Preparation method and application of microsphere catalyst for preparation of low-carbon olefin from methanol, ethanol or dimethyl ether

A technology of low-carbon olefins and dimethyl ether, which is applied in the field of preparation of microsphere catalysts to achieve the effects of enhanced strength, good repeatability, and increased interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

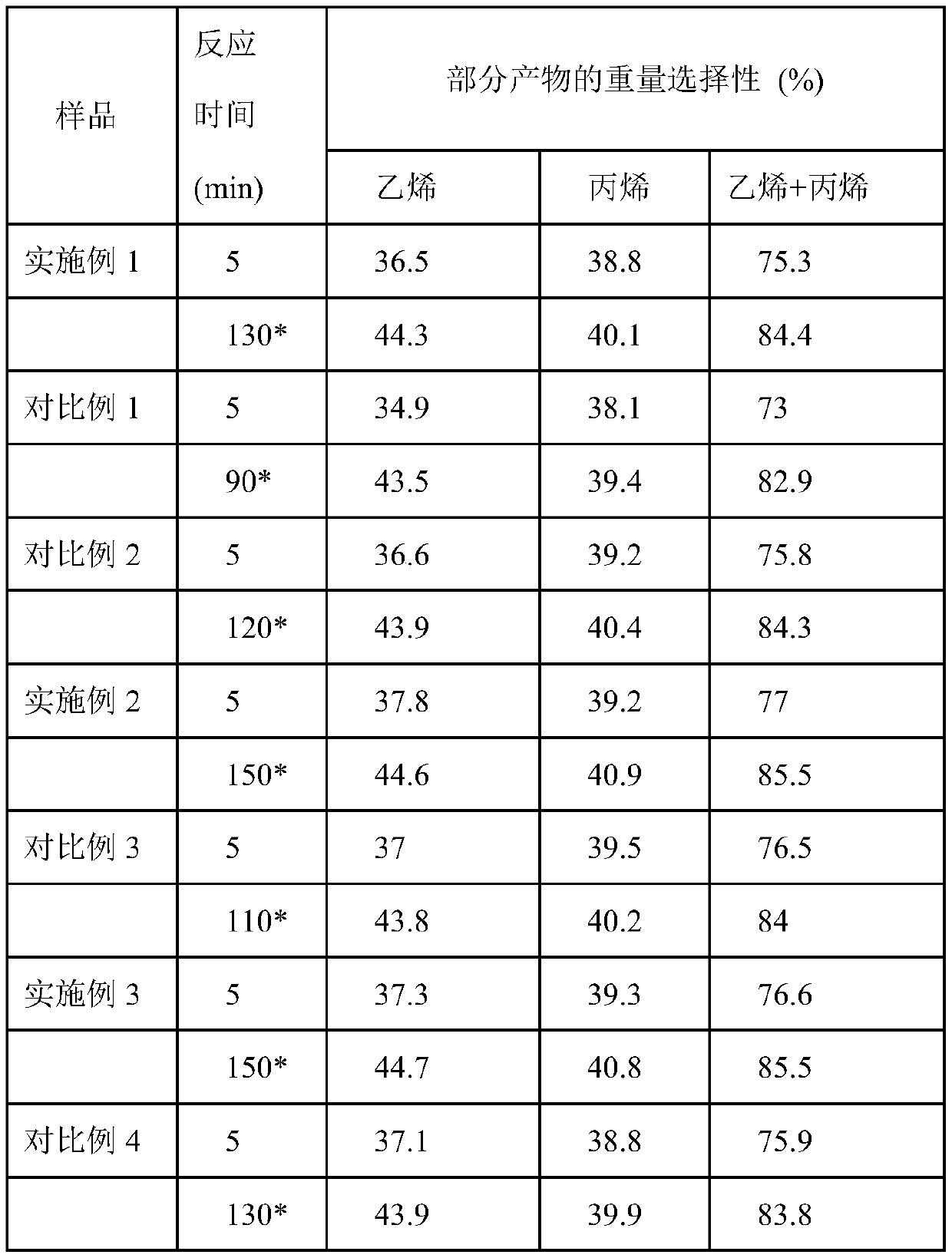

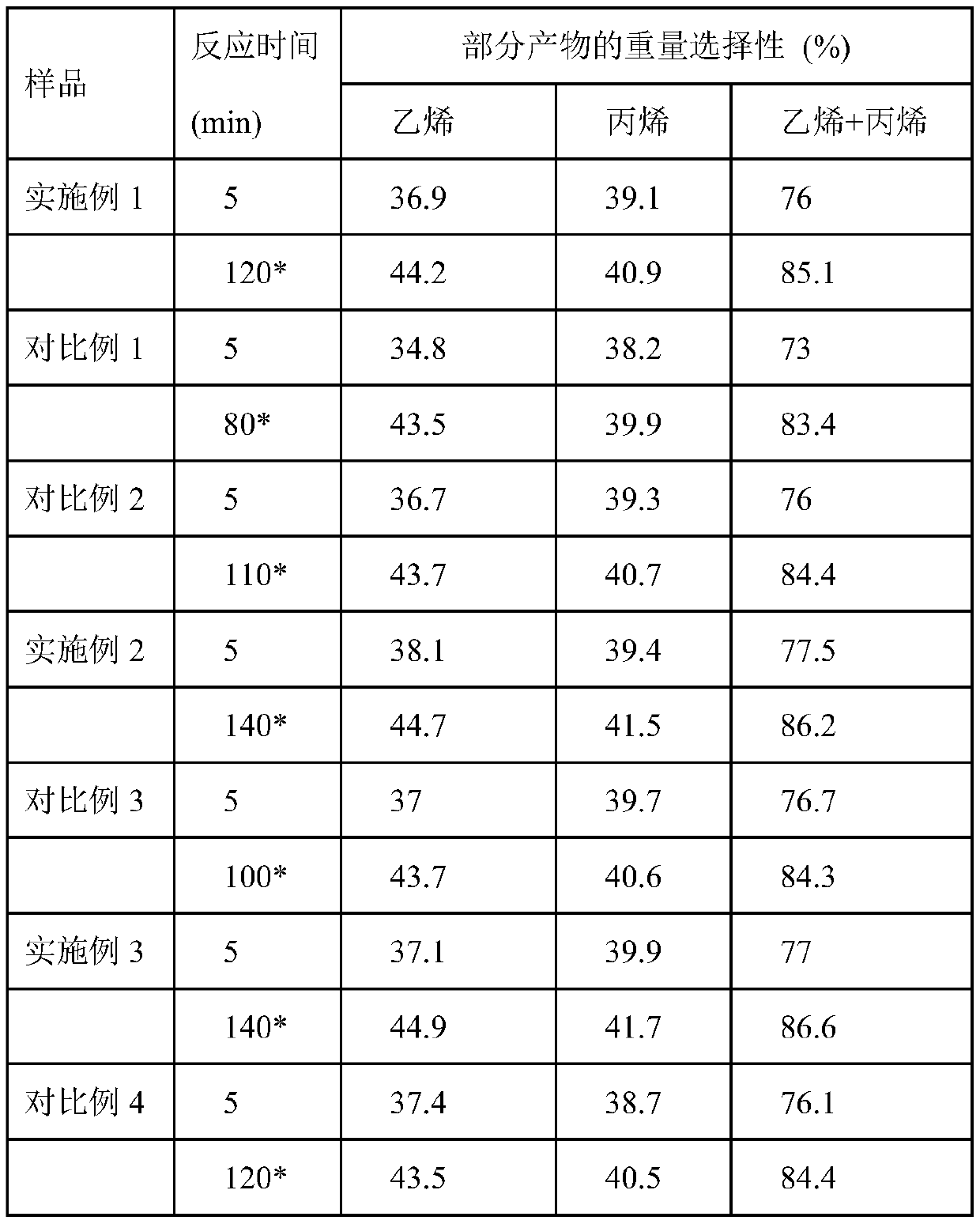

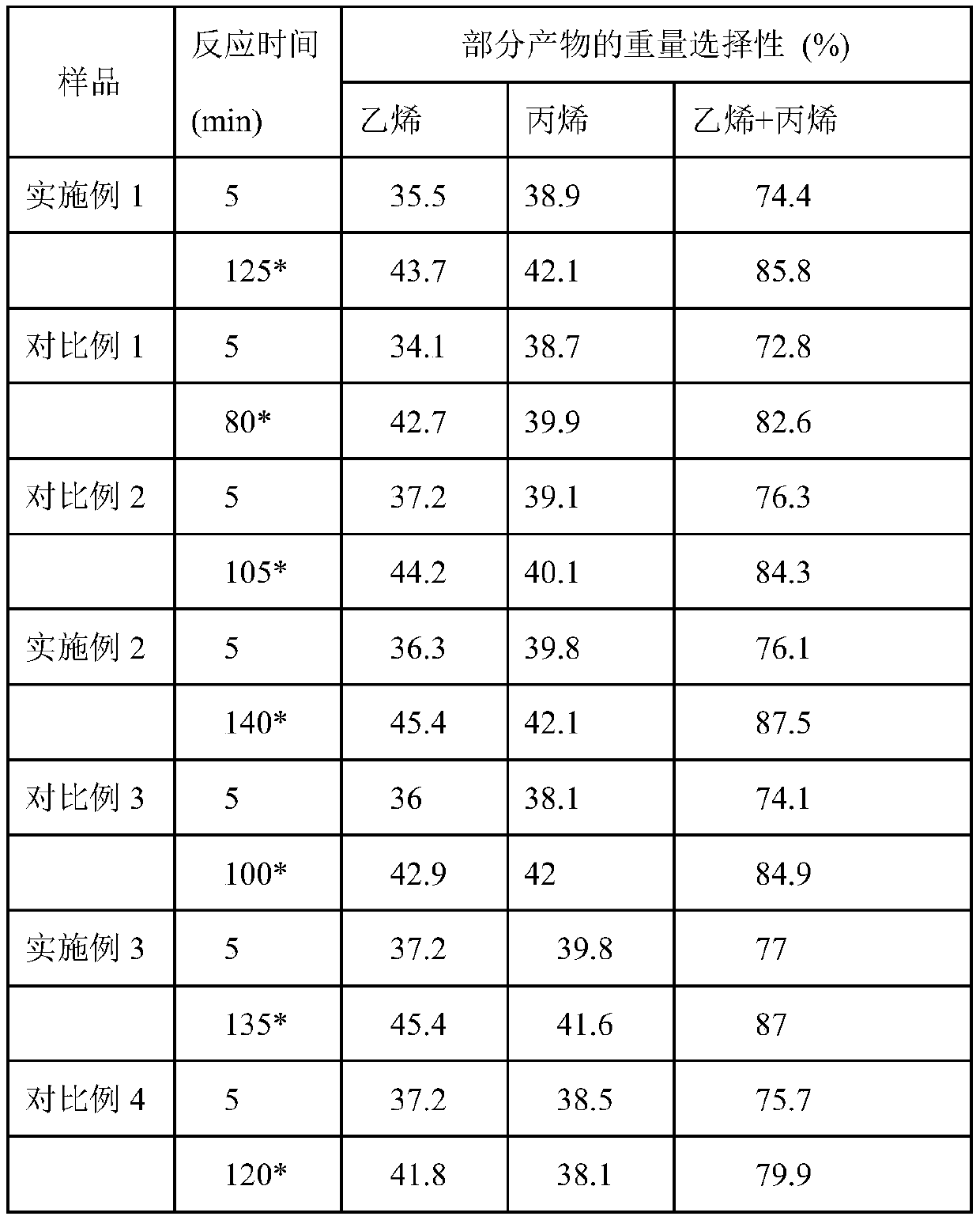

Examples

Embodiment 1

[0039] The preparation method of the microsphere catalyst used for the preparation of light olefins by methanol, ethanol or dimethyl ether of the present invention, the detailed steps of the preparation method are as follows:

[0040] a. Mix 1 kg of silicoaluminophosphate molecular sieve SAPO-34 raw powder with 1.3 kg, 0.25 mol / L aluminum chloride aqueous solution, and then stir at 40°C for 1.5 hours to obtain a mixed solution;

[0041] b, then at room temperature, add 0.5kg deionized water, 50g lanthanum nitrate, 30g polyethylene glycol 600, 2.6kg aluminum sol (solid content is 20%), 0.94kg silica sol to the mixed solution obtained in step a (solid content is 30%), 0.2kg pseudo-boehmite (solid content is 70%) and 1.25kg kaolin (solid content is 80%), stir after adding;

