Pre-setting supporting assembling die for plastic extruder

A combined mold and pre-setting technology, applied in the field of plastic extruders, can solve the problems of internal stress concentration of plastic products, increase of production costs of manufacturers, and decline of economic benefits, etc., to eliminate stress concentration, increase yield, and improve production efficiency effect on production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

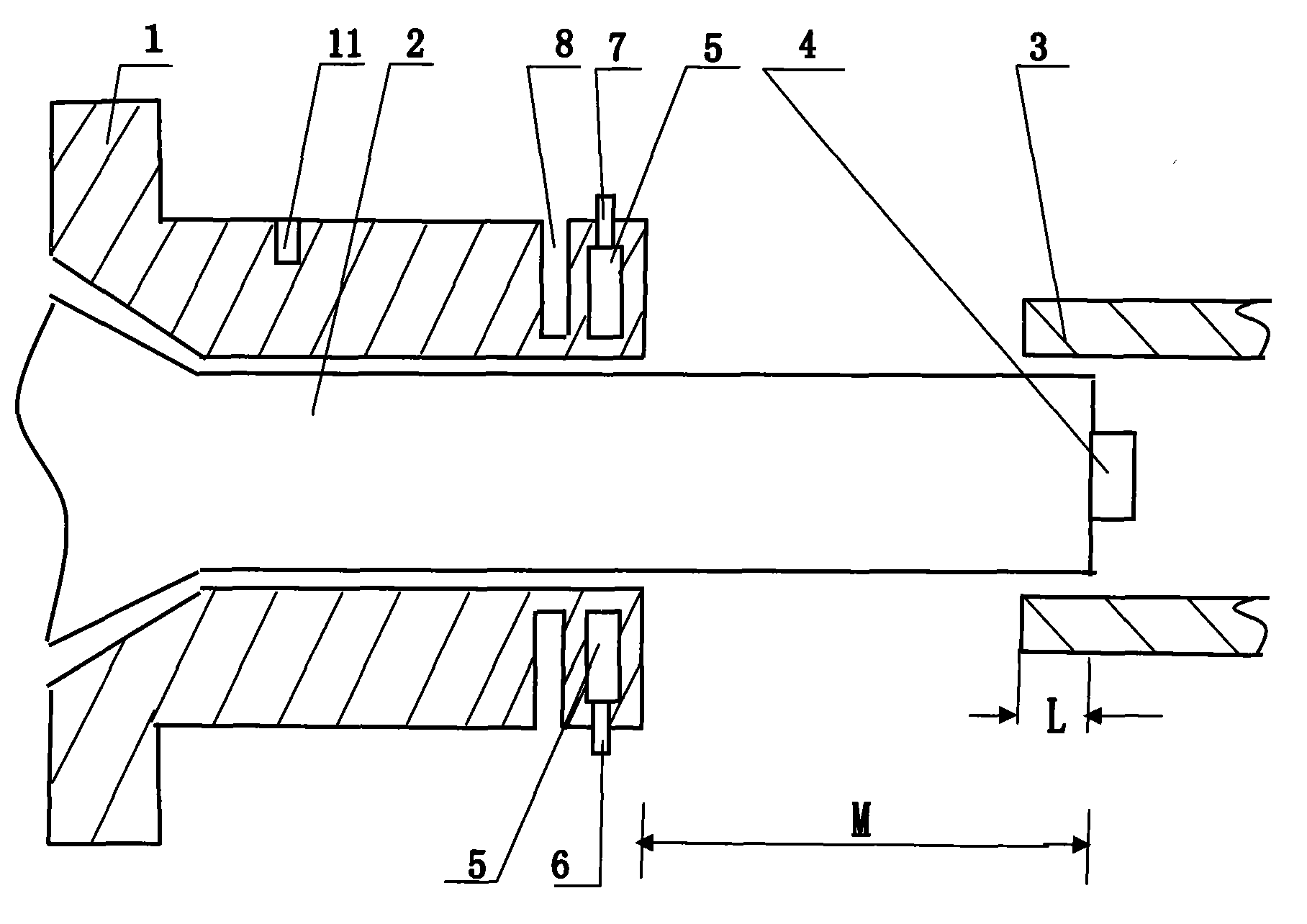

[0014] Such as figure 1 Shown: a plastic extruder pre-shaped support combination mold, including a die 1 and mandrel 2, the outlet end face of the mandrel 2 is longer than the outlet end face of the die 1, the outlet end face of the mandrel 2 is located in the sizing sleeve 3, the core The rod 2 and the sizing sleeve 3 form an overlapping section L, and the mandrel 2 forms a supporting section M between the outlet of the extrusion die and the sizing sleeve 3 . The support section M allows the high-temperature re-product plastic pipe to enter the sizing sleeve after being pre-shaped, and it will not be sucked flat by vacuuming, which eliminates the problem of stacking between the discharge port of the extrusion die and the feed port of the sizing sleeve. Phenomenon. The outlet end of the die 1 is provided with a refrigerant chamber 5 , and the outlet end of the die 1 is provided with a media inlet 6 and a media outlet 7 communicating with the refrigerant chamber 5 .

