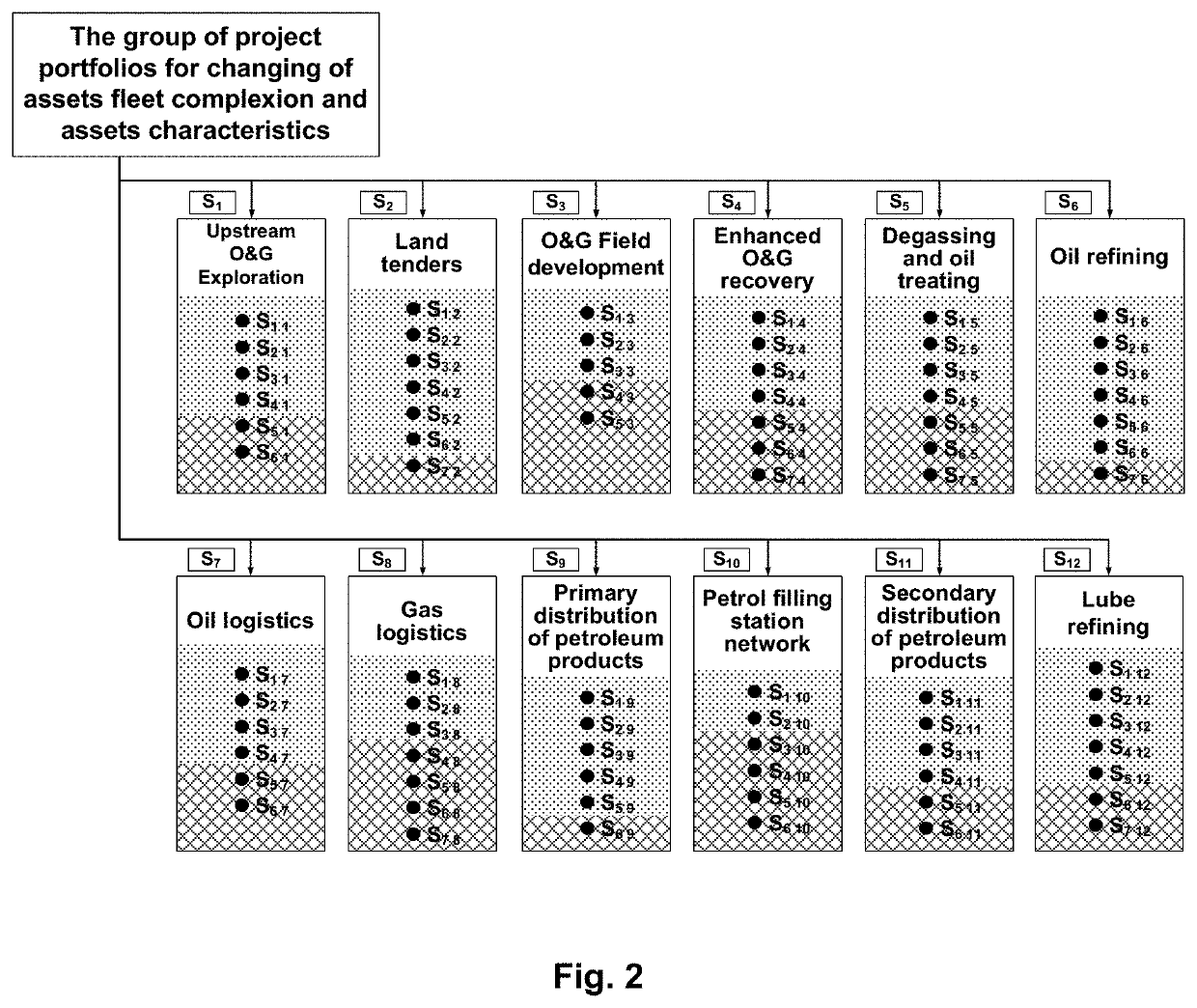

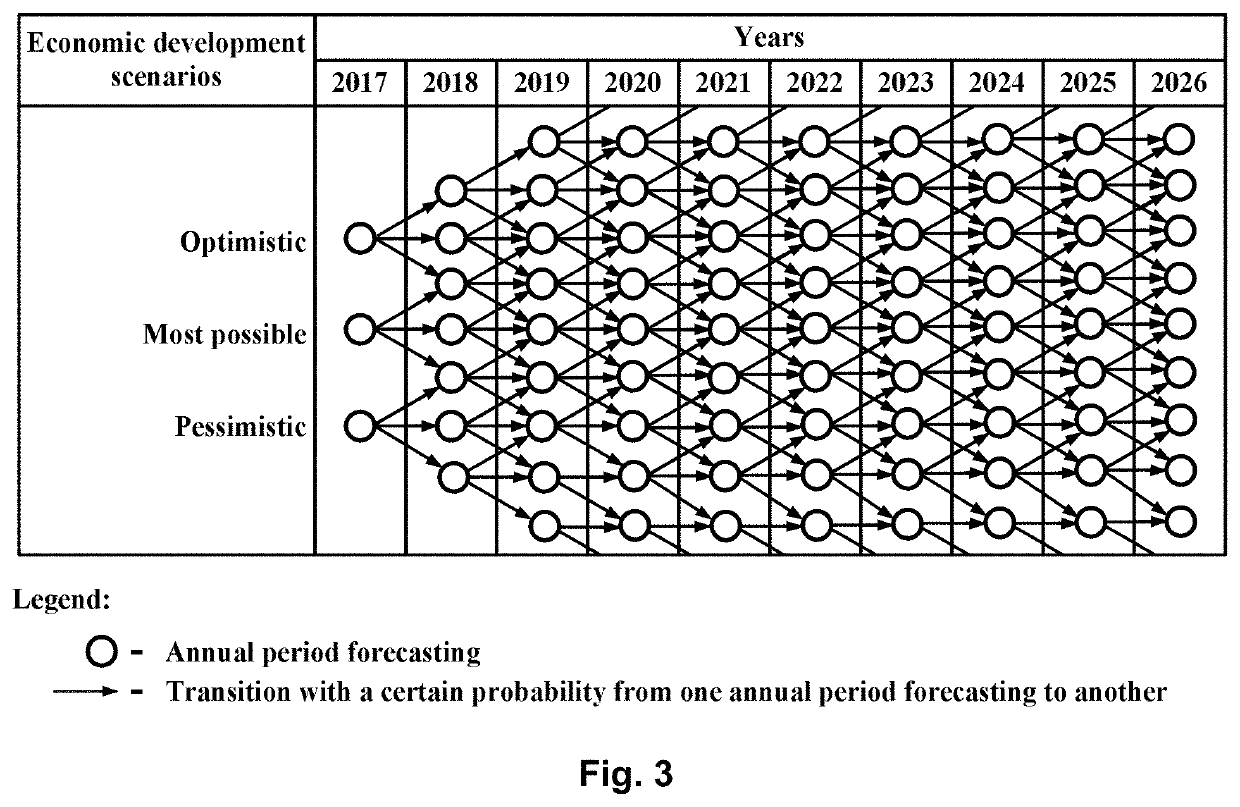

Method and device for planning company asset operations

Proposed is an algorithm for long-term optimal planning of asset operations for companies having large stocks of assets, which is conceptually similar to the MRP II algorithm for material requirements planning. The present algorithm envisages generating scenarios of the long-term development of a company, and sorting said scenarios for the purpose of identifying a scenario which provides the maximum net discounted profit for an entire period. The scenarios determine the completion dates of projects relating to the acquisition and building of new assets and the rebuilding of existing assets. Each scenario is broken up into yearly intervals, for which optimal internal supply chain plans are calculated, and an evaluation of the implementability of said supply chains on the basis of available assets is conducted. In essence, the proposed algorithm constitutes a combination of active and passive approaches to solving a Reinforcement Machine Learning class problem. For the purpose of implementing the proposed algorithm, a software architecture is proposed which includes: a main management module which implements the proposed algorithm, functional modules, and information / support modules.

