Method, system and equipment for determining material demand plan and obtaining material low level code

A technology of material requirements planning and low-bit code, applied in calculation, special data processing applications, instruments, etc., can solve problems such as low operating efficiency, achieve the effect of improving operating efficiency, reducing calculation amount, and reducing calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

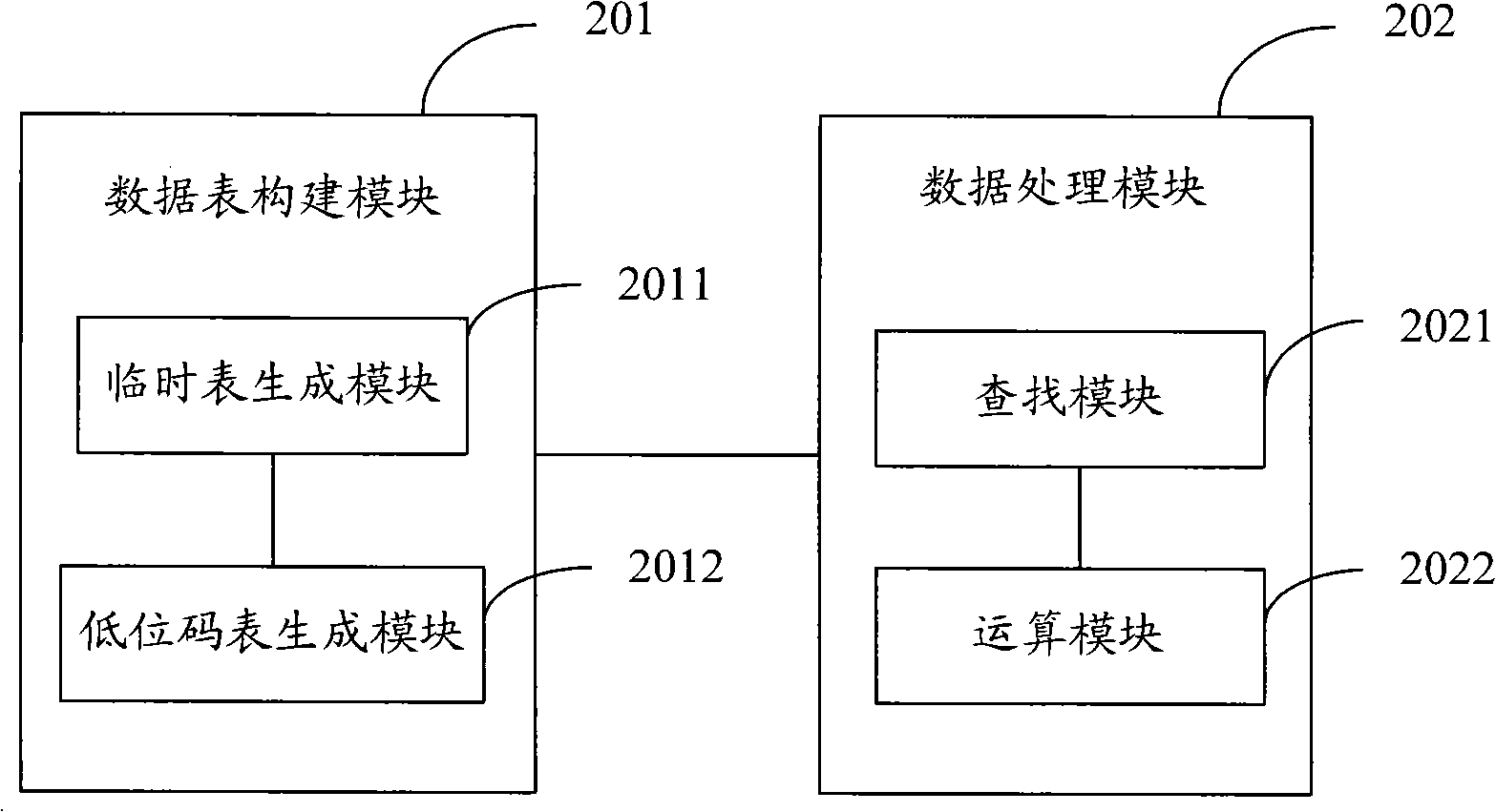

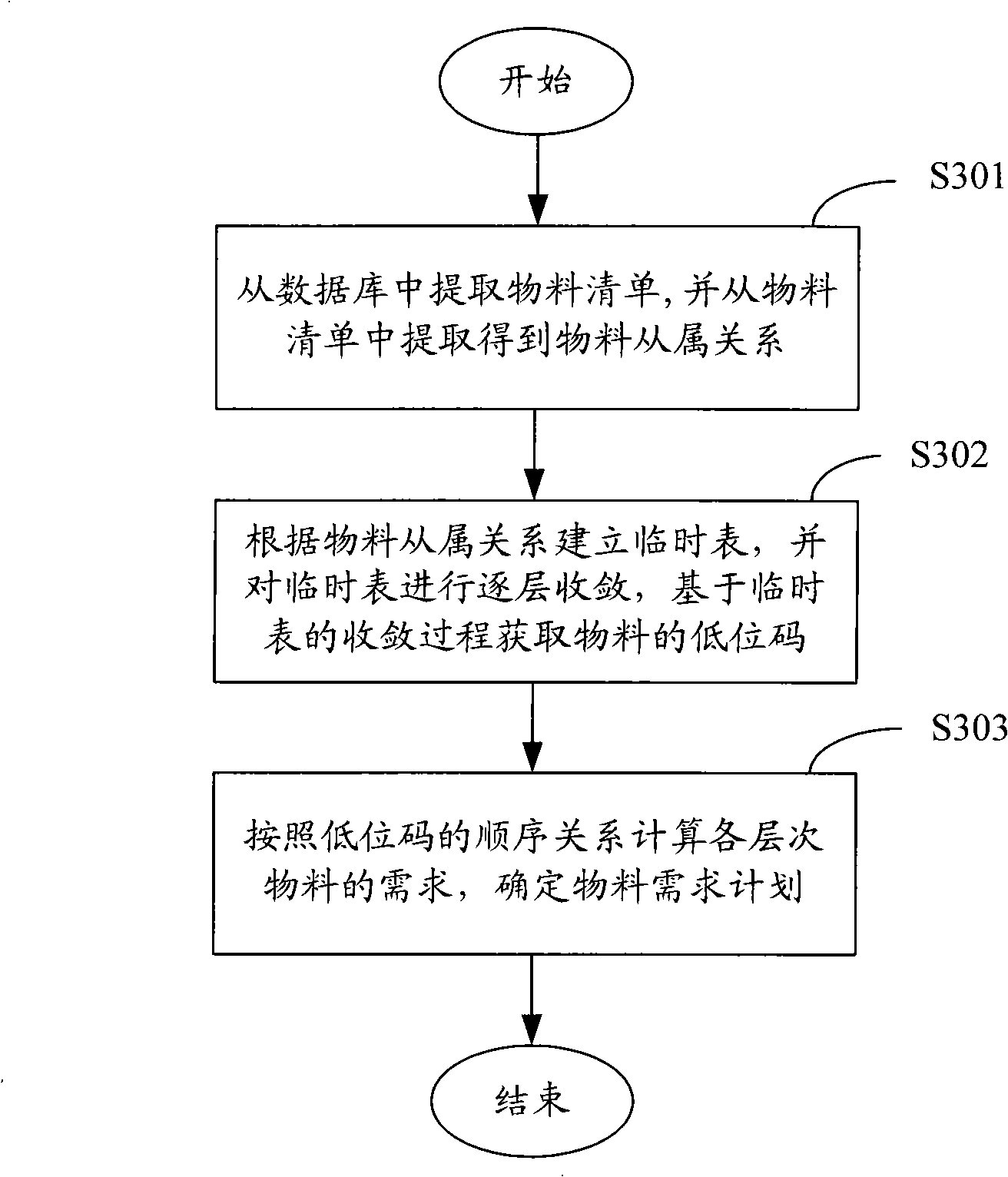

[0058] The present invention establishes a temporary table and a low-level code table, by searching the materials in the temporary table for overlapping parent items and child items, and extracting the affiliation data of the parent item in which the parent items and child