Needle bed jacquard mechanism on knitting circular weft machine

A technology for circular knitting machine and needle bed, which is used in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of shortening the service life of knitting needles and jacquard sheets, increasing the power load of the circular knitting machine, and increasing resistance and wear. , to achieve the effect of reducing driving power, avoiding precision requirements and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation manner of the present invention will be described in detail below in conjunction with the drawings and specific embodiments, so as to fully understand the present invention.

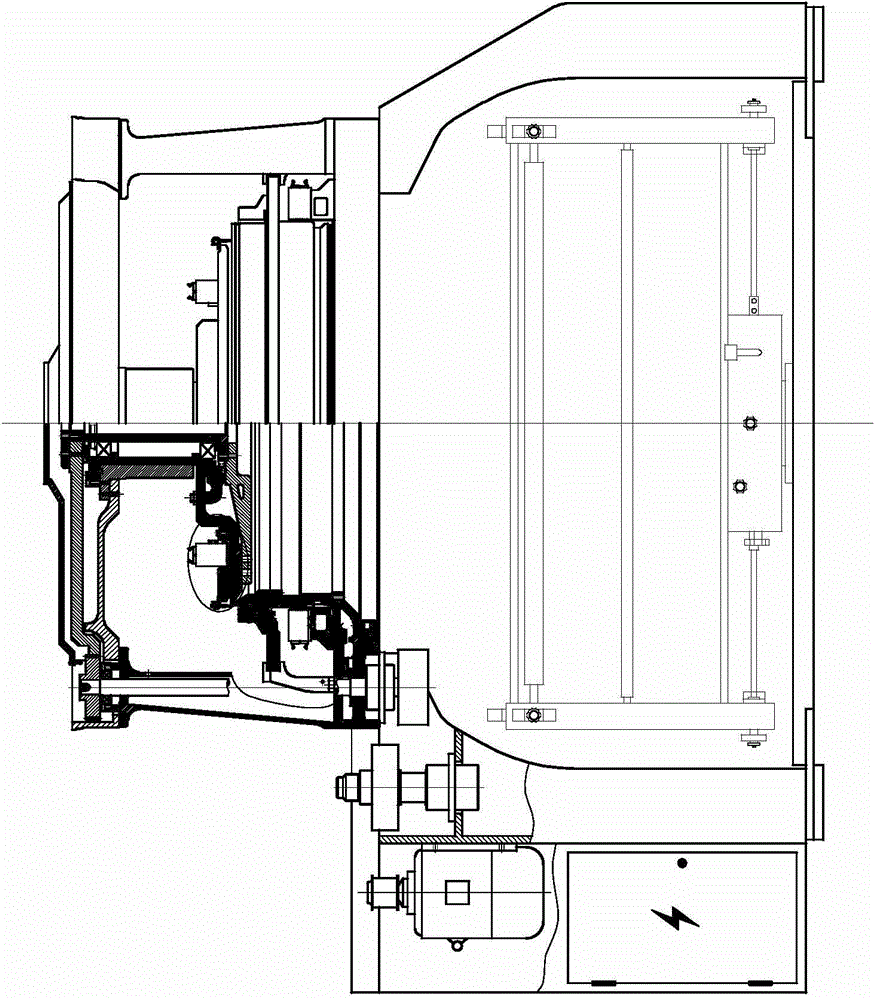

[0022] Such as figure 1 Shown is a schematic structural view of a circular knitting machine applying an embodiment of the present invention.

