Cobalt-based Fischer-Tropsch synthesis catalyst with high heavy hydrocarbon selectivity as well as preparation method and application thereof

A catalyst and Tropsch synthesis technology, applied in the field of cobalt-based Fischer-Tropsch synthesis catalysts and their preparation, can solve the problems of large differences in thermal stability of cobalt catalysts, expensive SiC support, limited practical application, etc., and achieves good reproducibility , enhance the interaction force, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

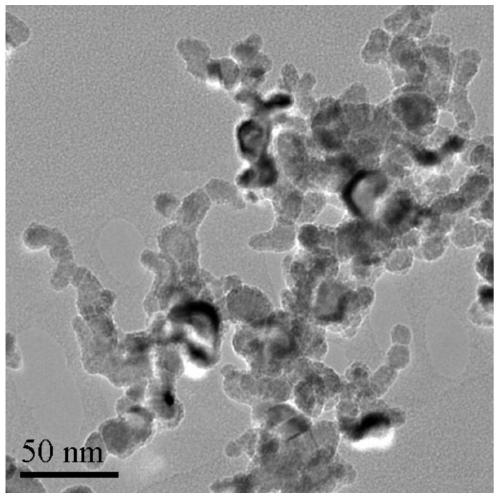

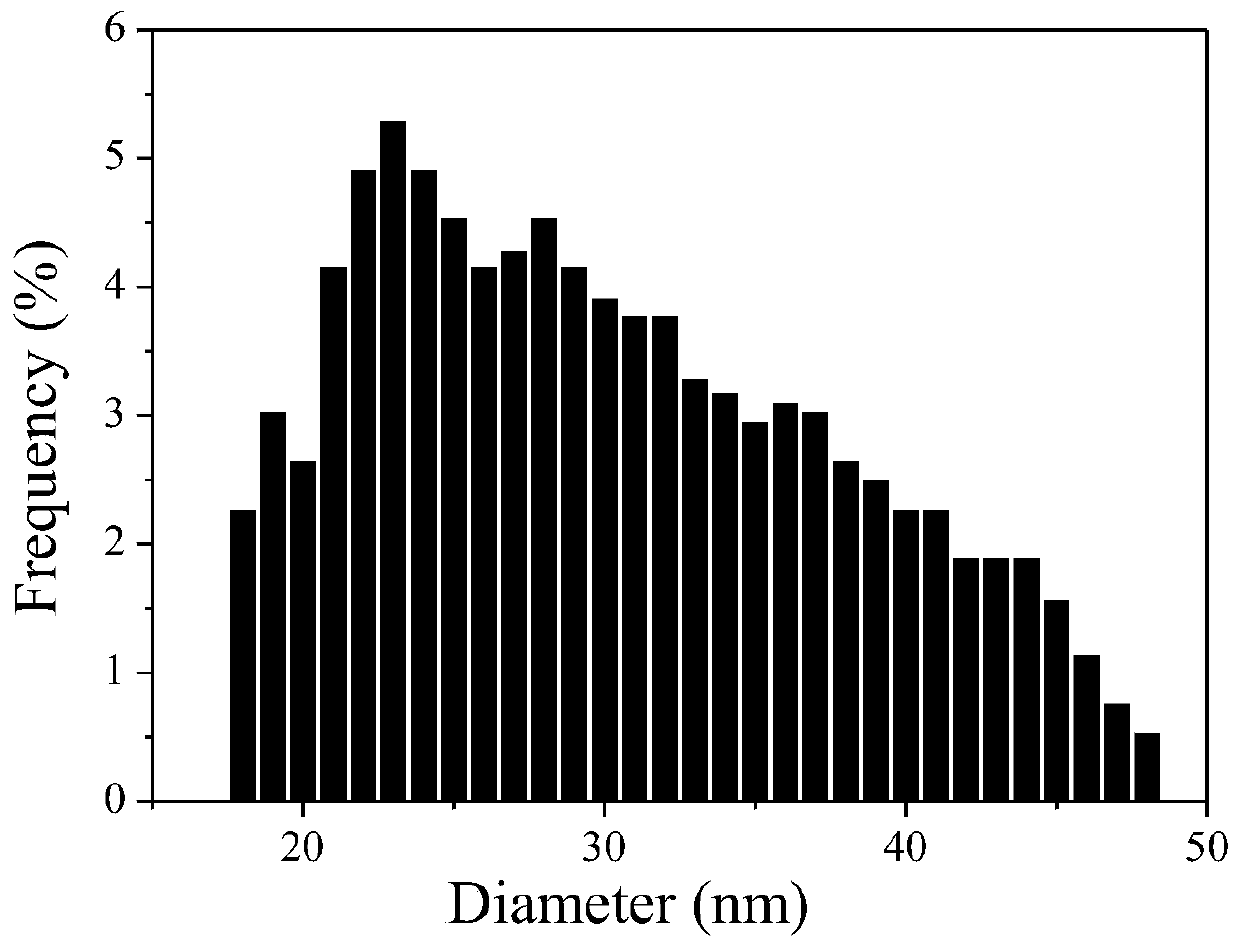

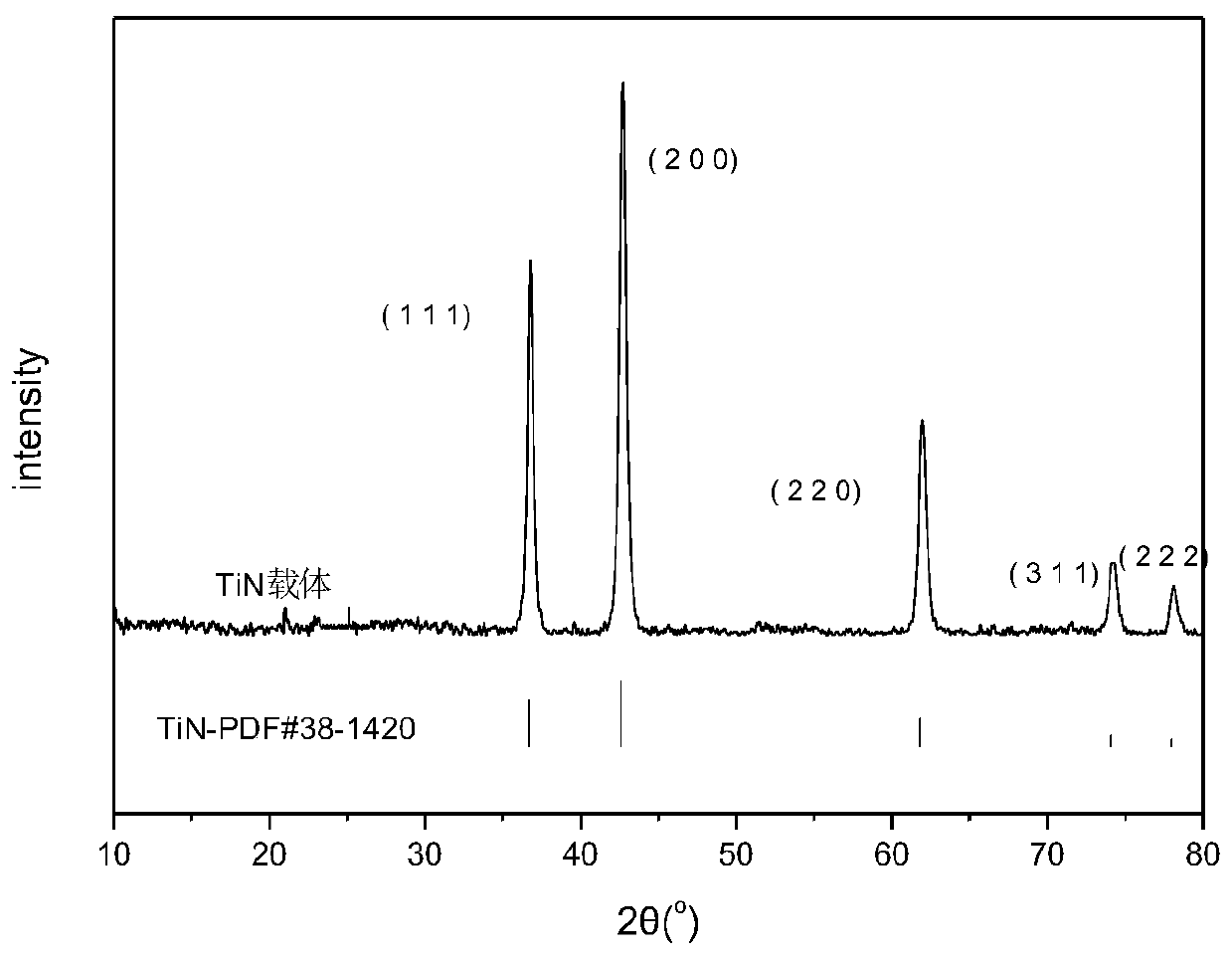

[0042] In the first step, 20g of titanium isopropoxide was added to 5g of citric acid (in the two substances, the mass ratio of titanium to carbon was 1:2.7) and 26mL of absolute ethanol, stirred evenly at 60°C, and the resulting mixture was transferred to Put it into a reaction kettle lined with polytetrafluoroethylene, collect the product after solvothermal reaction at 200 °C for 24 h, filter under reduced pressure, dry at 100 °C for 12 h, place in a tube furnace under NH 3 Nitriding at 1000°C under air atmosphere to obtain TiN carrier;

