Typical configuration model and system for auditing material requirement plan of power project

A technology of project planning and materials, applied in resources, calculations, instruments, etc., can solve problems such as insufficient research, large impact on the construction environment, and many types of materials, so as to improve the timely rate of declaration, ensure accuracy, and ensure timely and accurate supply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

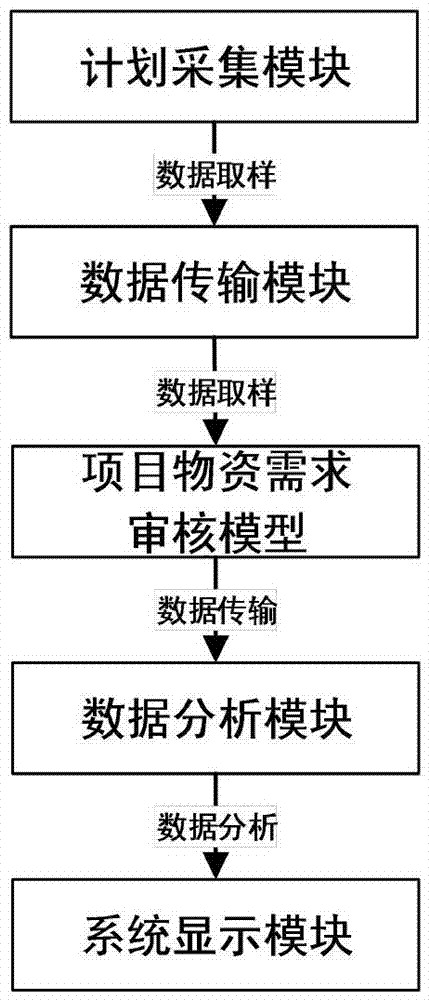

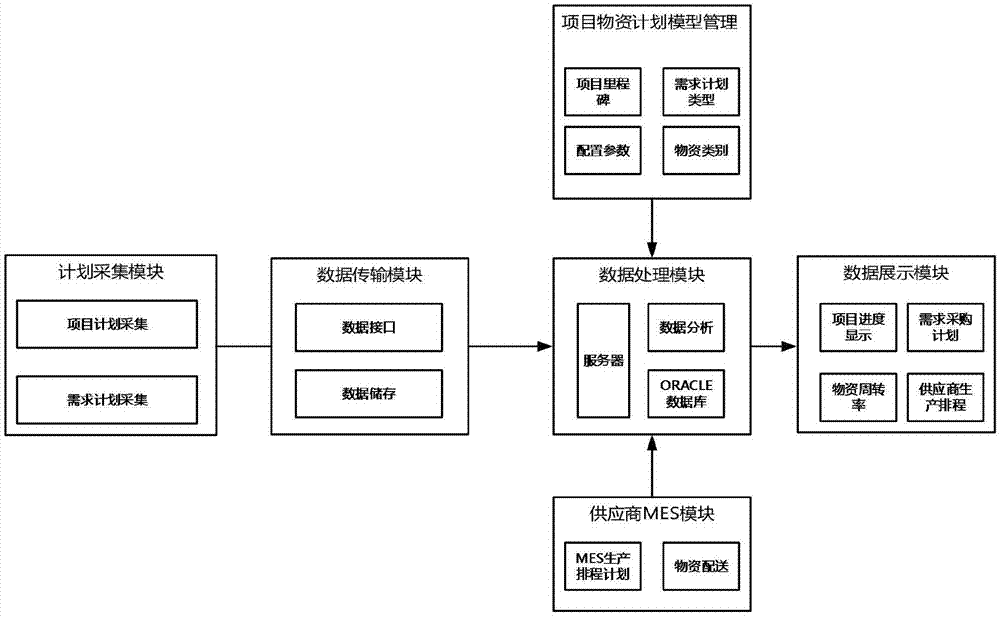

[0017] Combine below figure 1 , figure 2 The present invention is described in further detail:

[0018] A typical configuration model and system for material demand plan review of electric power projects. The present invention is characterized in that the model and system are sequentially connected and composed of a plan collection module, a data transmission module, a project material demand review model, a data analysis module, and a system display module; in:

[0019] A. The plan acquisition module is used as the data receiving module of the typical configuration model and system for material demand plan review, and receives the project plan and material demand plan data;

[0020] B. The data transmission module is used as a typical configuration model and system data transmission module for material demand plan review, and performs real-time data transmission and communication for the collected data;

[0021] C. The project material demand review model is a typical con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com