[0042] c. Stir the mixed solution obtained in step b to perform high-speed shear dispersion until ≥80% of the particle size in the obtained suspension is smaller than 8 microns;

[0043] d. The suspension ob...

Embodiment 2

[0046] The preparation method of the microsphere catalyst used for the preparation of light olefins by methanol, ethanol or dimethyl ether of the present invention, the detailed steps of the preparation method are as follows:

[0047] a. Mix 1.5kg silicoaluminophosphate molecular sieve SAPO-34 raw powder with 2.0kg, 0.10mol / L aluminum sulfate aqueous solution, and then stir at 30°C for 3 hours to obtain a mixed solution;

[0048] b, then at room temperature, add 0.5kg deionized water, 30g cerium nitrate, 20g polyethylene glycol 600, 2.4kg aluminum sol (solid content is 20%), 1.05kg silica sol to the mixed solution obtained in step a (solid content is 30%) and 1.4kg metakaolin (solid content is 80%), stir after adding;

[0049] c. Stir the mixed solution obtained in step b to perform high-speed shear dispersion until ≥80% of the particle size in the obtained suspension is smaller than 8 microns;

[0050] d. The suspension obtained by shearing and dispersing in step c is pressu...

Embodiment 3

[0053] The preparation method of the microsphere catalyst used for the preparation of light olefins by methanol, ethanol or dimethyl ether of the present invention, the detailed steps of the preparation method are as follows:

[0054] a. Mix 2kg of silicoaluminophosphate molecular sieve SAPO-34 raw powder with 3.0kg, 0.2mol / L aluminum nitrate aqueous solution, and then stir at 50°C for 1 hour to obtain a mixed solution;

[0055] b, then at room temperature, add 0.7kg deionized water, 15g lanthanum nitrate, 15g cerium nitrate, 20g polyacrylamide, 3.4kg aluminum phosphate sol (solid content is 20%), 0.25 kg to the mixed solution obtained in step a kg pseudo-boehmite (solid content is 70%) and 1.05kg alumina (solid content is 80%), stir after adding;

[0056] c. Stir the mixed solution obtained in step b to perform high-speed shear dispersion until ≥80% of the particle size in the obtained suspension is smaller than 8 microns;

[0057] d. The suspension obtained by shearing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com