A polyacrylate emulsion pressure-sensitive adhesive for electronic protective film, its preparation method and application

A polyacrylate emulsion, acrylate technology, applied in the direction of pressure sensitive film/sheet, ester copolymer adhesive, adhesive type, etc. Emissions and other issues, to ensure weather resistance, improve rigidity, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

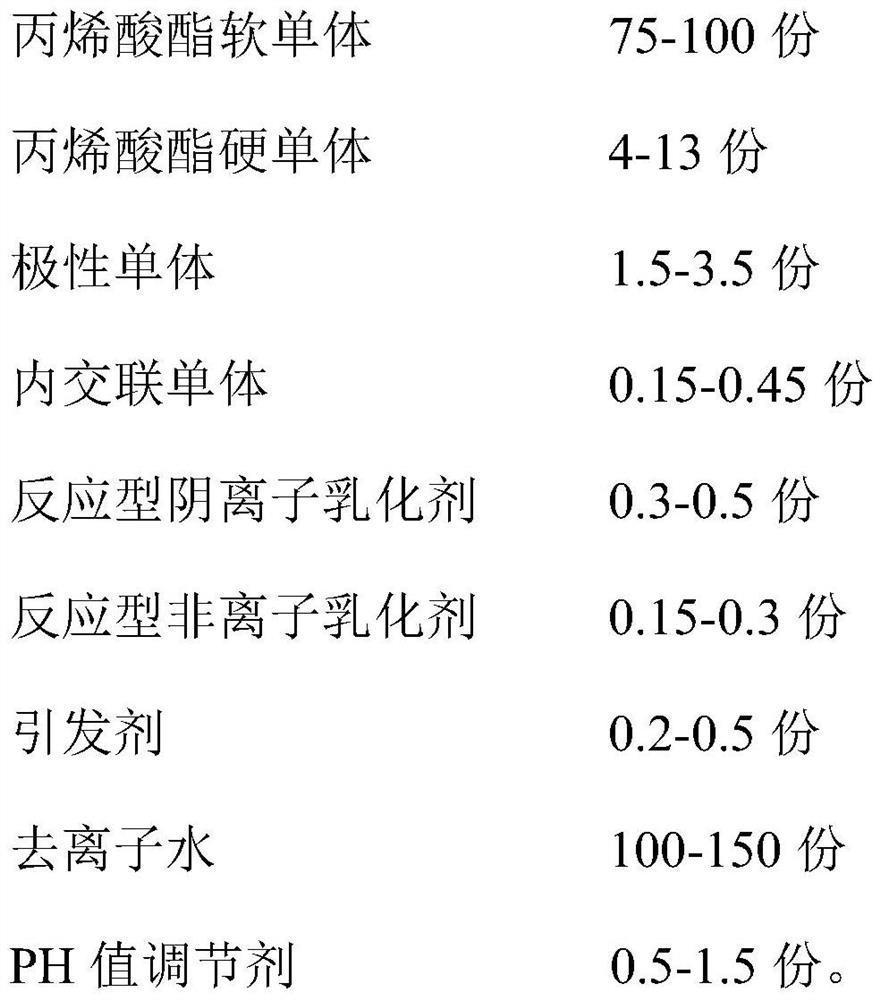

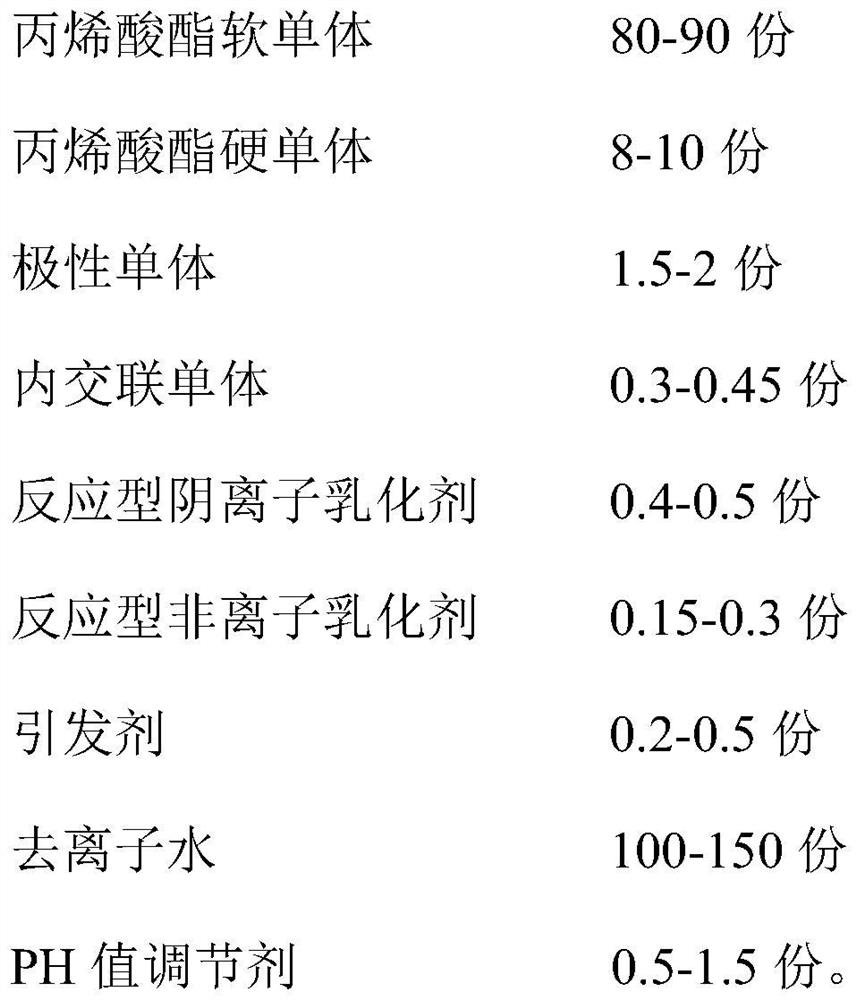

Method used

Image

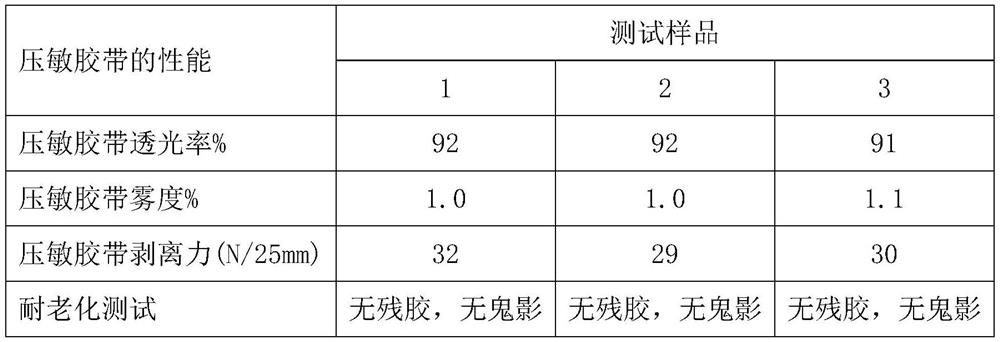

Examples

Embodiment 1

[0034] Weigh 0.3g reactive anionic emulsifier sodium vinylsulfonate, 0.1g reactive anionic emulsifier 1-propenyloxy 2-hydroxypropanesulfonate sodium, 0.15g reactive nonionic emulsifier allyloxypolyoxyethylene (10) Ether, 33g of deionized water, stirred at room temperature to obtain emulsifier aqueous solution; slowly add 0.3g of N-methylolacrylamide, then add 80g of isooctyl acrylate, 6g of isobornyl methacrylate, and 1.5g of methacrylic acid to form The mixed monomers were stirred for 45min at a stirring speed of 800r / min to prepare pre-emulsion 1.

[0035] Take 0.15g of glycidyl methacrylate, 10g of isooctyl acrylate, and 2g of methyl methacrylate and mix evenly to prepare mixed solution 2.

[0036] Weigh 0.2 g of potassium persulfate, add 10 g of deionized water to dissolve, and prepare initiator aqueous solution 3.

[0037] Heat 70g of deionized water to 80°C, add 10% of the initiator solution 3 prepared above, after 5 minutes, add 77% of the pre-emulsion 1 and initiator ...

Embodiment 2

