Range-assigned material demand planning method and relevant apparatus

A material requirement planning, material technology, applied in logistics, computing, instruments, etc., can solve problems such as inability to specify the scope, inconvenient use, etc., to achieve the effect of improving calculation speed, convenient use, and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

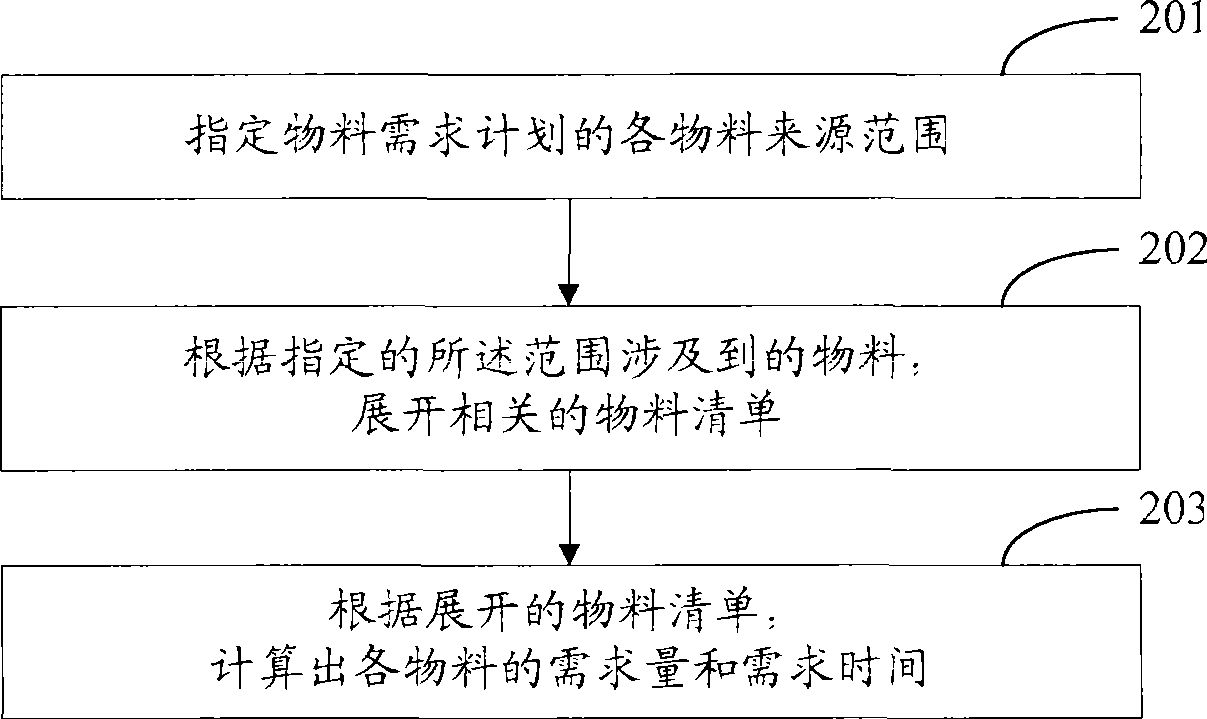

[0027] Embodiment one, see figure 2 Detailed description, figure 2 It is a schematic flow chart of the method in this embodiment.

[0028] Step 201: Designate the scope of each material source in the material requirements plan.

[0029] The scope of each material source can be the materials involved in an order, the materials involved in the production of a finished product, the materials in charge of a planner, the materials involved in all orders of a customer, the materials involved in a certain time period, etc. Affect the realization of the embodiments of the present invention.

[0030] Step 202: According to the materials involved in the specified scope, expand the related material list.

[0031] According to the specified range, determine the materials involved, and then expand the related material list.

[0032] Step 203: Calculate the demand quantity and demand time of each material according to the expanded material list.

[0033] After expanding the BOM, sort...

