Lean pulling production data processing system

A technology for production data and processing systems, applied in data processing applications, manufacturing computing systems, instruments, etc., can solve the problems of increasing company operating costs, unfavorable tracking control, and low work efficiency, so as to save paper usage and printing costs, information Deliver fast and efficient results that improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

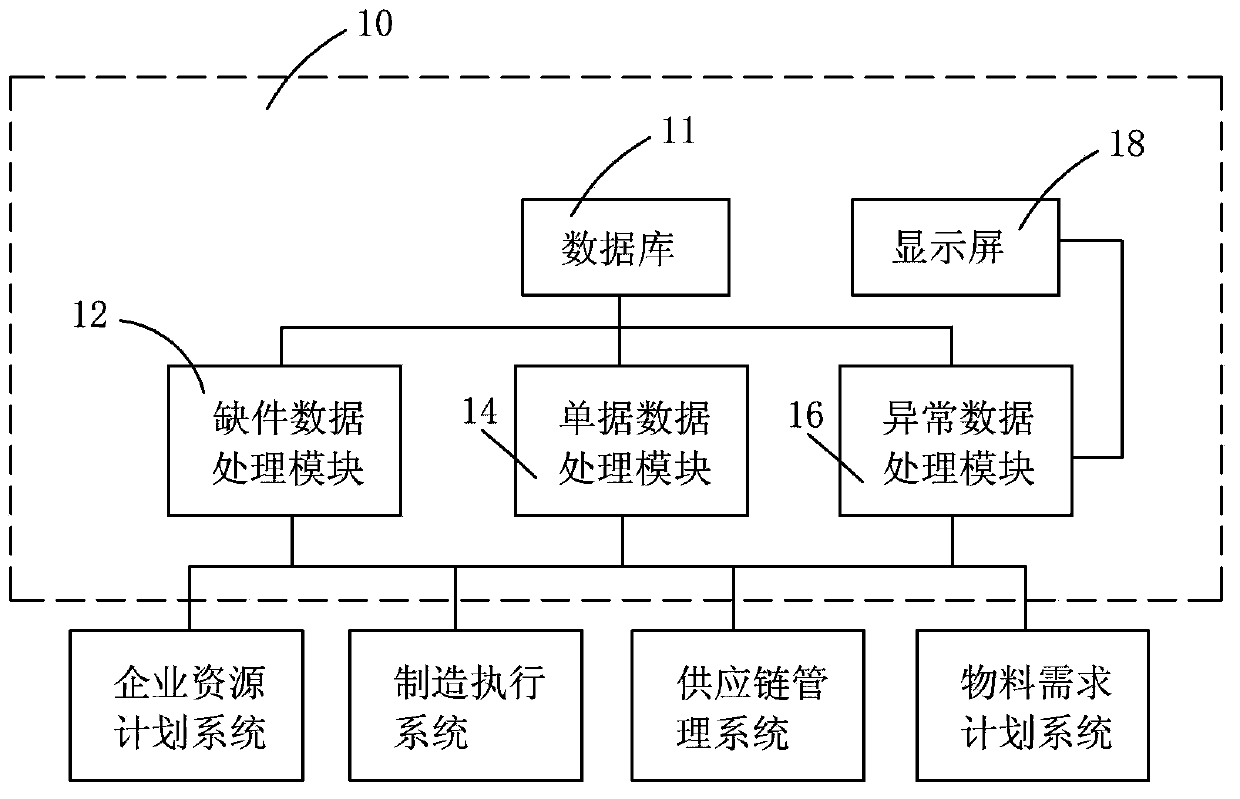

[0012] see figure 1 , which is a block diagram of the production data processing system of the present invention. The production data processing system 10 includes a database 11 , a missing parts data processing module 12 , a receipt data processing module 14 , an abnormal data processing module 16 and a display screen 18 . The missing parts data processing module 12 , receipt data processing module 14 , and abnormal data processing module 16 are respectively connected to the database 11 to store updated data in the database 11 . The display screen 18 is connected with the abnormal data processing module 16 to display abnormal data. And the production data processing system 10 is compatible with an enterprise resource planning system (ERP, Eenterprise Resource Planning), a manufacturing execution system (MES, Manufacturing Execution System), a supply chain management system (SCM, Supply Chain Management) and a material requirements planning system (MRP, Material Requirement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com