Owner:OPTIMAL MANAGEMENT LLC RU RU

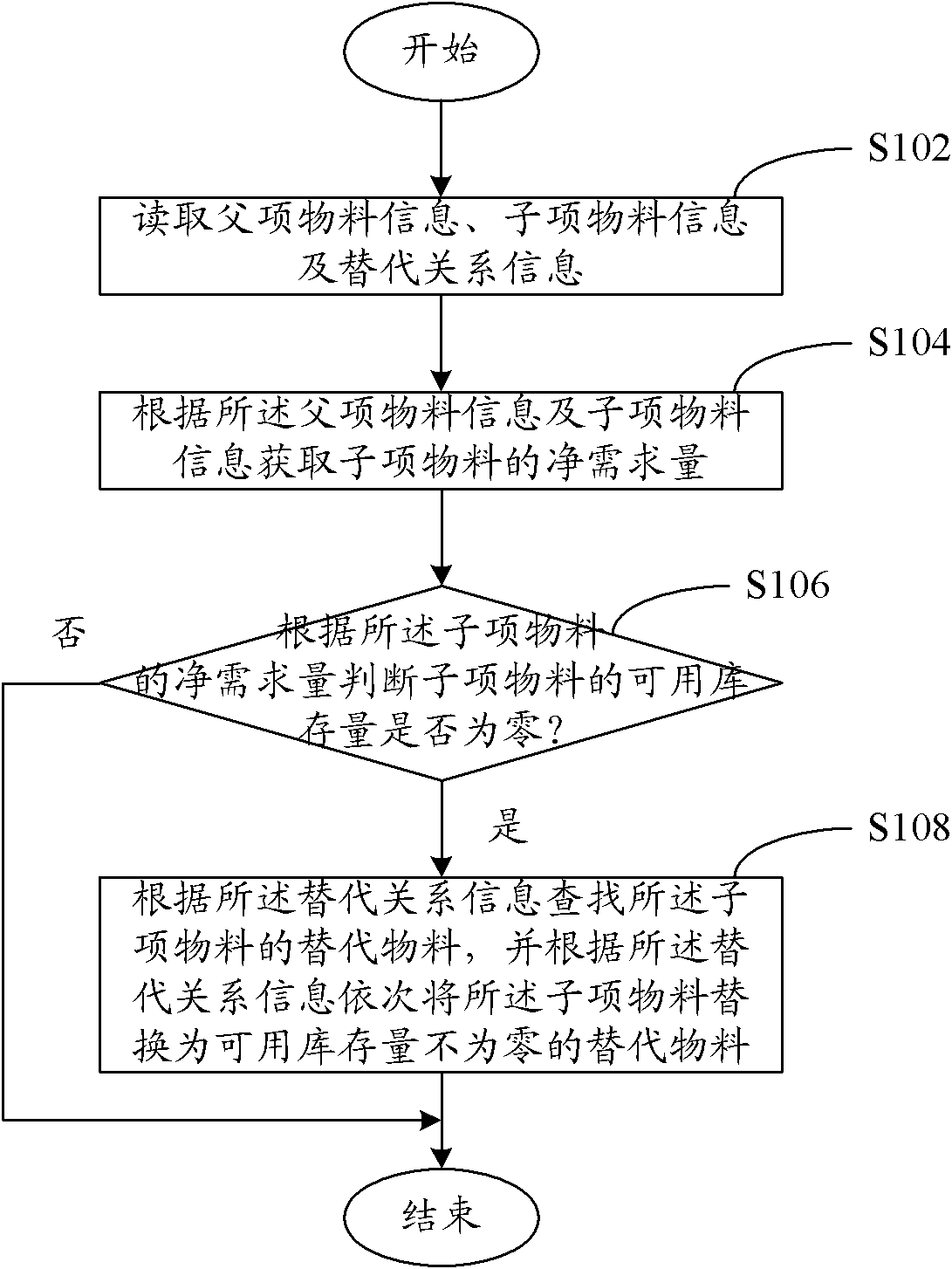

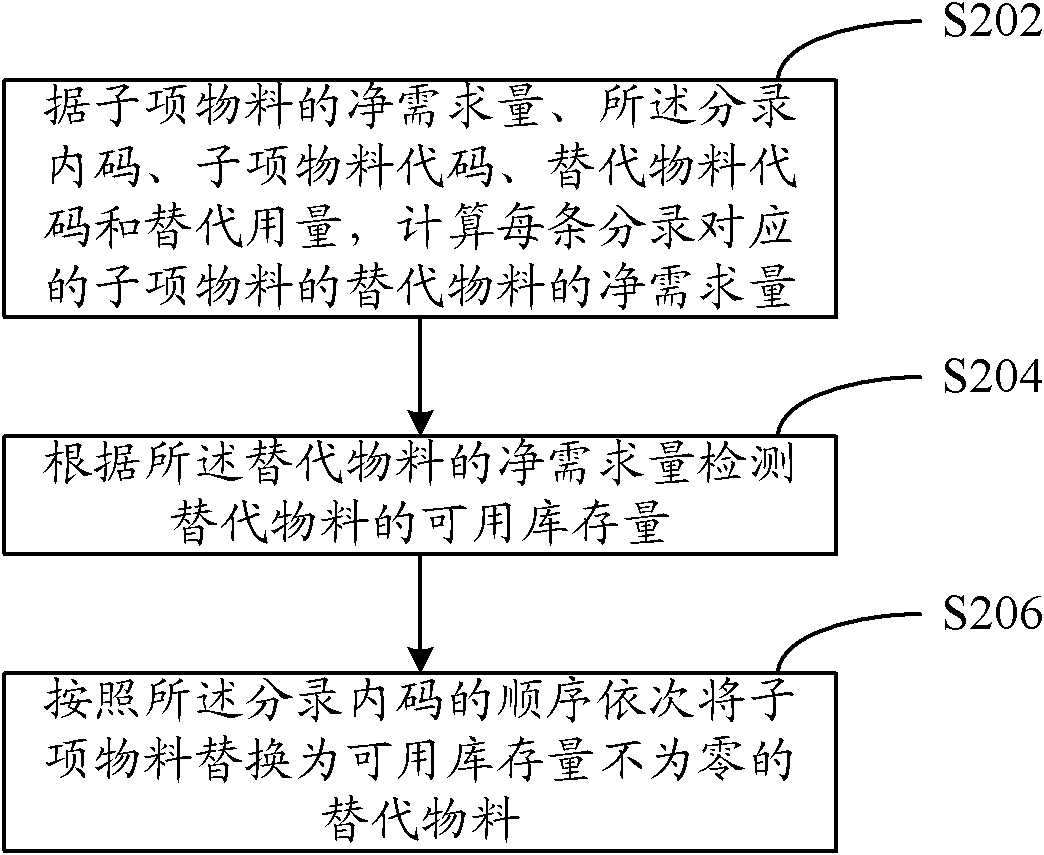

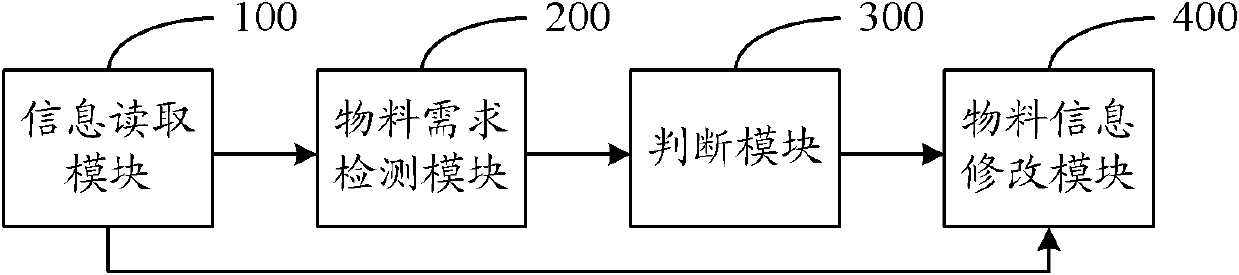

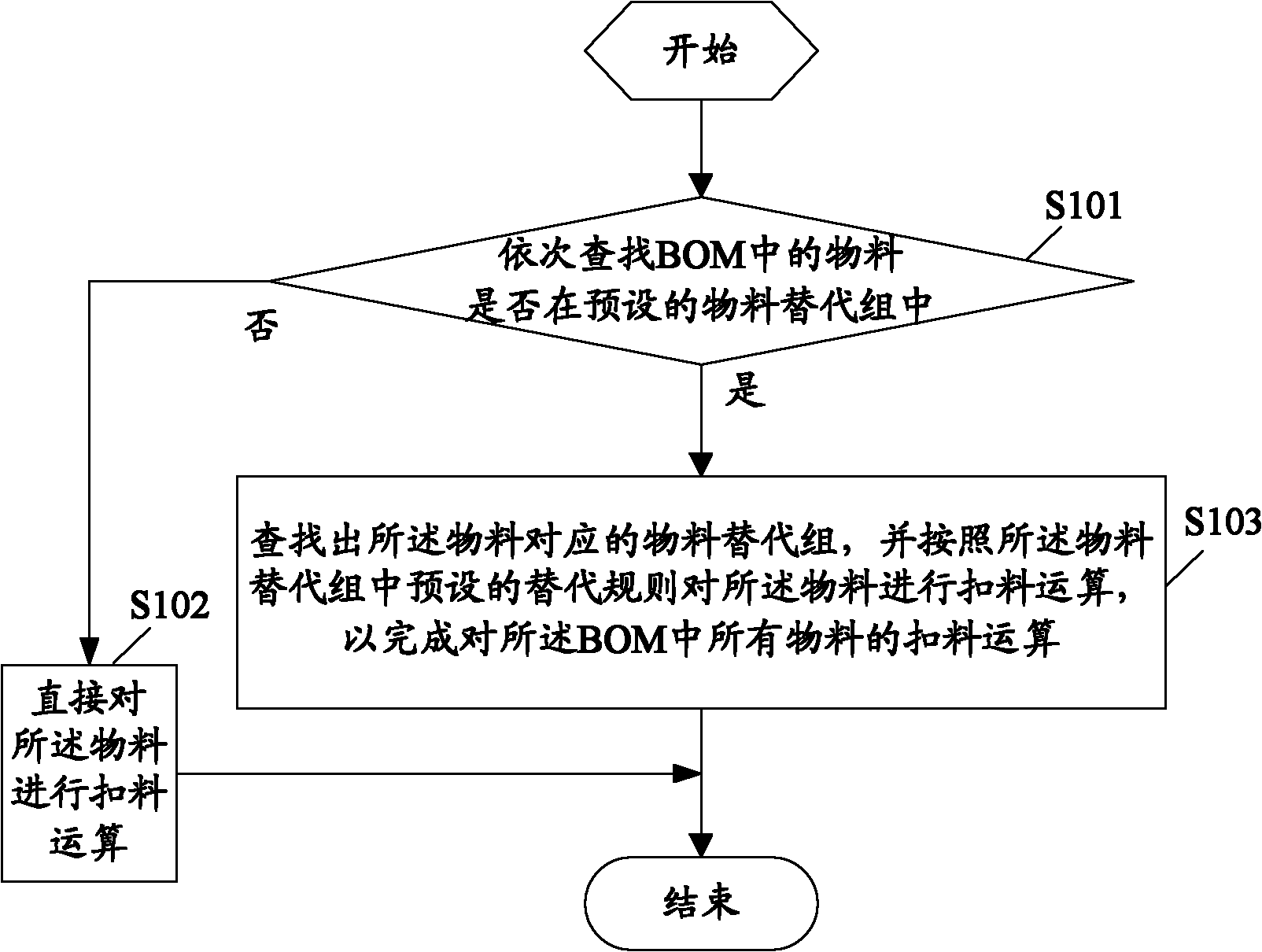

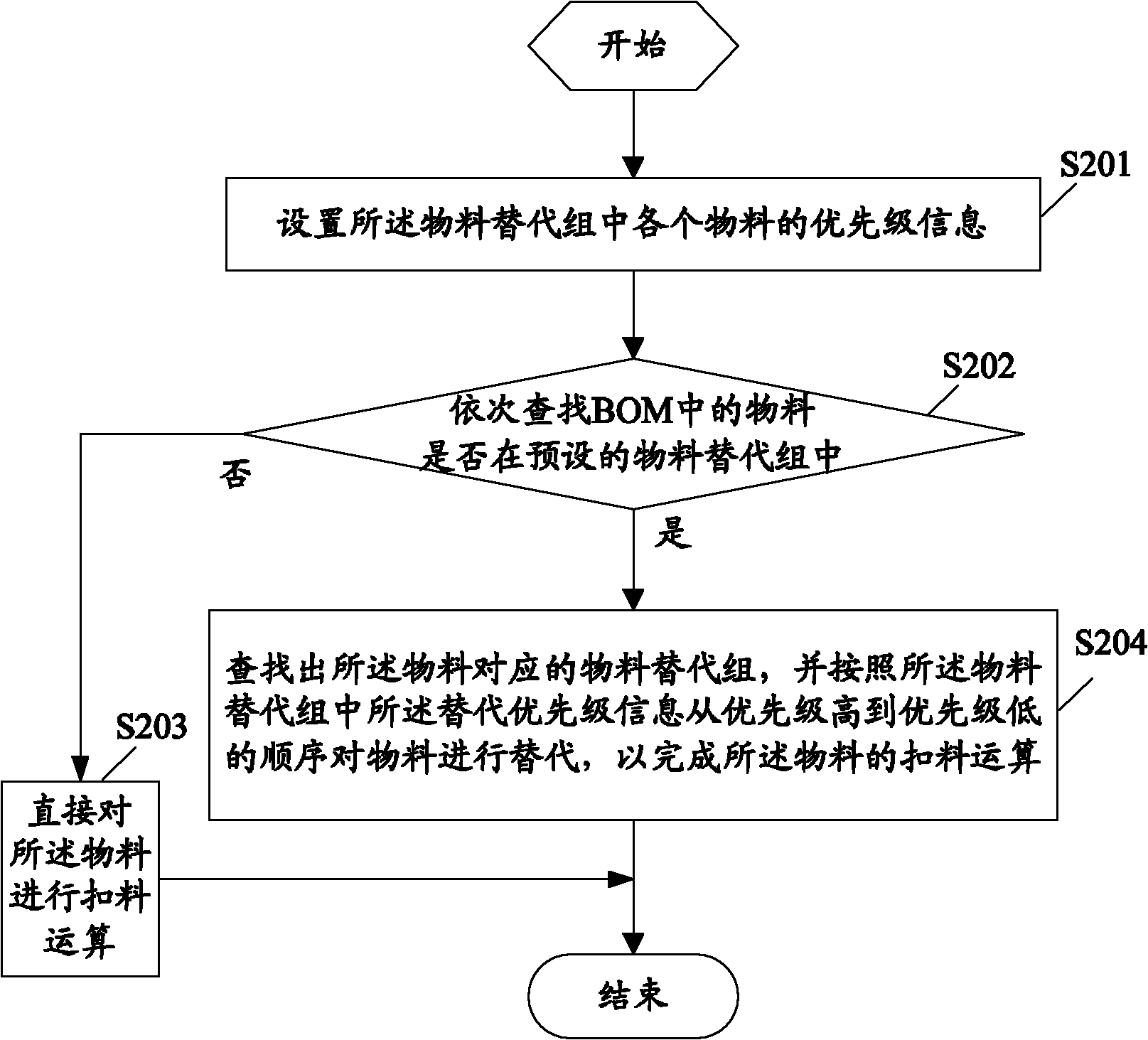

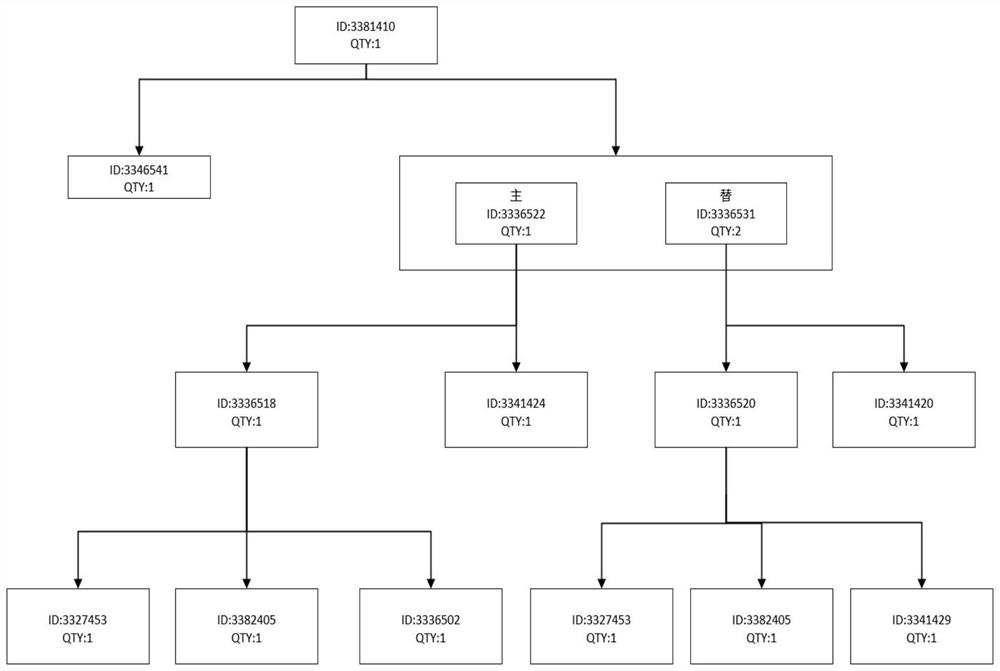

Material substitution method and device in material requirement planning system

ActiveCN102567864AAlternative implementationImprove usabilityLogisticsMaterial requirements planningSubstitution method

The invention provides a material substitution method in a material requirement planning system. The method comprises the following steps of: reading the parent item material information, the child item material information and the substitution relation information; obtaining the net requirements of the child item material according to the parent item material information and child item material information; judging whether the available inventory of the child item material is zero according to the net requirements of the child item material; and if the available inventory of the child item material is zero, searching for a substitution material of the child item material according to the substitution relation information, and substituting the substitution material of which the available inventory is not zero for the child item material according to the substitution relation information. Through the method, the material substitution for the designated child item can be realized, and the availability of the system is improved. Moreover, the invention also provides a material substitution device in a material requirement planning system.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

