Patents

Literature

236 results about "Distribution centre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

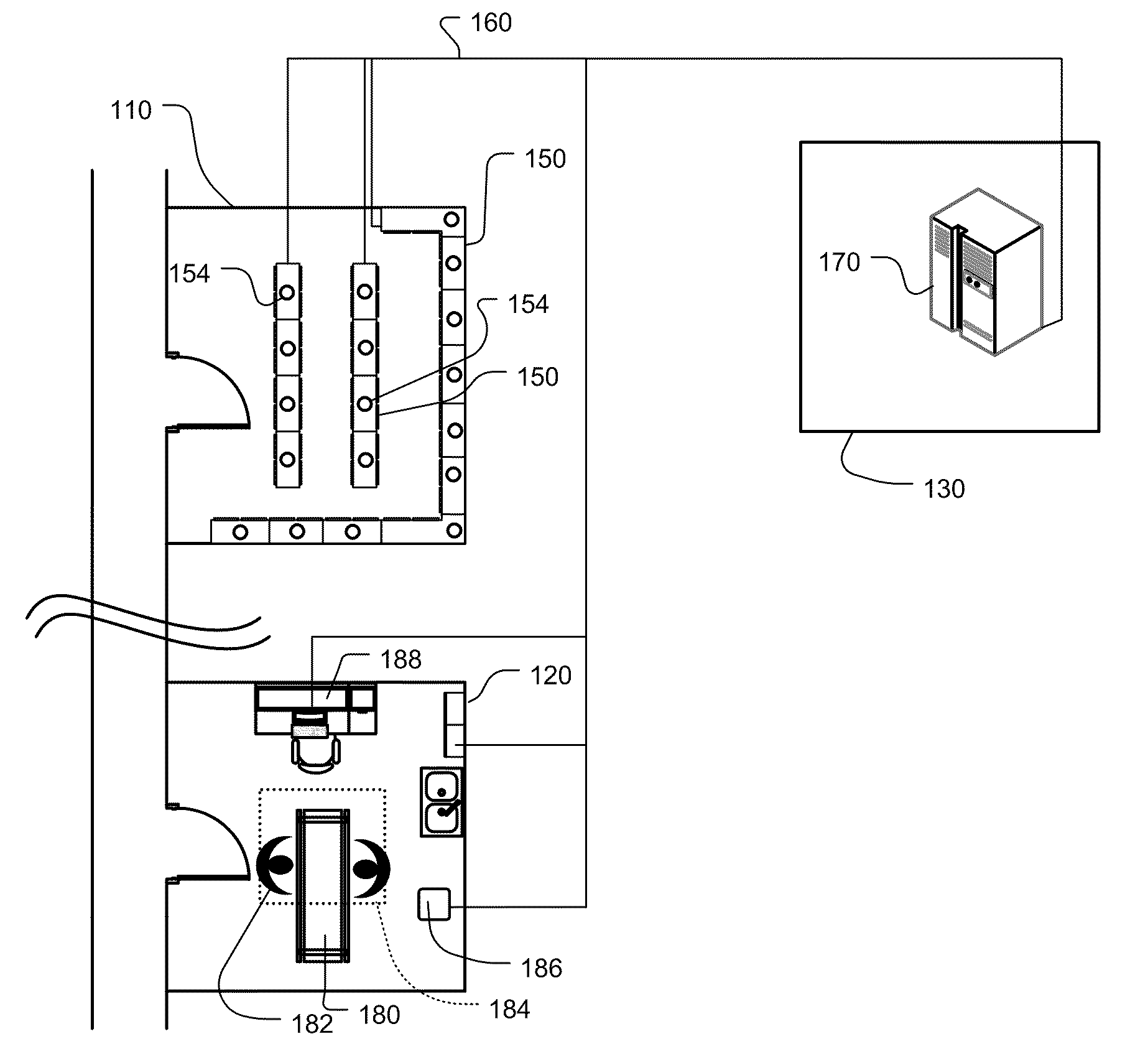

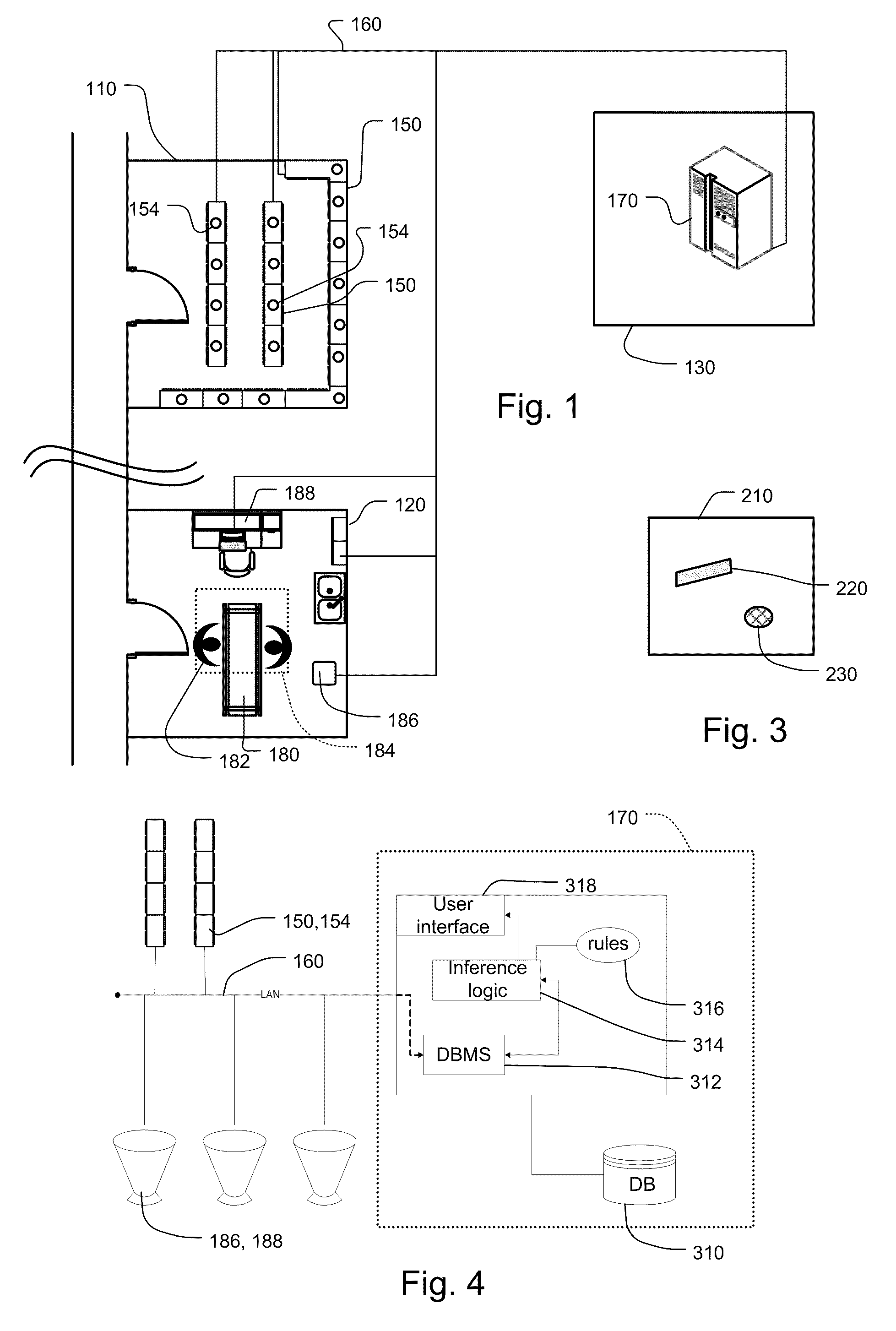

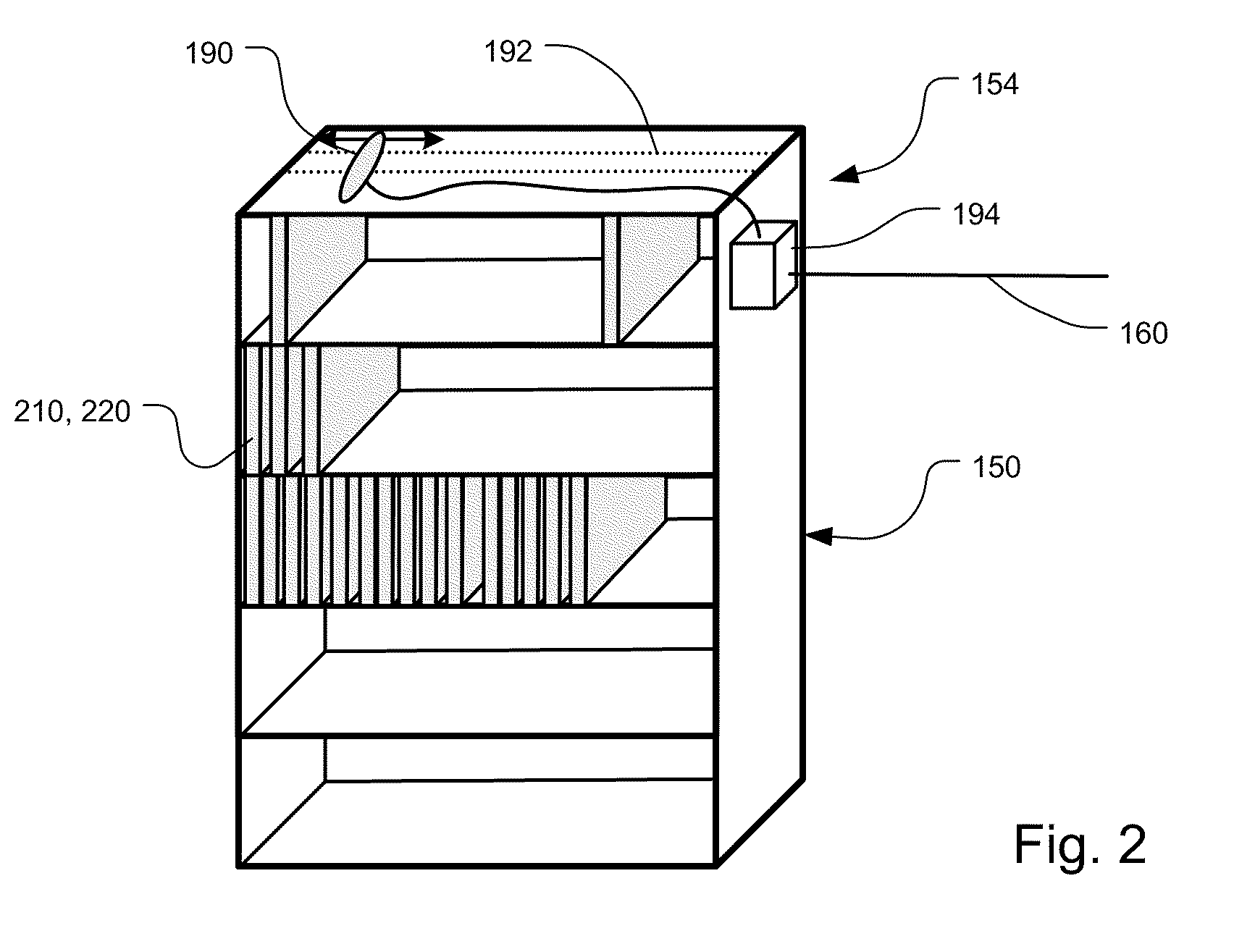

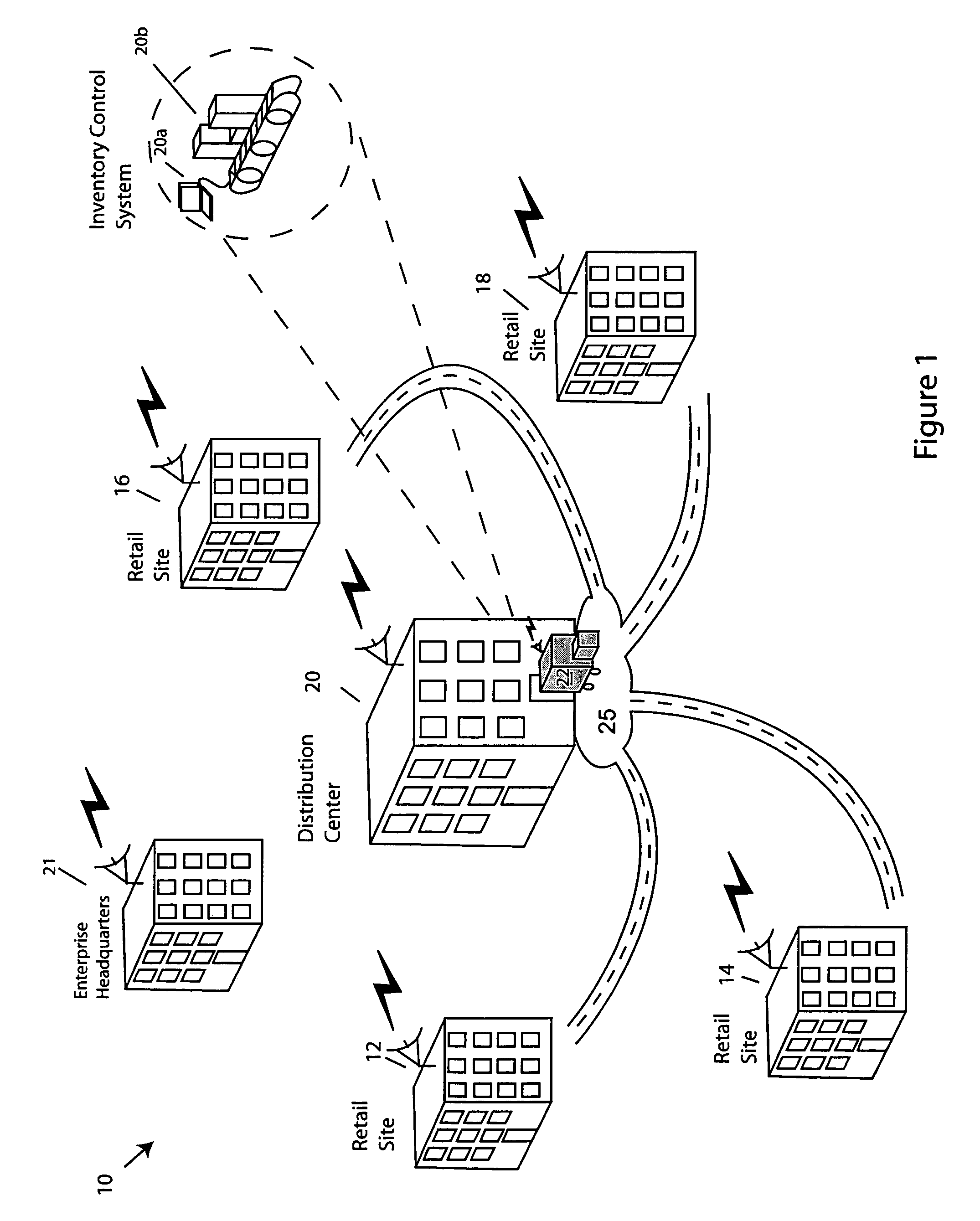

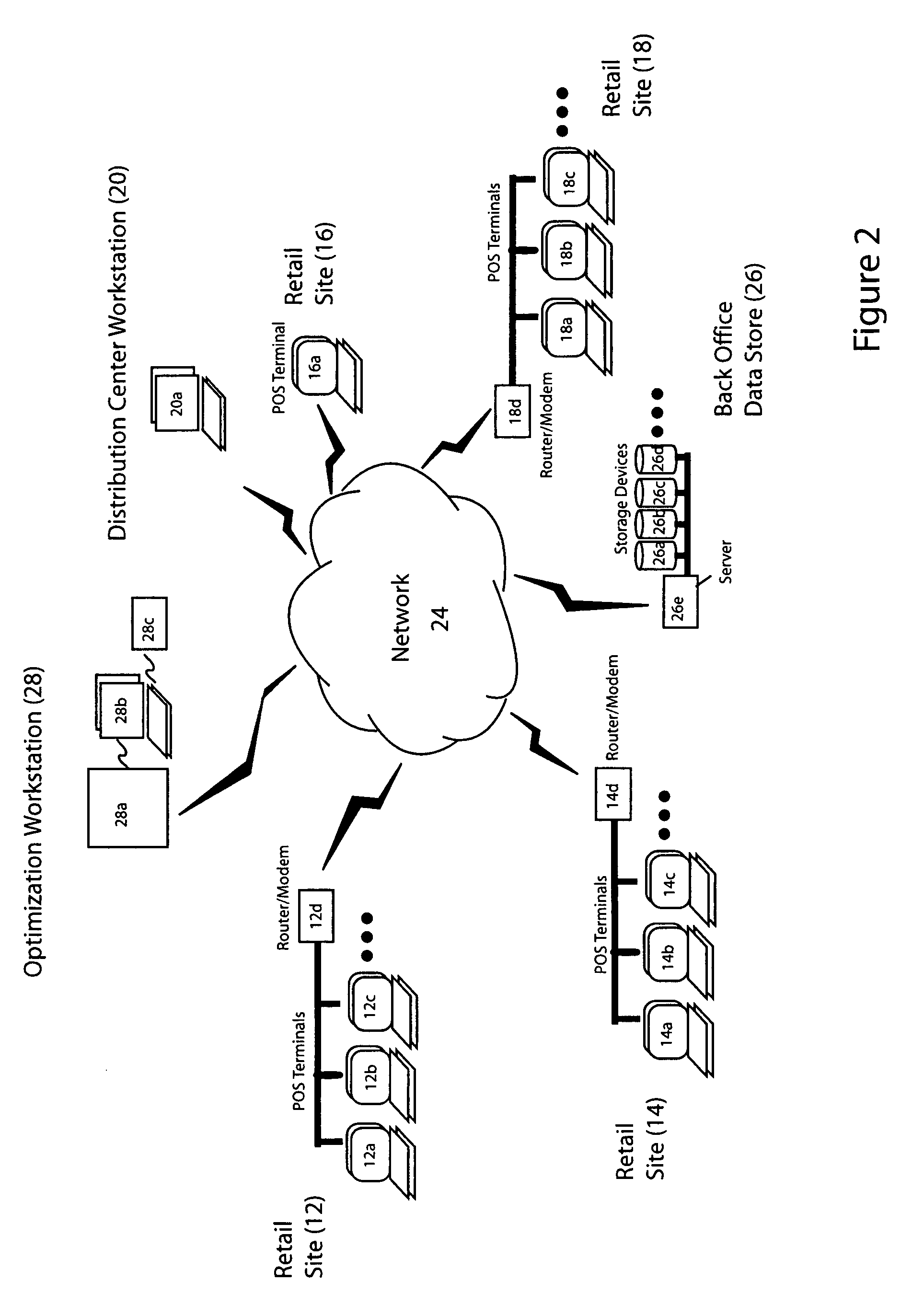

Method and system for automated transport of items

ActiveUS20160176638A1Programme controlAutonomous decision making processAutomated guided vehicleIndustrial engineering

