Method for synchronizing data between BOMs by utilizing implicit BOM model

A process and model technology, applied in the field of synchronizing data between BOMs by using the implicit process BOM model, can solve problems such as information inconsistency, affecting the accuracy of enterprise procurement plans and production plans, and differences in calculation results

Inactive Publication Date: 2010-10-13

INSPUR COMMON SOFTWARE

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the traditional erp software, the manufacturing BOM is generally established first, and then the process BOM used in the workshop operation is initialized in combination with the product processing technology. In the initial stage of initialization, the data of the parts in the two BOMs are consistent, but as the parts in the manufacturing BOM change Component data changes or production order process information is adjusted according to on-site conditions. These changed component data and process information need to be reflected in the process BOM to achieve data synchronization between the manufacturing BOM, process BOM and production order; but in practice In the process of using the software, due to the negligence of the user or changes in the on-site processing technology of the workshop, the information among the three is often inconsistent, resulting in differences in the calculation results of the material requirements plan, which ultimately affects the accuracy of the enterprise's procurement plan and production plan.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0048] Embodiment: The present invention has been successfully applied to Inspur ERP-PS (v10.1) management software, helping many enterprises whose BOMs often change types to solve product BOM synchronization requirements and material demand plans to generate accurate procurement plans and production according to accurate BOMs program needs.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

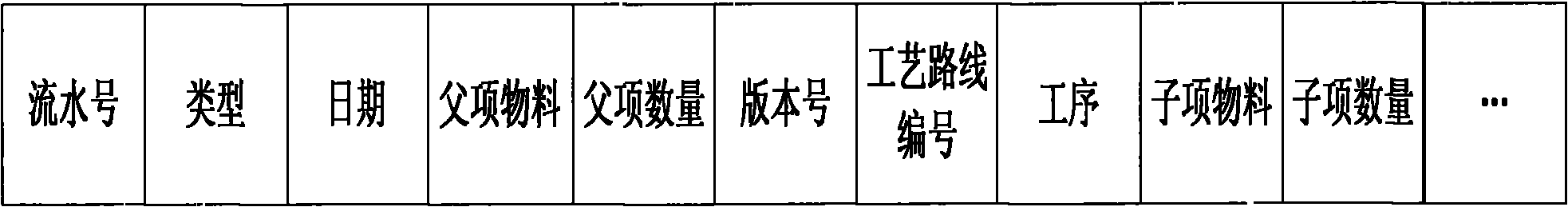

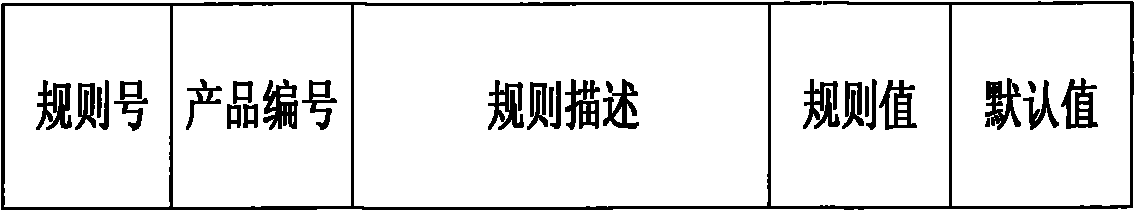

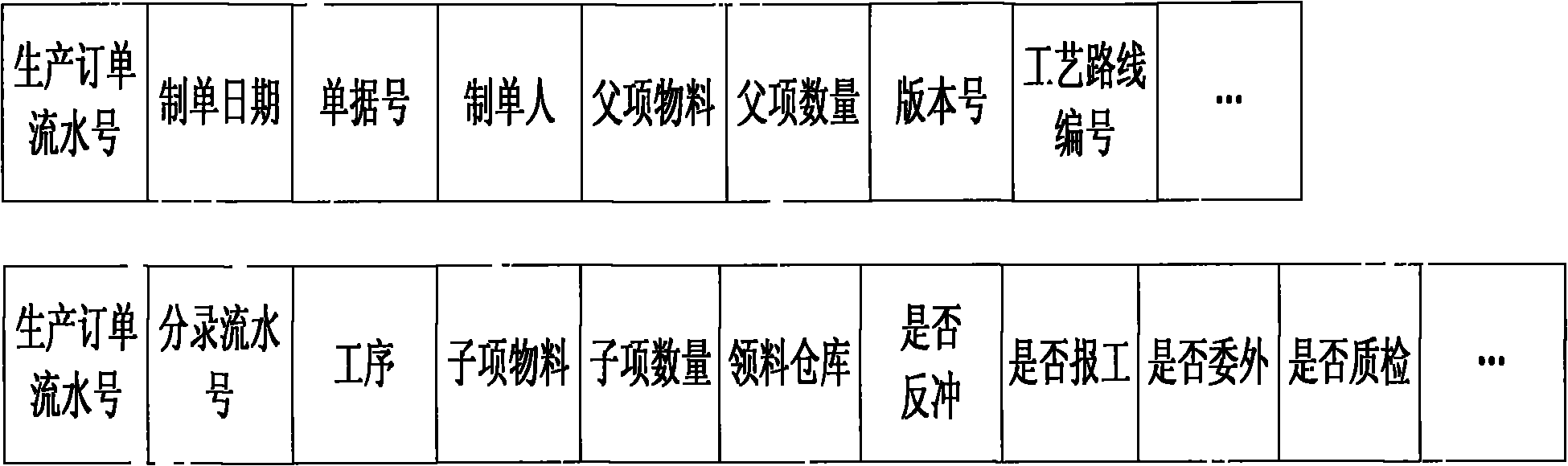

The invention provides a method for synchronizing data between BOMs by utilizing an implicit BOM model, in particular to a realization method for synchronizing data between BOMs and production order process information by utilizing an implicit BOM model in the field of erp management software, which realizes the data synchronization among manufacturing BOM, process BOM and production order process information through the restriction of a synchronization rule. The synchronization rule is defined by users according to the actual needs in the use process, and a production order automatically forms the table information of the production order according to the defined rule and the process route information of products; conversely, a system forms a new-edition process BOM according to the new production order table information to be used for next scheduling, and the system presets up the synchronization rule of the manufacturing BOM and the process BOM, the synchronization rule of the process BOM and the production order and the data update rule of the process BOM; the change of the manufacturing BOM is predominant, and the rules are utilized to automatically form the implicit process BOM; and simultaneously, the synchronization rule of the process BOM and the production order process information is established so as to realize the synchronization of the data among the manufacturing BOM, the process BOM and the production order process information, so that the purchasing plan and the production plan are more accurate after the calculation of the MRP.

Description

technical field [0001] The patent of the invention is an implementation method for synchronizing data between BOMs using the implicit process BOM model in ERP management software Background technique [0002] In the traditional erp software, the manufacturing BOM is generally established first, and then the process BOM used in the workshop operation is initialized in combination with the product processing technology. In the initial stage of initialization, the data of the parts in the two BOMs are consistent, but as the parts in the manufacturing BOM change Component data changes or production order process information is adjusted according to on-site conditions. These changed component data and process information need to be reflected in the process BOM to achieve data synchronization between the manufacturing BOM, process BOM and production order; but in practice In the process of using the software, due to the negligence of the user or changes in the on-site processing t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06Q10/00G06Q10/06

Inventor 陈明忠焦学瑞

Owner INSPUR COMMON SOFTWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com