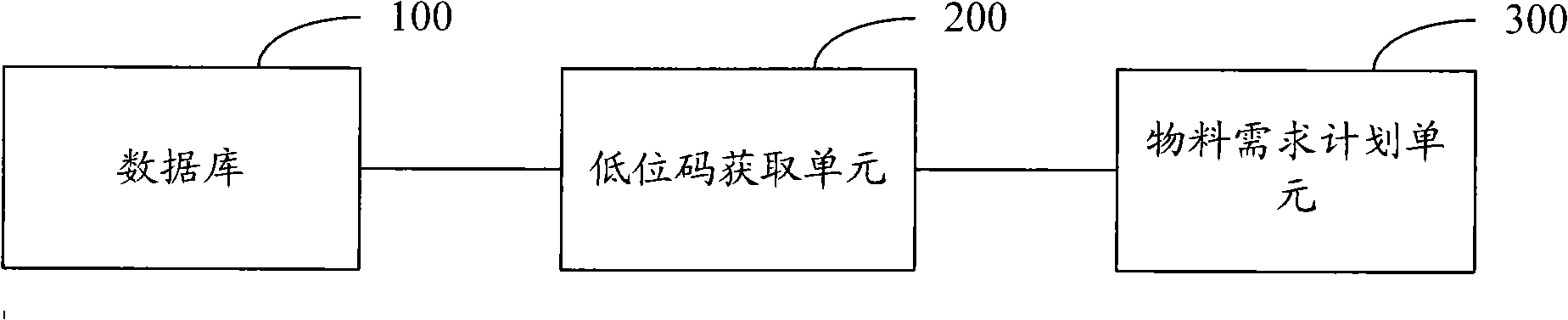

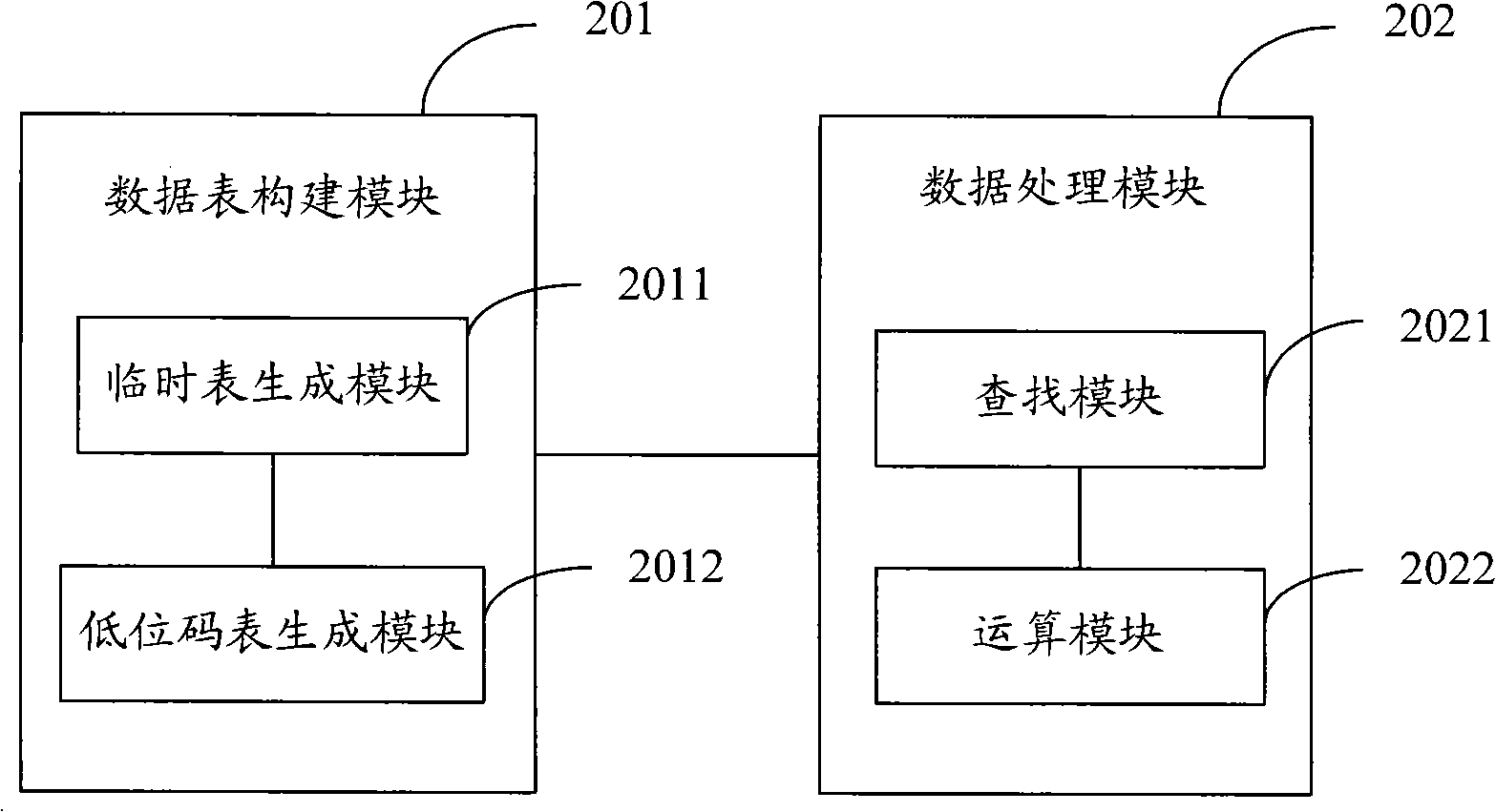

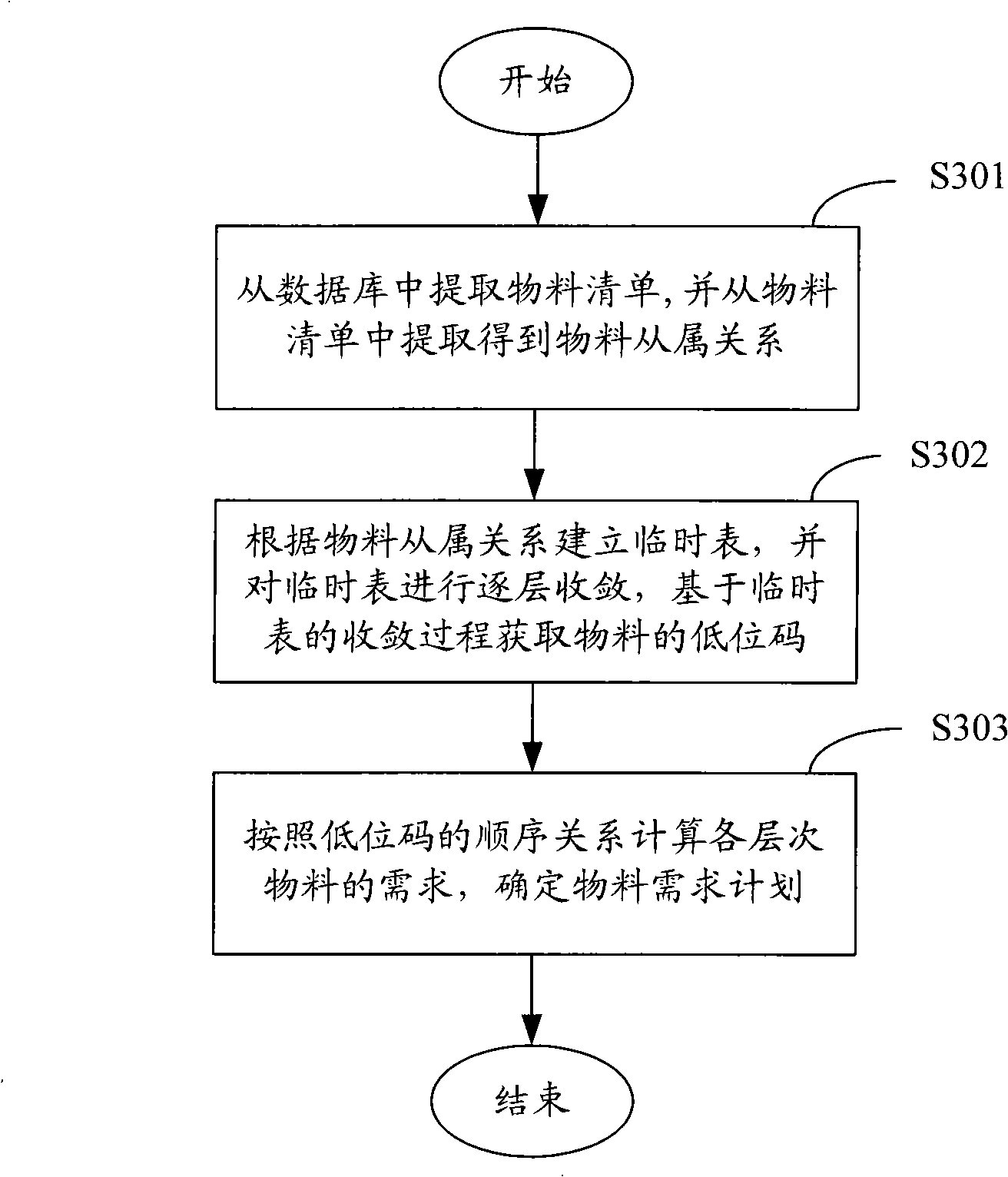

Method, system and equipment for determining material demand plan and obtaining material low level code

InactiveCN101339635ASmall amount of calculationImprove operational efficiencyResourcesSpecial data processing applicationsBill of materialsMaterial requirements planning

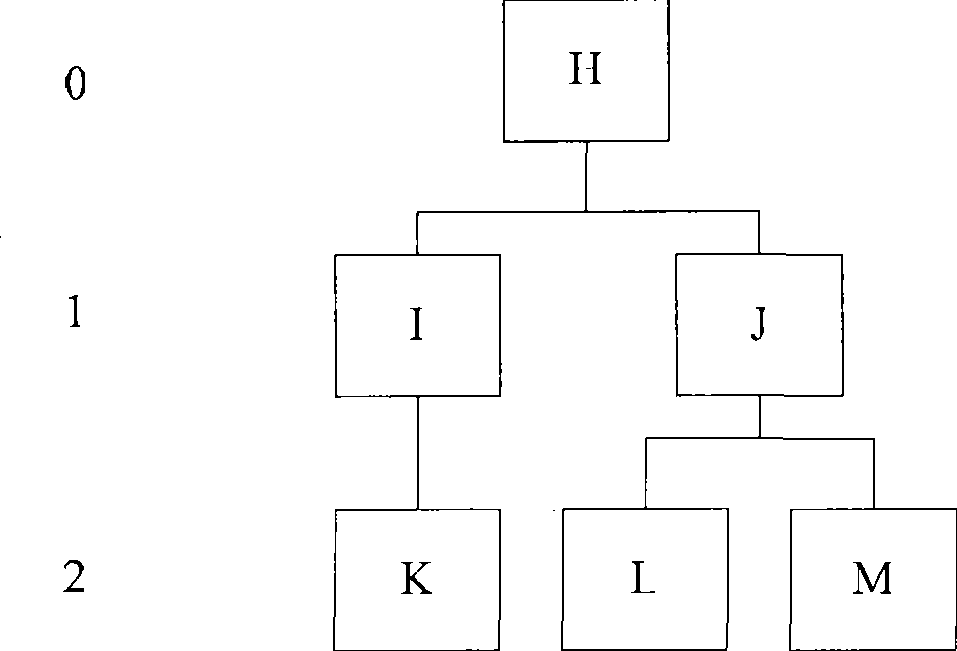

The invention relates to the field of material management and provides a method for determining the plan of material requirements and obtaining material low level code, a system and a device thereof. The method for determining the plan of material requirements comprises the following steps: A a bill of materials is extracted from a database, and the relation of subordination of material is extracted from the bill of materials; B. a temporary table is established according to the relation of subordination of the material and is converged layer by layer, and the material low level code is obtained based on the convergent process of the temporary table; C. the material requirements of each level is calculated according to the ordinal relation of the low level code, thus determining the plan of the material requirements. Each bill of materials in the process of obtaining the low level code in the invention need not to be processed, and the data in the temporary table can be converged layer by layer, thus greatly reducing calculated amount and improving the efficiency of obtaining the material low level code and determining the plan of the material requirements.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

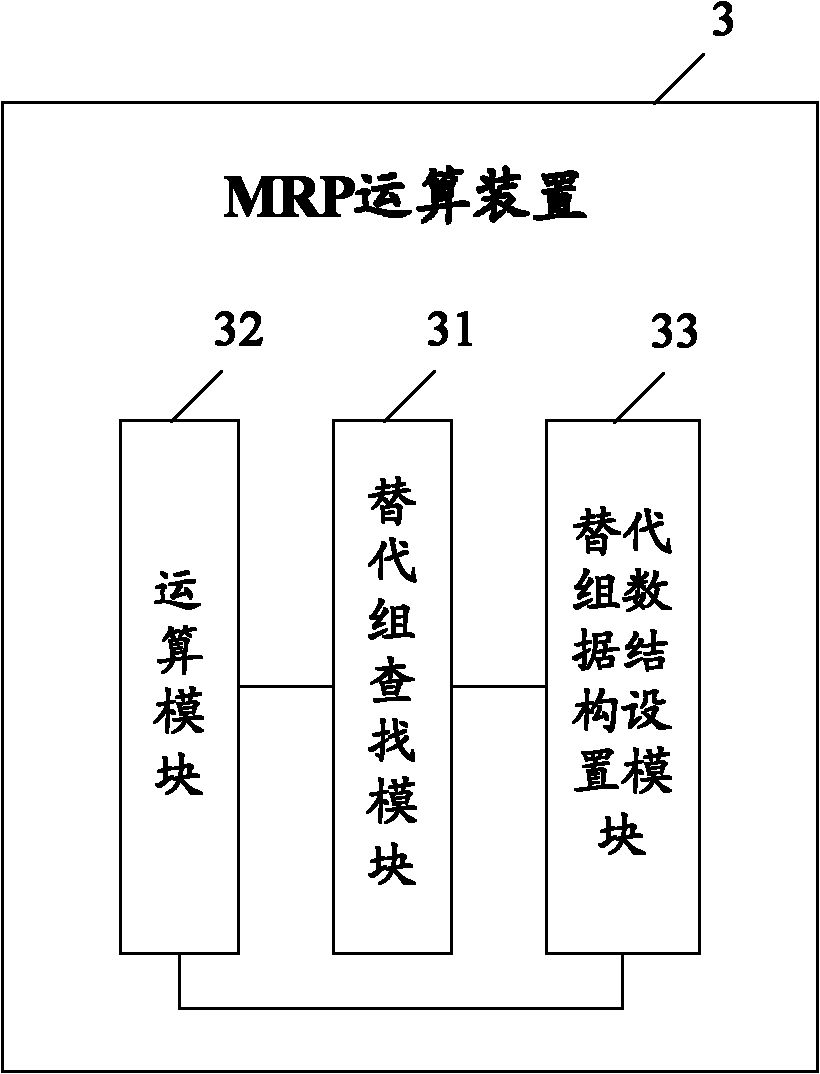

Material requirement planning (MRP) operation method and device

InactiveCN102034162AIncrease flexibilitySolve the problem of low computing efficiencyInstrumentsBill of materialsMaterial requirements planning

