High-current jack contact

A jack contact, high current technology, applied in electrical components, parts of connecting devices, circuits, etc., can solve the problems of unreliable contact with the adapter pins, high resistance, etc., to increase pressure, reduce resistance, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

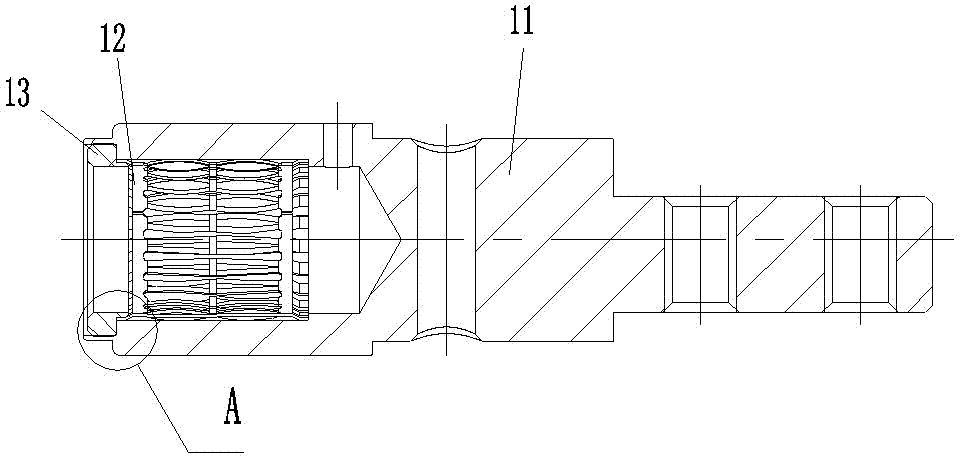

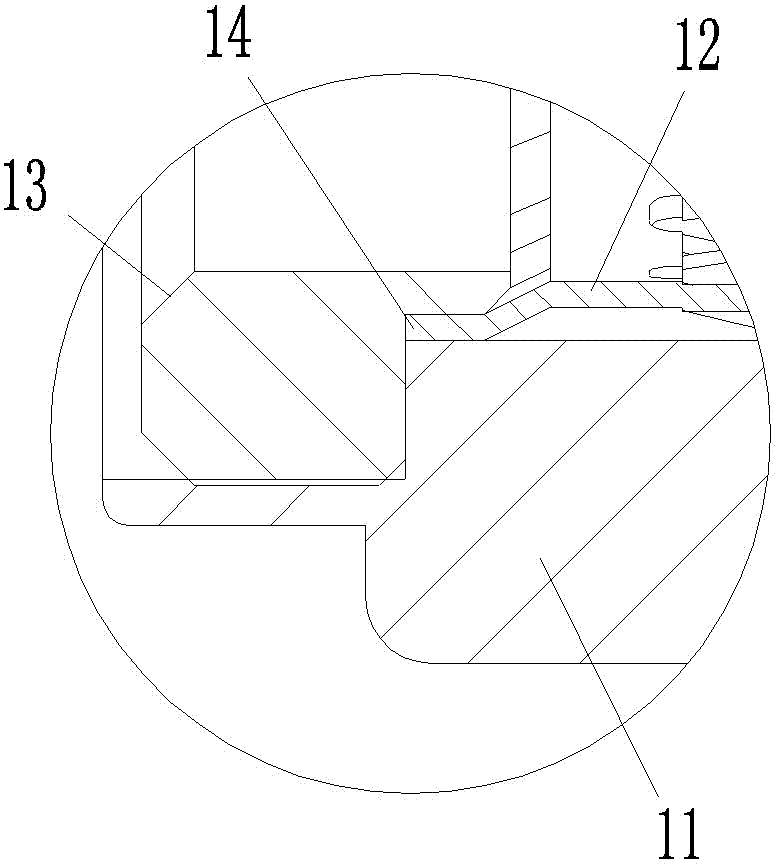

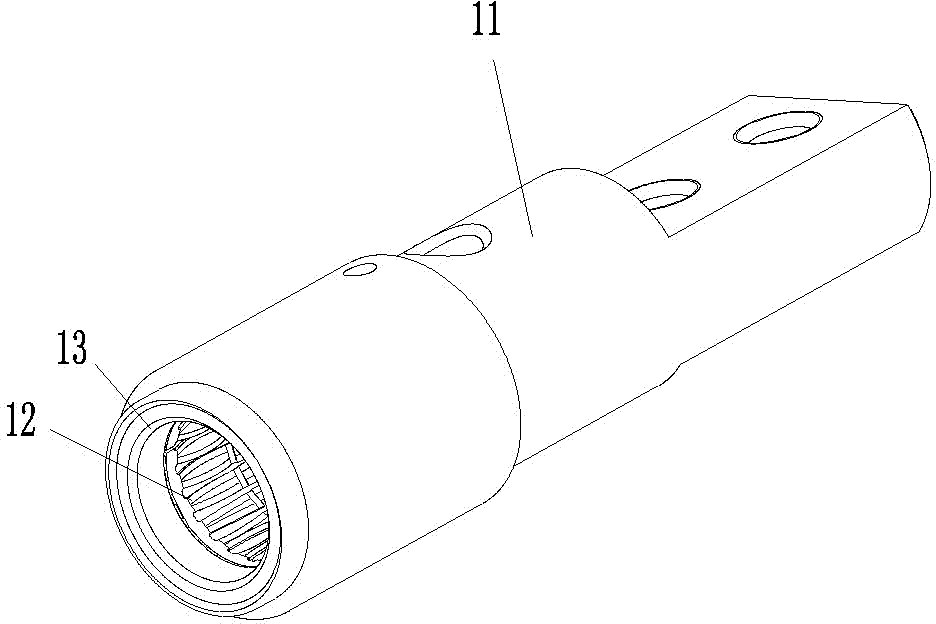

[0015] Examples of high current jack contacts, such as Figure 1-4 As shown, the high-current socket contact includes a socket rear sleeve 11 and a core sleeve 12 assembled in the socket rear sleeve 11 .

[0016] Except for the front port structure of the jack rear cover 11, other structures are all prior art, therefore, only the front port position of the jack rear cover 11 is introduced in detail here. The main difference from the prior art is that the front port of the socket rear sleeve 11 in this embodiment is provided with an enlarged diameter structure, which makes the front part of the inner hole of the socket rear sleeve 11 form a large front and a small rear. step hole.

[0017] The core sleeve 12 is the main part used to cooperate with the adapter pin. In this embodiment, the core sleeve 12 specifically adopts a torsion spring, which is curled in the socket rear sleeve 11 along the circumferential direction of the socket rear sleeve. A cylindrical structure connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com