[0043] In the second step, use 300mL of ethanol aqueous solution (mixed with water and absolute ethanol at a volume ratio of 50:1) as a solvent to dissolve 4.7g of cobalt acetate tetrahydrate, then add 25mL of 15mol / L ammonia water, and use acid and alkali to neutralize The precursor of nano-cobalt oxide was obtained by the method, and the nano-cobalt oxide particles were obtained after hydrothermal treatment at 180°C for 5h, drying at 100°...

Embodiment 2

[0048] Catalyst A was placed in a fixed-bed reactor (TORCH) for catalytic reaction performance evaluation, and the activation conditions were: under normal pressure, H 2 In the atmosphere, the temperature is 300°C and the volume space velocity is 1000h -1 , the activation time is 8h; the reaction conditions are: the reaction temperature is 240℃, 260℃ and 300℃ respectively, H 2 : CO (volume ratio) is 2:1, volume flow rate is 600h -1 , the pressure is 2.0MPa. to N 2 As an internal standard, used to calculate the conversion rate of CO. The tail gas after the reaction was connected to an Agilent GC3000A gas chromatograph for online analysis. Table 1 shows the average reaction data within 100 hours of stable operation of the catalytic reaction to reach the target temperature.

Embodiment 3

[0050] Take 4g of the TiN carrier and 0.96g of nano-cobalt oxide particles prepared in Example 1, first use the mechanical dispersion method to grind for 2h, mix evenly, and then add 60mL of ethanol aqueous solution (the volume ratio of ethanol to water is 1:2) and ultrasonically disperse for 1h Catalyst B was obtained after vacuum rotary evaporation at 60°C for 3h and drying at 100°C for 12h.

[0051] The mass of Co element in catalyst B accounts for about 15% of the mass of the catalyst (theoretical calculation value).

[0052] The catalyst evaluation test was carried out in a fixed-bed reactor (TORCH), and the activation conditions were: under normal pressure, H 2 In the atmosphere, the temperature is 300°C and the volume space velocity is 1000h -1 , the activation time is 8h; the reaction conditions are: the reaction temperature is 240℃, 260℃ and 300℃ respectively, H 2 : CO (volume ratio) is 2:1, volume flow rate is 600h -1 , the pressure is 1.0MPa. The reaction time w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com