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

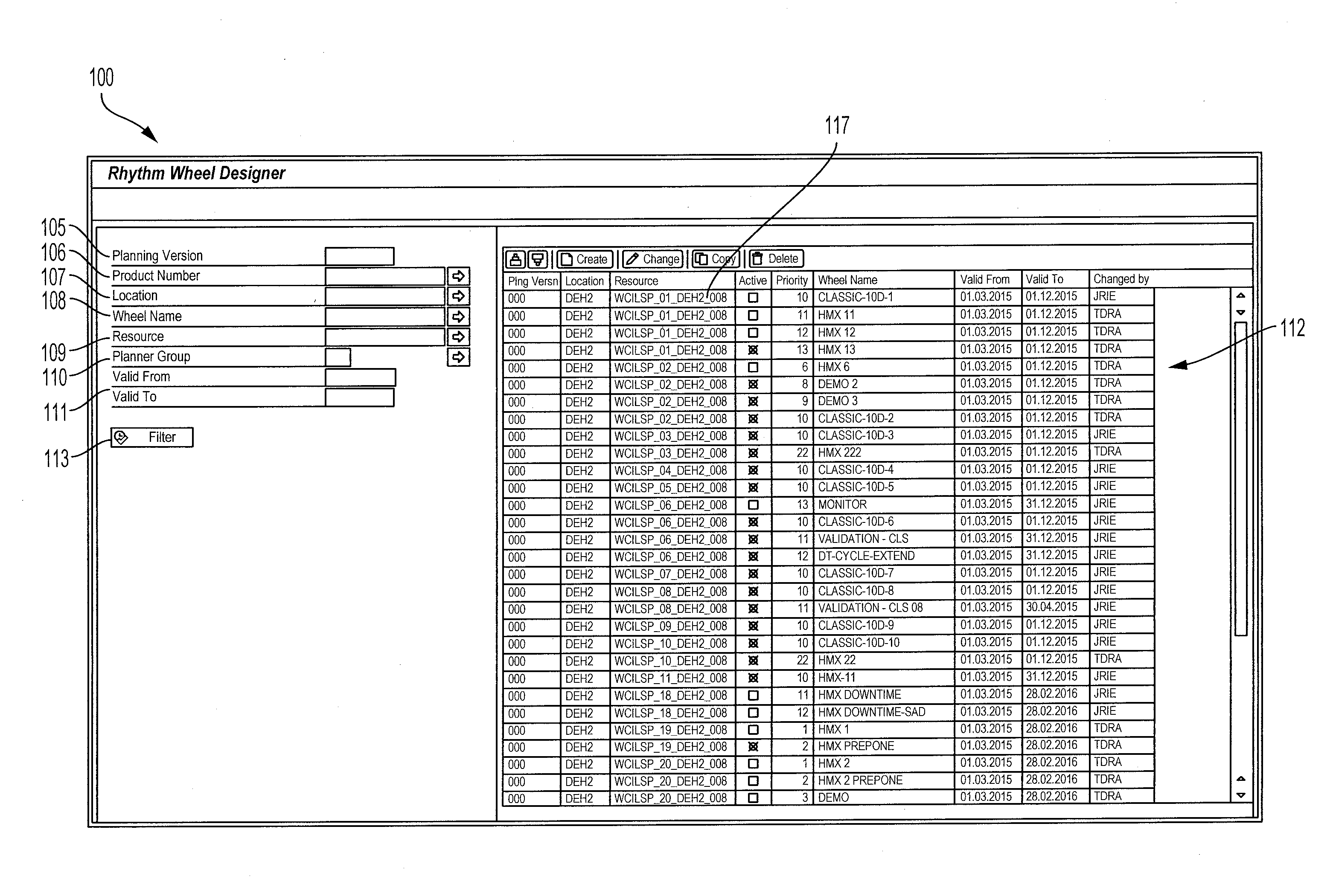

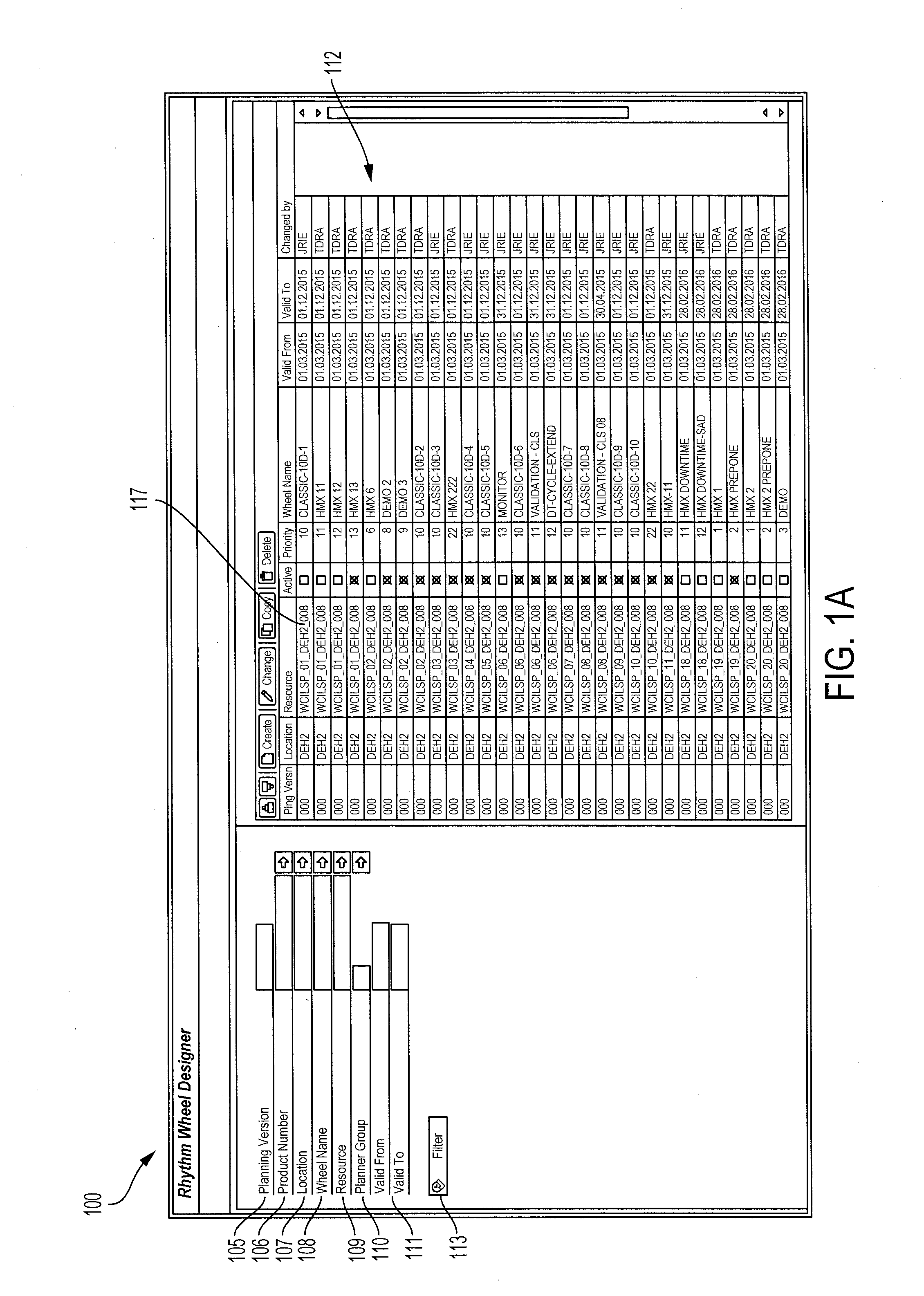

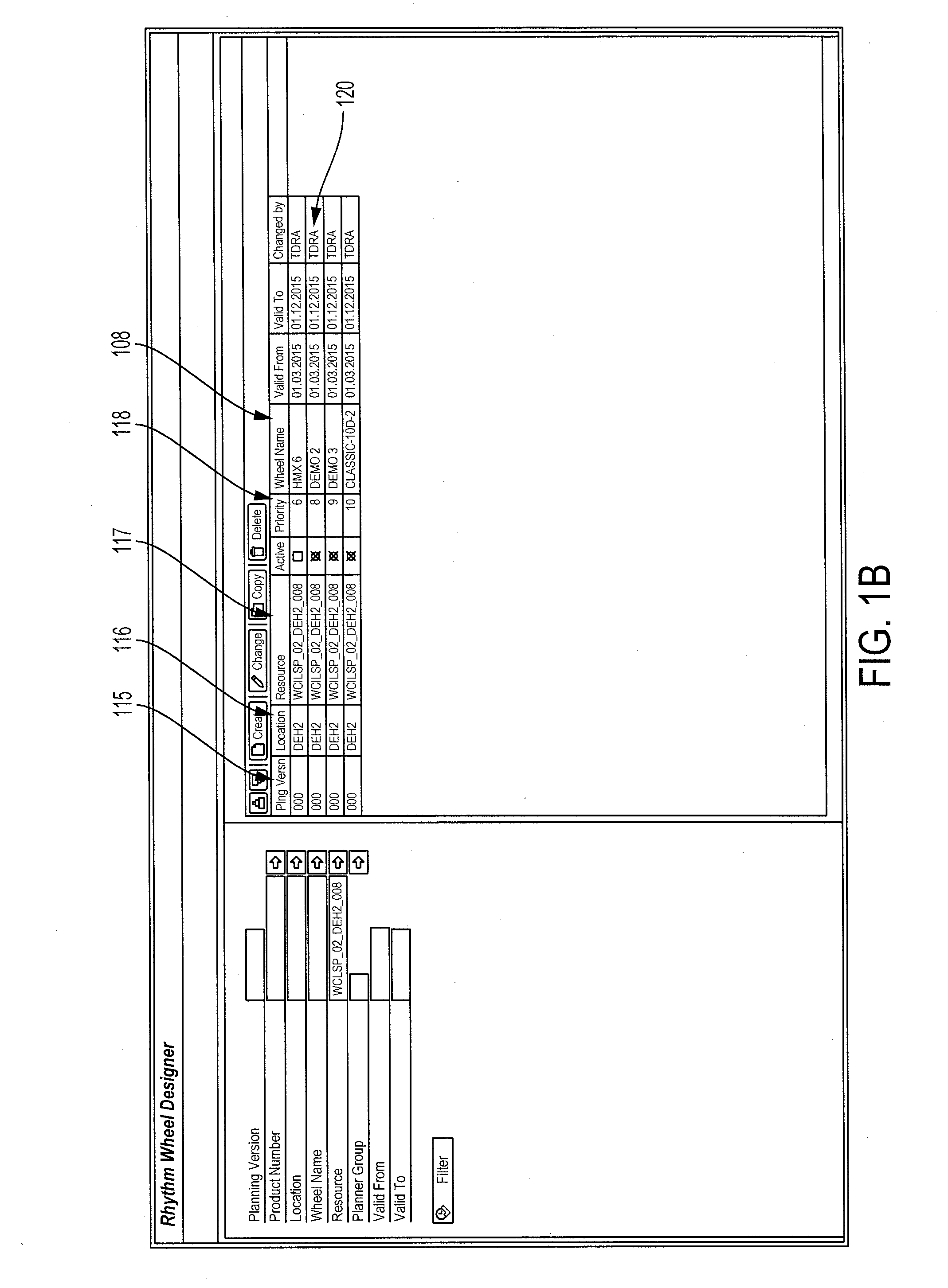

System and method for high-mix wheels for capacity planning resource planning and material resource planning

InactiveUS20160307136A1Better and faster planning resultsEnhanced Lean Planning algorithmsResourcesFeature setProgram planning

A system and method for enhance planning concepts by adding High-Mix Wheels to the feature set of existing SAP ERP / SCM system landscapes and may also combine planning concepts with an automatic material resource planning (MRP) and capacity resource planning (CRP) logic enhanced by factoring algorithms. This is the first time that MRP, CRP and factoring against constraints can be done in one single planning step, enabling better and faster planning results. Extreme tight integration of planning optimization based on Lean paradigm is provided that may include enhanced Lean Planning algorithms that extend rhythmic planning.