[0044] Weigh 0.3g reactive anionic emulsifier sodium vinylsulfonate, 0.1g reactive anionic emulsifier allylsulfonate sodium, 0.2g reactive nonionic emulsifier allyloxy polyoxyethylene (10) ether, 30g Deionized water, stirred at room temperature to obtain emulsifier aqueous solution; slowly add 75g of butyl acrylate, 3g of methyl methacrylate, 1.5g of methacrylic acid, 1g of hydroxyethyl methacrylate, 0.2g of N-methylolacrylamide The monomer was stirred for 45 minutes at a stirring speed of 800 r / min to prepare pre-emulsion 1.

[0045] Mix 10 g of isooctyl acrylate and 3 g of methyl acrylate to prepare mixed solution 2.

[0046] Weigh 0.3 g of sodium persulfate, add 24 g of deionized water to dissolve, and prepare initiator aqueous solution 3.

[0047] Heat 66g of deionized water to 82°C, add 12% initiator aqueous solution, add pre-emulsion 1 and 73% initiator aqueous solution 3 to the reaction solution dropwise at the same time for 2.5h, then raise the temperature to 86°C, an...

Embodiment 3

[0054]Weigh 0.5g reactive anionic emulsifier sodium vinyl sulfonate, 0.3g reactive nonionic emulsifier allyloxy polyoxyethylene (10) ether, 25g deionized water, stir at room temperature to obtain emulsifier aqueous solution; slowly add 45g A mixed monomer composed of isooctyl acrylate, 15g butyl acrylate, 2.4g isobornyl methacrylate, 1.5g methacrylic acid and 0.15g N-methylolacrylamide was stirred for 40min at a stirring speed of 800r / min to obtain Pre-emulsion 1.

[0055] Mix 15g of isooctyl acrylate and 1.6g of isobornyl methacrylate evenly to prepare mixed solution 2.

[0056] Weigh 0.5 g of sodium persulfate, add 10 g of deionized water to dissolve, and prepare initiator aqueous solution 3.

[0057] Heat 70g of deionized water to 79°C, add 8% initiator aqueous solution, drop pre-emulsion 1 and 75% initiator aqueous solution 3 into the reaction solution at the same time for 2.5h, then raise the temperature to 86°C, and keep it warm for 0.5h. Then, the mixed solution 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com