Double-metal integral type plasma catalyst as well as preparation method and application of double-metal integral type plasma catalyst

A plasma-integrated technology, applied in the field of ionic catalyst materials and their preparation, and the removal of volatile organic pollutants, can solve the problems of unfavorable promotion of industrialization, easy poisoning and deactivation, complicated processes, etc., and achieve complete degradation of VOCs, Easy to use in industrial applications, good for degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

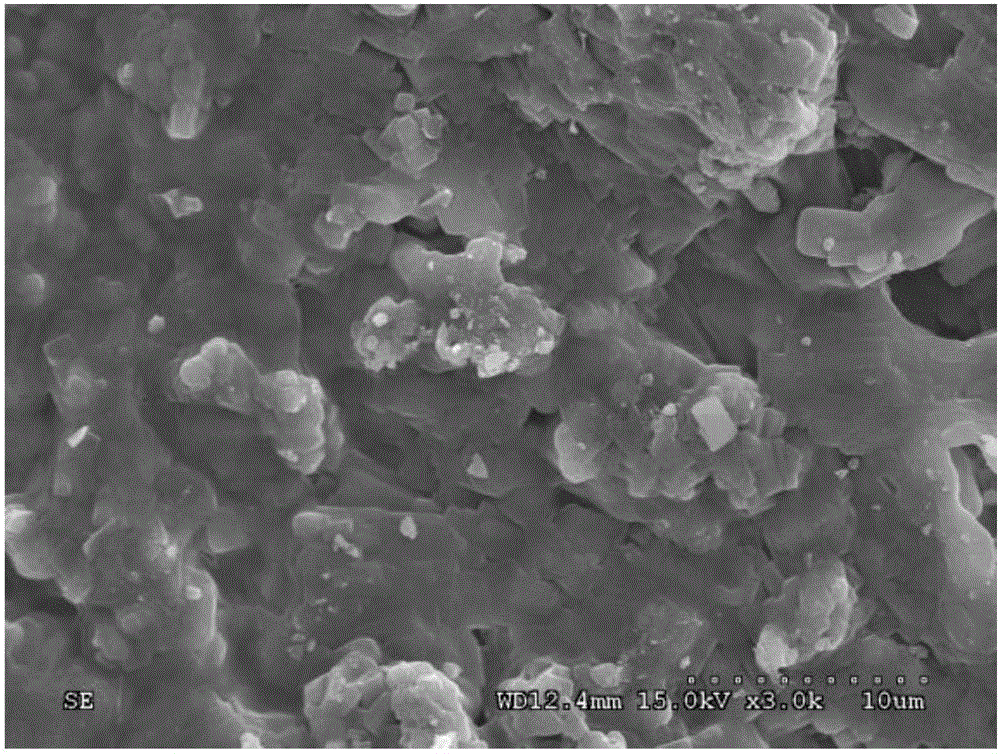

[0032] (1) Take the 400-mesh cordierite honeycomb ceramic carrier that is artificially cut and polished into a cylinder, clean it with deionized water, and dry it in an oven at 110°C for 2 hours; pickle it in 20% boiling oxalic acid solution for 2 hours, remove Rinse with ionized water until neutral, and dry at 110°C for 2 hours; put the above-mentioned cordierite honeycomb ceramic carrier in excess industrial silica gel solution and soak for 20 minutes, blow off the excess silica gel solution in the channels of the cordierite honeycomb ceramic carrier, and dry at 110°C for 2 hours ; Calcined in a muffle furnace at 180°C for 1h and at 500°C for 3h.

[0033] (2) A certain amount of manganese acetate, cerium nitrate and γ-Al 2 o 3 The powder was dissolved in deionized water and stirred ultrasonically at 30° C. for 1 h to obtain the precursor slurry. Among them, the mass of the transition metal element Mn is γ-Al 2 o 3 7.5% of the powder, the mass of rare earth metal element ...

Embodiment 2

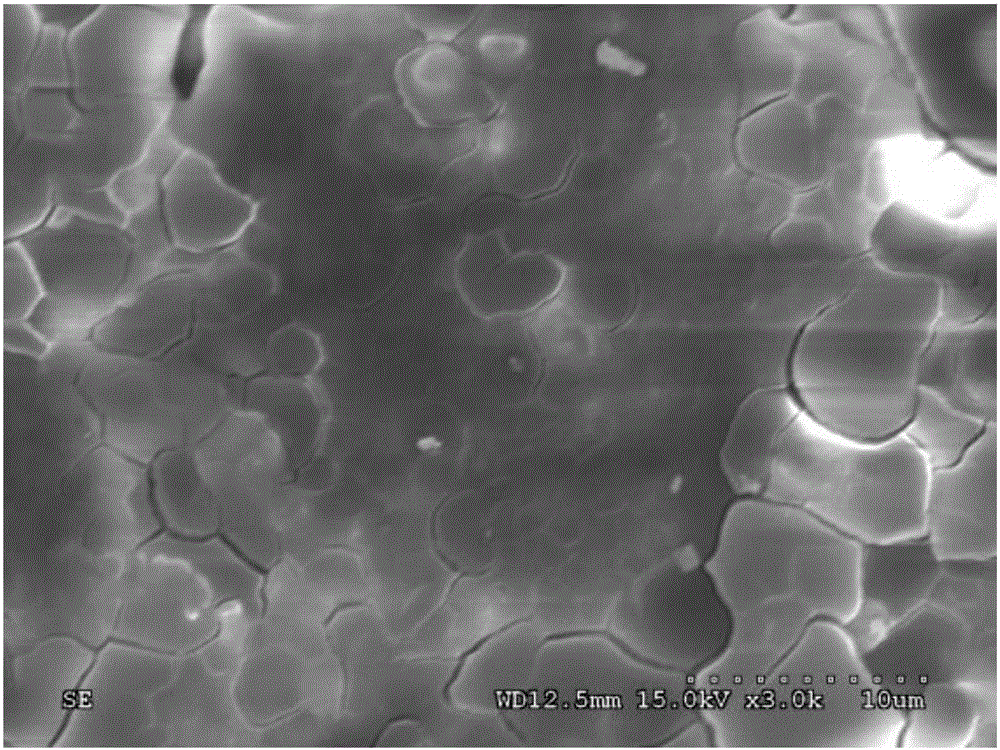

[0036] (1) Take the 400-mesh cordierite honeycomb ceramic carrier that is artificially cut and polished into a cylinder, clean it with deionized water, dry it in an oven at 110°C for 2 hours, pickle it in 20% boiling oxalic acid solution for 2 hours, remove Rinse with ionized water until neutral, and dry at 110°C for 2 hours; put the above-mentioned cordierite honeycomb ceramic carrier in excess industrial silica gel solution and soak for 20 minutes, blow off the excess silica gel solution in the channels of the cordierite honeycomb ceramic carrier, and dry at 110°C for 2 hours , baked in a muffle furnace at 180°C for 1h, and at 500°C for 3h.

[0037] (2) A certain amount of manganese acetate, lanthanum nitrate and γ-Al 2 o 3 The powder was dissolved in deionized water and stirred ultrasonically at 30° C. for 1 h to obtain the precursor slurry. Among them, the mass of the transition metal element Mn is γ-Al 2 o 3 7.5% of the powder, rare earth metal element La mass is γ-Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com