Owner:CAMELOT ITLAB GMBH

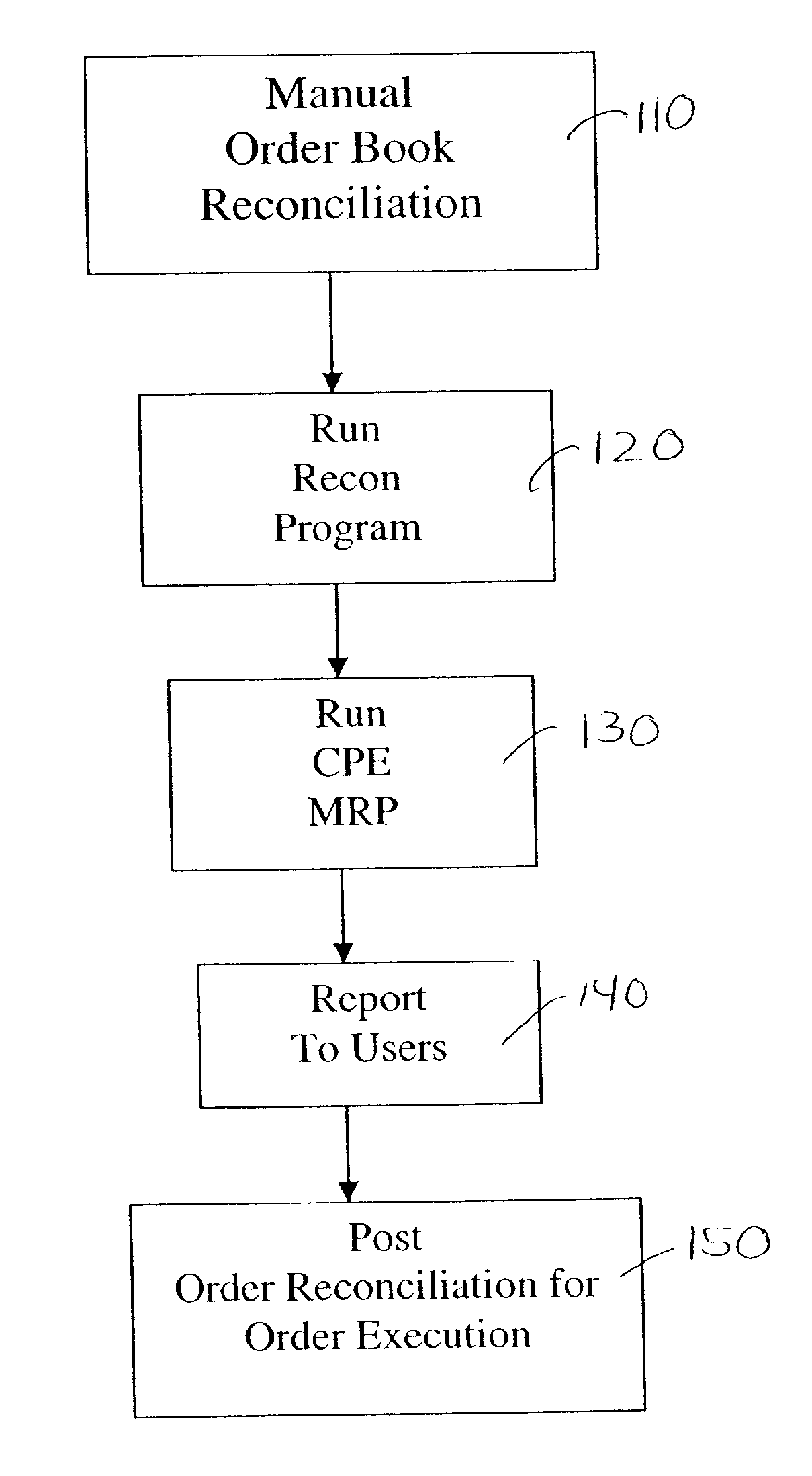

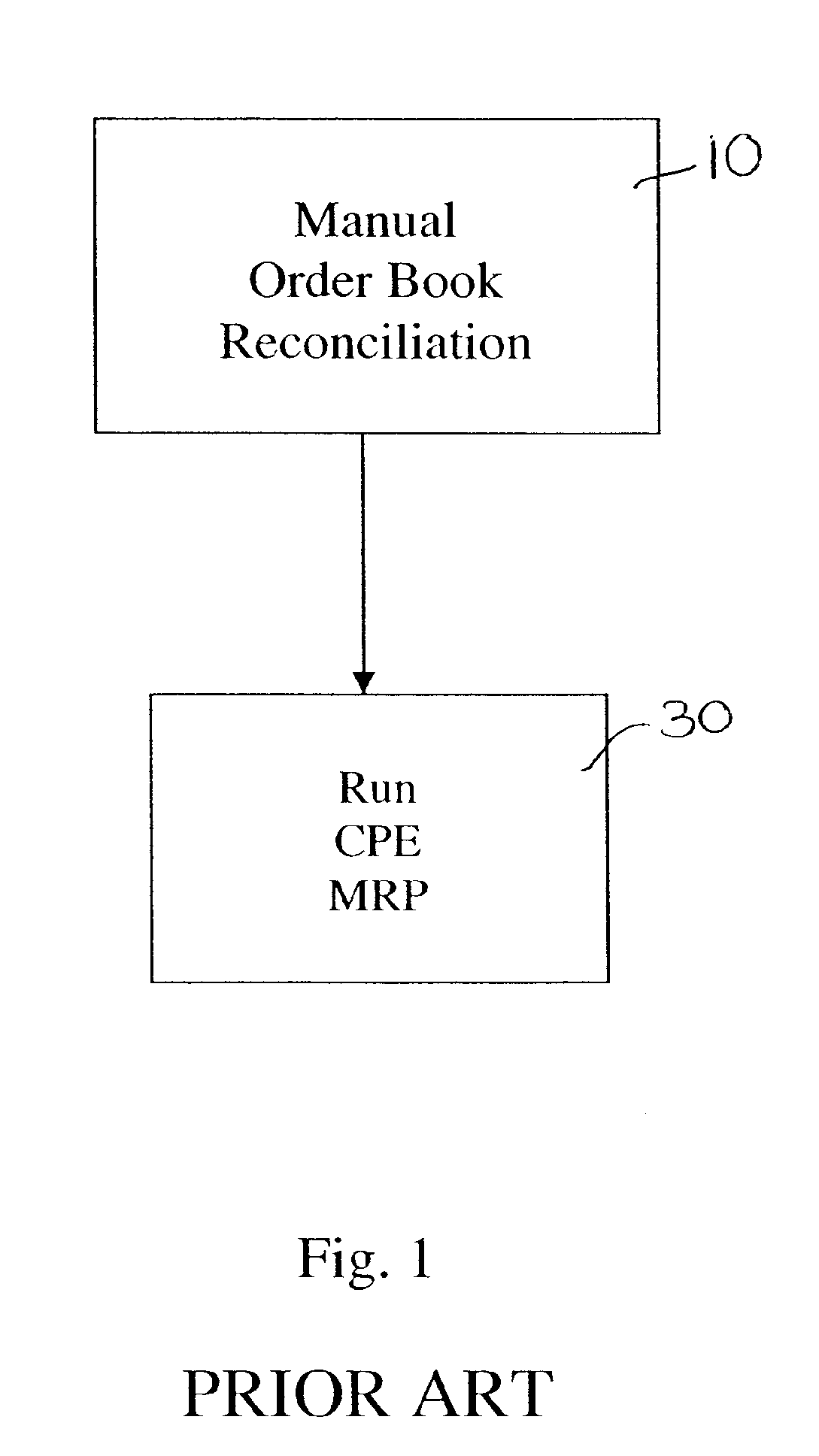

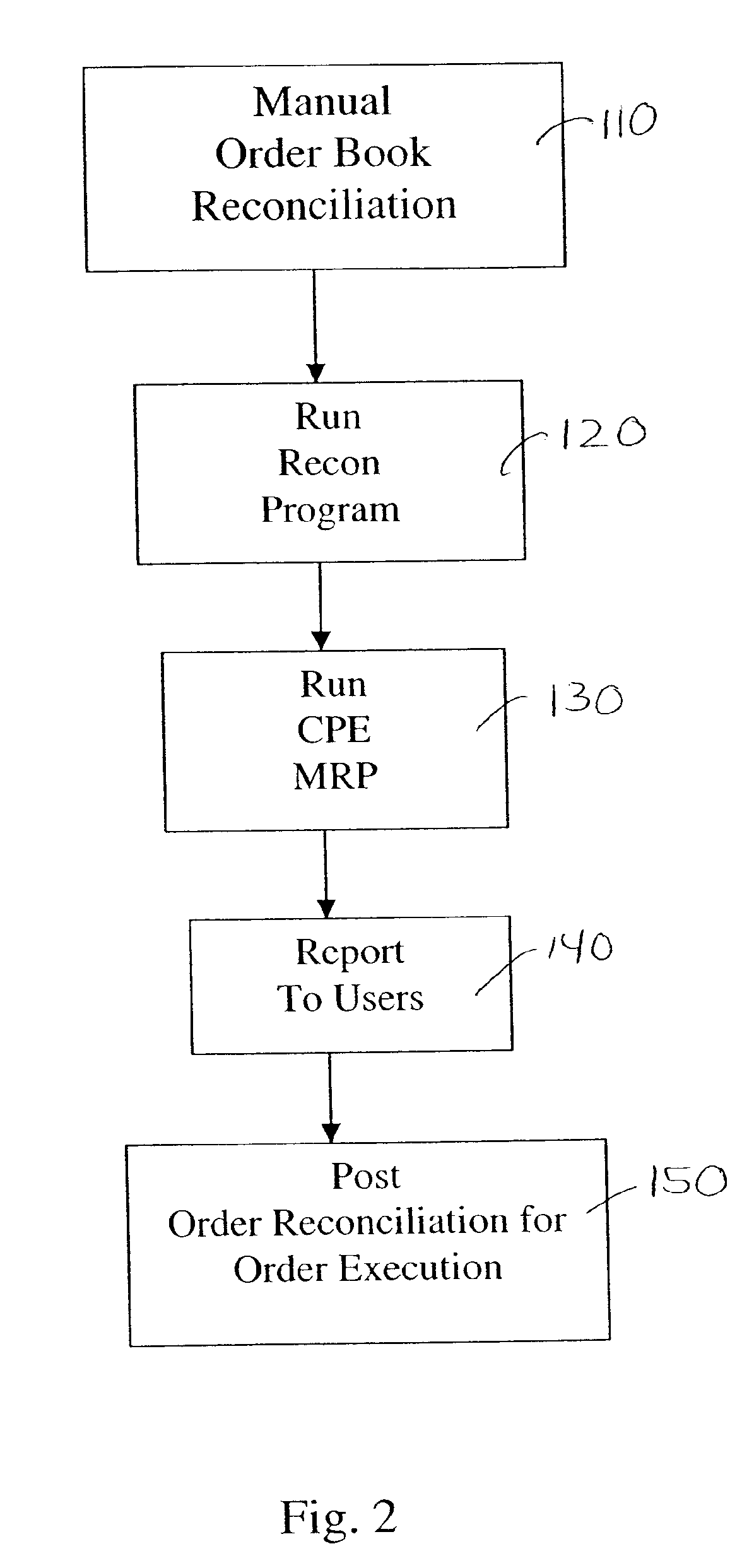

Automated order book reconciliation process

InactiveUS20070055575A1Avoid under-shipment and over-shipmentAvoid undesired supplier over-stockCommerceMaterial requirements planningMaterial requirements

Methods, systems and apparatus for determining a current state of an order book for order request reconciliation. A customer inputs an order request for a desired quantity of items to be shipped to a recipient into the system. A supplier inputs a shipment quantity of any such previously shipped items into an input table, while a recipient inputs into another table a receipt quantity of any such received items. These input shipment and receipt quantities are then transmitted to a reconciliation program of the system for determining an in-transit quantity that is used along with the receipt quantity to generate an updated, current state of the order book. This current state of the order book substantially avoids any over-shipments, under-shipments and unwanted inventory returns. A Materials Requirement Planning component then generates an order book reconciliation output table for viewing by users using the current state of the order book.

Owner:IBM CORP

Range-assigned material demand planning method and relevant apparatus

InactiveCN101388088AImprove timelinessImprove targetingLogisticsMaterial requirements planningMaterial resources

