Method for rolling computation of material requirement in production management process

A material demand planning and material demand technology, applied in the direction of calculation, logistics, data processing applications, etc., can solve the problems of inconsistent sales quantity, short delivery period, long calculation cycle, etc., and achieve the effect of improving capital turnover rate and reducing inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] A. The instantiation method of rolling calculation of product material demand in the production management process:

[0040] Before the production management system realizes the rolling calculation of product material demand described by the model, it needs to use the model to describe the production quantity and output date of the enterprise's production forecast products, and generate input for the production plan. Model instantiation requires the following steps:

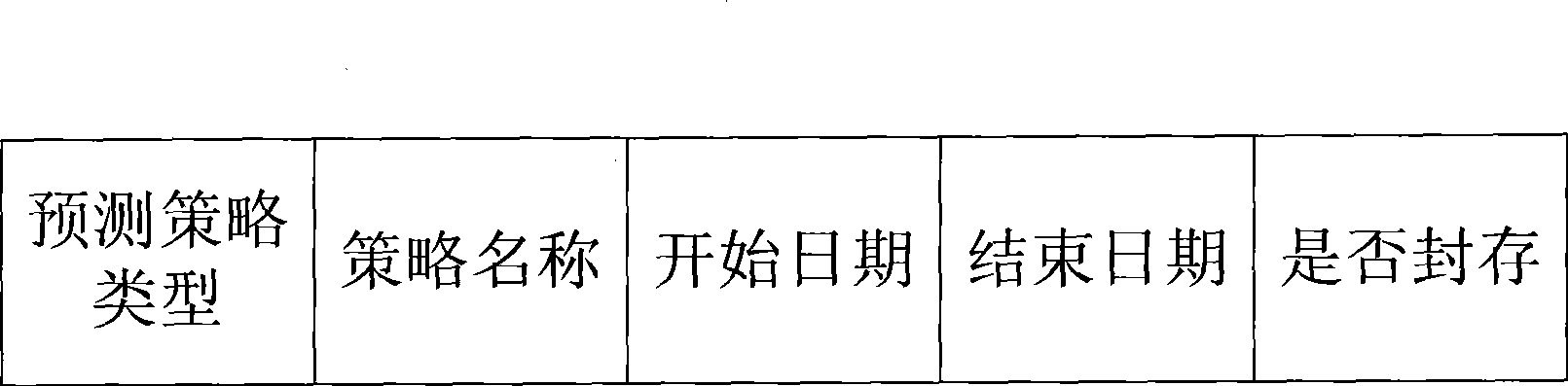

[0041] 1) According to the attached figure 1 Describe the data structure and predict the strategy first, and realize the user-defined prediction strategy.

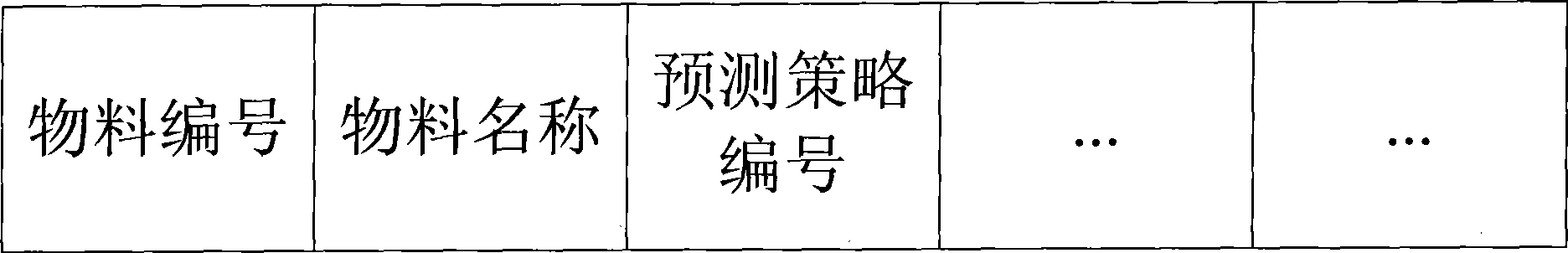

[0042] 2) According to the attached figure 2 Describe the data structure to establish the relationship between materials and forecasting strategies.

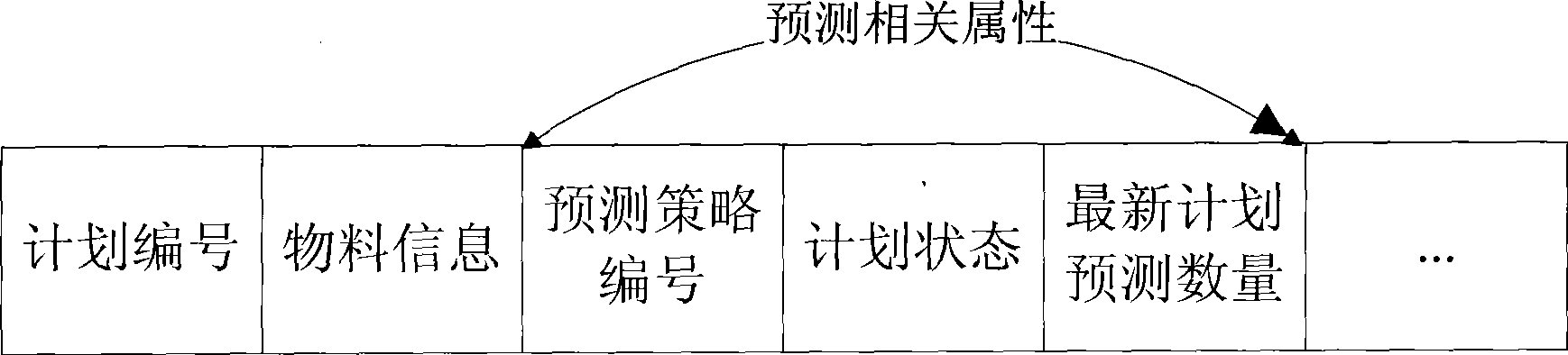

[0043] 3) According to the attached image 3 Describes the data structure used to hold the production plan.

[0044] 4) According to the attached Figure 4 Describe the data structure used to save...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com