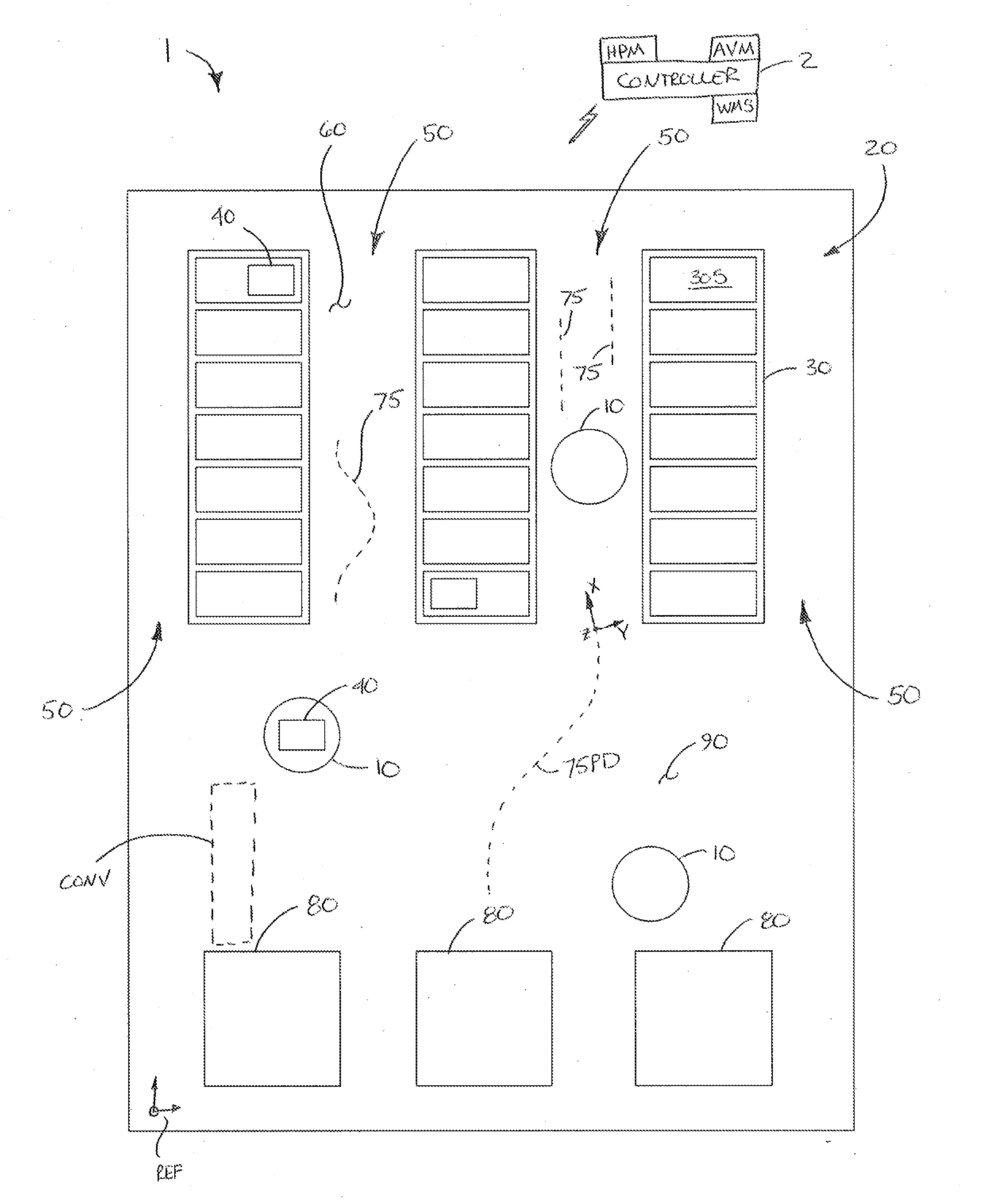

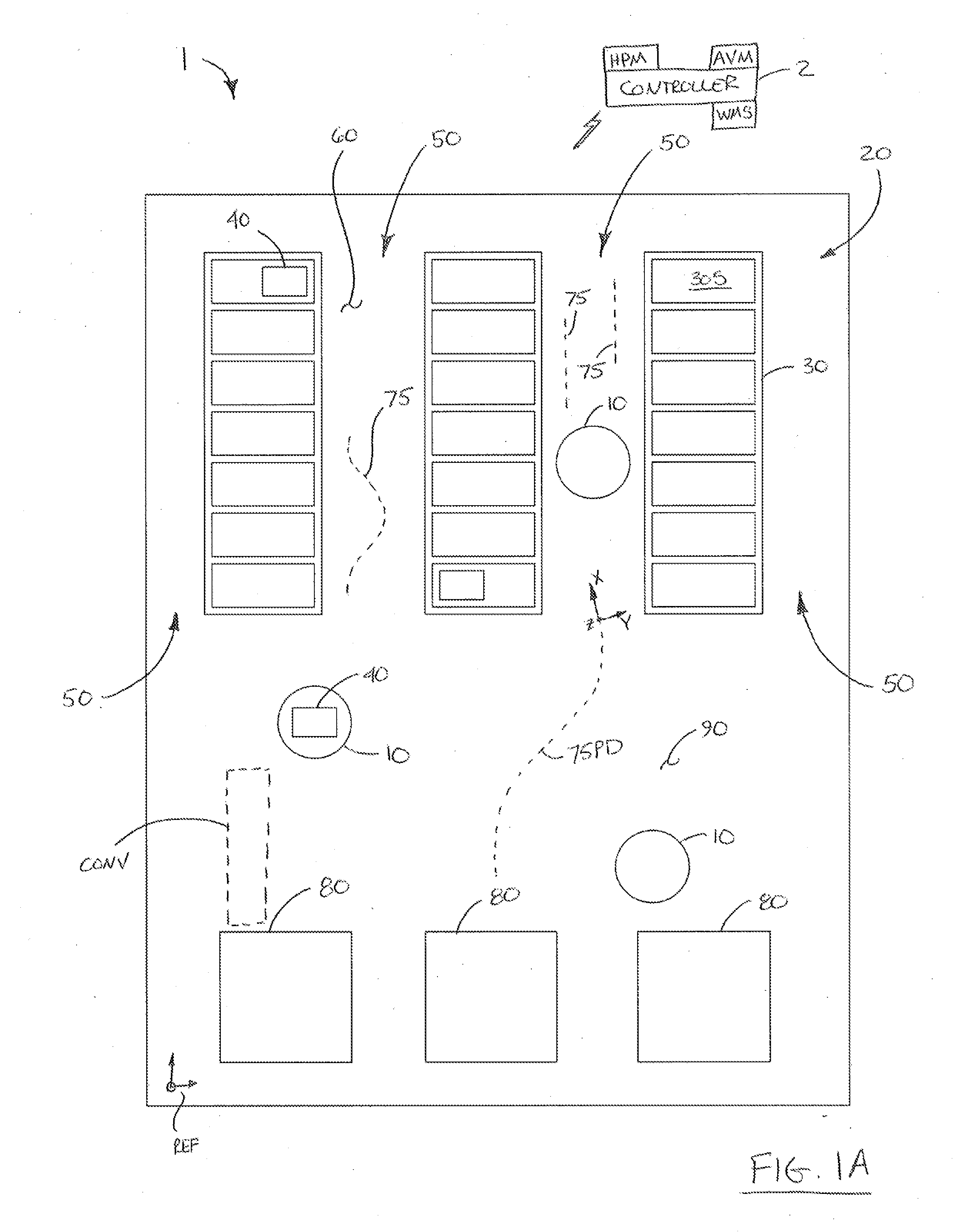

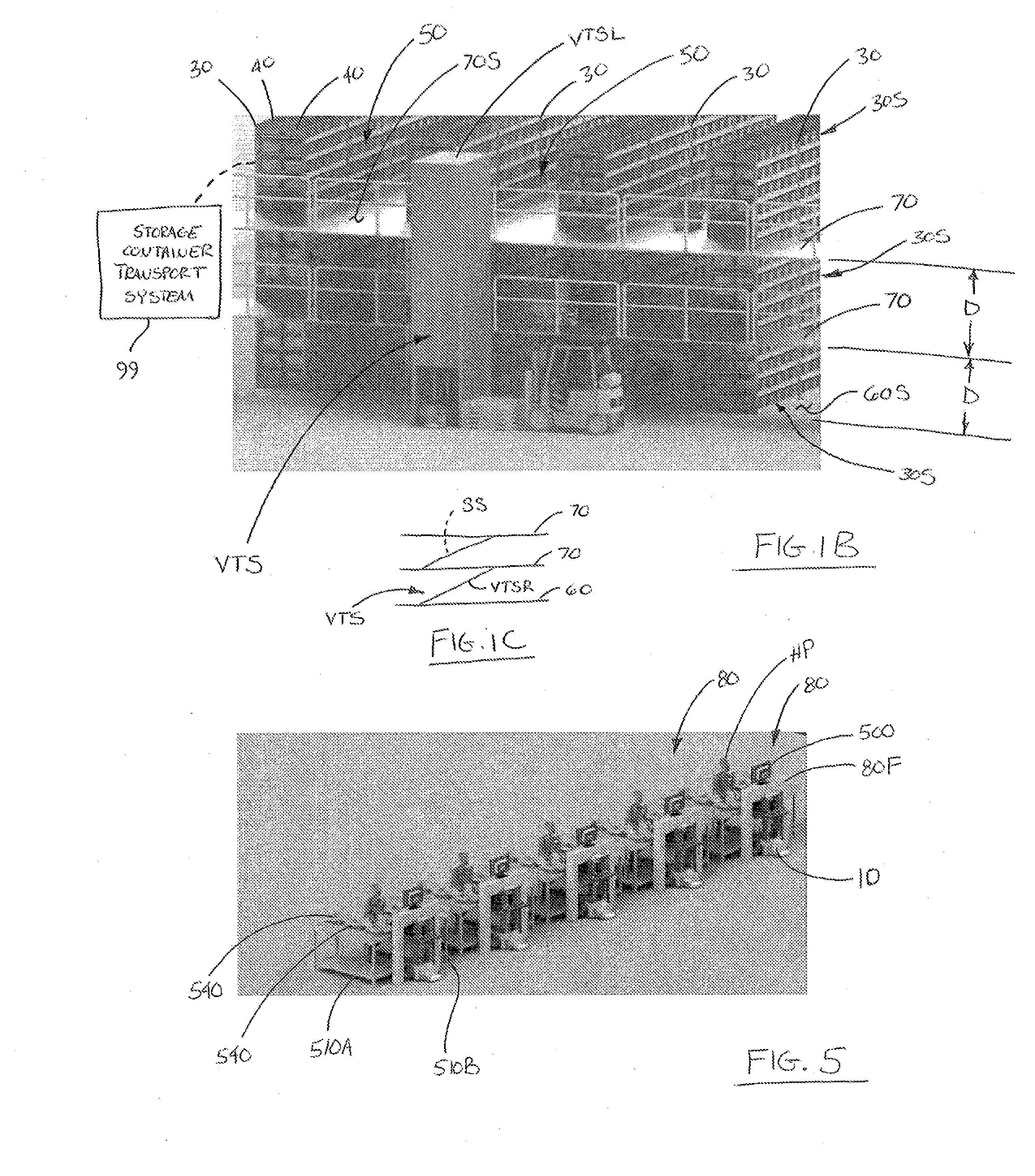

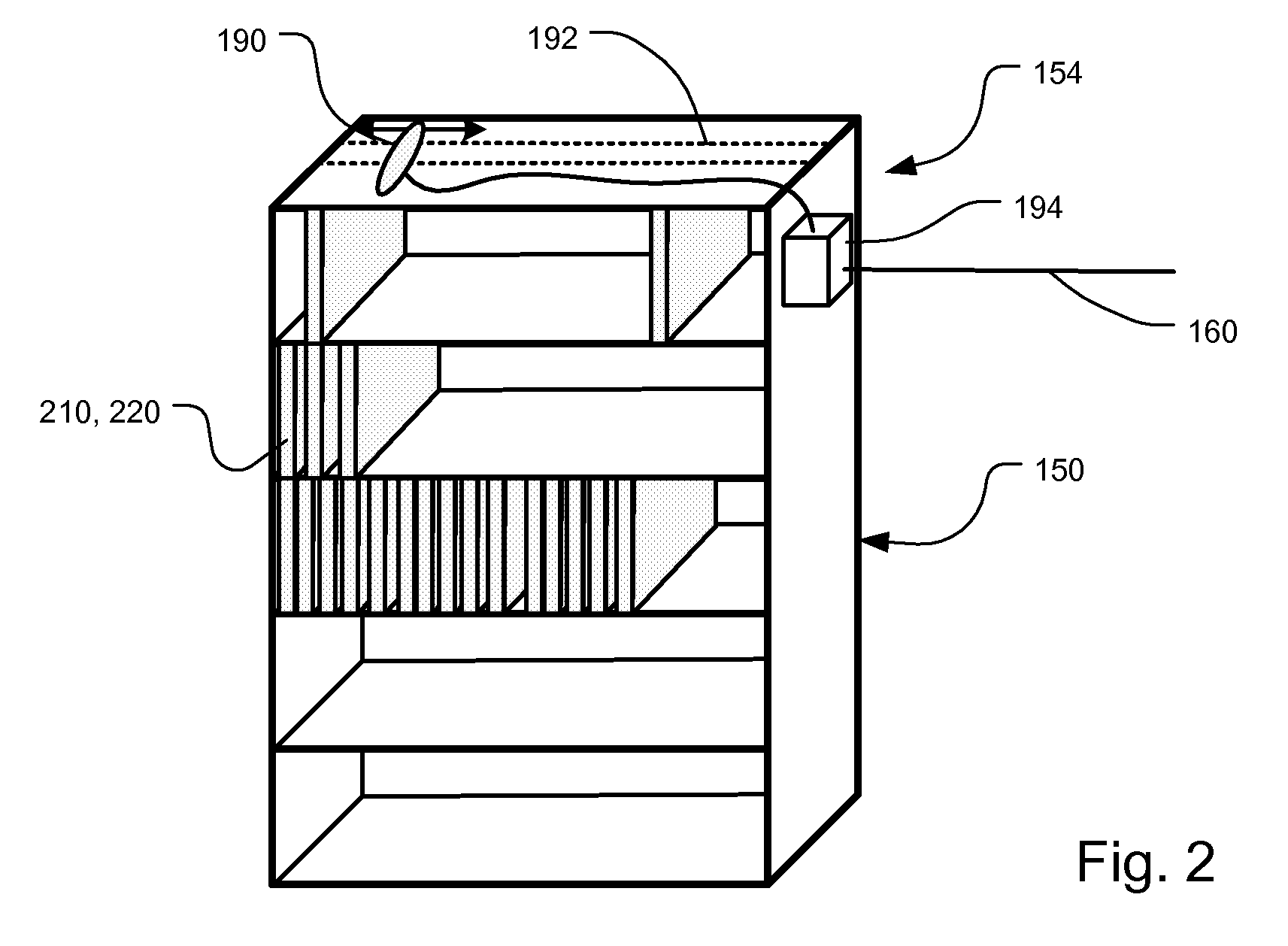

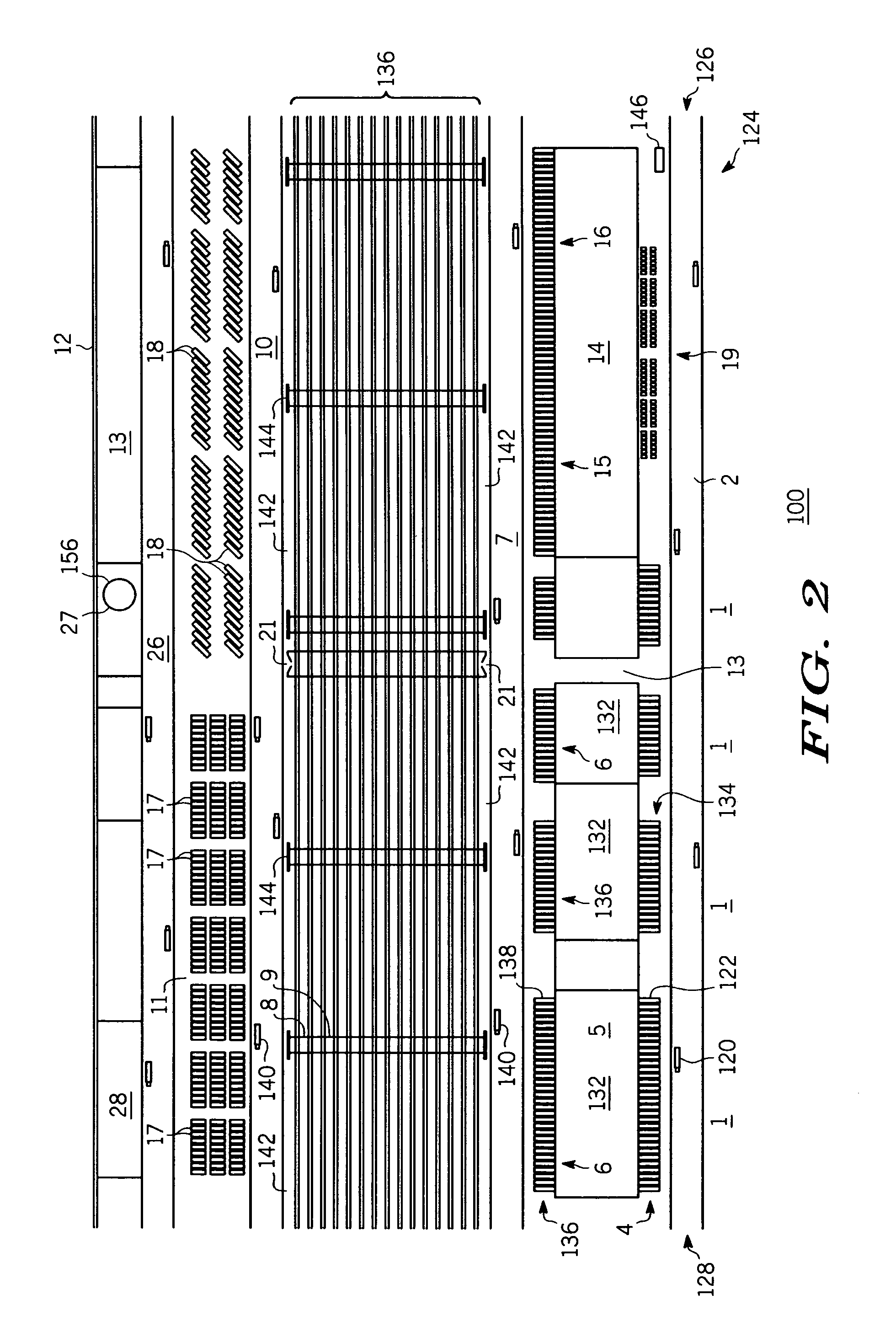

An automated distribution center includes an array with storage locations arranged along aisle(s) having a floor, and a mezzanine platform above the floor, the floor and mezzanine being configured for human picker access to the storage locations, an automated guided vehicle (AGV) configured for traverse of the floor and mezzanine to the storage locations, and for transporting a storage container to and from the storage locations, the floor and mezzanine each having an undeterministic traverse surface for the AGV, the AGV is configured so that the surface provides holonomic selectable paths for the AGV substantially everywhere on the surface, each path being selectable by the AGV, and an order filling station, where one or more goods are picked from container(s) to fill order(s), wherein the AGV is configured to pick the container from a storage location and transport the container on the surface between the storage array and the station.

Owner:NEXTSHIFT ROBOTICS INC

Methods and apparatus for inventory allocation and pricing

ActiveUS20050060270A1Market predictionsDiscounts/incentivesBusiness enterpriseIndustrial engineering

Owner:ORACLE INT CORP

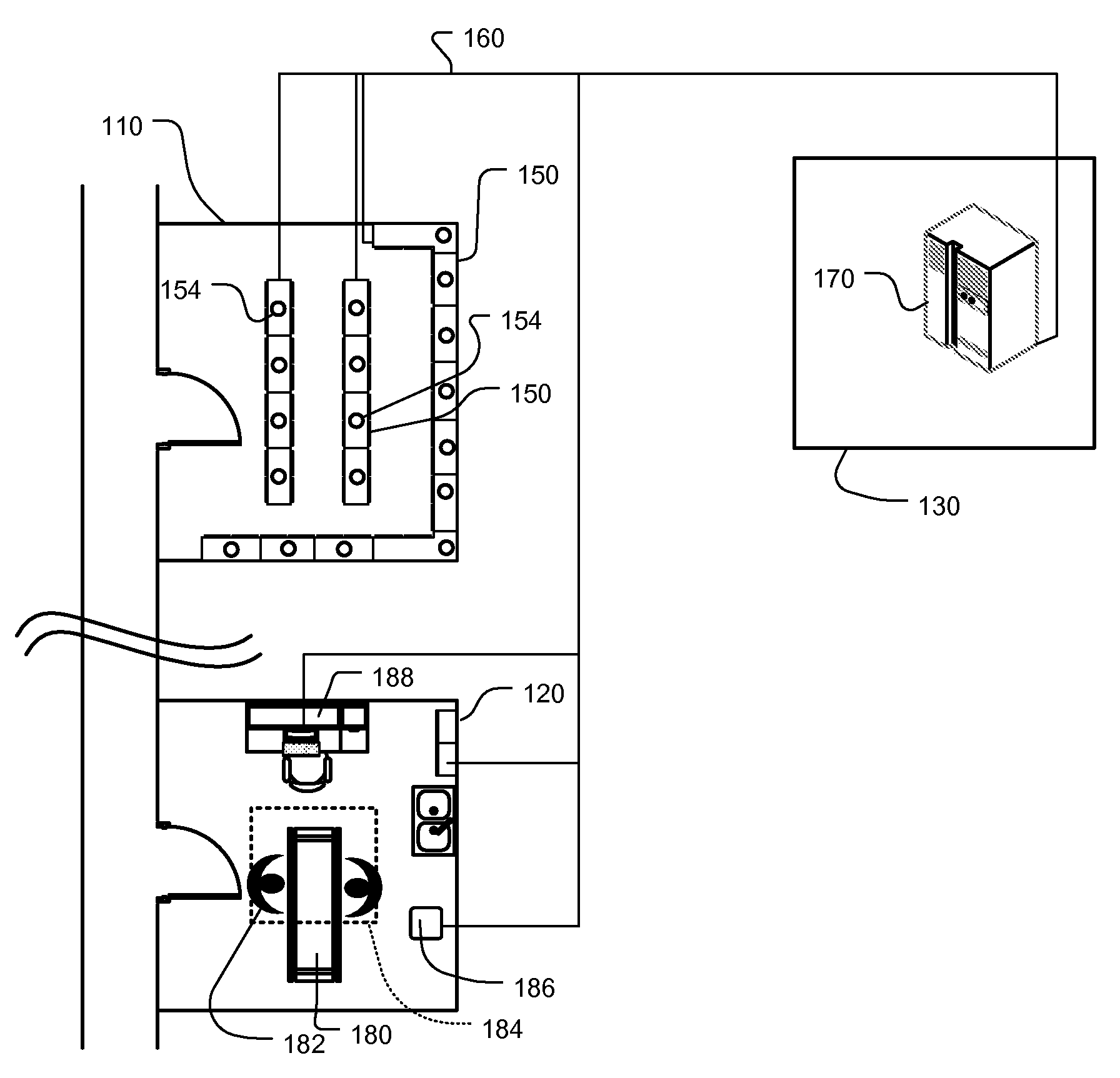

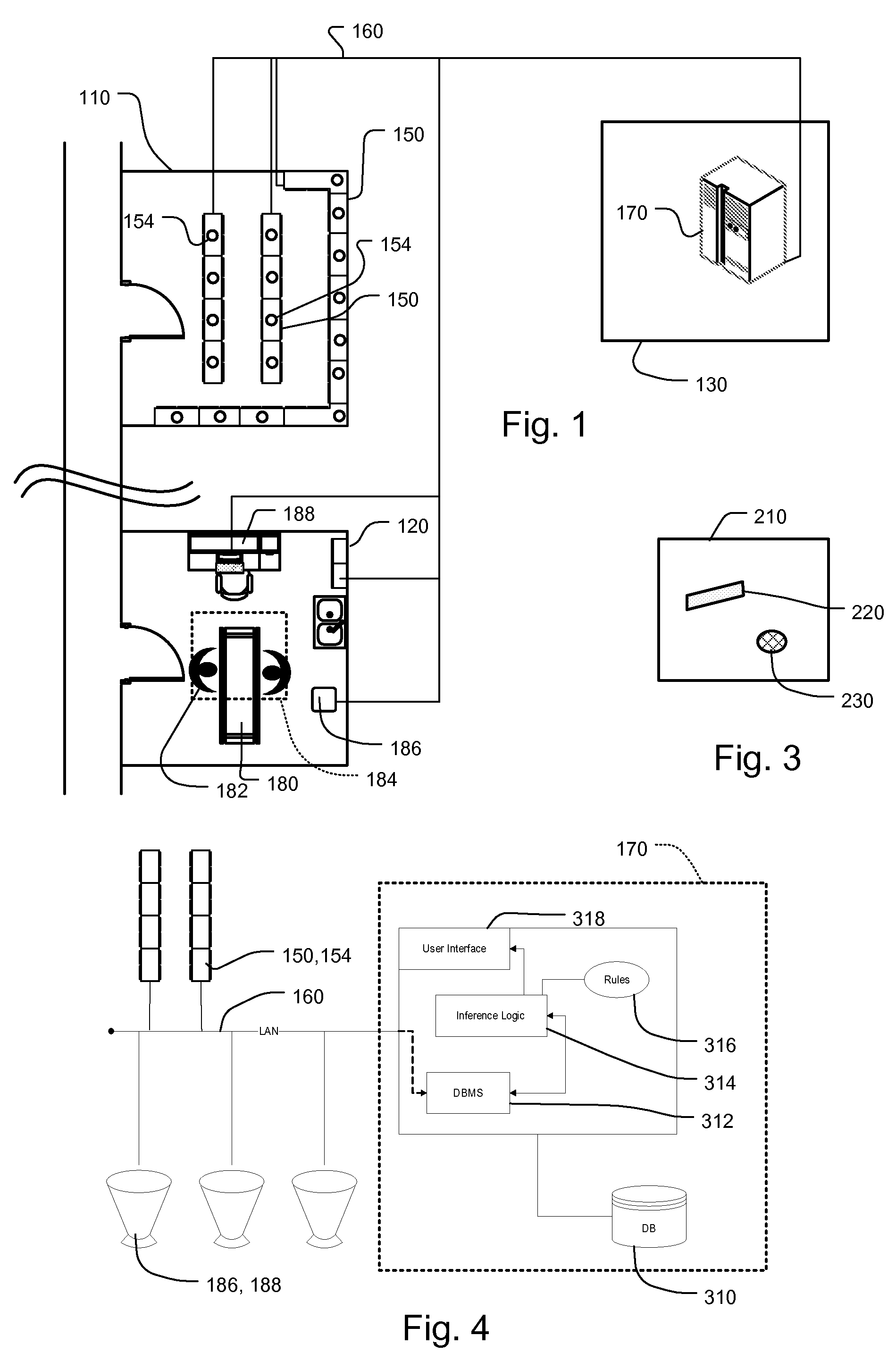

RFID medical supplies consumption monitoring system and method

ActiveUS7639136B1Accurate confirmationHealthcare resources and facilitiesLogisticsMonitoring systemEngineering

A system and method for tracking supplies, particularly medical supplies, and specifically individual medical items, to the end of the product lifecycle to the point of utilizes. RFID tag technology is utilized. This has the advantage of enabling a system that requires less or no active intervention by the medical services delivery staff, such as nurses and doctors. Nonetheless, the system is applicable to other stand-off identification systems including taggant-based systems. The system provides for the monitoring of items, such as medical items, between the distribution center, facility stock rooms and inventory cabinets, and the procedure rooms in which the items are put into use. In one example, system and method associate stand-off, such as RFID, readers with waste-disposal or refuse containers and / or readers located near the point of usage, such as in or associated with the procedure rooms in order to monitor the endpoint of the product lifecycle. Thus, the knowledge of medical item disposal or disposal of the medical item's packaging is combined with one or more prior detections of the medical item, e.g., at acquisition and when moved to a different location such as storage, to generate a usage history for the item. In all or more cases, this knowledge is acquired with out human intervention by judicious location of readers at the distribution center and / or medical facility.