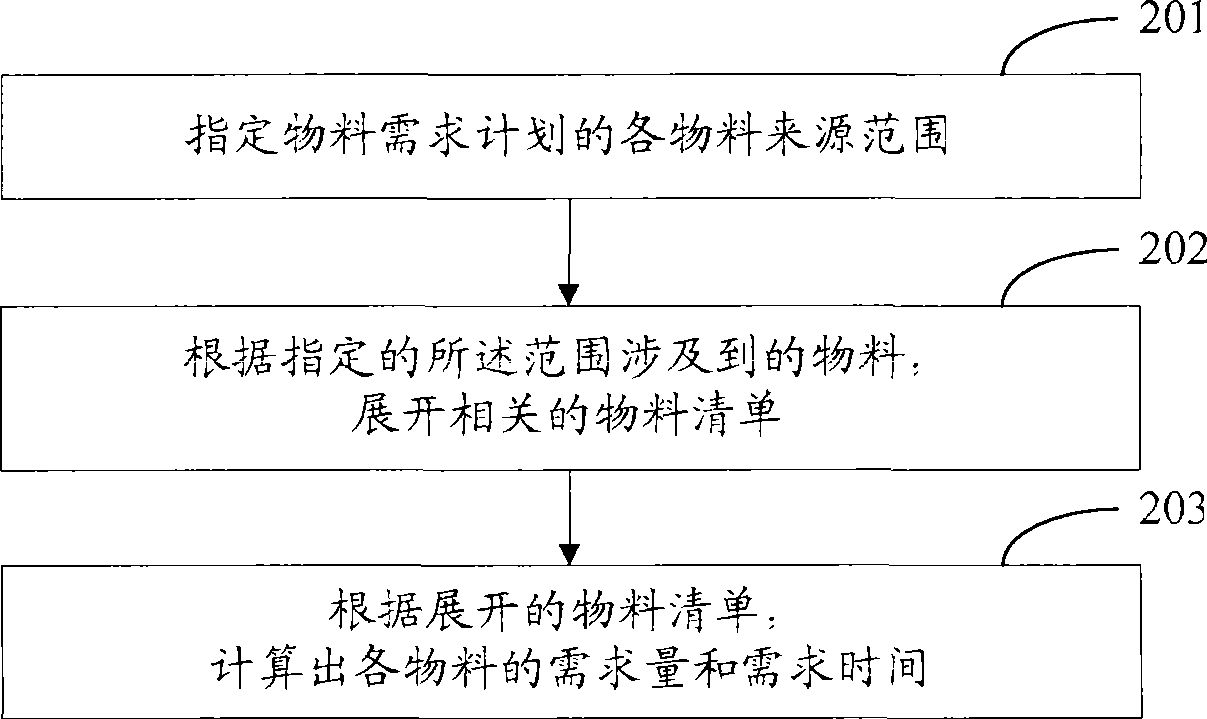

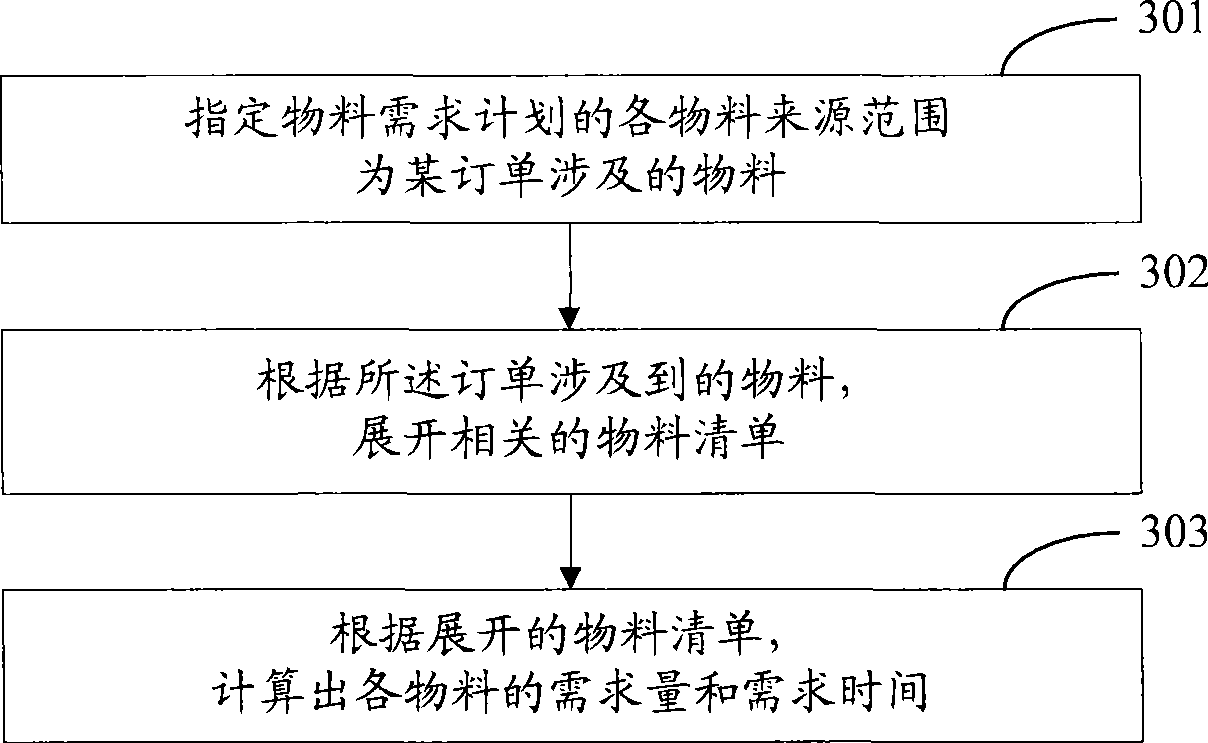

An embodiment of the invention discloses a material requirement planning method and a relative device, which designates a range. The steps of the method comprise designating a material resource range of a material requirement plan, developing a relative material list according to materials related in the designated range, and calculating the requirement quantity and the requirement time of each material according the developed material list. The embodiment of the invention calculates the requirement quantity of each material through designating the resource range of each material of the material requirement plan according to the designated range, and enables the calculation of the material requirement plate to be capable of designating a range, for example, calculating aiming at a specific sales order, further, the invention is convenient in use, increases the timeliness and the direction of the material requirement plan, and reduces the calculation and increases the calculation speed because of shortening the calculation range.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

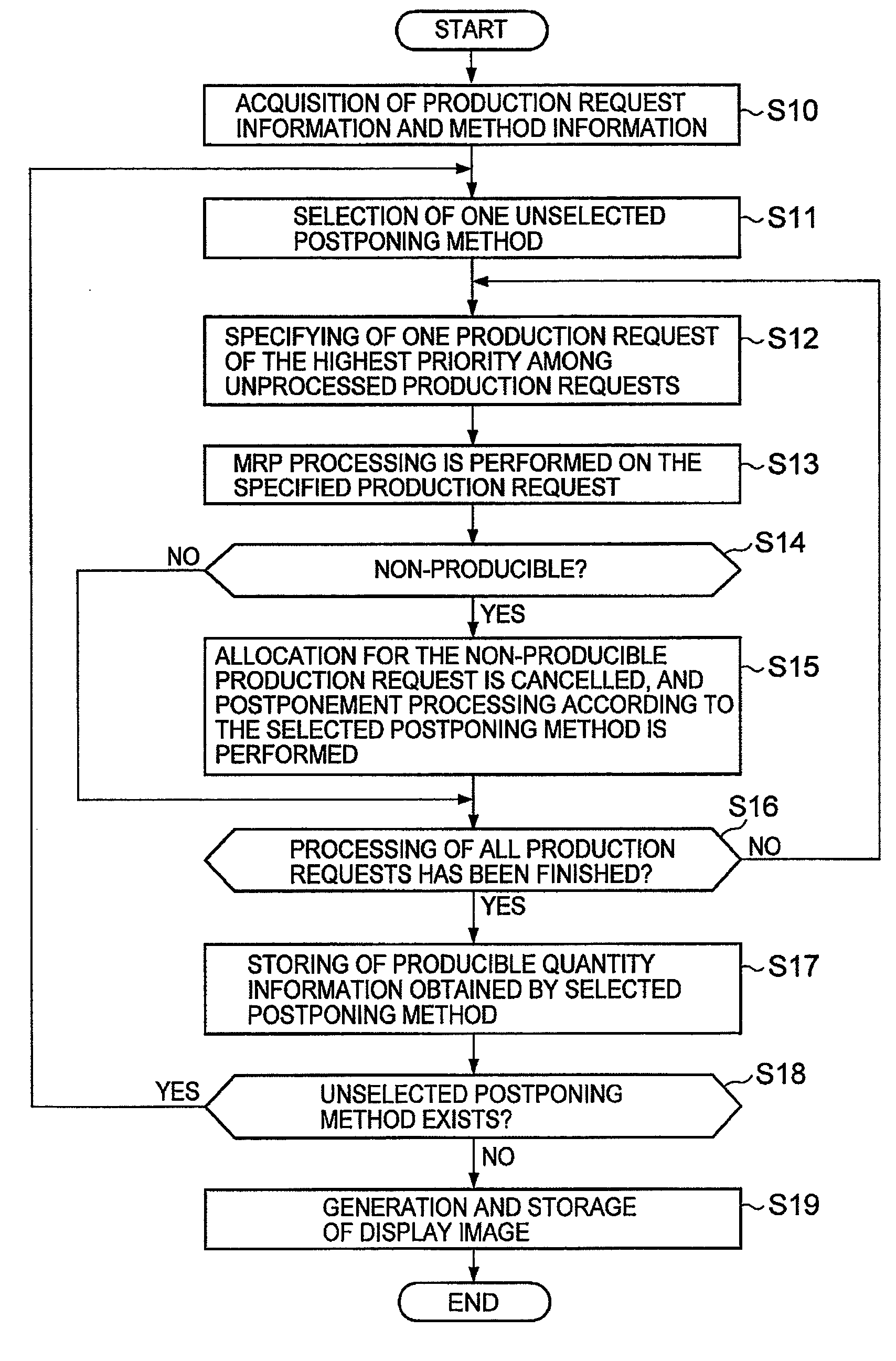

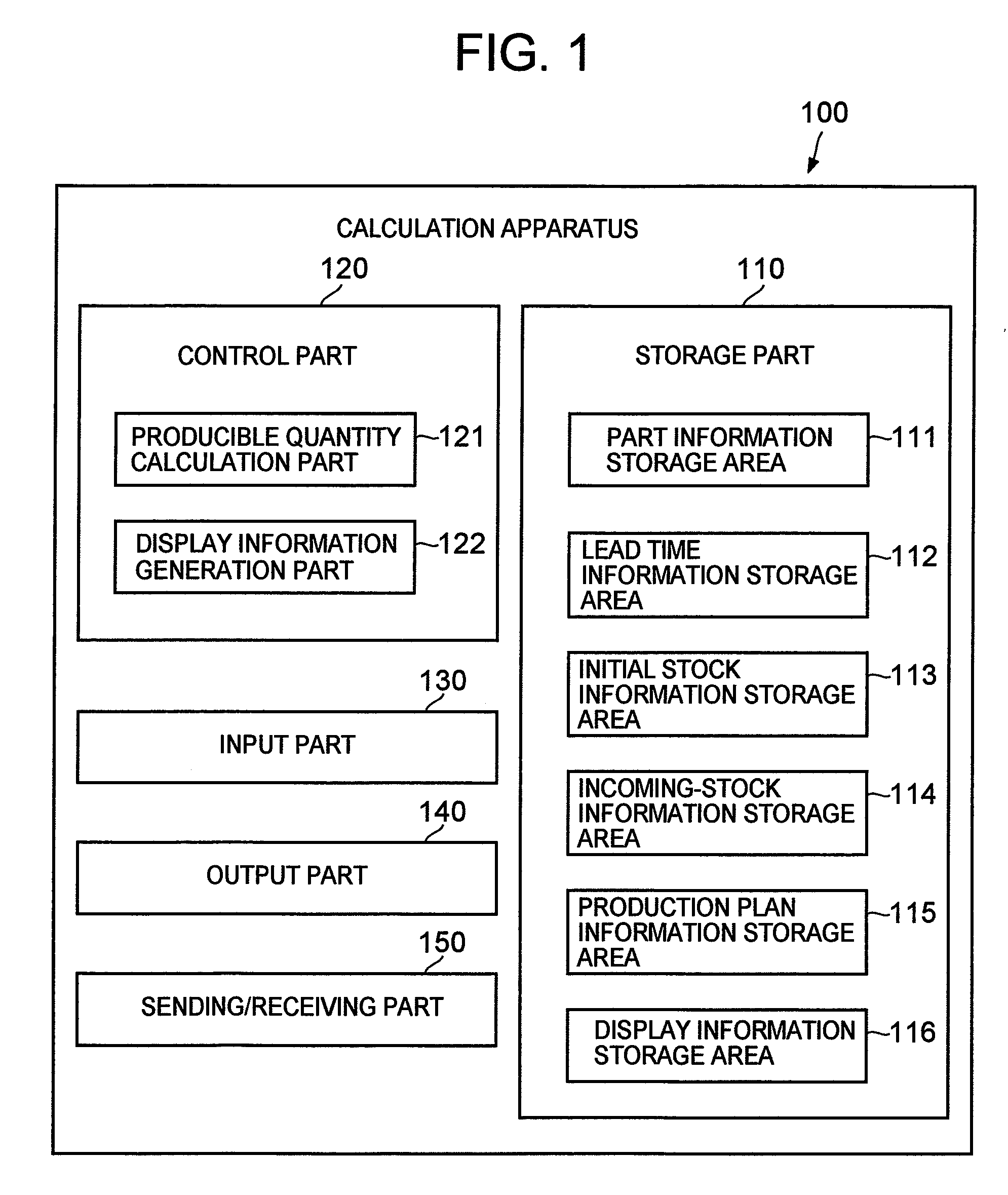

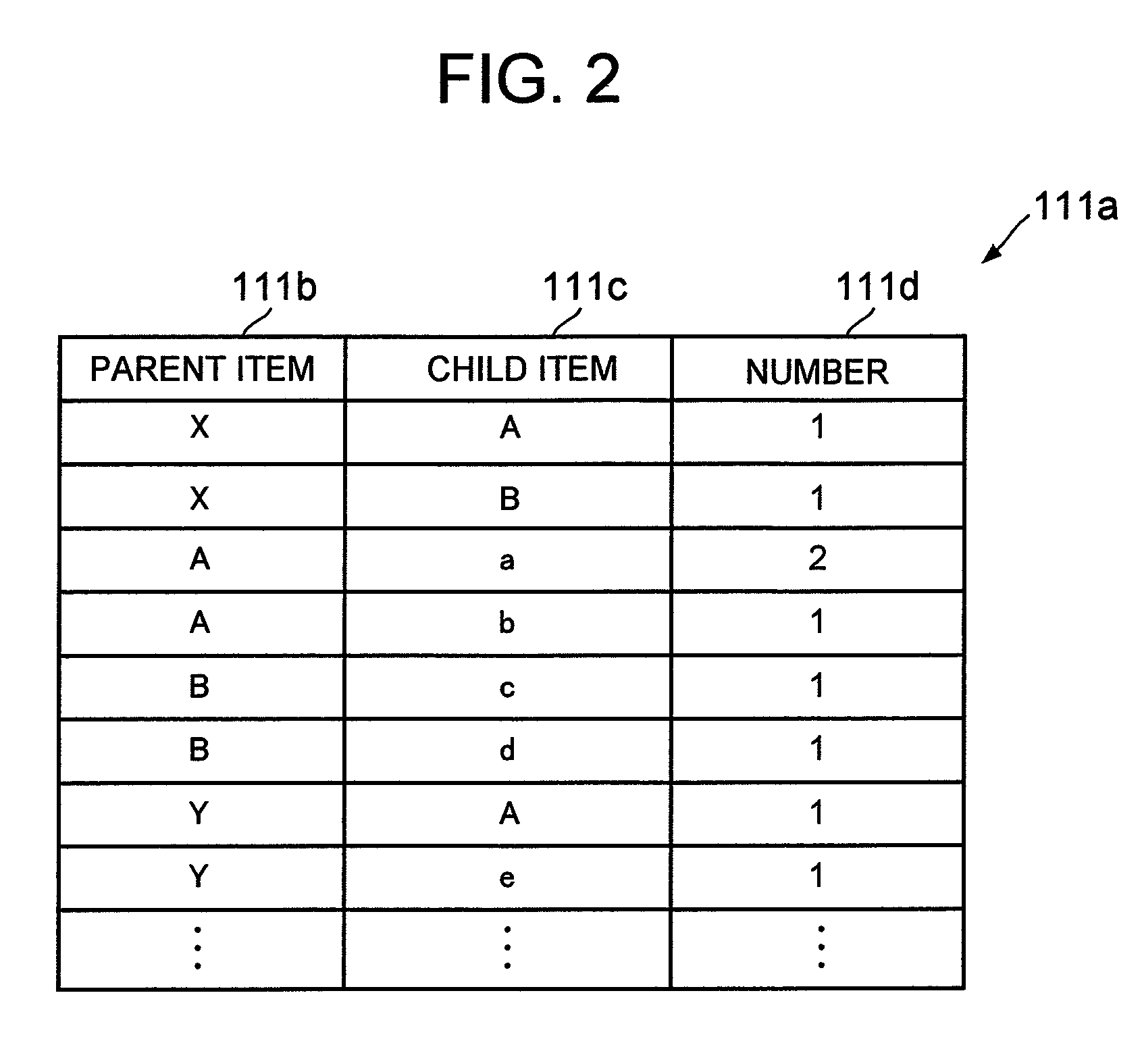

Calculation apparatus, program, calculation system and calculation method for production plan

A technique that can make a flexible production plan adaptable to circumstances of a production request-issuing side.A producible quantity calculation part performs Material Requirements Planning for obtaining a producible quantity and a possible production date, with respect to production request information that has at least one production request specifying a requested production quantity of a product, a requested production date, and a priority. If the producible quantity calculation part judges that a requested production quantity in one production request cannot be produced by the requested production date in that production request, then the producible quantity calculation part postpones the requested production date to a later date according to a plurality of methods, to obtain producible quantities and possible production dates. The producible quantity calculation part generates image data that display, in a table, the producible quantities and possible production dates obtained by the methods.

