Preparation, use and regeneration methods of green adsorbent for flue gas desulfurization and denitrification

A desulfurization, denitrification, and adsorbent technology, applied in the field of flue gas purification, can solve the problems of enhanced solvent acidity, corrosive equipment, and increased operating costs, and achieve the effects of improved interaction force, high removal efficiency, and good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

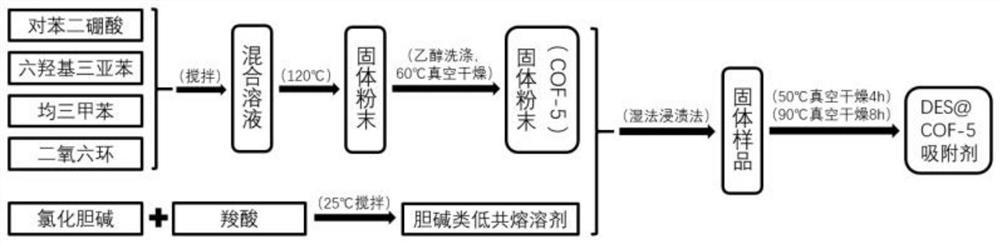

[0038] At normal temperature and pressure, 100mg 1,4-benzenediboronic acid (BDBA), 10mL mesitylene, 10mL 1,4-dioxane and 150mg 2,3,6,7,10,11-hexahydroxytriphenylene (HHTP) was added to the tetrafluoroethylene liner and stirred for 10 minutes. Then put the liner with the mixture into the autoclave, seal the autoclave, heat to 120°C, take out the powder at the bottom of the liner after staying for 72 hours, wash with ethanol and put the washed powder in a vacuum Dry in a drying oven at 60°C. Finally, the gray-purple solid powder was obtained as a covalent organic framework material (COF-5).

[0039] Get 20g choline chloride and 26mL oxalic acid according to the mol ratio 1:2 of choline chloride and oxalic acid, temperature is controlled at 25 ℃, stirs at a constant speed, obtains choline chloride-oxalic acid deep eutectic solvent ( DES).

[0040] According to the impregnation ratio of covalent organic framework and deep eutectic solvent of 0.15, take 5.00g of covalent organic...

Embodiment 2

[0042] The preparation method of the covalent organic framework material (COF-5) is the same as in Example 1.

[0043] According to the molar ratio of choline chloride and oxalic acid 1:3, take 20g choline chloride and 39mL oxalic acid, control the temperature at 25°C, and stir at a constant speed to obtain the choline chloride-oxalic acid deep eutectic solvent (DES).

[0044] The preparation method of the covalent organic covalent framework-loaded deep eutectic solvent adsorbent (DES@COF-5) is the same as in Example 1, and the covalent organic covalent framework-loaded deep eutectic solvent adsorbent B is obtained.

Embodiment 3

[0046] The preparation method of the covalent organic framework material (COF-5) is the same as in Example 1.

[0047] According to the molar ratio of choline chloride and oxalic acid 1:4, take 20g choline chloride and 52mL oxalic acid, control the temperature at 25°C, and stir at a constant speed to obtain the choline chloride-oxalic acid deep eutectic solvent (DES).

[0048] The preparation method of the covalent organic covalent framework-loaded deep eutectic solvent adsorbent (DES@COF-5) is the same as in Example 1, and the covalent organic covalent framework-loaded deep eutectic solvent adsorbent C is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com