Owner:WAVEMARK

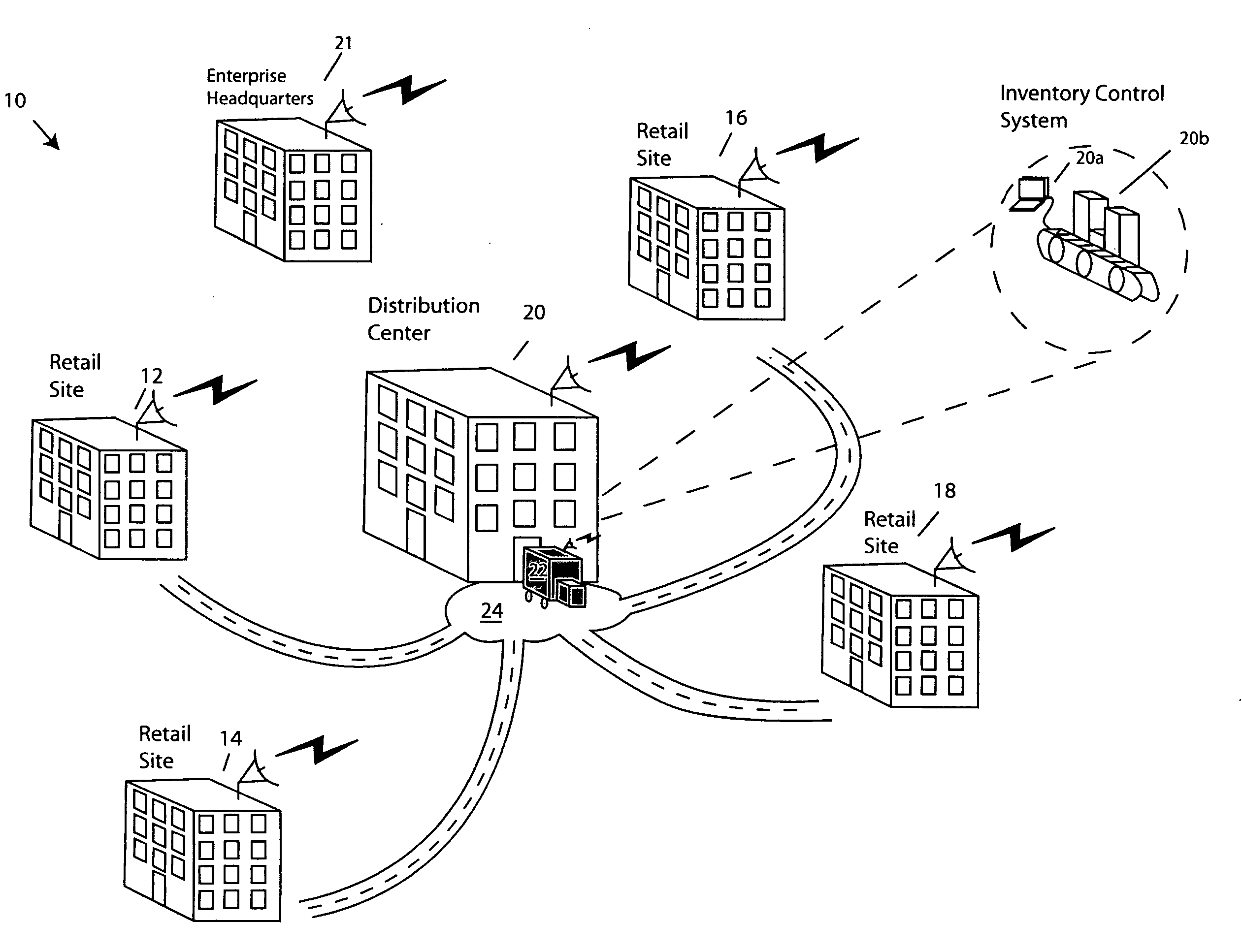

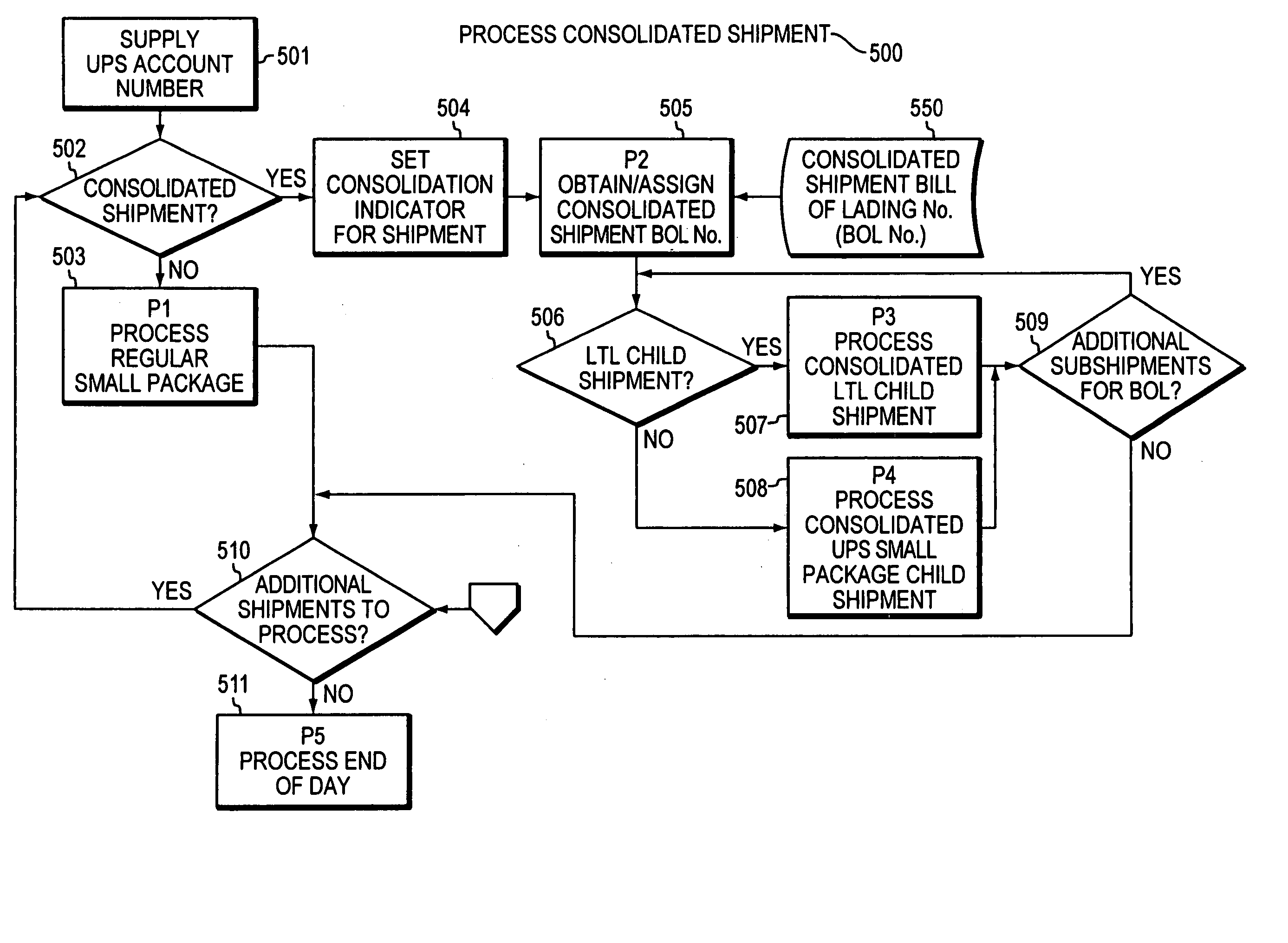

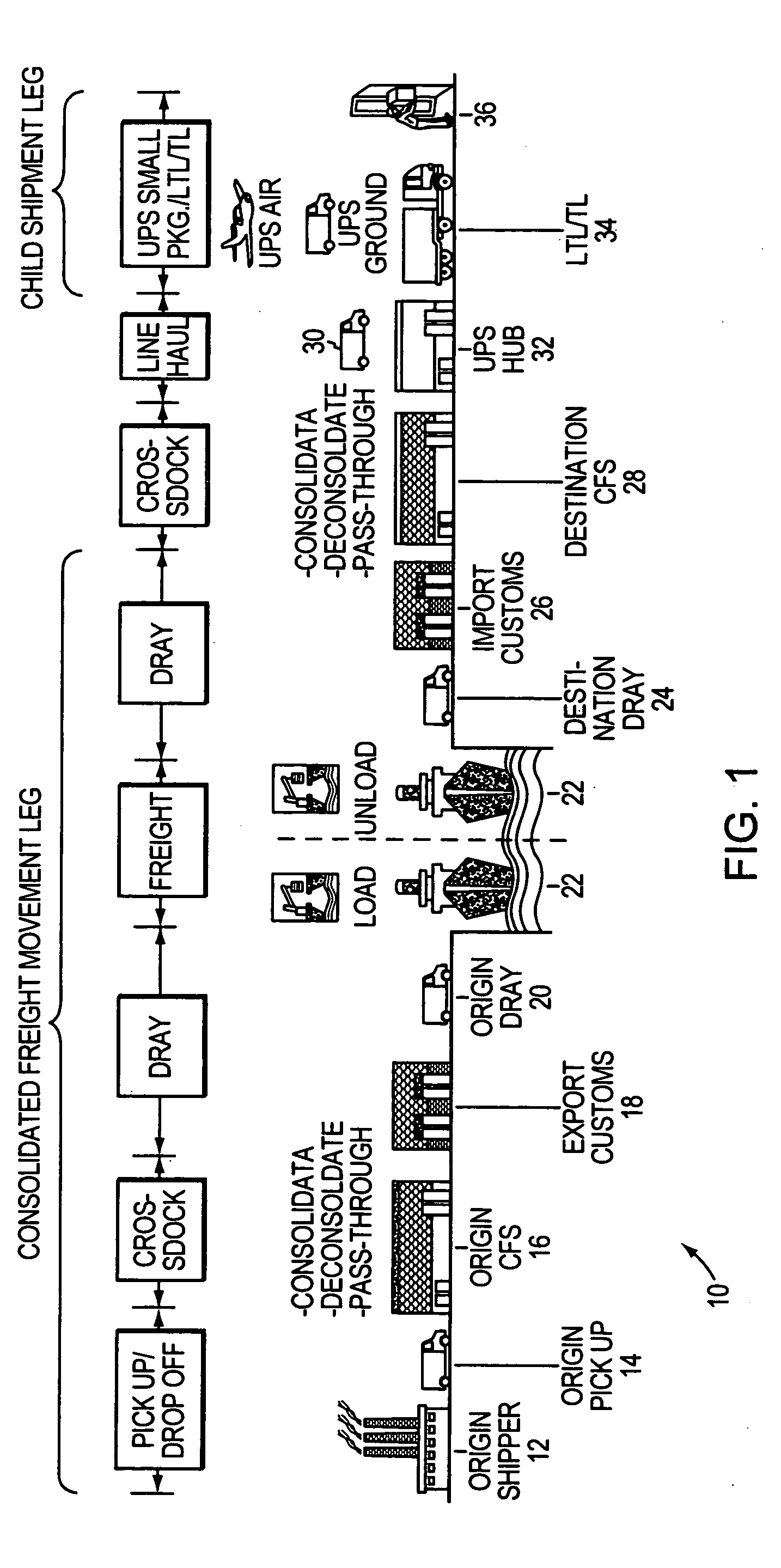

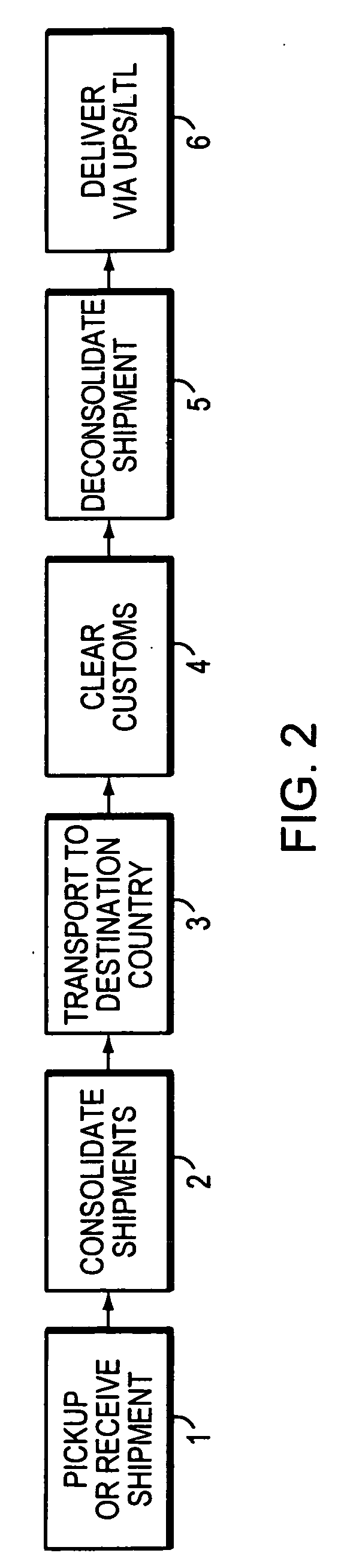

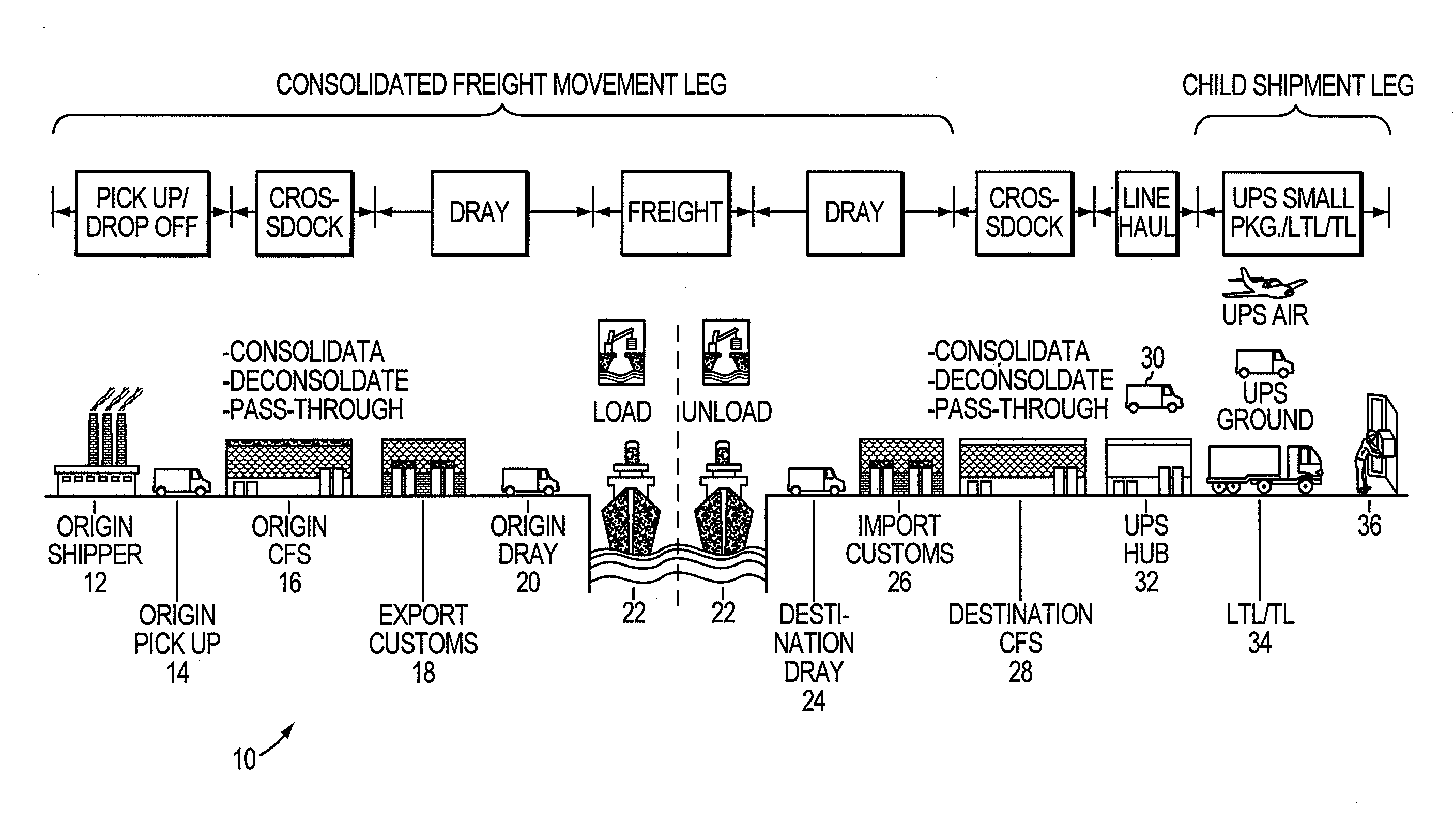

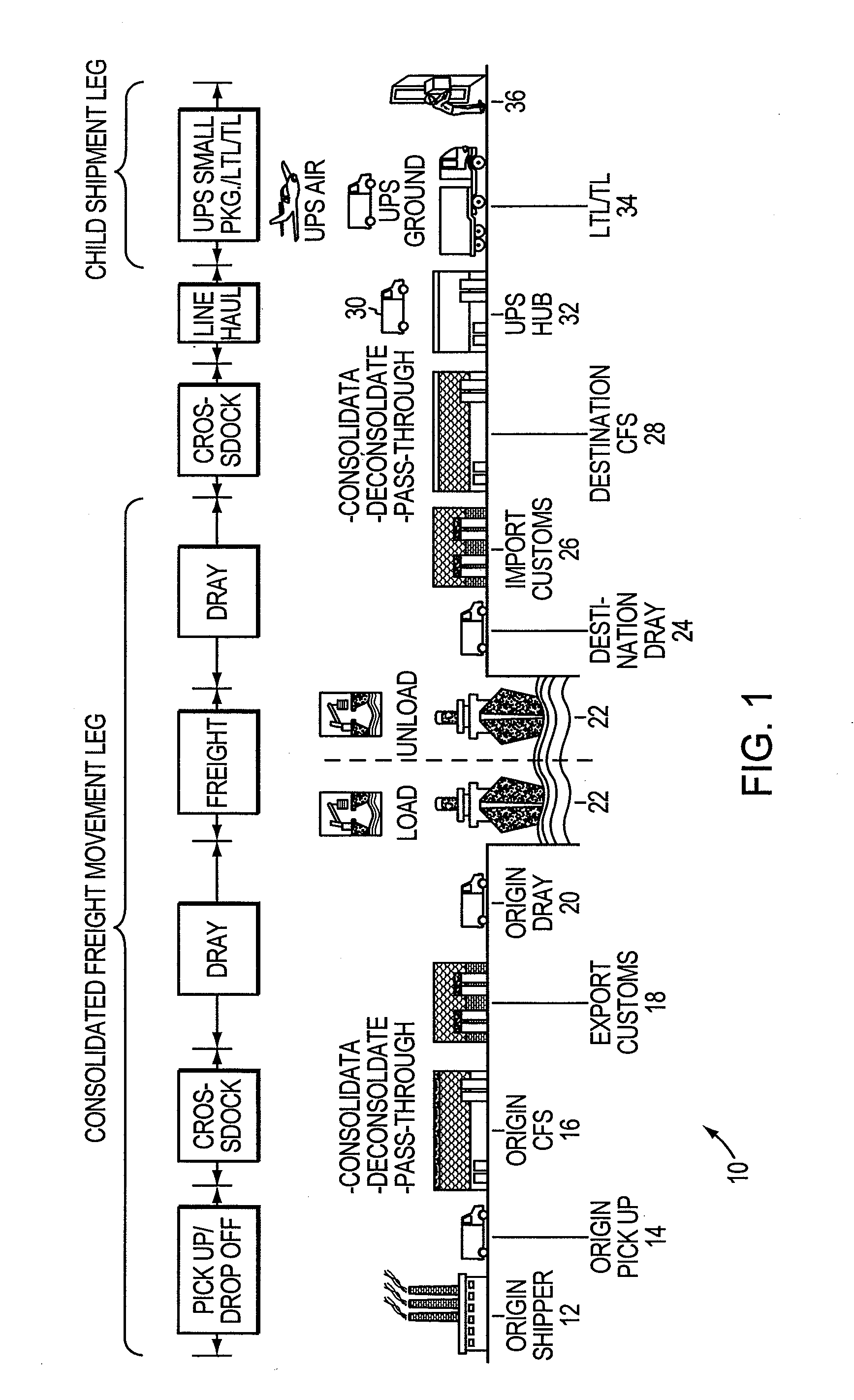

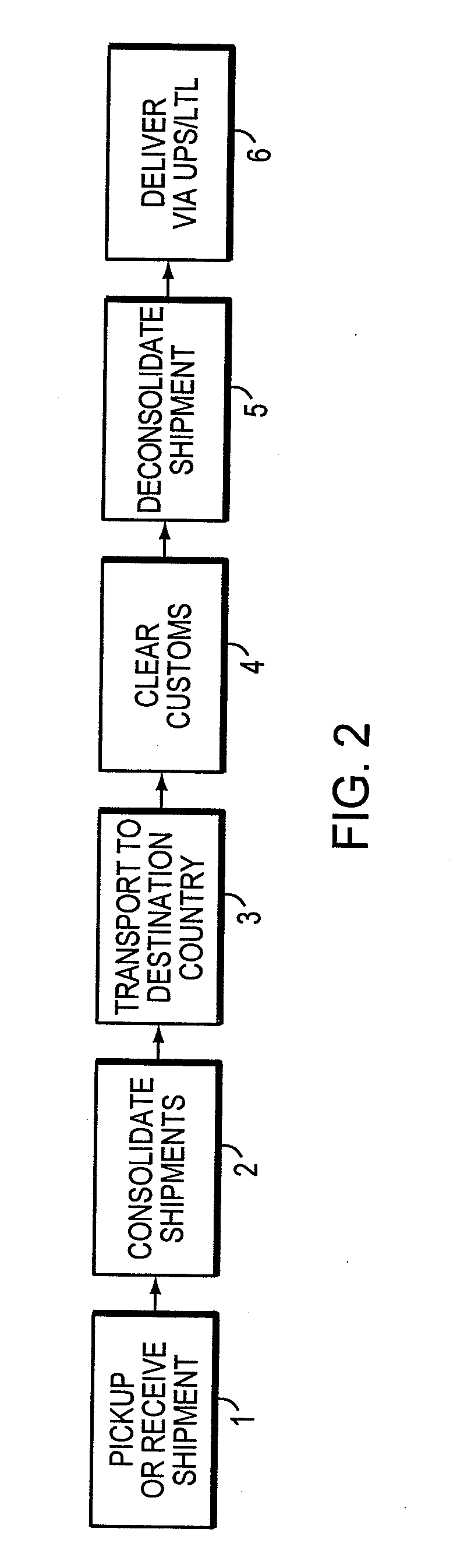

Systems and methods for integrated global shipping and visibility

InactiveUS20050149453A1Promote sportsEnhanced inventory managementPackaging vehiclesContainers for machinesInventory managementDelivery system