Owner:HITACHI LTD

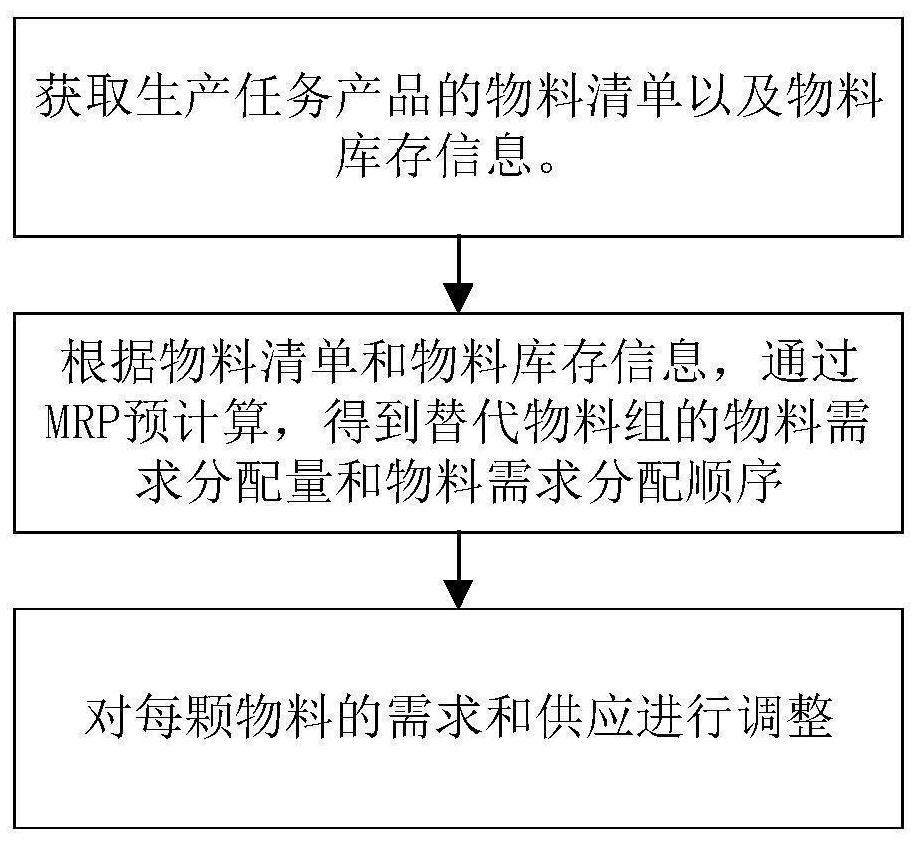

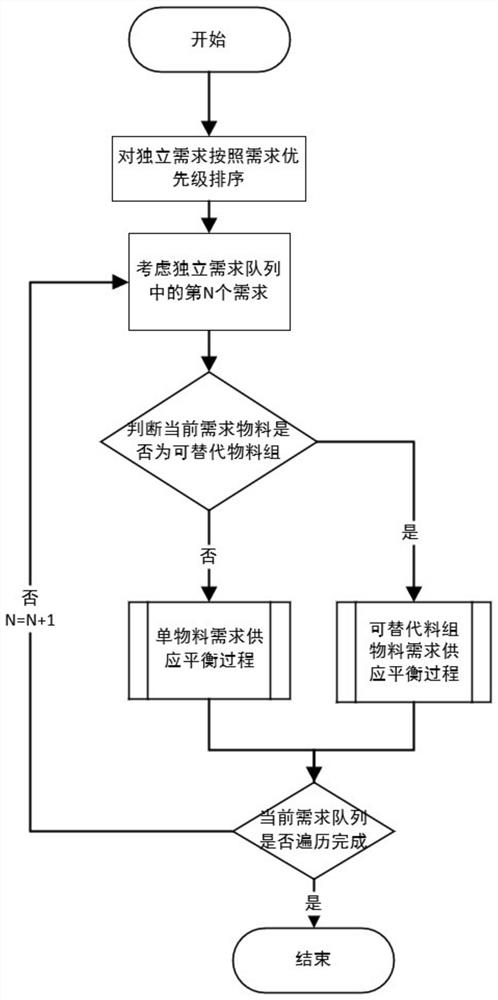

Material demand distribution method, device and system and storage medium

PendingCN112801448AImprove turnover rateOptimizing Purchase Planning RequirementsResourcesLogisticsBill of materialsDistribution method

The invention relates to a material demand distribution method, device and system and a storage medium. The method comprises the steps: executing a single material demand supply balance algorithm for materials of a non-alternative material group, and obtaining the demand distribution amount of each material in the non-alternative material group; for the materials in the substitute material group, calculating the demand distribution priority of each material in the substitute material group, and determining the material demand distribution amount of each material in the substitute material group according to the demand distribution priority; using a standard MRP algorithm to perform demand distribution on the materials of the substitute material group by adopting a material demand distribution amount and a material demand distribution sequence obtained by MRP pre-calculation; and carrying out material distribution on the materials of the non-alternative material group according to single material demand supply balance, realizing supply and demand balance adjustment of all the materials in the bill of materials, and obtaining material demand plan information of the production task product.