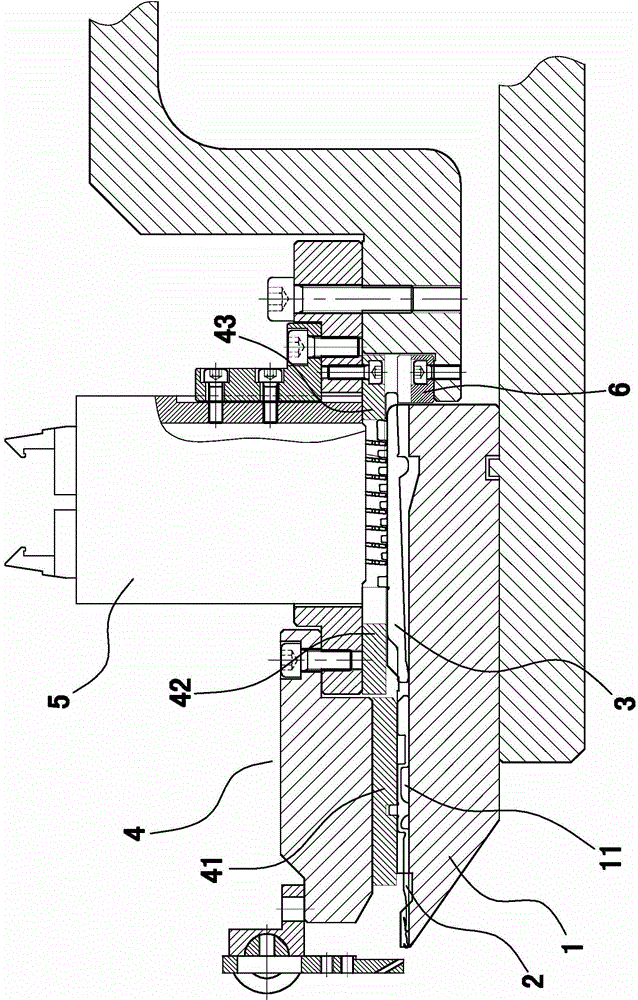

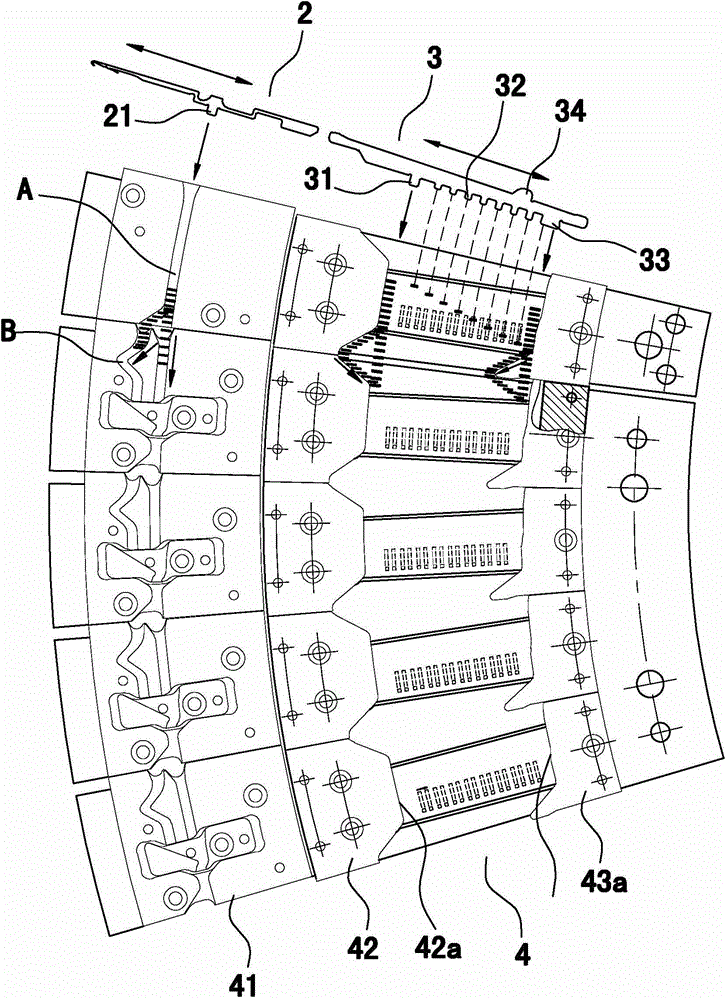

[0023] A needle bed jacquard mechanism on a circular knitting machine, such as figure 2 As shown, it includes a dial 1, knitting needles 2 and jacquard needles 3 placed in the needle grooves, a cam unit 4 arranged above the dial 1 for cooperating with the knitting needles 2 and jacquard sheets 3, and a cam unit 4 arranged above the dial 1 for The needle selector 5 for toggling the selected jacquard piece and the reset triangle 6 arranged under the tail end of the jacquard piece 3 are used to push the jacquard piece 3 to the state to be selected.

[0024] Such as figure 2 , Figure 4 As shown, the knitting needle 2 is placed in front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com