Disclosed is an integrated global shipment system that provides end-to-end visibility of the movement of a package. The integrated global shipment system employs a shipment consolidating application for integrating one or more freight tracking systems with one or more end-delivery systems. As a result, shippers are provided with complete visibility of the movement of their shipments of goods from an origin country to a destination country and till the final consignees. In addition, the integrated shipment system significantly decreases the cost of managing inventories by providing a virtual inventory solution. Under this virtual inventory solution, suppliers are able to bypass distribution centers and delay allocation of goods until after the importation of goods into a destination country.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

System and method for electronic article surveillance

InactiveUS20070222595A1Electric/electromagnetic visible signallingResourcesCritical hoursRemedial action

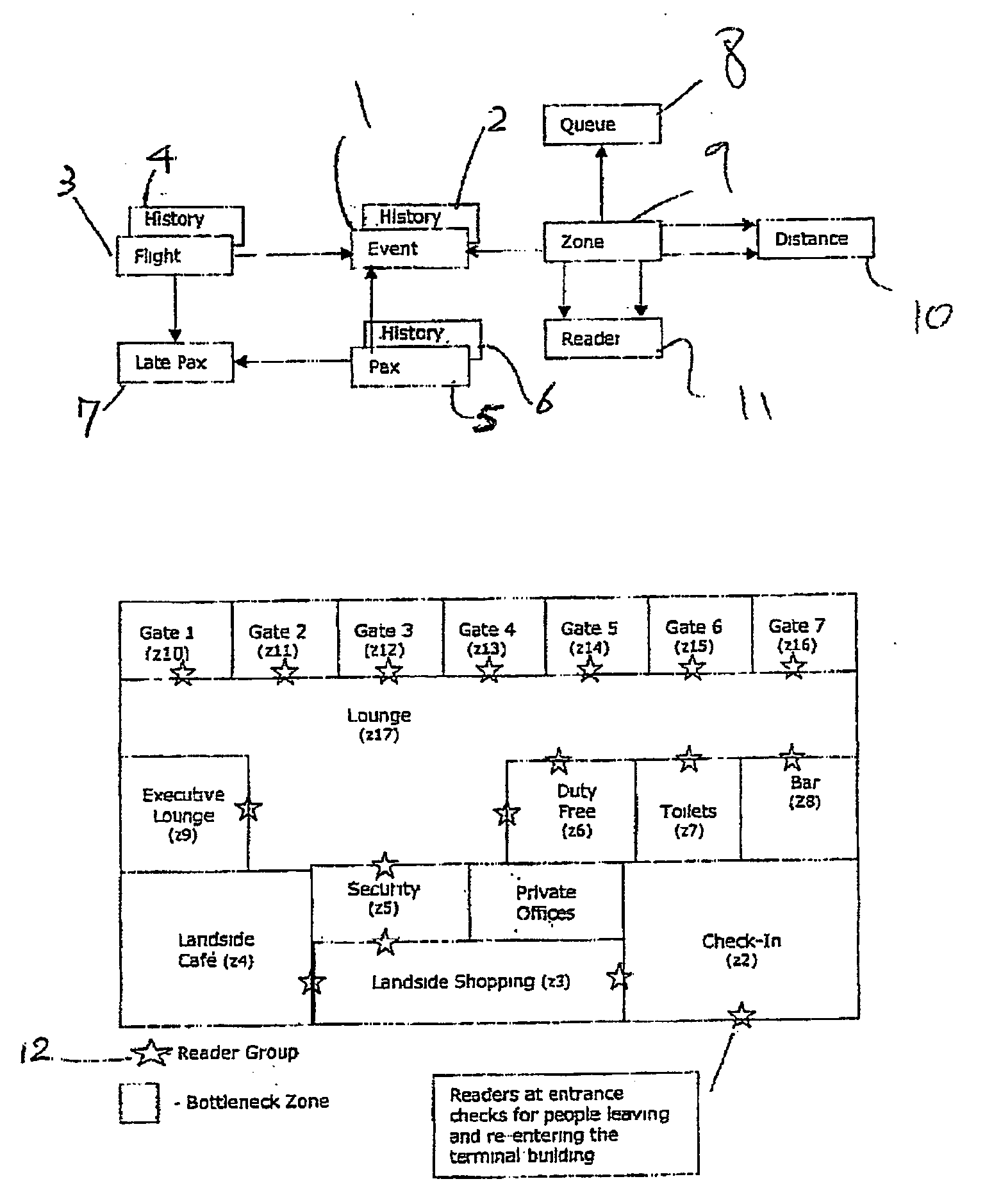

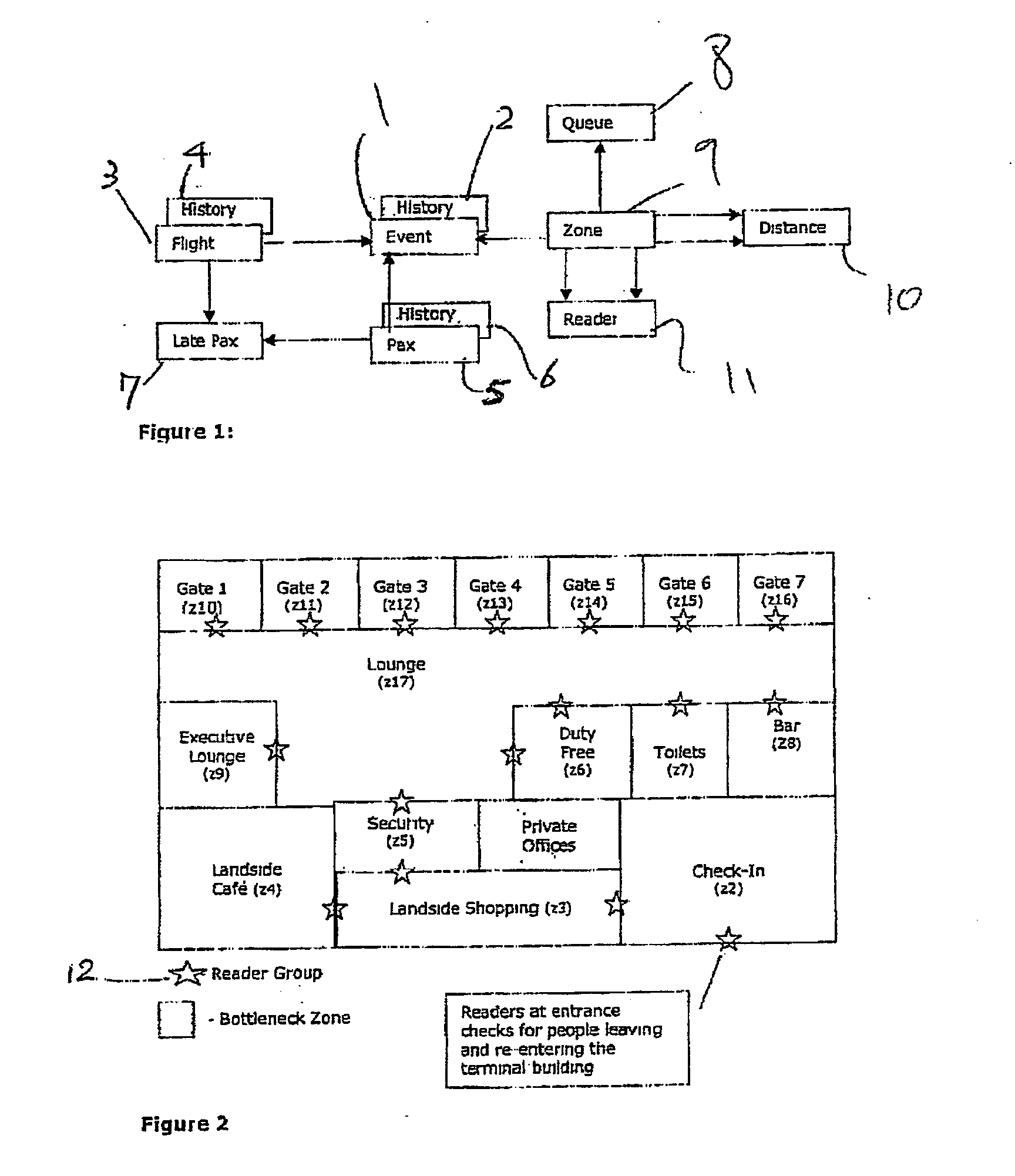

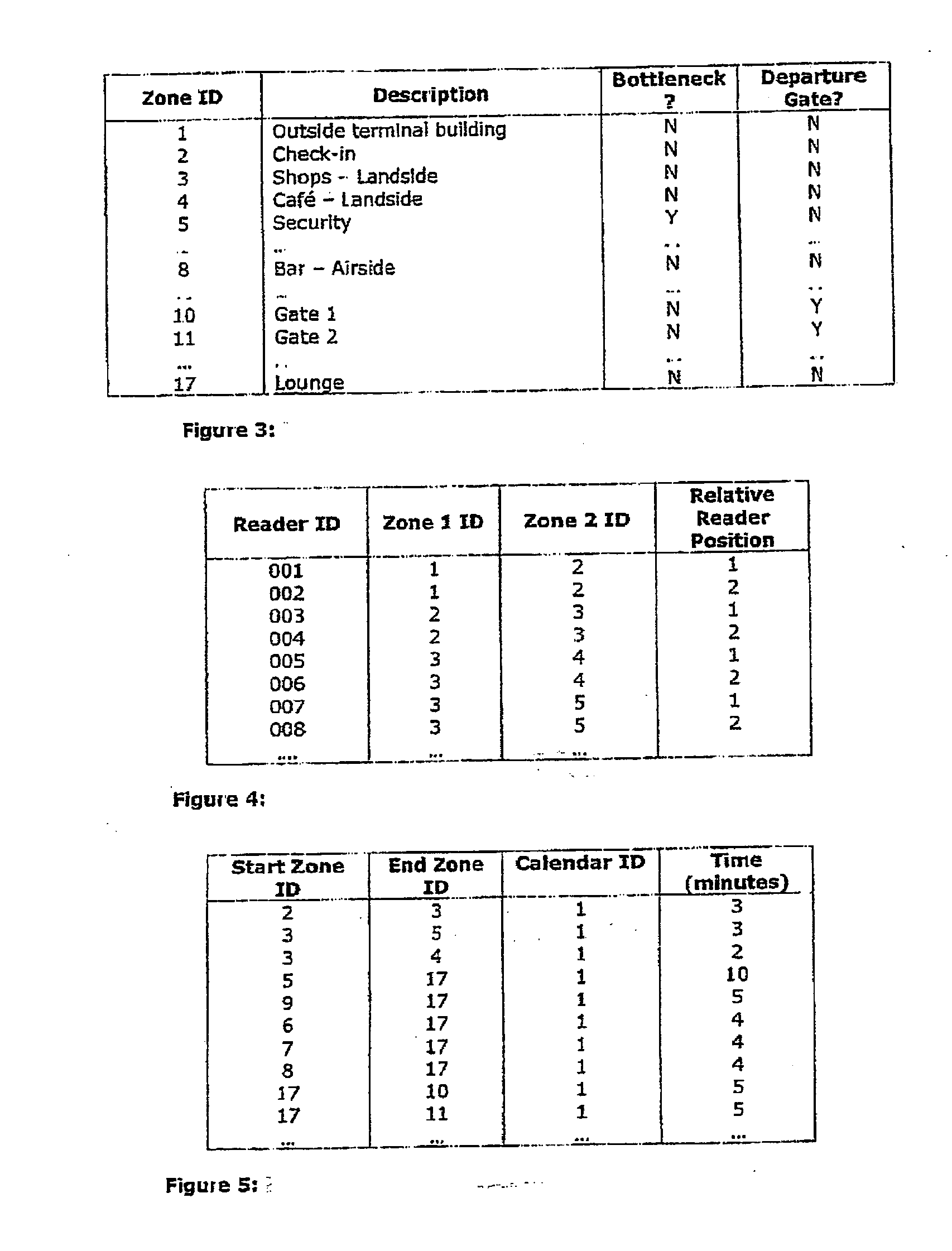

There is disclosed a system and method for electronic article surveillance wherein the time taken for articles to move from a starting point to a destination point by way of a series of zones is monitored in real time, taking into account bottleneck and non-bottleneck zones. A set of simple rules is applied so as to give estimated times of arrival for any given article. When it is calculated that an article will arrive after a predetermined critical time, an alert is triggered and remedial action may be taken. Various attributes of each zone may additionally be monitored, for example the number of articles in the zone or the temperature of the zone. The system and method may be applied to passengers in an airport, a warehouse or distribution centre, or any other application where articles are being moved from one place to another.

Owner:MANTIC POINT SOLUTIONS

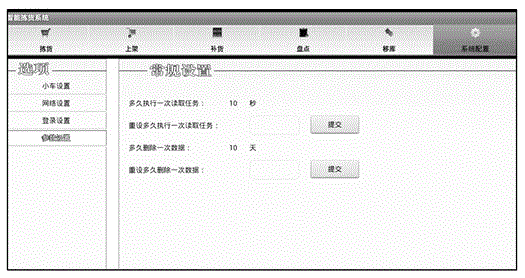

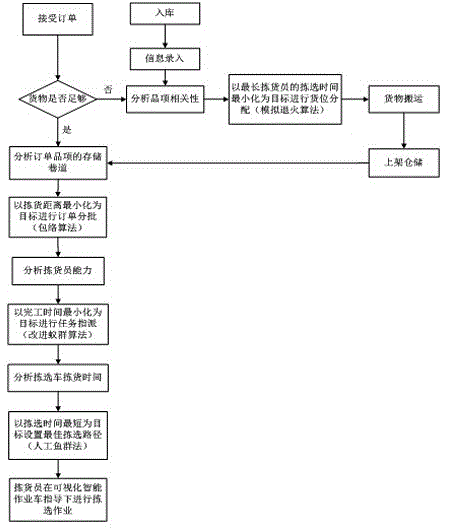

Method for logistics dispensing center work task processing and scheduling

The invention relates to a method for logistics dispensing center work task processing and scheduling. The method comprises steps that, a first step, according to correlation of items in historical orders, storage location assigning for in-stockroom items is carried out; a second step, batch setting for out-stockroom orders in an order pool is carried out; a third step, sorter assignment for the out-stockroom orders after batch setting is carried out; and a fourth step, optimal walking paths are set for sorters. According to the method, storage optimization for items of new orders is realized according to a shipment trend of the historical orders, sorted task assigning for the sorters is carried out, optimization of the walking paths of the sorters is carried out, complex sorting work is made to be simple, work intensity is reduced, the work flow is standardized, and work efficiency is improved.

Owner:ZHEJIANG UNIV OF TECH

RFID Medical Supplies Consumption Monitoring System and Method

ActiveUS20100141457A1Accurate confirmationHealthcare resources and facilitiesLogisticsMonitoring systemEngineering