Owner:苏州慧工云信息科技有限公司

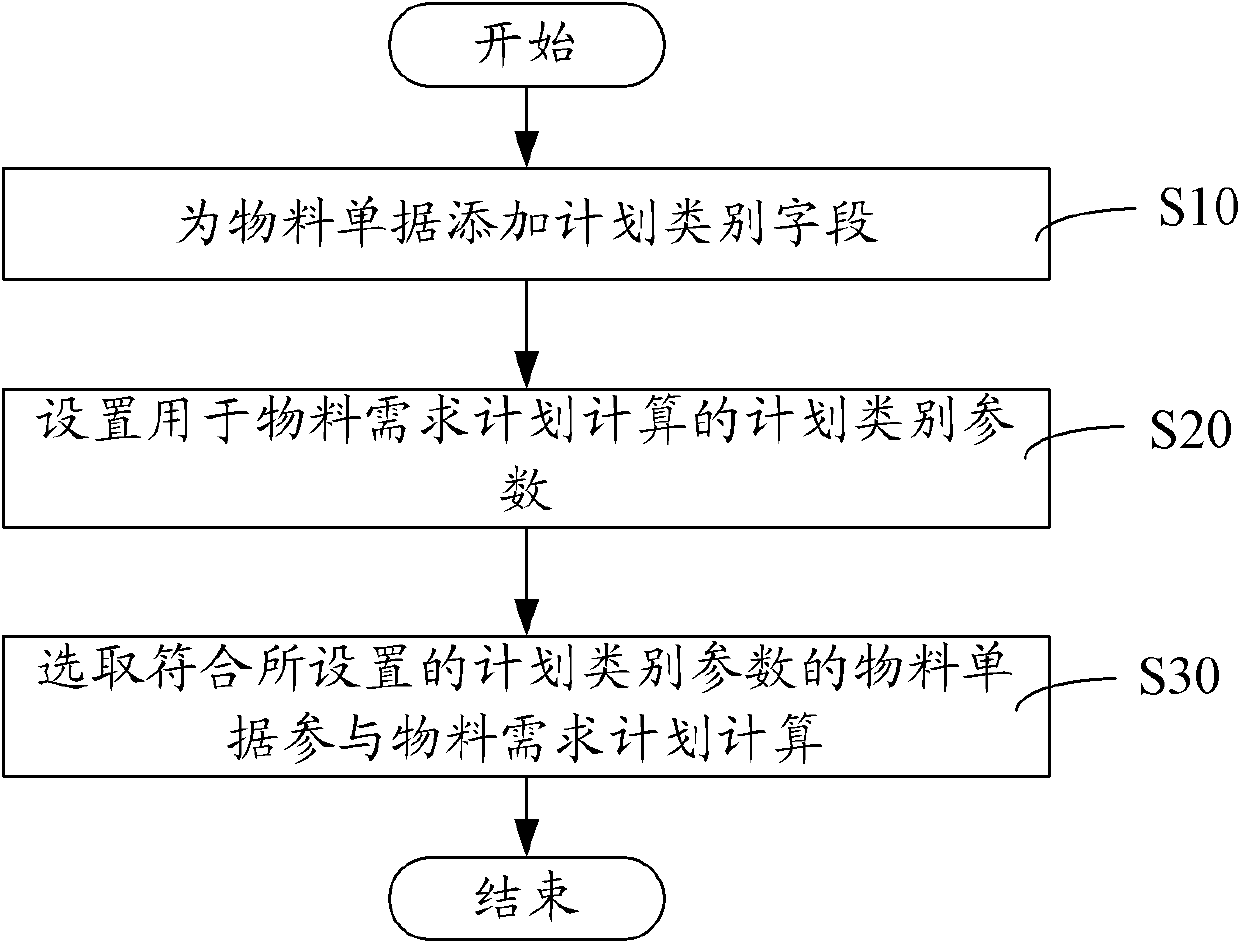

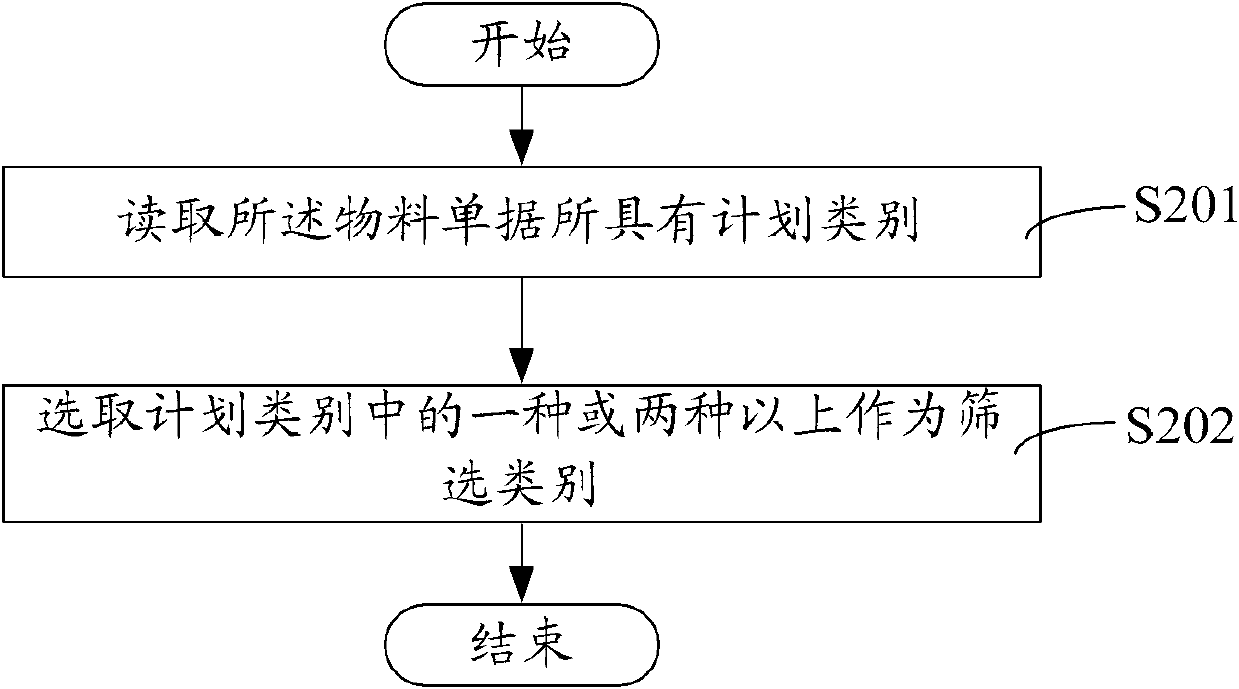

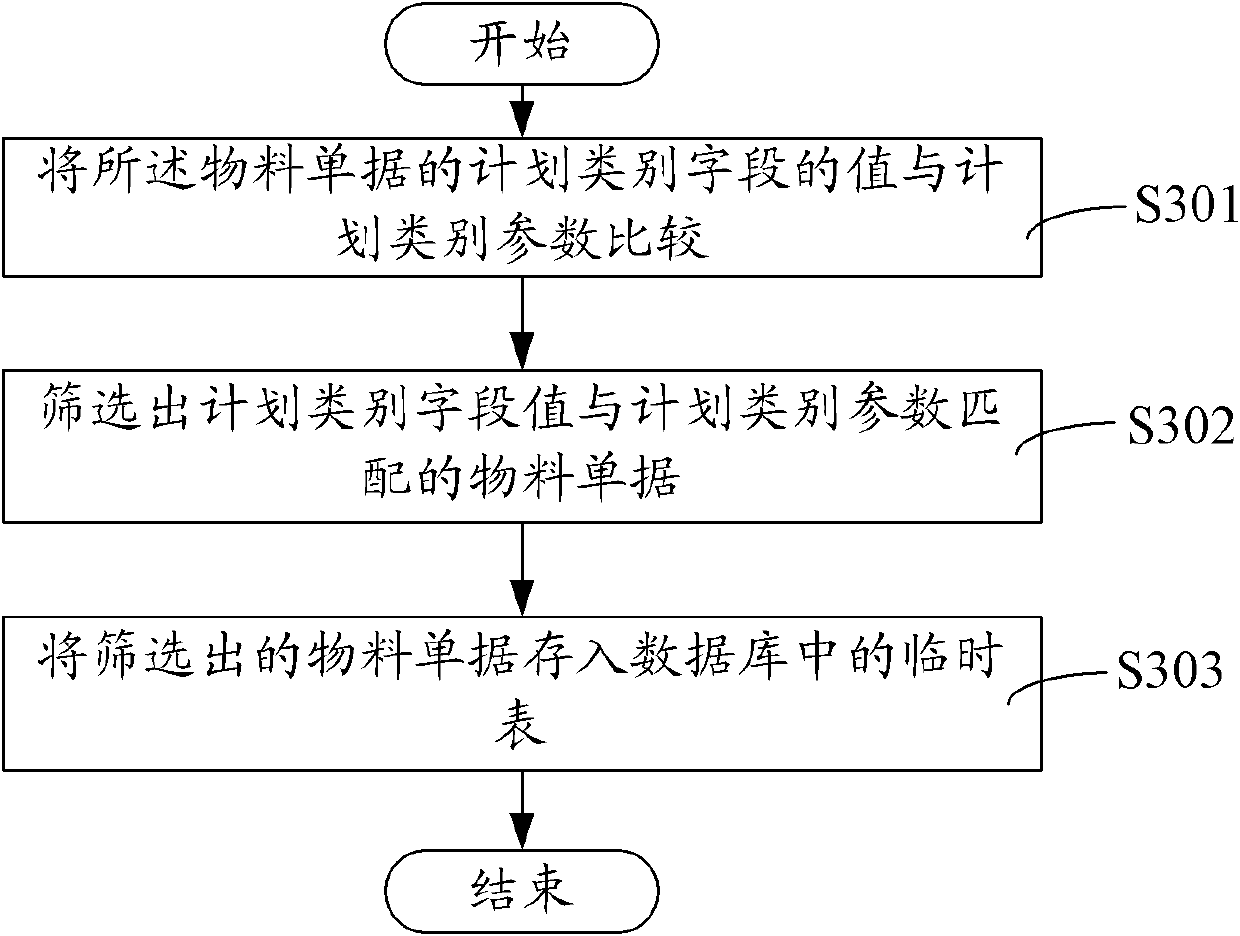

Method and system for processing material bills

The invention relates to a method for processing material bills, which comprises the following steps of: adding plan category fields for the material bills; setting plan category parameters for calculating a material requirement plan; and selecting the material bills according with the set plan category parameters to participate in calculation of the material requirement plan. A system for processing the material bills comprises a bill setting module, a parameter setting module and a calculating module, wherein the bill setting module is used for adding the plan category fields for the material bills; the parameter setting module is used for setting the plan category parameters for calculating the material requirement plan; and the calculating module is used for selecting the material bills according with the set plan category parameters to participate in calculation of the material requirement plan. According to the method and the system, by adding the plan category fields for the material bills, an auxiliary material management system of a computer can identify the bills with different production categories, so that the calculation of the material requirement plan can be selectively carried out. The method and the system are simple and effective.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

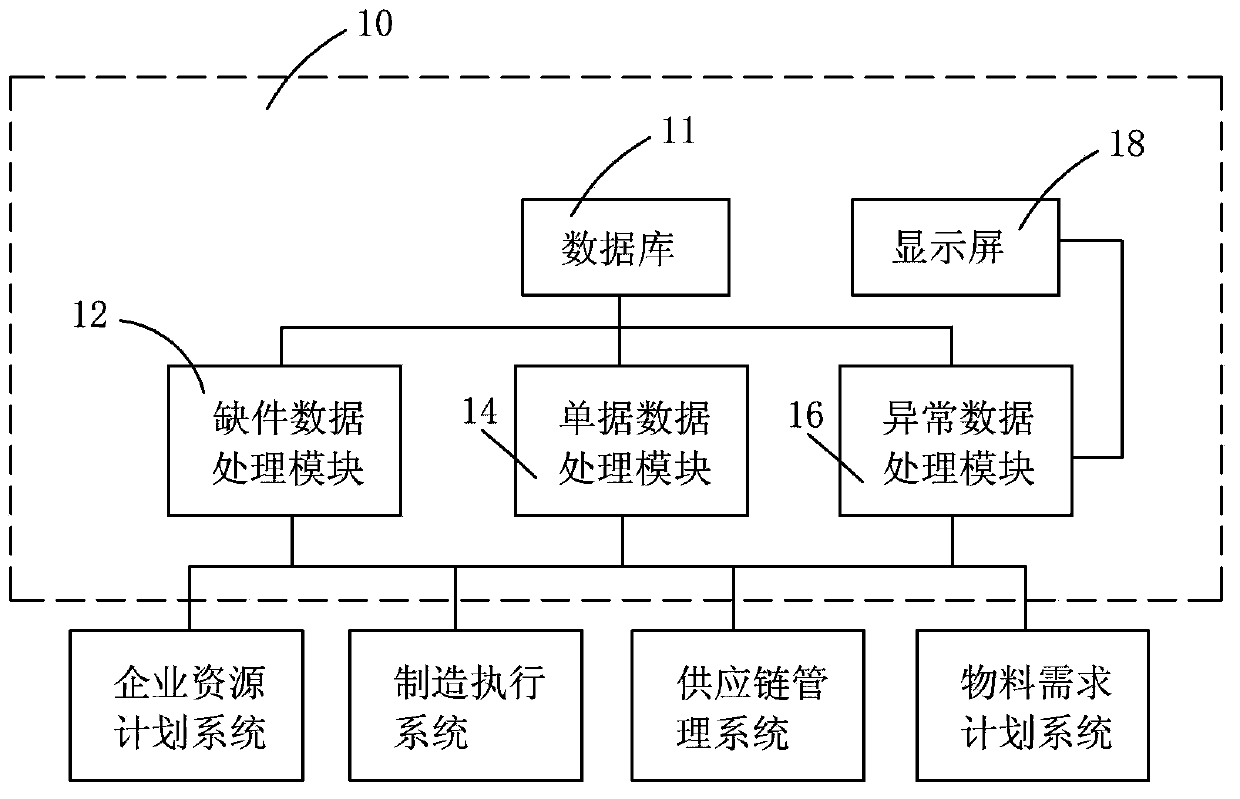

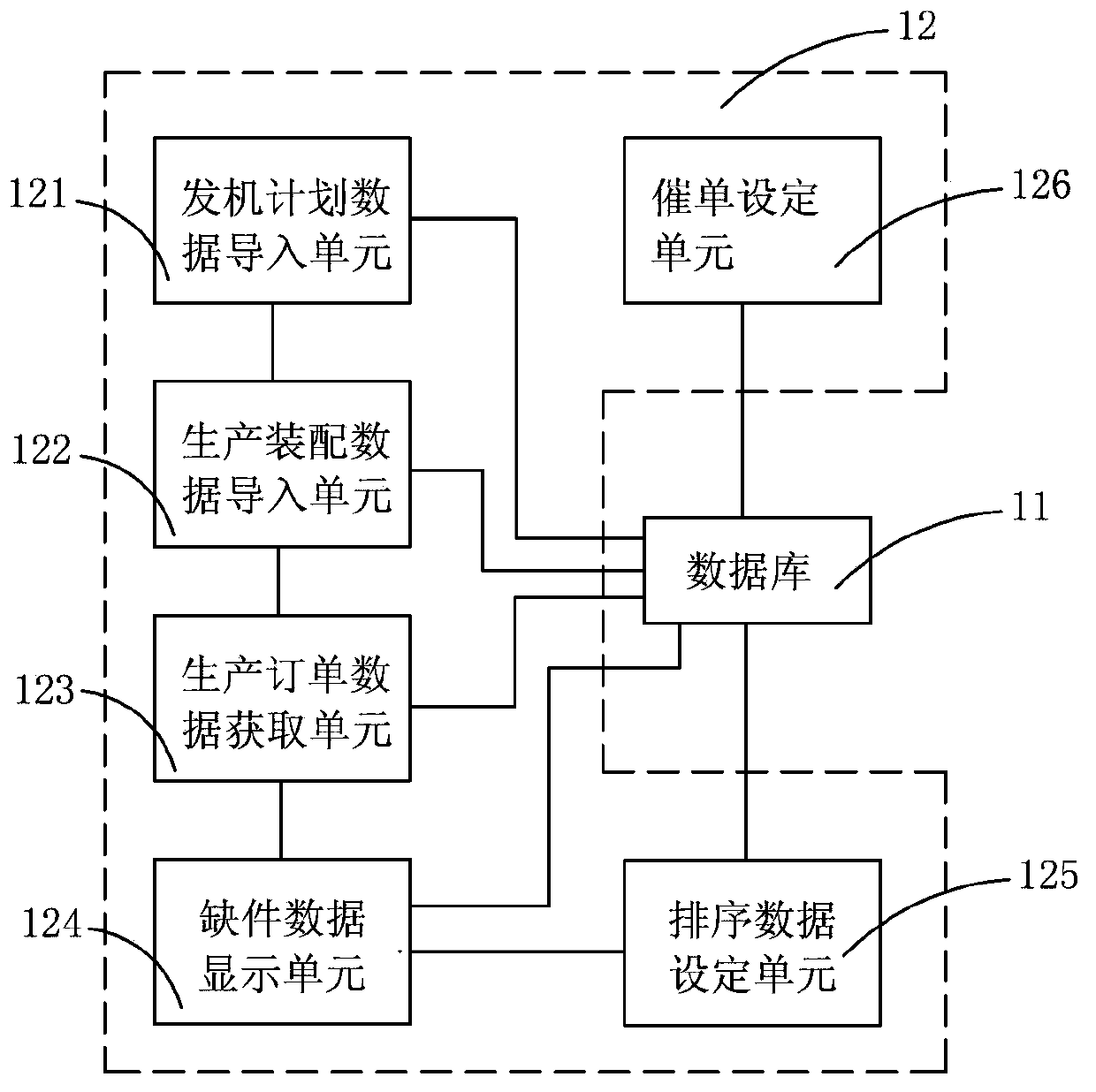

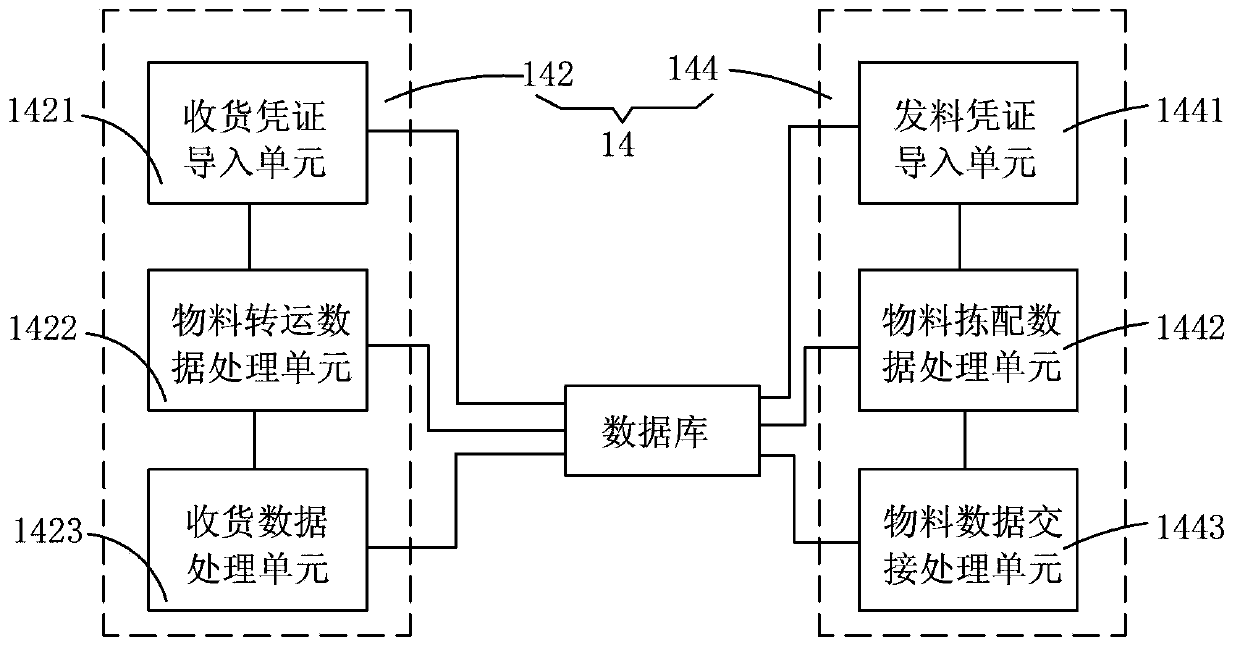

Lean pulling production data processing system

InactiveCN103870903AReduce workloadSave costResourcesLogisticsManufacturing execution systemEnterprise resource planning

The invention relates to a lean pulling production data processing system which comprises a database, a missing-part data processing module, a document data processing module, an abnormal data processing module and a display screen. The missing-part data processing module, the document data processing module and the abnormal data processing module are respectively connected with the database so as to store updated data into the database. The display screen is connected with the abnormal data processing module so as to display abnormal data. The production data processing system is connected with an external enterprise resource planning system, a manufacturing execution system, a supply chain management system and a material requirement planning system and performs data exchange processing. In comparison with the prior art, the production data processing system has the following advantages: workload of business personnel is reduced; work efficiency is raised; and as original manual operations are replaced with automatic operation by a computer, information transfer is fast and efficient, and cost is saved.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com