[0015] ...

Embodiment 2

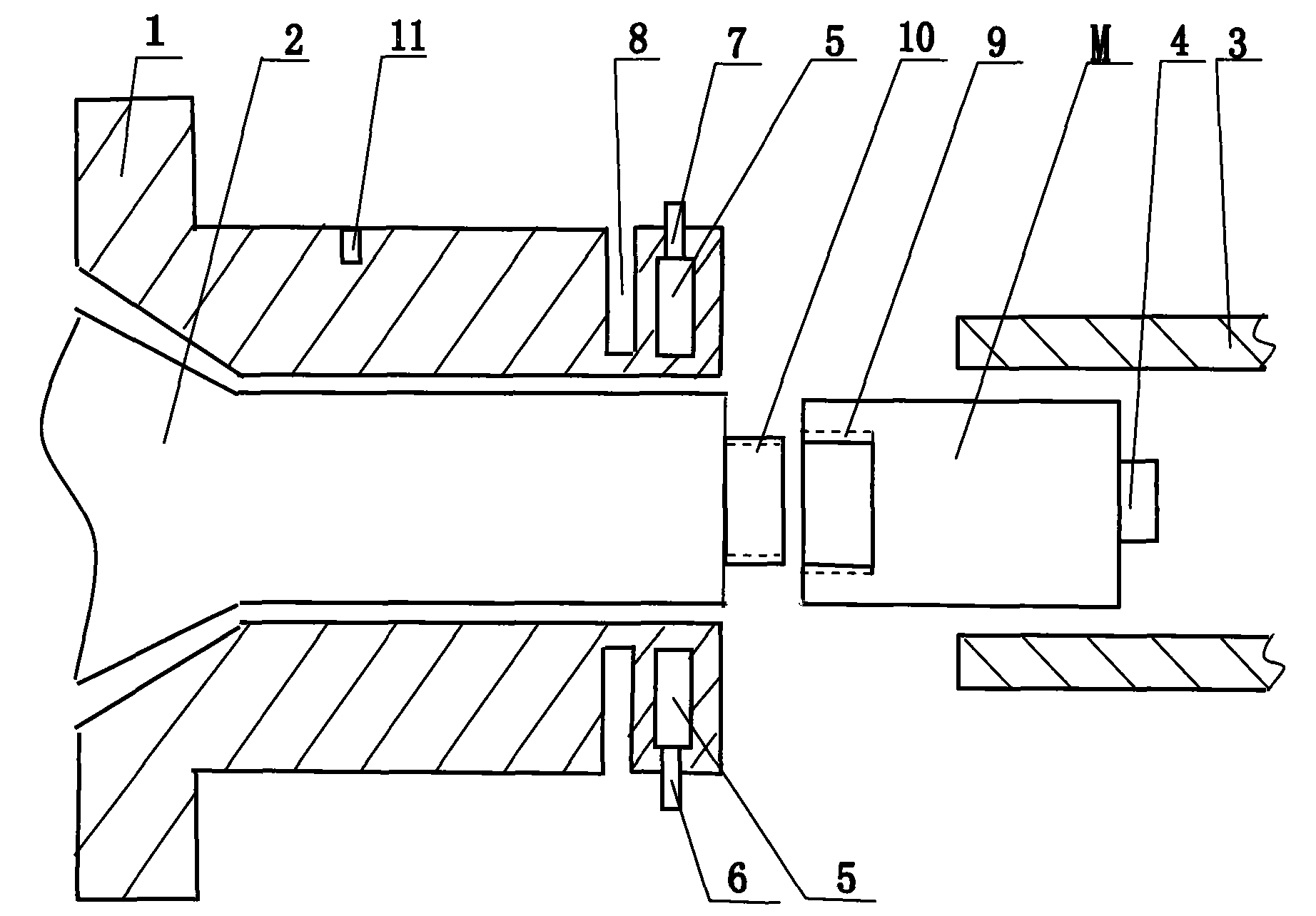

[0017] Embodiment 2 The front section of the mandrel 2 of this embodiment is a split type, such as figure 2 Shown: the support section M is threadedly connected with the mandrel 2 main body. In this way, the existing extruder mold can be directly modified. In this embodiment, the support section M is provided with an internal thread 9, and the main body of the mandrel 2 is provided with an external thread 10, and vice versa. In order to facilitate the assembly and disassembly of the support section M, a dismounting nut 4 is provided at the front end of the support section M.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com