Owner:WAVEMARK

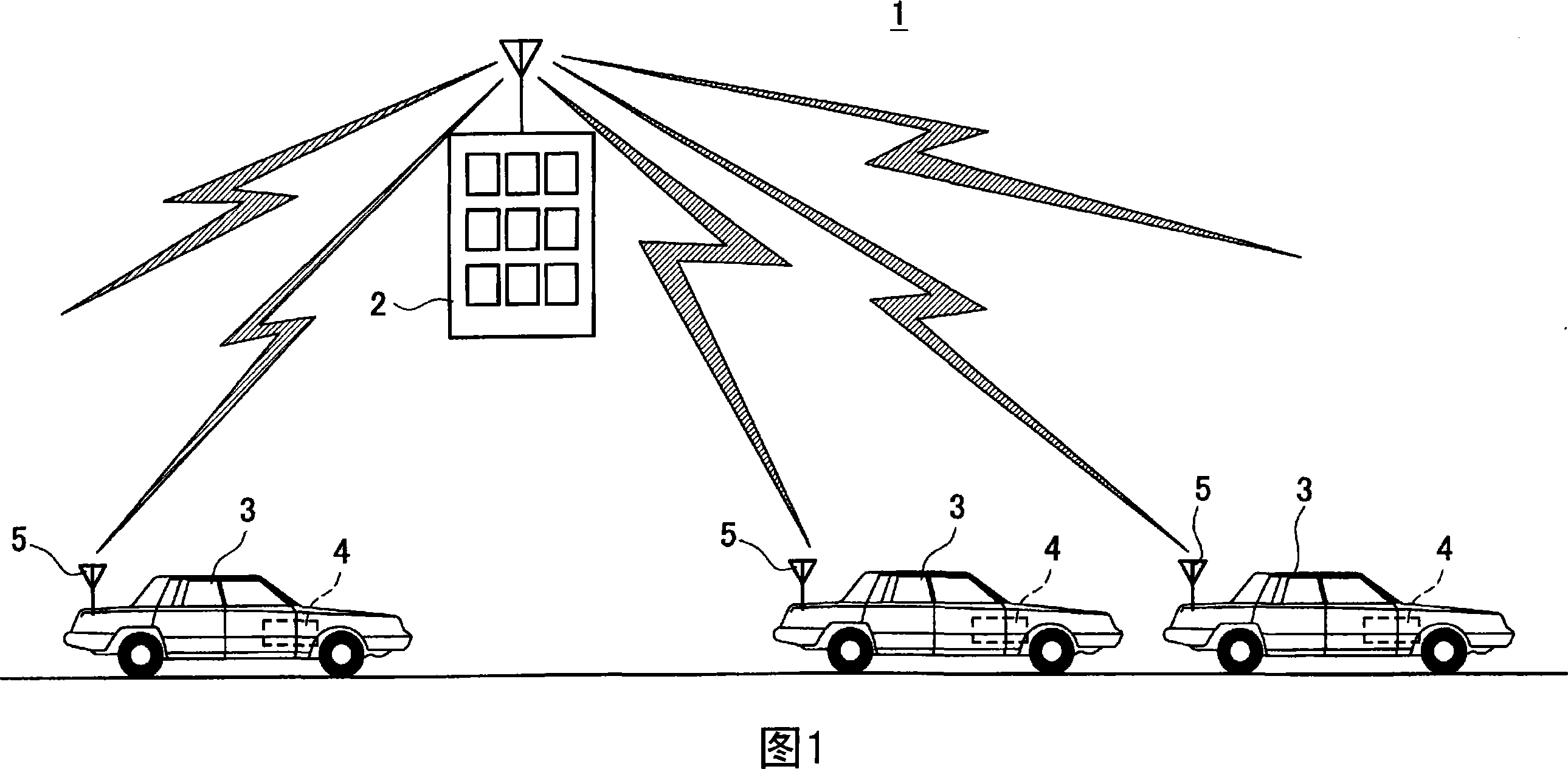

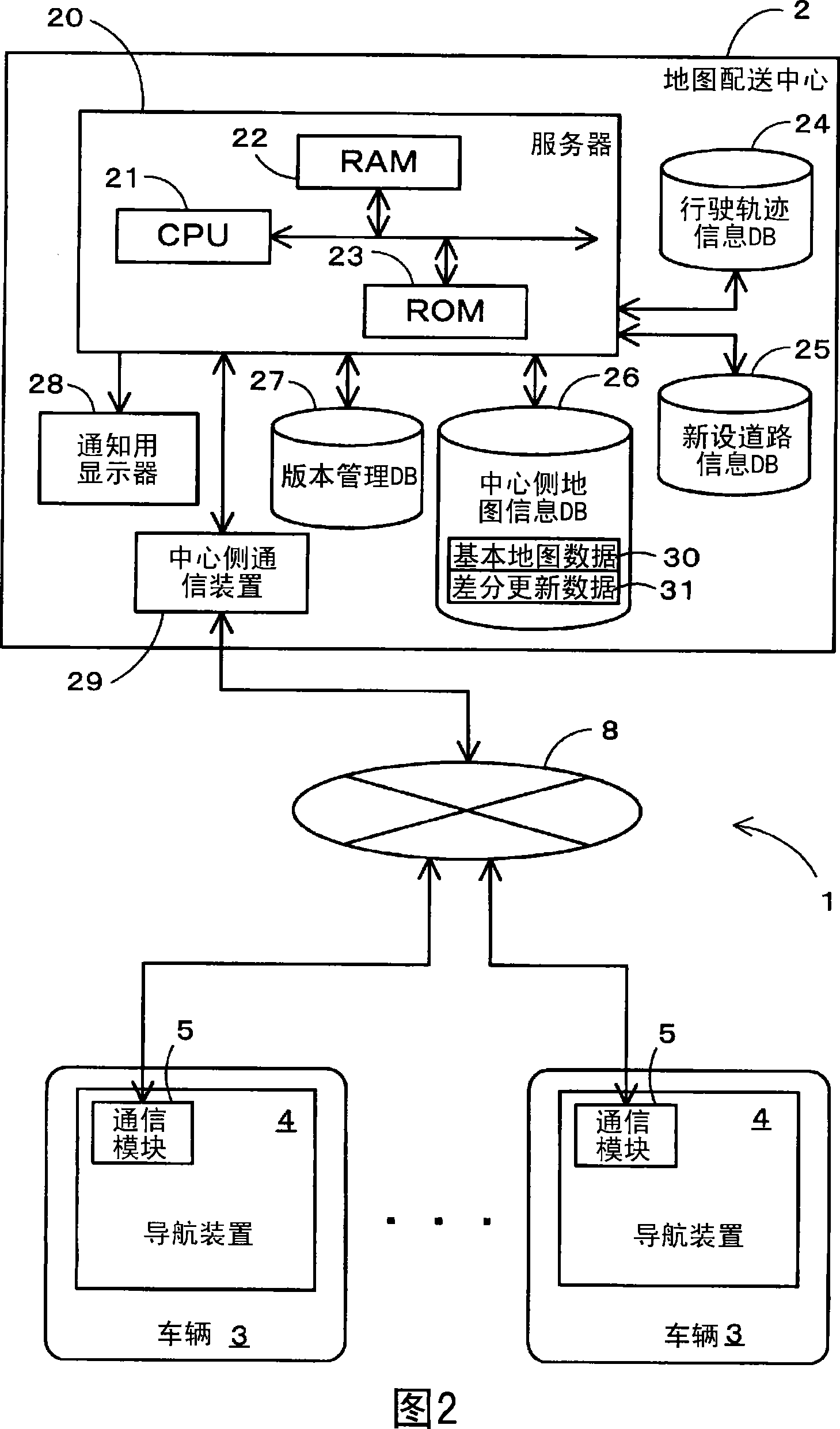

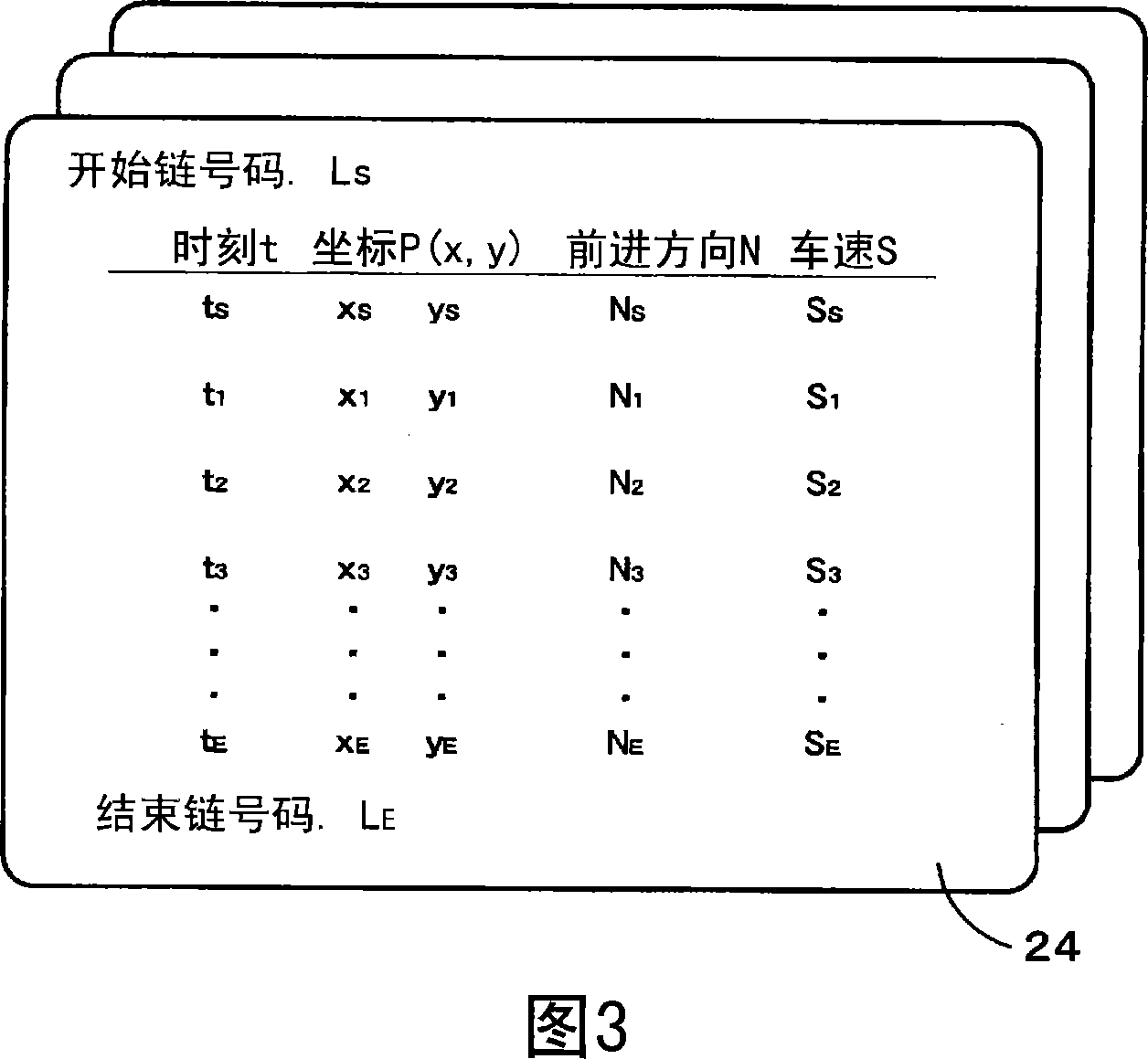

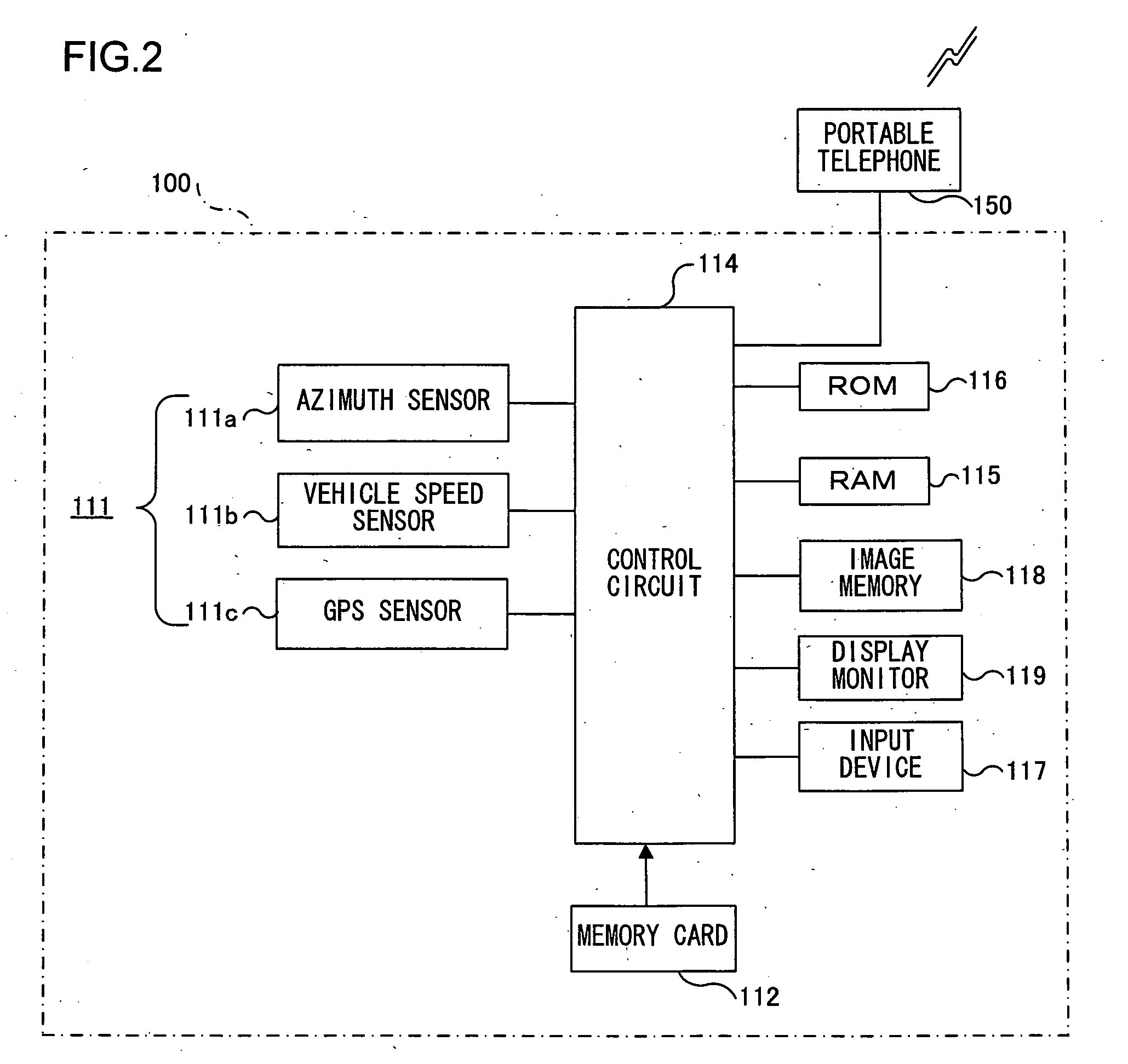

Map information generating systems

InactiveCN101210825AGenerate quickly and correctlyExclude correctInstruments for road network navigationRoad vehicles traffic controlComputer scienceDistribution centre

The invention provides a cartographic information generating system which is used for generating information about the new added roads to the cartographic information stored in a navigation device and etc.. The traveling locus information generated when vehicles (3) serving as probe cars travel along paths that are not included in navigation map data (53) provided in the navigation device (4) is transmitted to a map distribution center (2) as probe data. After receiving the traveling locus information from the navigation device (4) of each vehicle (3), the map distribution center (2) gathers together the received data, groups together traveling locus information relating to the same path, and then generates new road information relating to a single new road in each group.

Owner:AISIN AW CO LTD

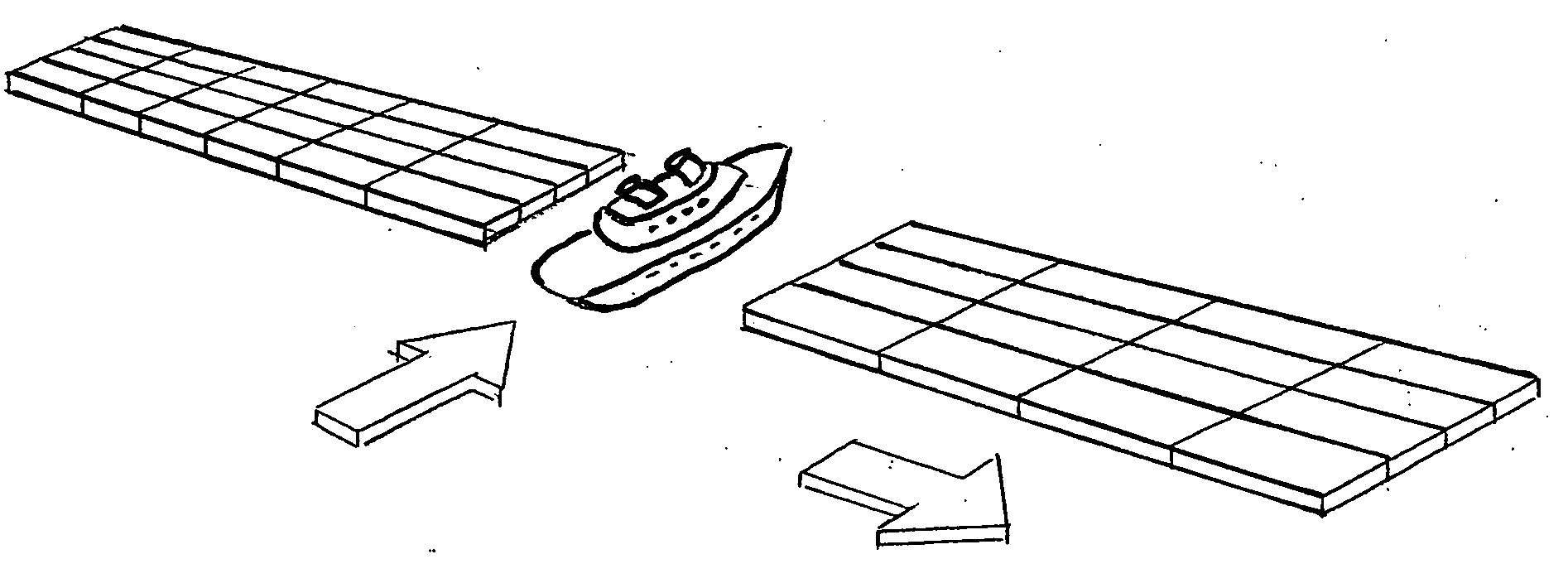

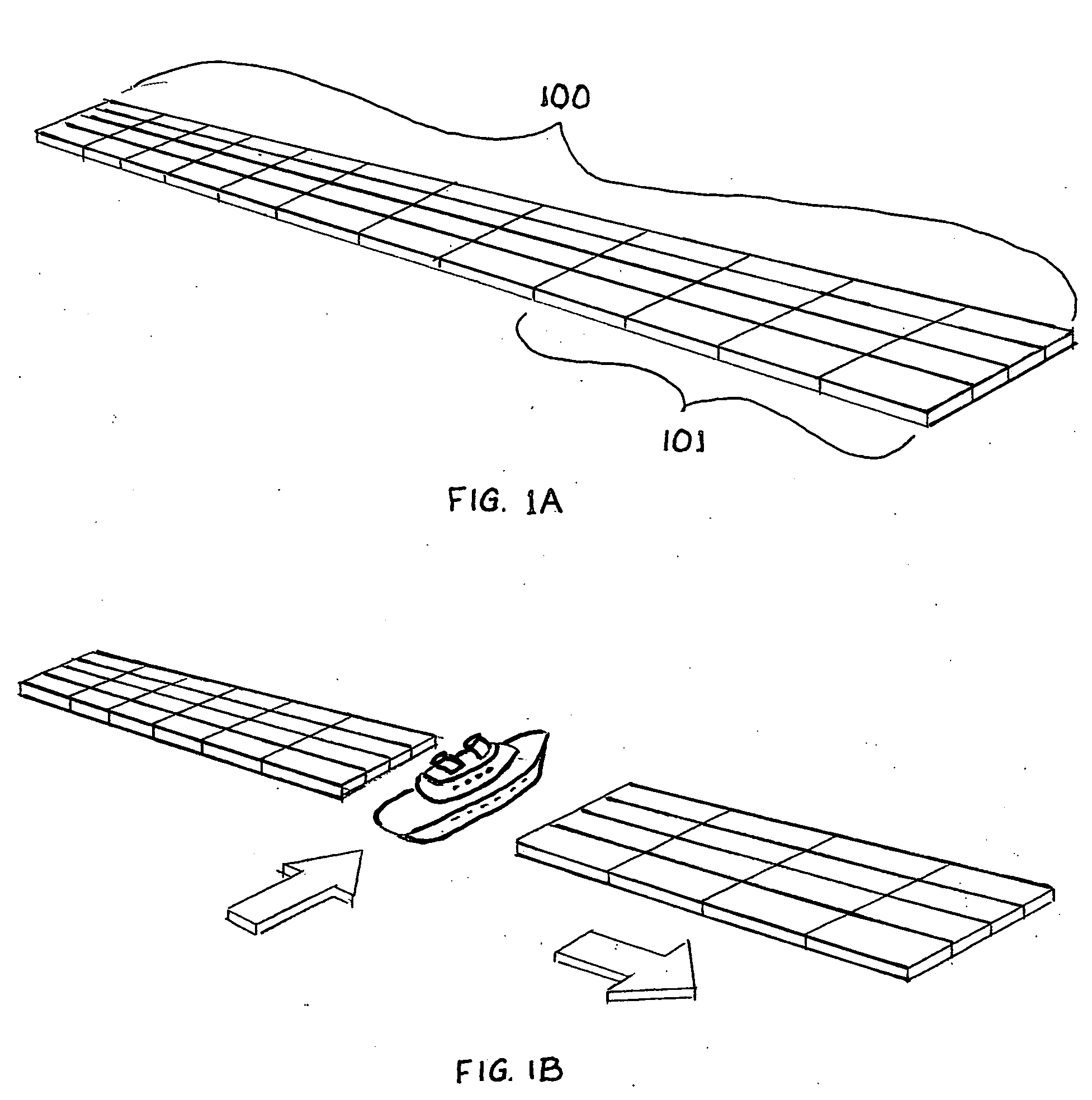

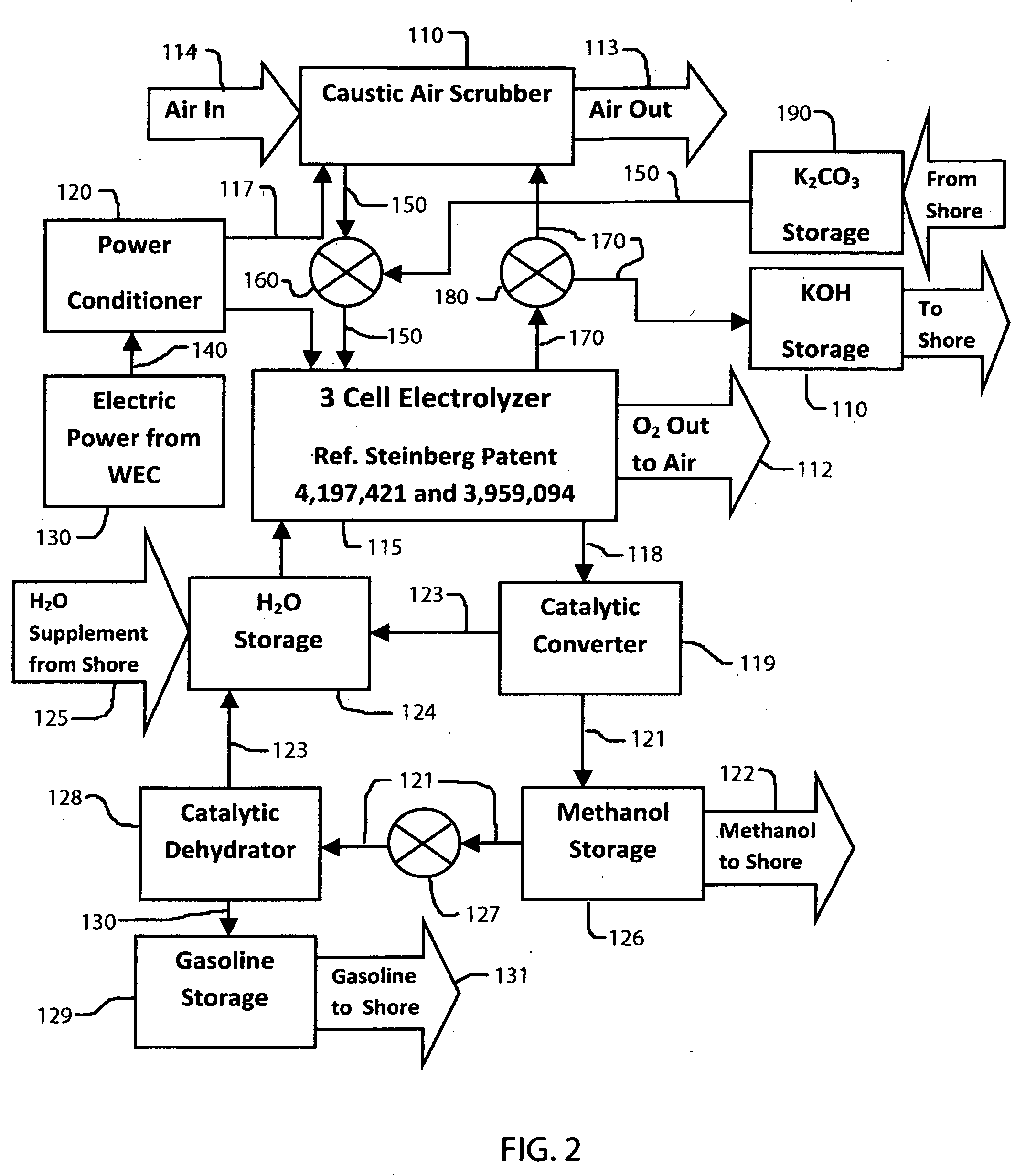

Method and apparatus for ocean energy conversion, storage and transportation to shore-based distribution centers

A fleet of vessels attached together longitudinally (rows), and transversely (columns) and operating in unison convert wave energy to electrical energy which is stored in either a chemical or electrical form. The vessels when detached from the fleet provide transportation to coastal or by navigable waterway ports of call for distribution to market centers. Both wind wave and swell wave energy conversion is performed by use of the differential motion between the vessels. Means are provided for the energy conversion systems to adapt to changes in wave direction, wave length, amplitude, and phase. Such vessels are self powered for off shore or inland waterway navigation, either singularly or in multiples, with which to deliver energy to other sea going vessels or to land based ports of call. Two or more of such vessels are capable of using the energy of waves during the delivery process. The fleet can maintain a designated geographical location by dynamic positioning. Alternatively, the fleet may maintain its designated position by moorage of a designated centrally located vessel in the fleet to a permanent anchoring system when operating at appropriate depths.