items overlap in the temporary table, and converging the temporary table layer by layer, The low-order code table is operated on the low-order code table based on the convergence process of the temporary table, so as to obtain the low-order code of the material. Since the temporary table can be converged layer by layer, the maximum number of operations on low-level codes is only the number of layers of the bill of materials, so the amount of calculation is greatly reduced, thereby improving the efficiency of obtaining material low-level codes and determining material demand plans.

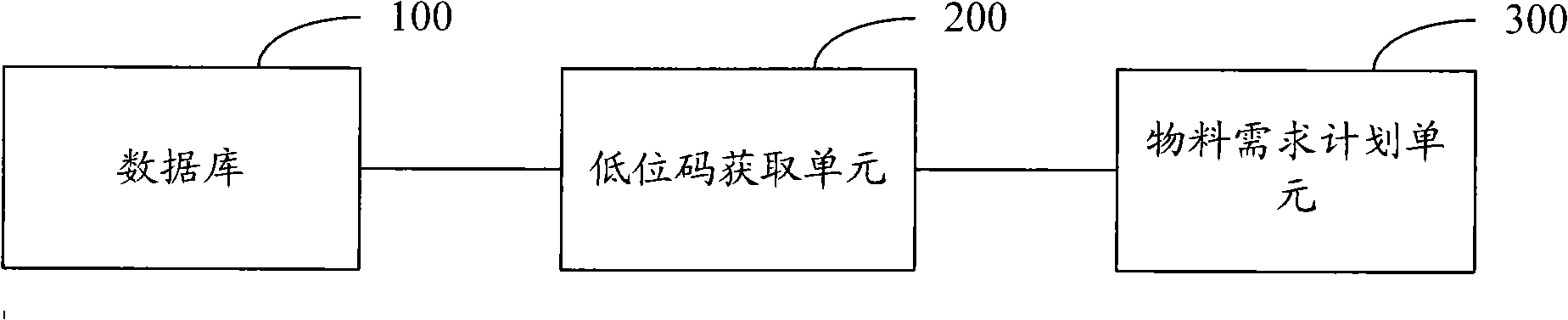

[0059] figure 1 A system structure for determining material requirement planning in an embodiment of the present invention is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com