Embodiment 2

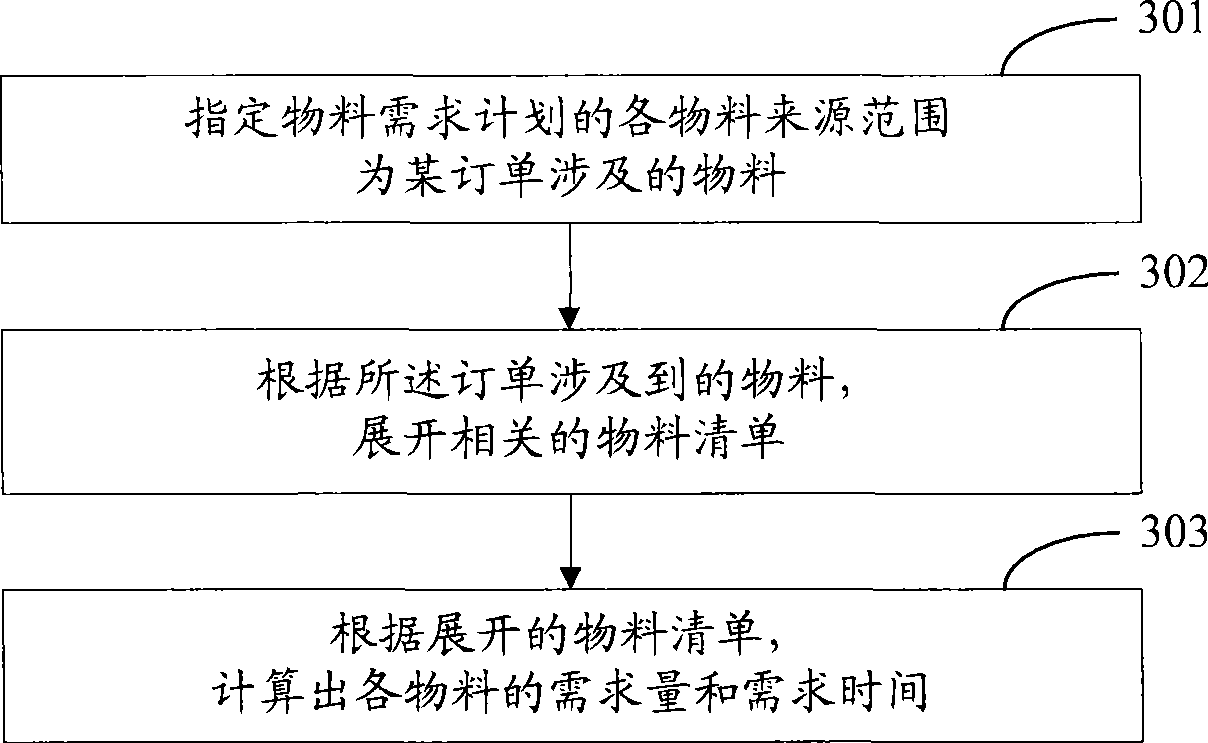

[0038] Embodiment two, see image 3 Detailed description, image 3 It is a schematic flow chart of the method in this embodiment.

[0039] Step 301: Designate the scope of each material source in the MRP as the materials involved in an order.

[0040] Before the MRP calculation starts, the scope of each material source of the specified material requirement plan is the material involved in the order SE0001.

[0041] Step 302: According to the materials involved in the order, expand the related material list.

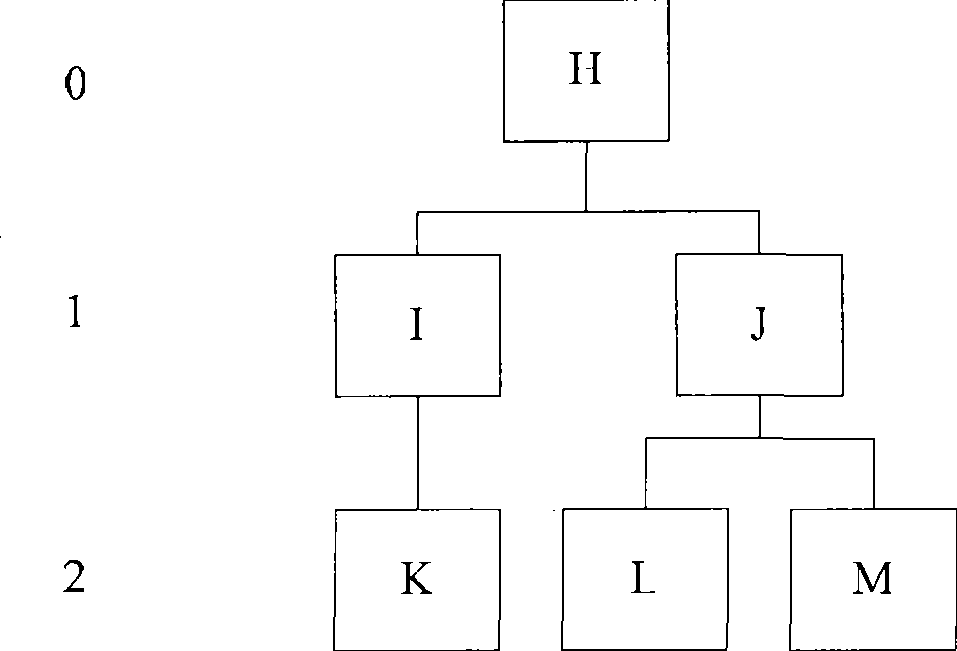

[0042] Order SE0001 involves the production of finished product A, so expand the bill of materials of finished product A, a material can have multiple BOMs, but only one BOM is a valid BOM at a point in time. Such as Figure 4 , Figure 4 It is the bill of materials of finished product A in the embodiment of the present invention. According to the list, finished product A is processed from semi-finished products C and D, semi-finished product C is processed from raw...

Embodiment 3

[0056] Embodiment three, refer to Figure 5 Detailed description, Figure 5 It is a schematic flow chart of the method in this embodiment.

[0057] Step 401: Designate the source range of each material in the material requirements plan as a certain material.

[0058] Before the MRP calculation starts, specify the material source range of the material requirements plan as material C.

[0059] Step 402: According to the specified material, expand the related material list.

[0060] Expand the BOM of material C, which can be expanded up and down at the same time. A material can have multiple BOMs, but only one BOM is a valid BOM at a time point.

[0061] Step 403: Calculate the required quantity and required time of each material according to the expanded material list.

[0062] After expanding the BOM, sort the materials according to the size of the low-level codes in the BOM to perform MRP calculation.

[0063] The calculation can be performed after the BOM is expanded, or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com