Owner:LIGHTFOOT FRED M +3

Methods and apparatus for inventory allocation and pricing

Owner:ORACLE INT CORP

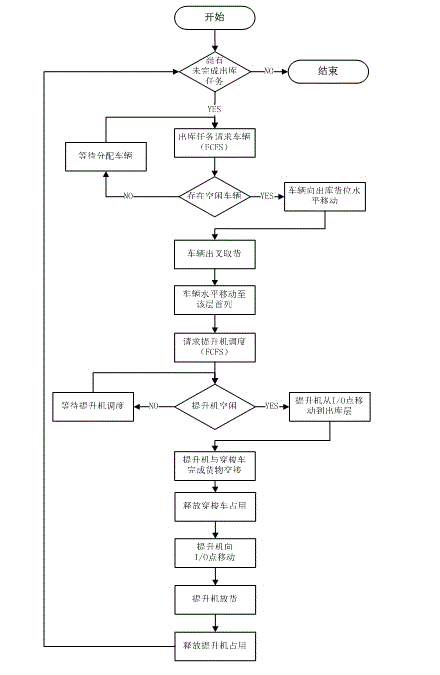

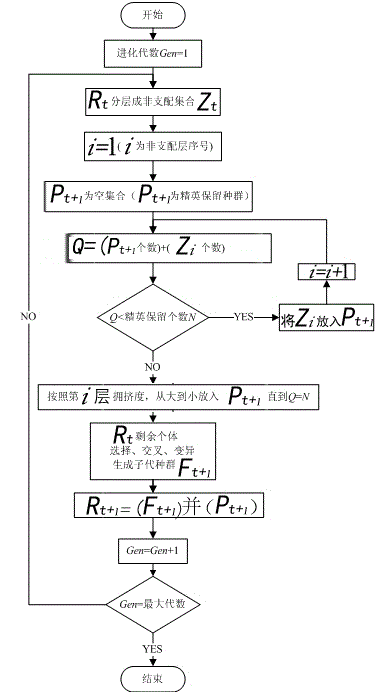

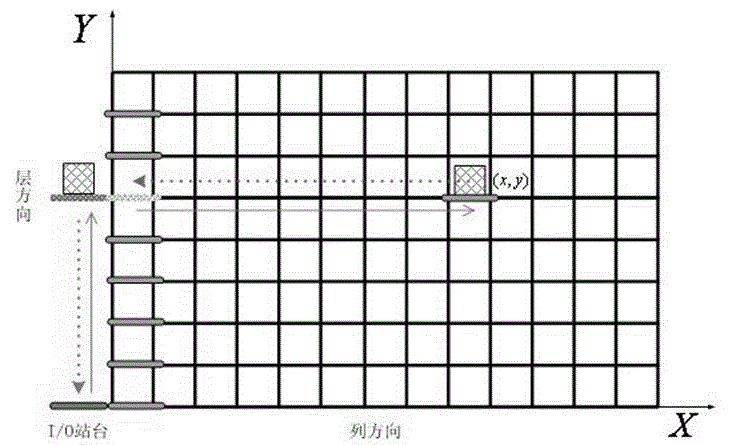

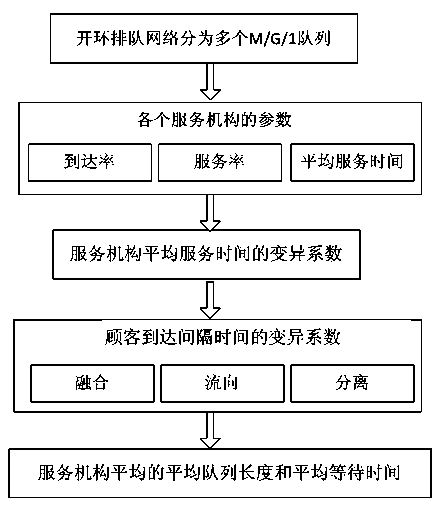

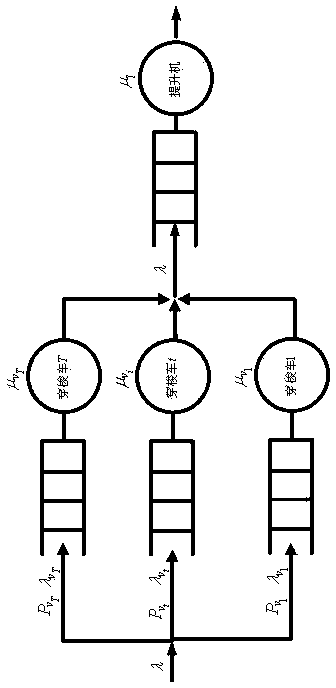

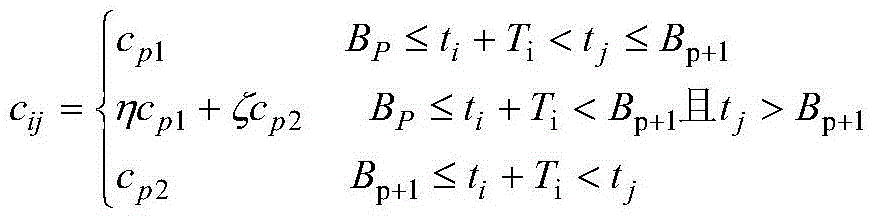

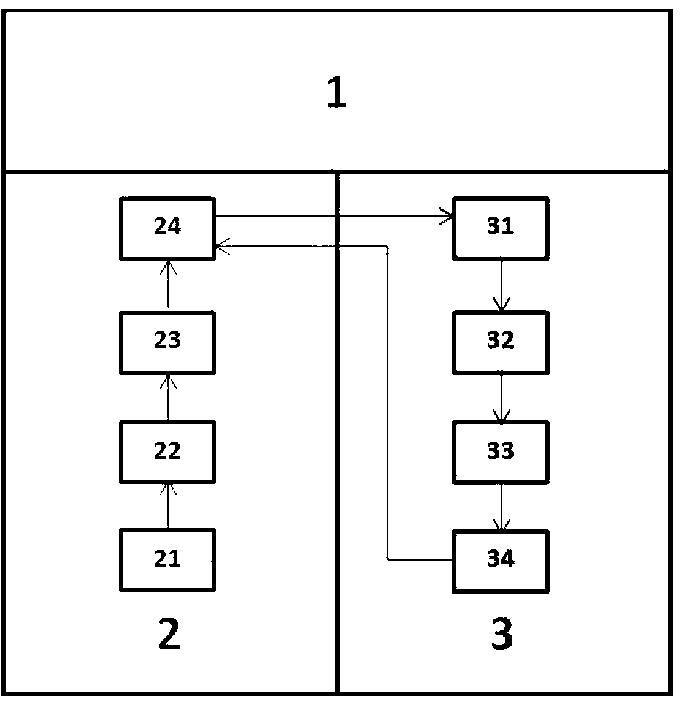

Task scheduling method of multilayer shuttle vehicle automatic warehousing system

The invention discloses a task scheduling method applied to a multilayer shuttle vehicle automatic warehousing system. The task scheduling method comprises the steps of firstly establishing an operation time model of the system according to the operation execution process of a device; then changing the scheduling problems of a multilayer shuttle vehicle and an elevator into a production line parallel operation problem, establishing a task scheduling mathematic model for a task queue in a time window designated in size; for solving the multi-task multi-target optimization problem, designing a non-dominated sorting genetic algorithm with an elitist strategy based on a pareto optimality so as to perform model solution. By applying the task scheduling method, the waiting time of the shuttle vehicle and the idle time of the elevator can be effectively shortened, and accordingly the device utilization rate and handling capacity of a distribution center are improved.

Owner:SHANDONG UNIV

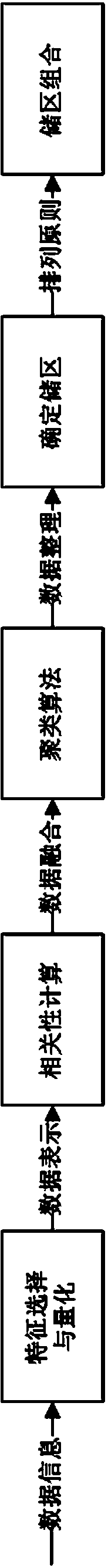

Goods location allocating method applied to automatic warehousing system of multi-layer shuttle vehicle

The invention discloses a goods location allocating method applied to an automatic warehousing system of a multi-layer shuttle vehicle. The method comprises the following steps: firstly, according to the quantities of goods shelves and tunnels, generating plane layout structure data of the system; then analyzing the waiting time of the shuttle vehicle executing an outbound task as well as the idle time of a hoister; establishing an open queuing network model for describing the system; analyzing the relationship among the waiting time of the shuttle vehicle, the idle time of the hoister and the time of inbound and outbound works by a decomposition process; determining that the higher the reaching rate of a task serviced by the shuttle vehicle is, the lower the goods location of the task is, and the goods with highest correlation are allocated at different layers, so that multiple shuttle vehicles can provide service simultaneously; finally putting forward a principle of dividing storage zones in light of item correlation, establishing a correlation matrix of outbound items, clustering the items by an ant colony algorithm, and combining and arranging the storage zones in a two-dimensional plane according to the analysis result of the queuing network model, thereby realizing the allocation of goods location. By the method, the waiting time of the shuttle vehicle and the idle time of the hoister can be effectively shortened, so that the rate of equipment utilization and the throughput capacity of a distribution center are increased.

Owner:SHANDONG UNIV

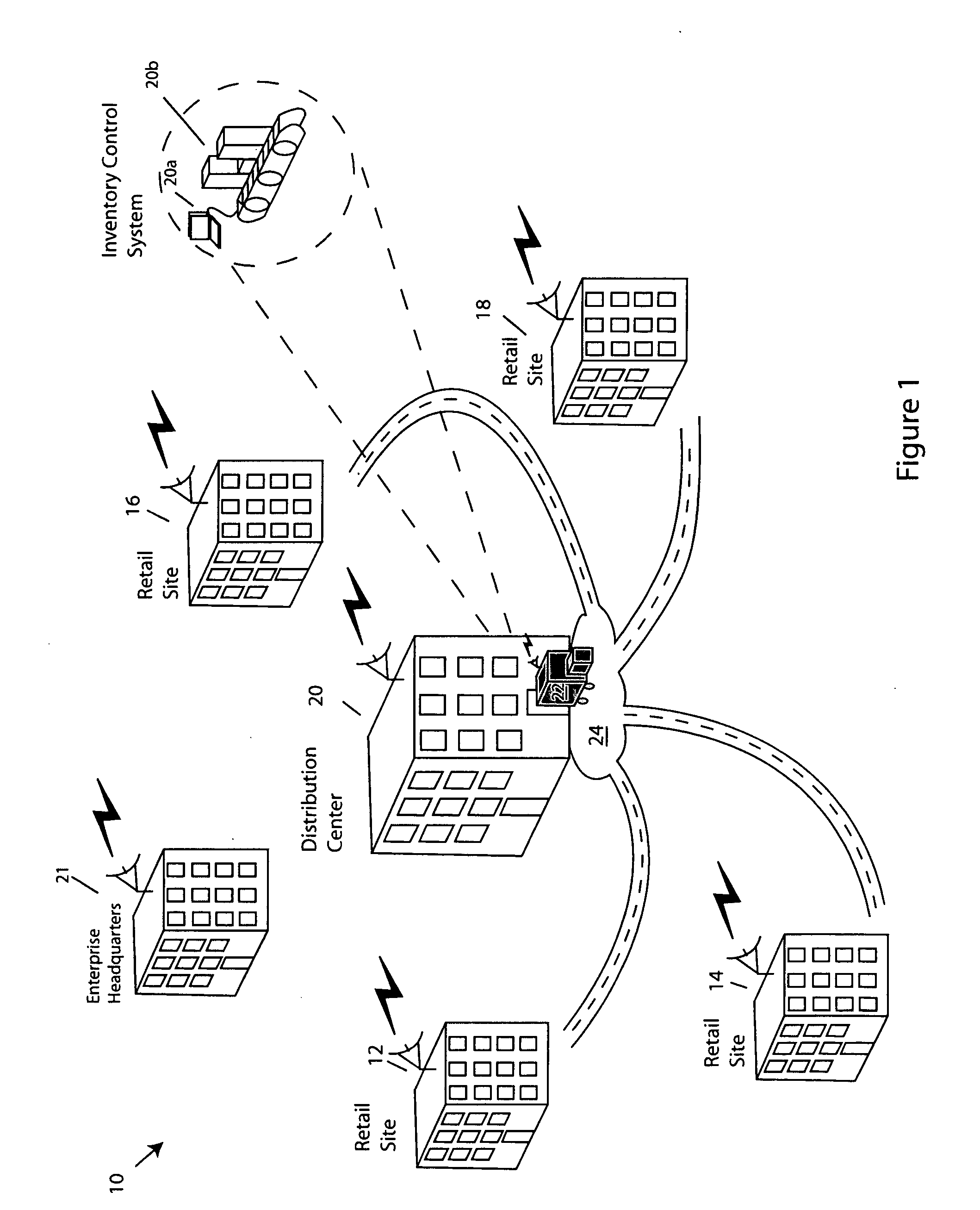

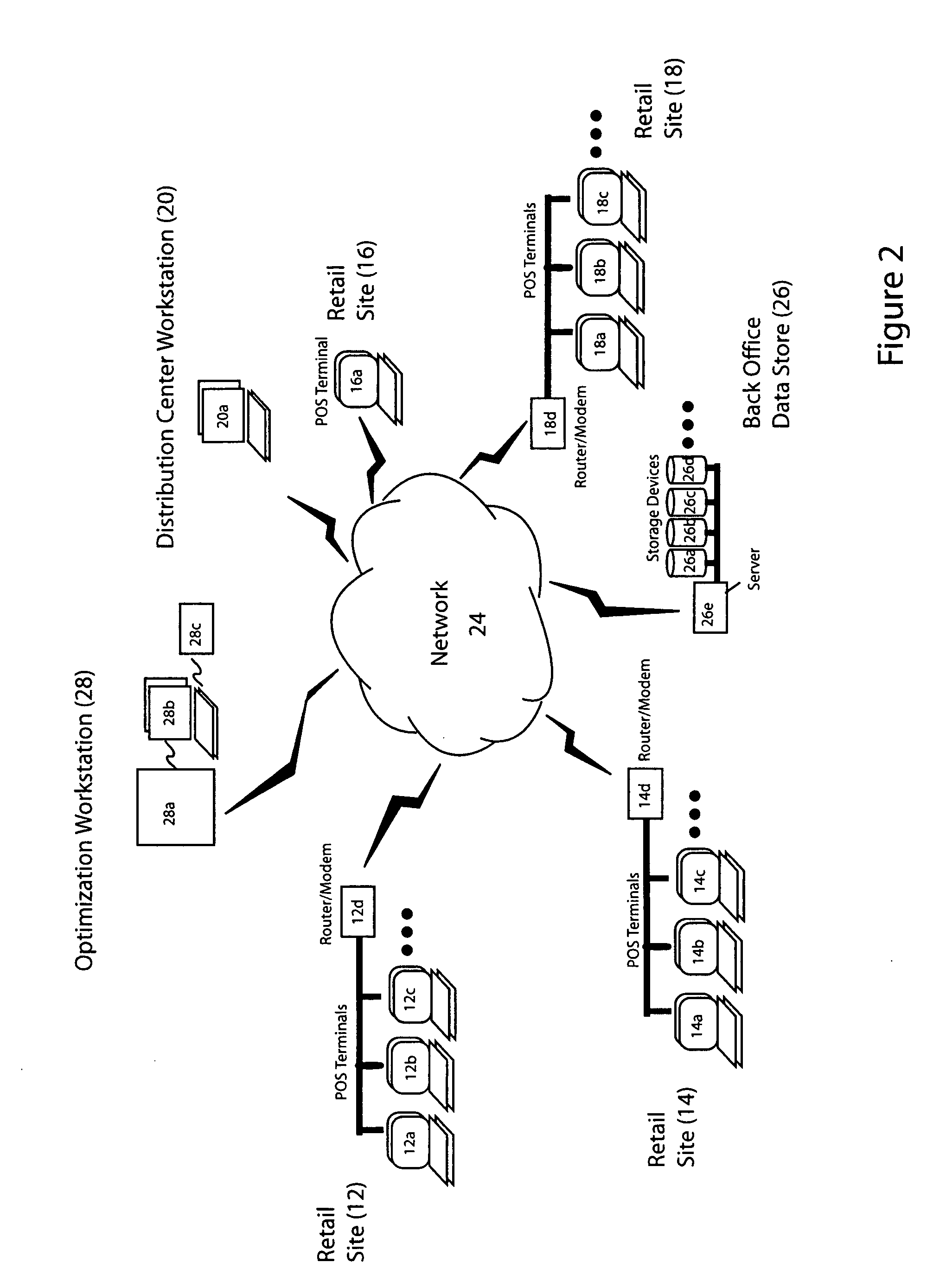

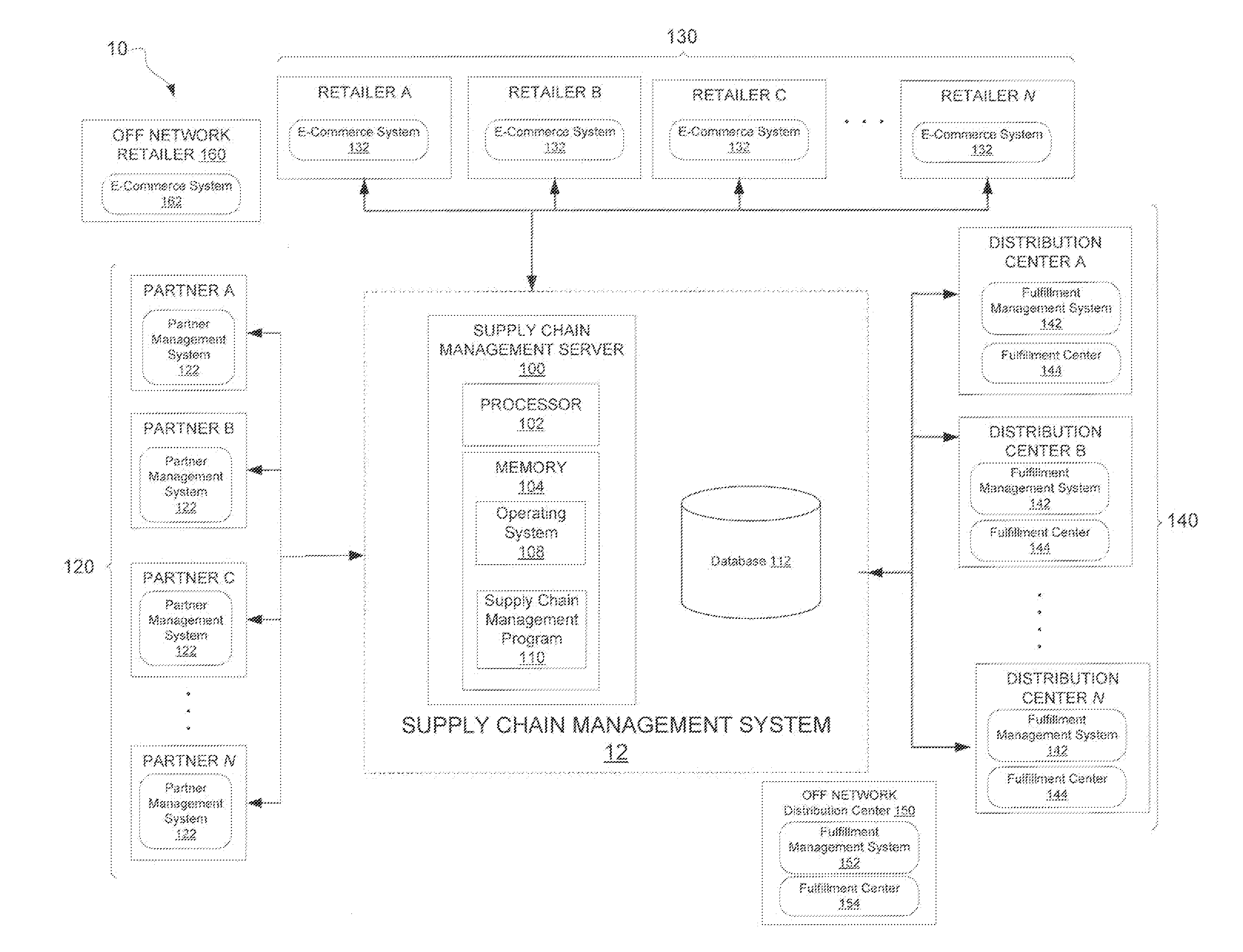

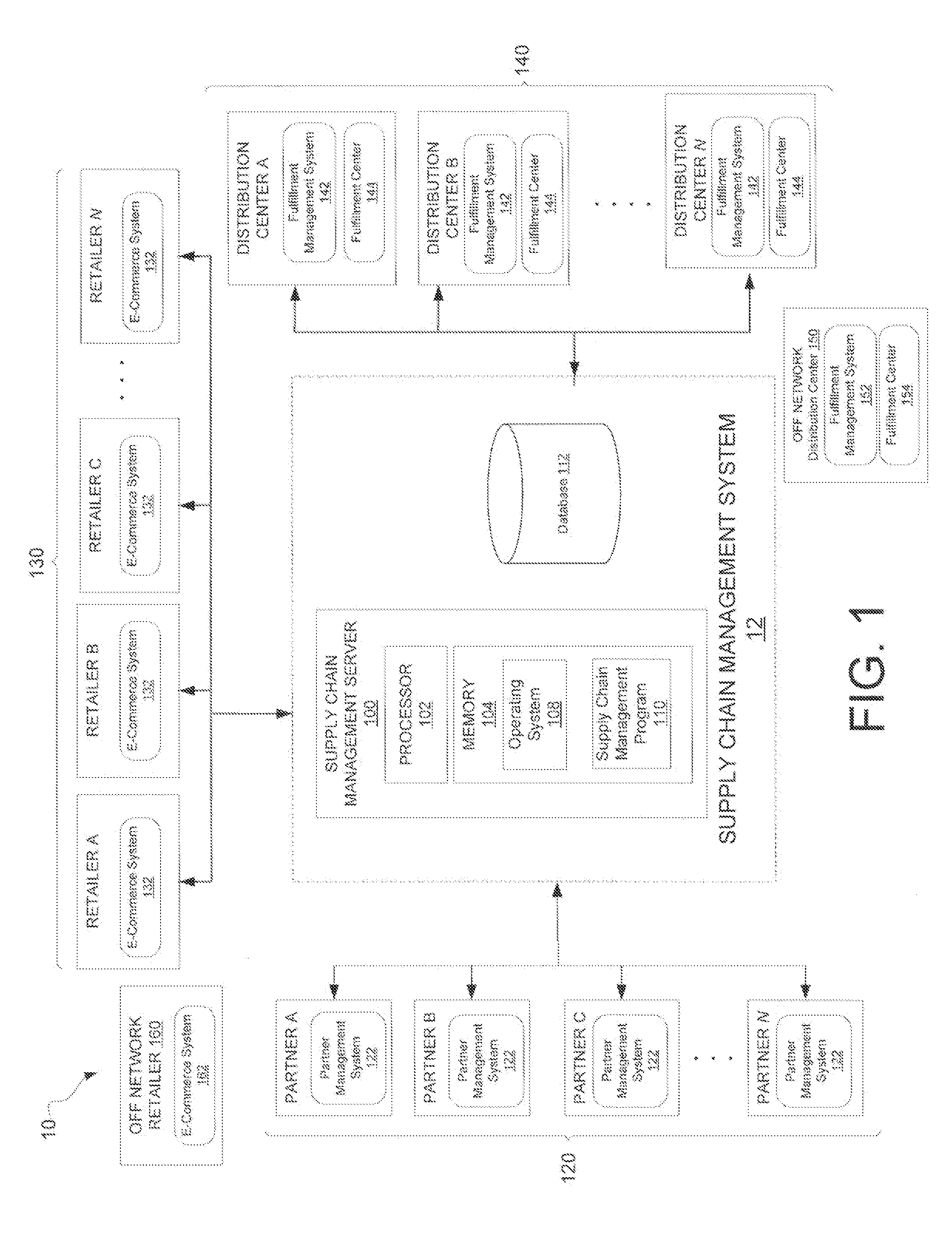

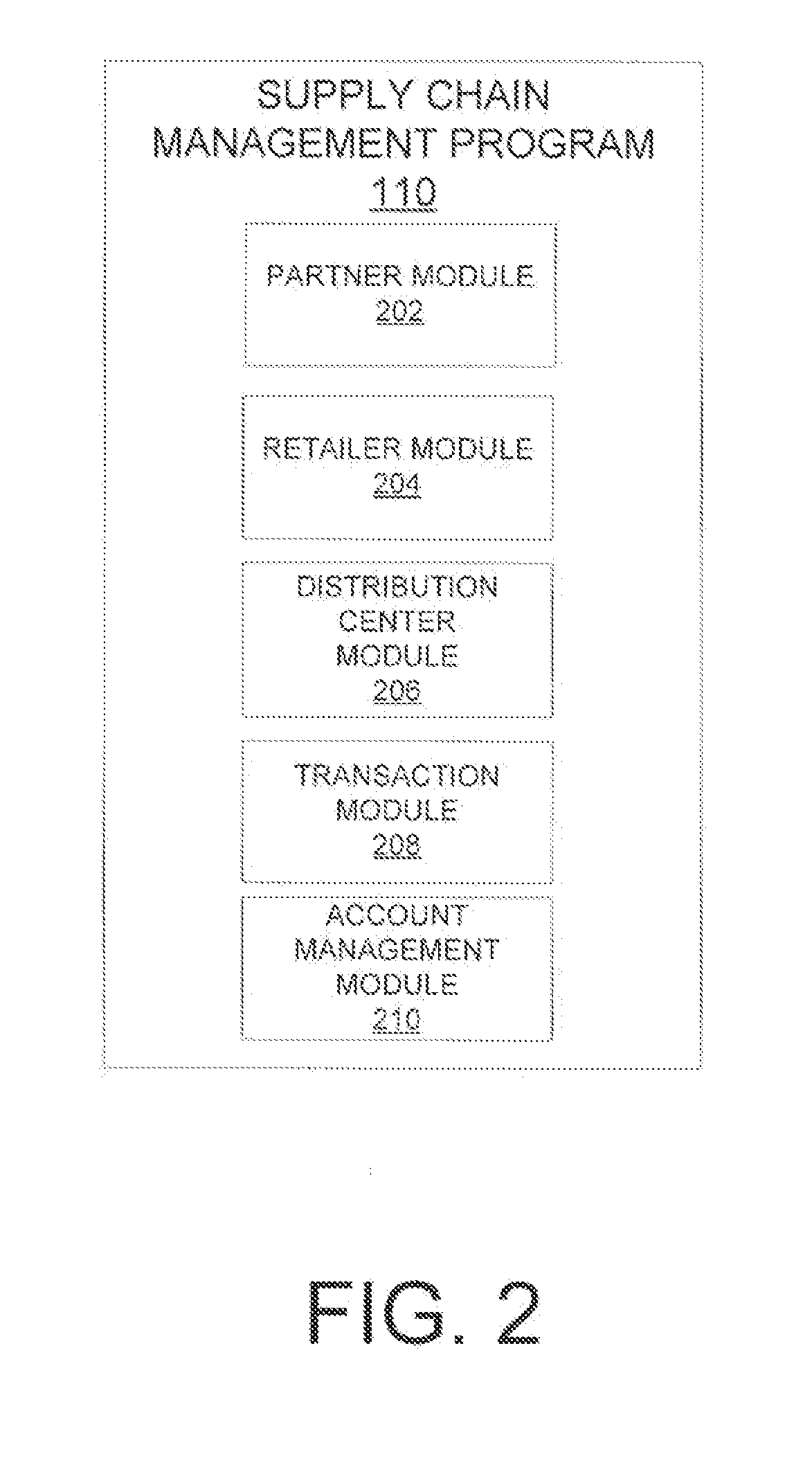

Supply chain management system

A supply chain management system that provides a single integration point to partners, retailers and distribution centers is described. The partners, retailers, and distribution centers register with a supply chain management system. Through the system, partners select those retailers with whom they desire to do business. Partners may further allocate inventory among selected retailers. The supply chain management system recommends distribution centers for maintaining product inventory.

Owner:OVERSTOCK COM

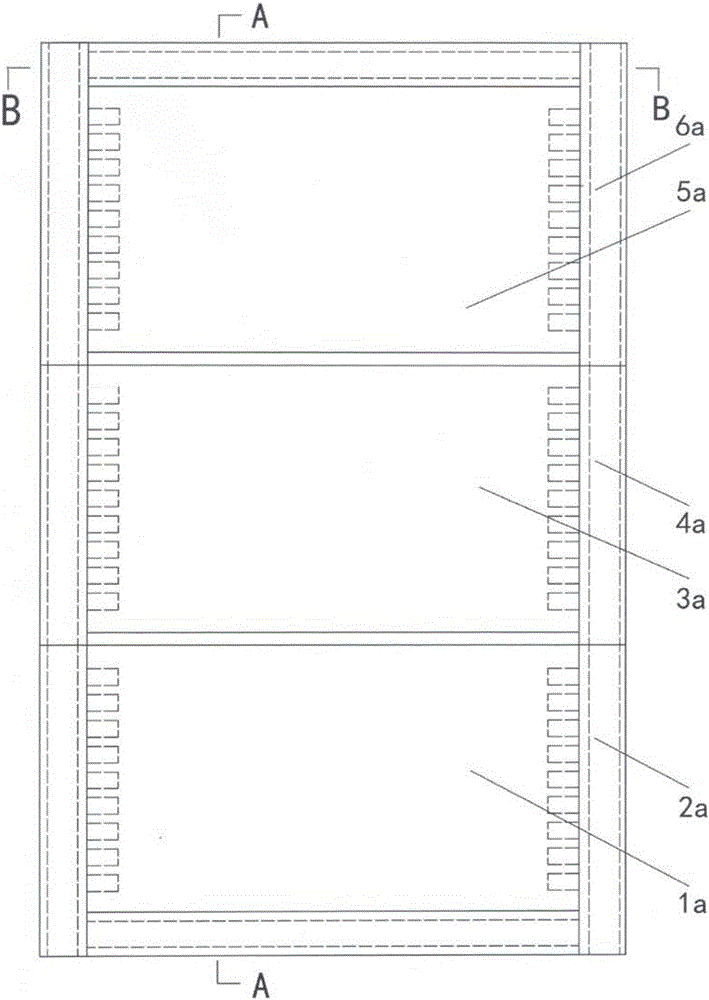

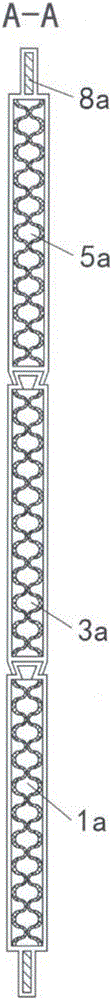

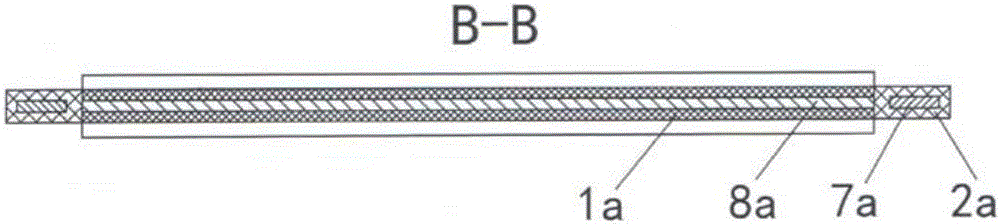

Combined rubber-plastic corrugated board and RFID circulation box manufactured from corrugated board

ActiveCN106081300AConvenient shipmentImprove buffering effectContainer decorationsLevel indicationsLogistics managementShortest distance

The invention provides a combined rubber-plastic corrugated board and an RFID circulation box manufactured from the corrugated board and belongs to the field of packaged product transporting and logistics conveying equipment. Rubber-plastic corrugated spliced panels are re-combined into the circulation box, or rubber-plastic corrugated non-spliced panels can be directly combined into the circulation box, and an information module composed of a GPS chip, an RFID chip for information storage and exchange and an electronic lock is arranged. The circulation box serves as an informationalized material carrier, has modularized, standardized and informationalized characteristics, and achieves good buffering performance. The circulation box is applied to various procedures inside enterprises, between the enterprises and e-commerce distribution centers, between the e-commerce distribution centers and express companies, between outside-city long distance and inside-city short distance of the express companies and standardization and universality of express delivery men, automatic carrying, stacking and vehicle loading and transporting are convenient, and the remarkable advantages of being high in use efficiency and safety are achieved.

Owner:章军

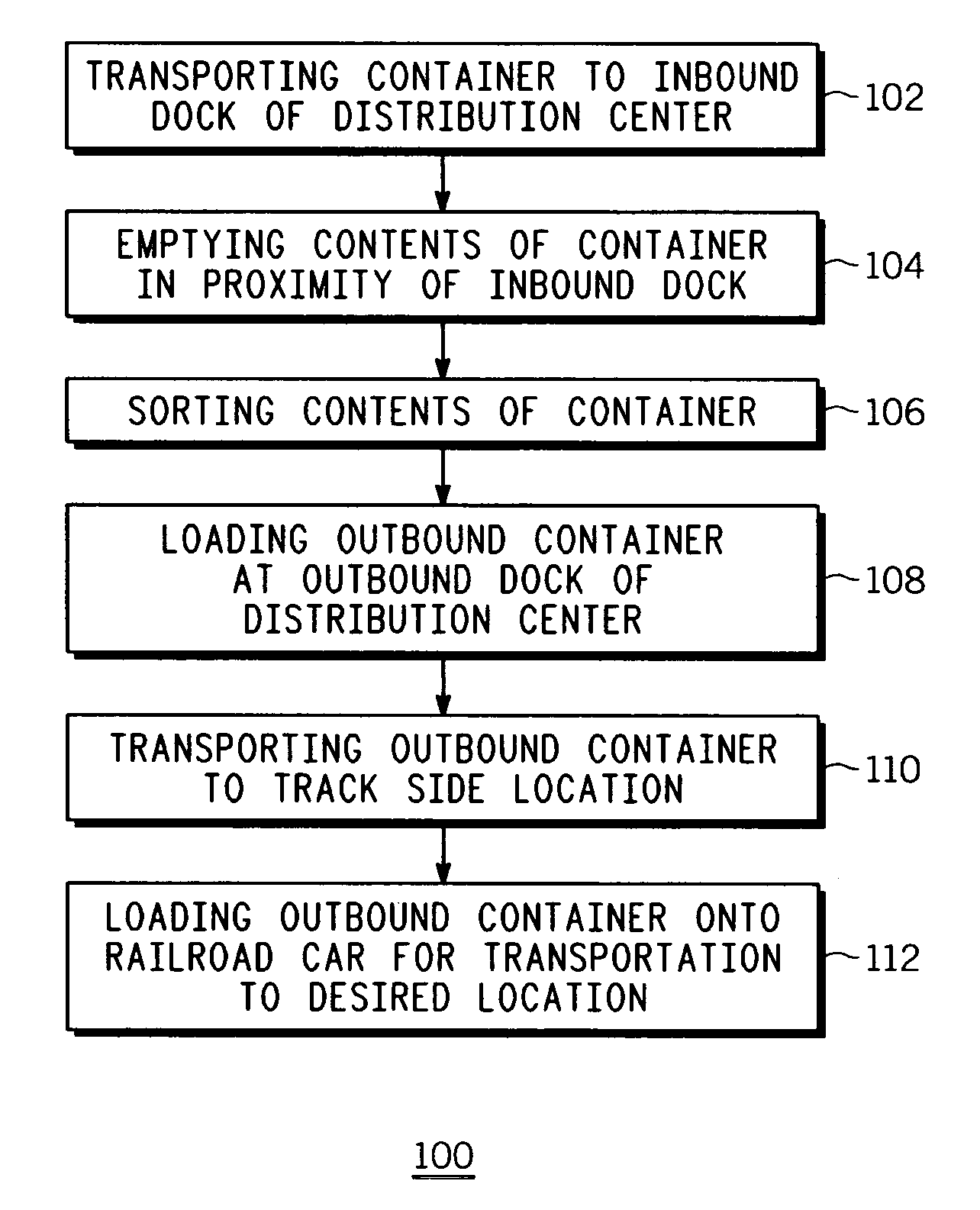

Inline terminal, hub and distribution system

InactiveUS20080141895A1Refuge islandsRailway system combinationsDistribution systemComputer terminal

The present invention provides an inline terminal, hub and distribution system. It comprises the steps of: transporting (102) a container to an inbound dock of a distribution center; emptying (104) the contents of the container in proximity to the inbound dock; sorting (106) the contents of the container; loading (108) an outbound container at an outbound dock of the distribution center; transporting (110) the outbound container to a track side location; loading (112) the outbound container onto a railroad car for transportation to a desired location.

Owner:LANIGAN JOHN J +1

Method and device for spectral optical reflector therapy for improving vision (variants)

The invention relates to medicine. In the first variant, the inventive method consists in a cyclic modification of a degree of tension for eye accommodation. Said modification is produced by changing the frequency content of the more intense light flux. One flux forms images of visual stimulus on the retina, the other flux forming colour backgrounds thereof. The frequency content is modified using a cyclic magnification and reduction of a wavelength value of a location of the spectral distribution centre of the more intensive light flux. In the second variant, cyclic modification of the intensity ratio of the light fluxes is carried out. One flux forms images of a visual stimulus on the retina, the other flux forms the colour backgrounds thereof, said fluxes being embodied in such a way that they alternately become more intensive. The inventive device comprises a unit embodied in such a way that the light-luminance characteristics of the visual stimulus and the colour backgrounds thereof are modifiable. Said unit makes it possible to carry out a cyclic modification of the light-luminance characteristics of the more luminous visual stimulus and the colour backgrounds thereof with respect to each other.

Owner:EREMEEV ALEXANDR PAVLOVICH

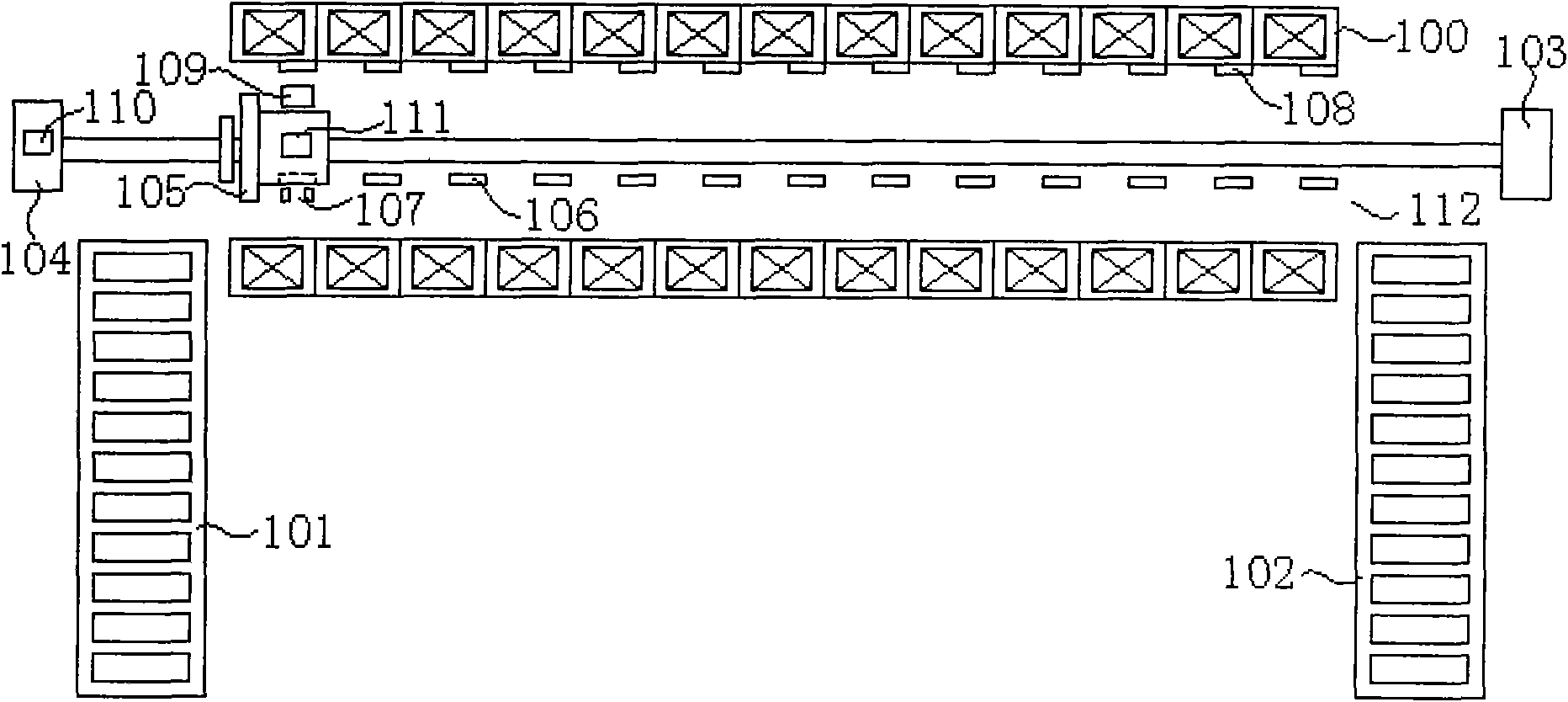

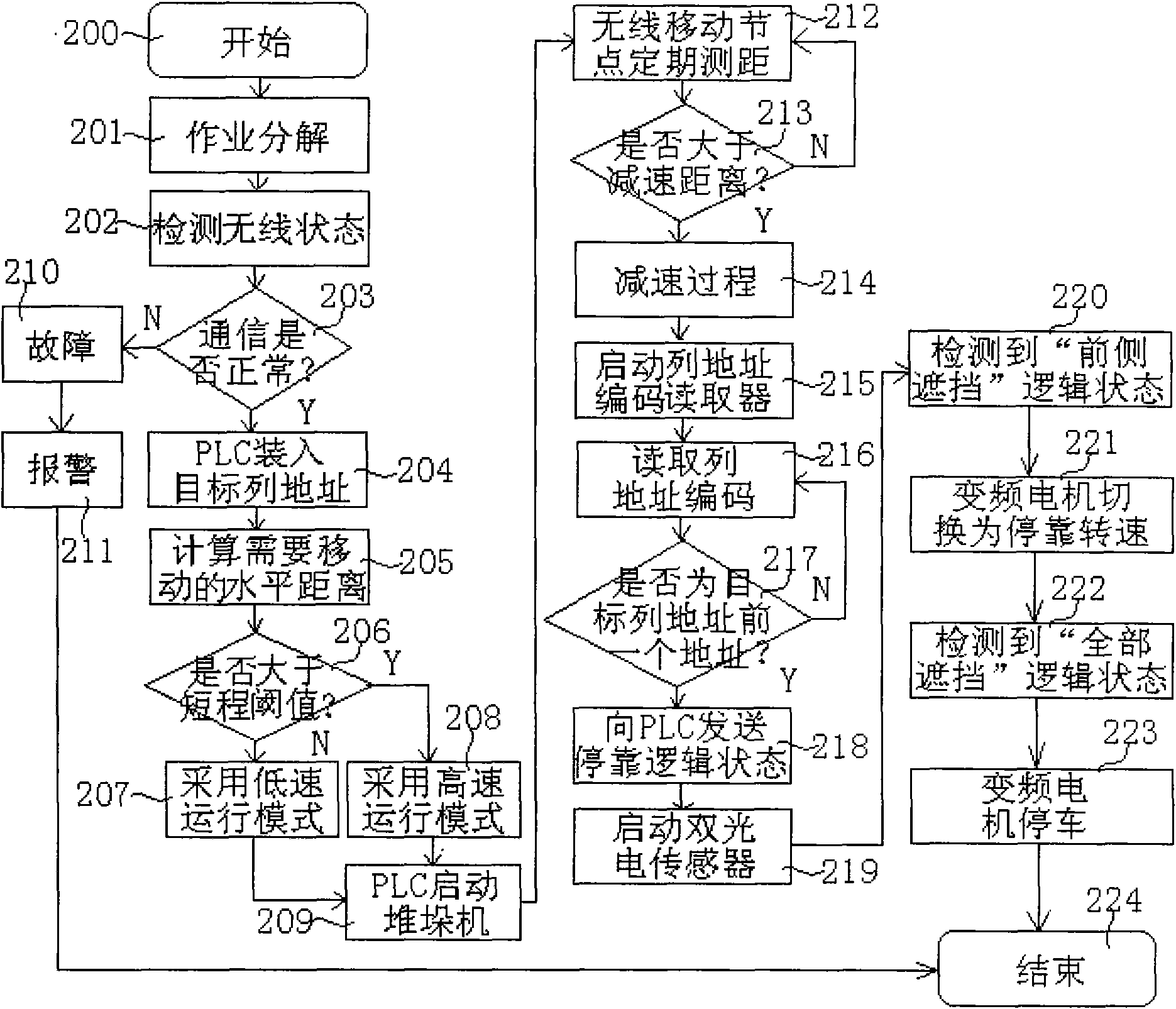

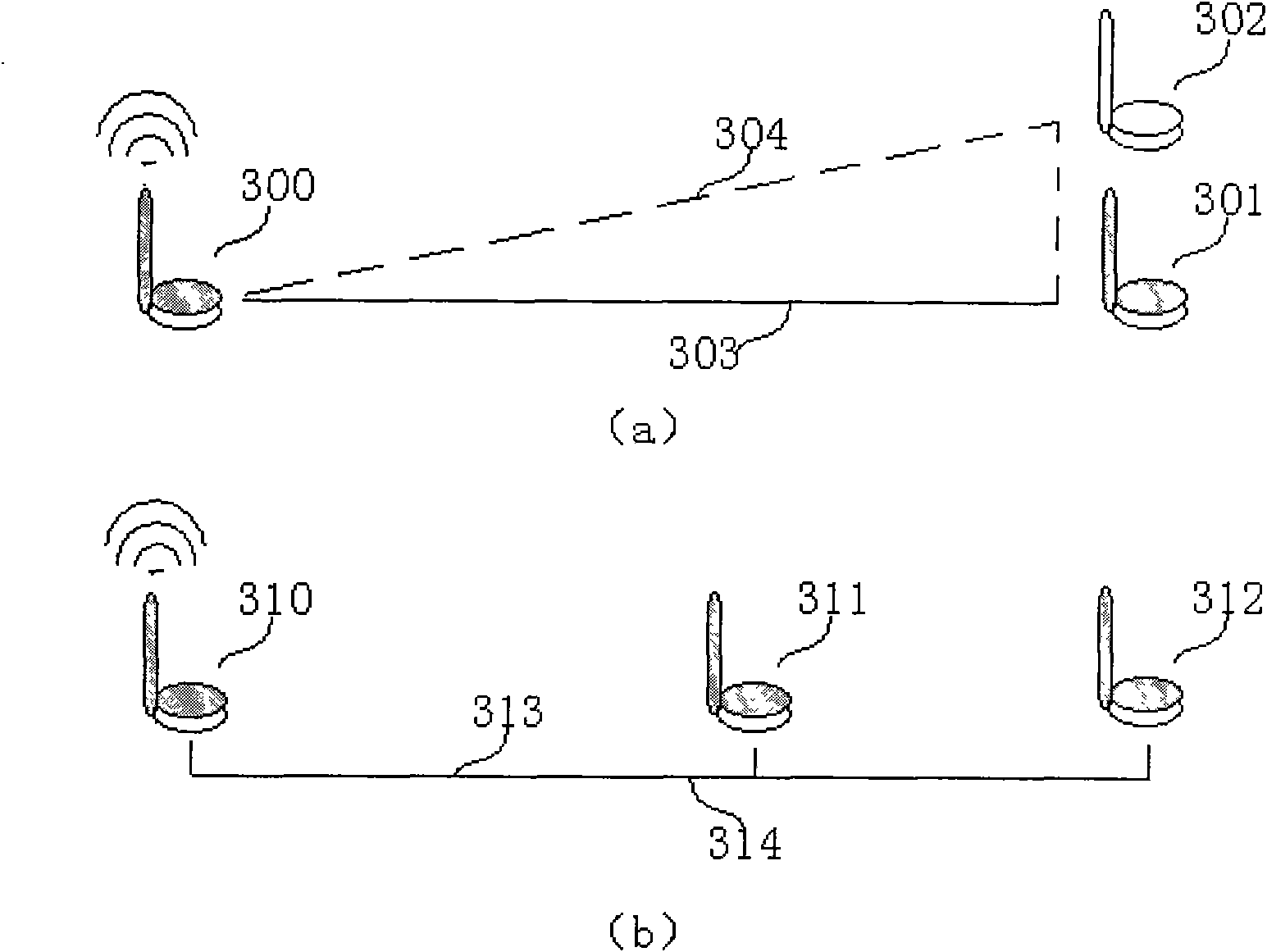

Method for regulating speed of high-speed stocker by adopting wireless indoor positioning technique

InactiveCN102040072AShorten turnaround timeReduce energy consumptionStorage devicesLow speedThree stage

The invention relates to a positioning and speed regulation method of a high-speed stocker applied to a full-automatic three-dimensional warehousing system, in particular to a method for carrying out three-stage positioning on a stacker by adopting a wireless indoor positioning technique, an address encoding positioning technique and an address slice photoelectric positioning technique and carrying out three-section optimized speed regulation on the stacker by selecting a high-speed / low-speed movement mode according to a moving distance. The method has the advantages of low cost, high throughput, low power consumption, high reliability and flexible application and can be widely applied to the fields of material-flow warehousing centers, modern distribution centers and the like, thereby having wide application prospect in the market.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

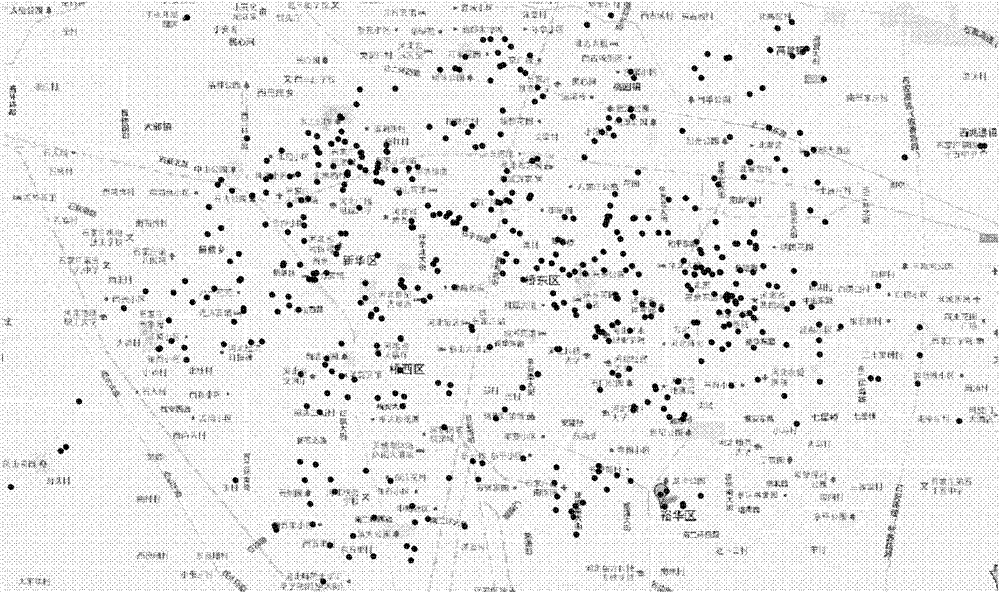

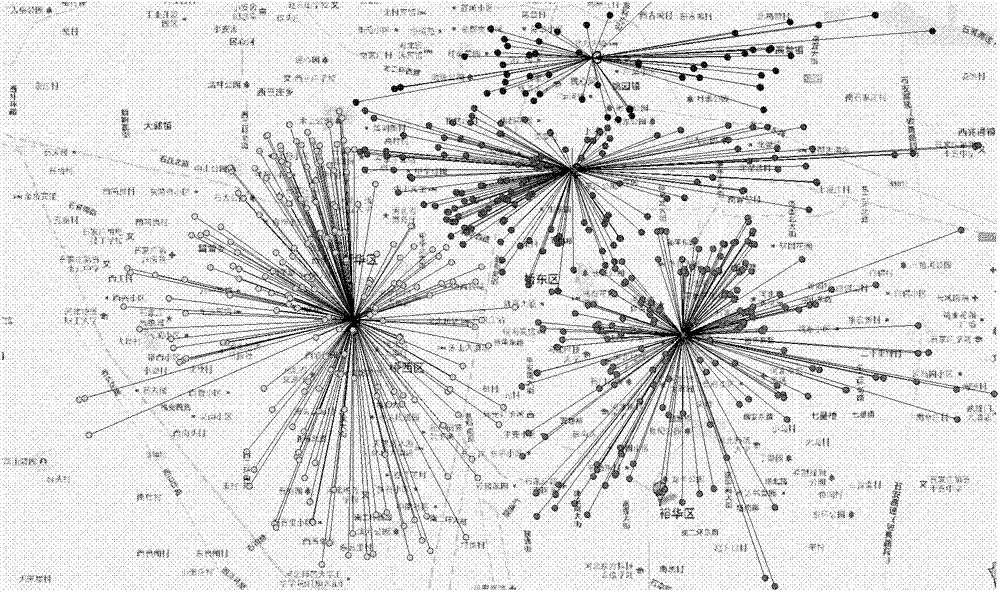

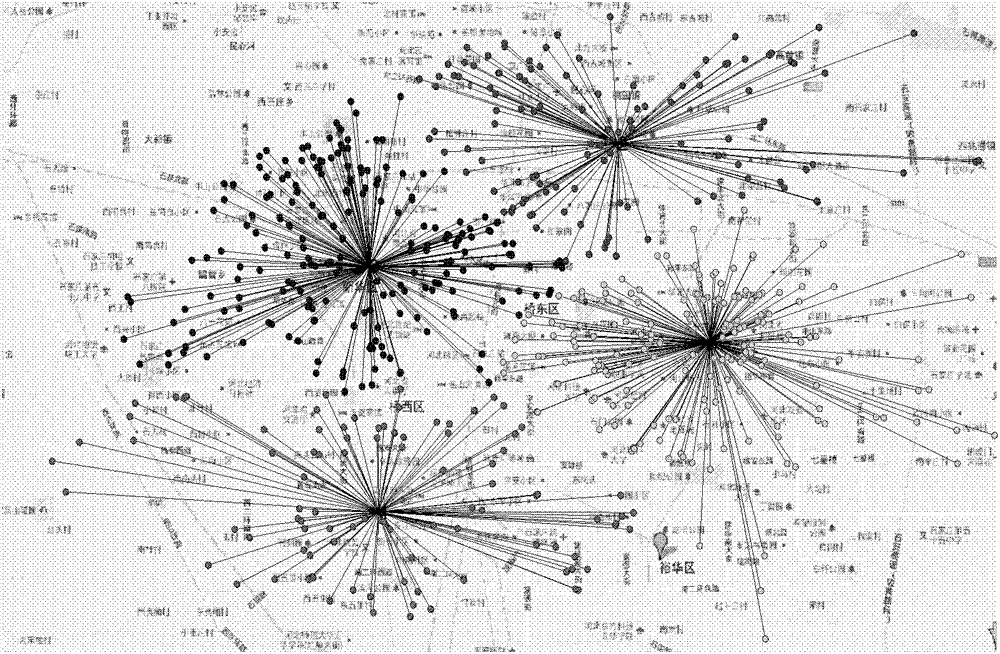

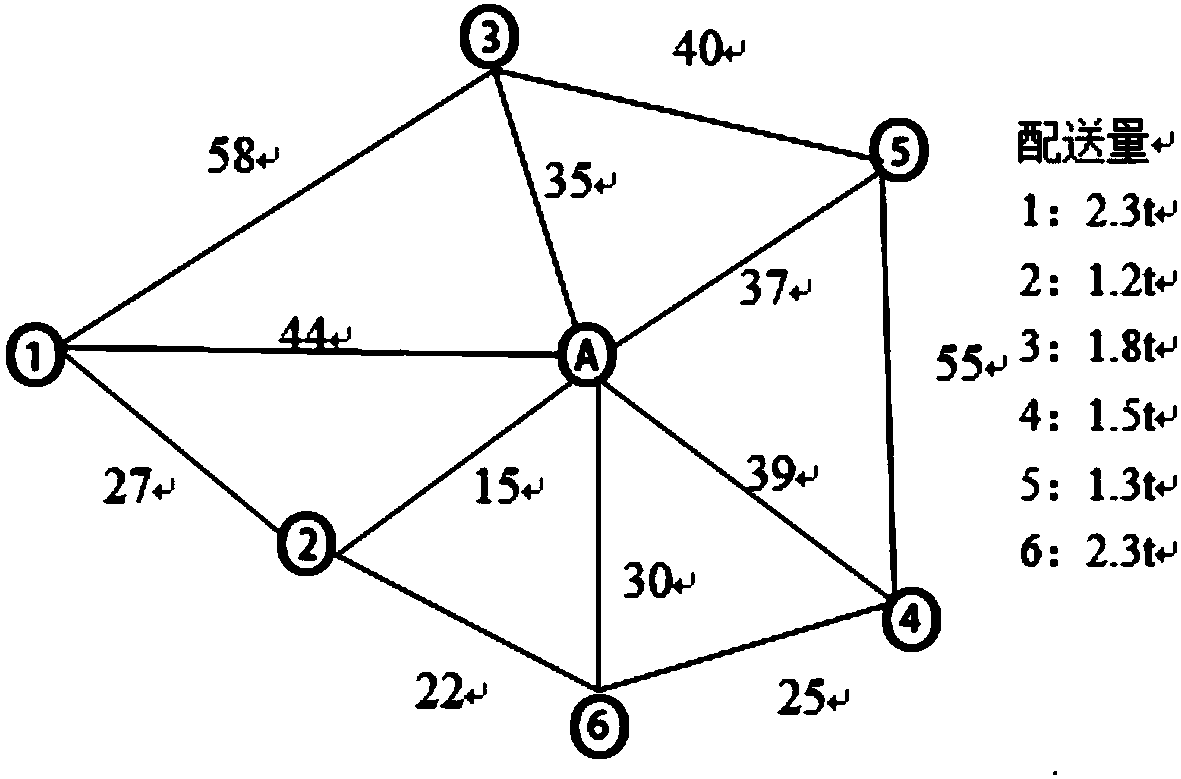

Siting method of distribution centers

InactiveCN102903037AImprove distribution efficiencySave human effortLogisticsLocal optimumHistorical distribution

The invention discloses a siting method of distribution centers. The method includes the steps of firstly, optionally selecting m sites as candidate sites of the distribution centers on a map of a target city; secondly, assigning historical distribution sites to the candidate sites of the distribution centers the nearest to the historical distribution sites according to the distances from the historical distribution sites to the candidate sites of the distribution centers; thirdly, calculating an average site of the distribution site assigned to the candidate site of each distribution center as a new candidate site of the distribution center; fourthly, repeating the first and second steps till a standard measure function starts converging and the m average sites being the sites of the distribution centers. By siting by the siting method, the distribution sites of the distribution centers are as compact as possible, and the distribution centers are as separate as possible. Finally, distribution cost is locally optimized.

Owner:北京拉手网络技术有限公司

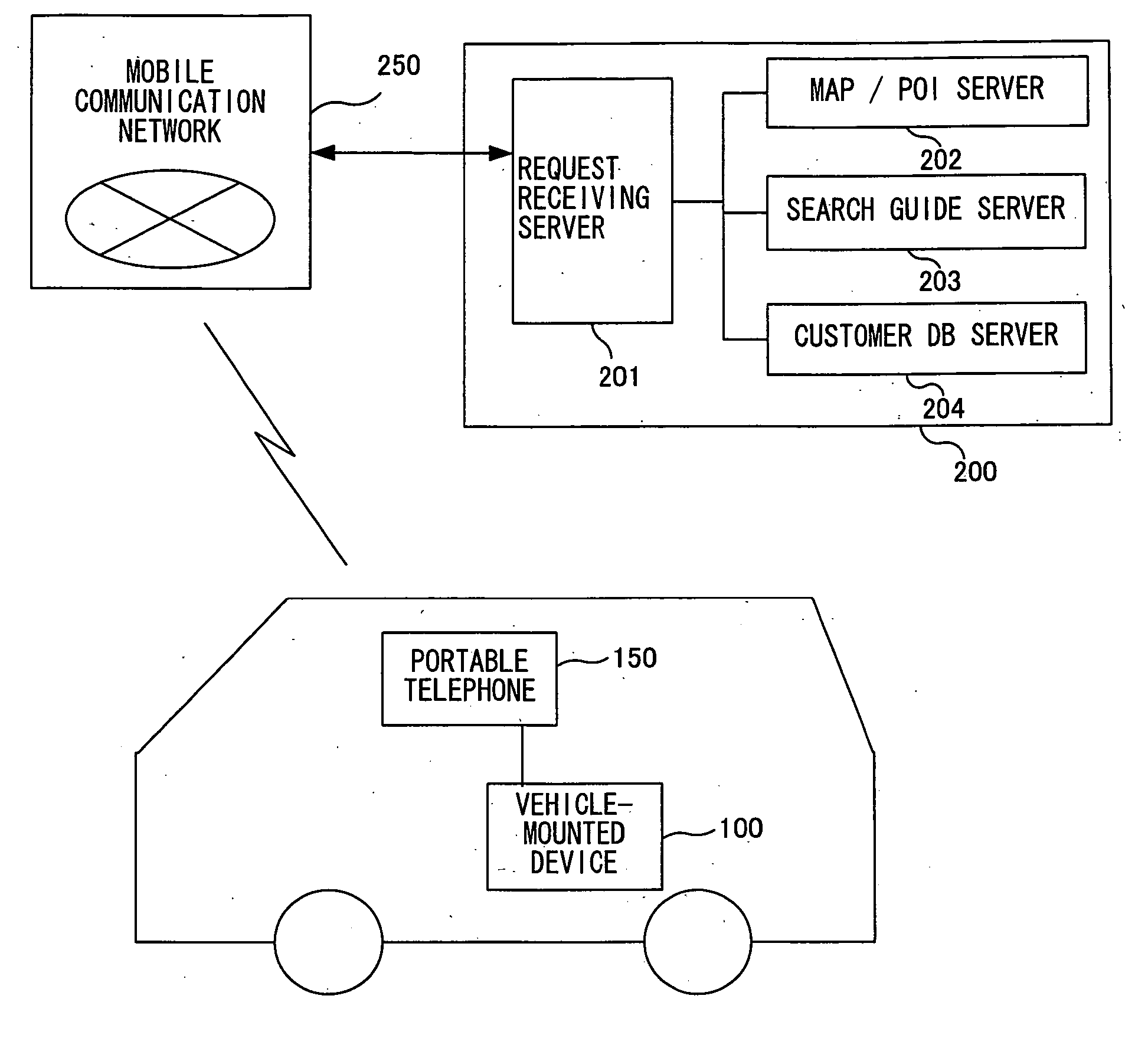

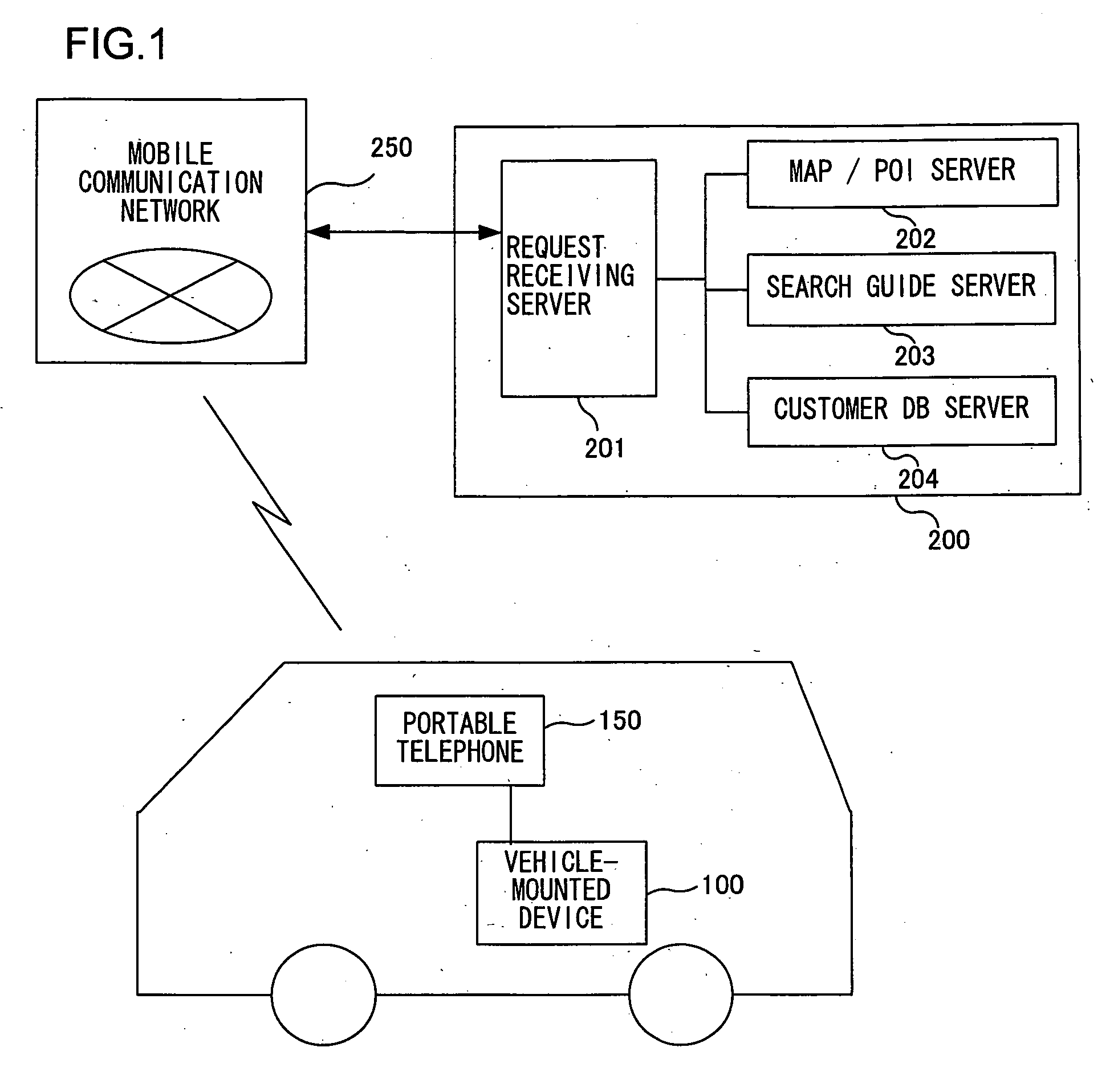

Route guide information delivery method, route guidance method, information terminal and information delivery center

InactiveUS20060149463A1Instruments for road network navigationRoad vehicles traffic controlDistribution centreReal-time computing

Upon receiving a request from a vehicle-mounted device 100, a distribution center 200 executes a recommend route calculation and a guide calculation and transmits recommended route information and the data size of guide information to the vehicle-mounted device 100. The vehicle-mounted device 100 calculates the estimated download time based upon the size of the guide information and displays it. If the driver requests a split download, the vehicle-mounted device 100 outputs a split-download instruction to the distribution center 200. The distribution center 200 transmits to the vehicle-mounted device 100 guide information to be used to guide the vehicle from the start point to the first guidance-requiring intersection. While executing the route guide processing, the vehicle-mounted device 100 downloads the remaining guide information in the background.

Owner:XANAVI INFORMATICS +2

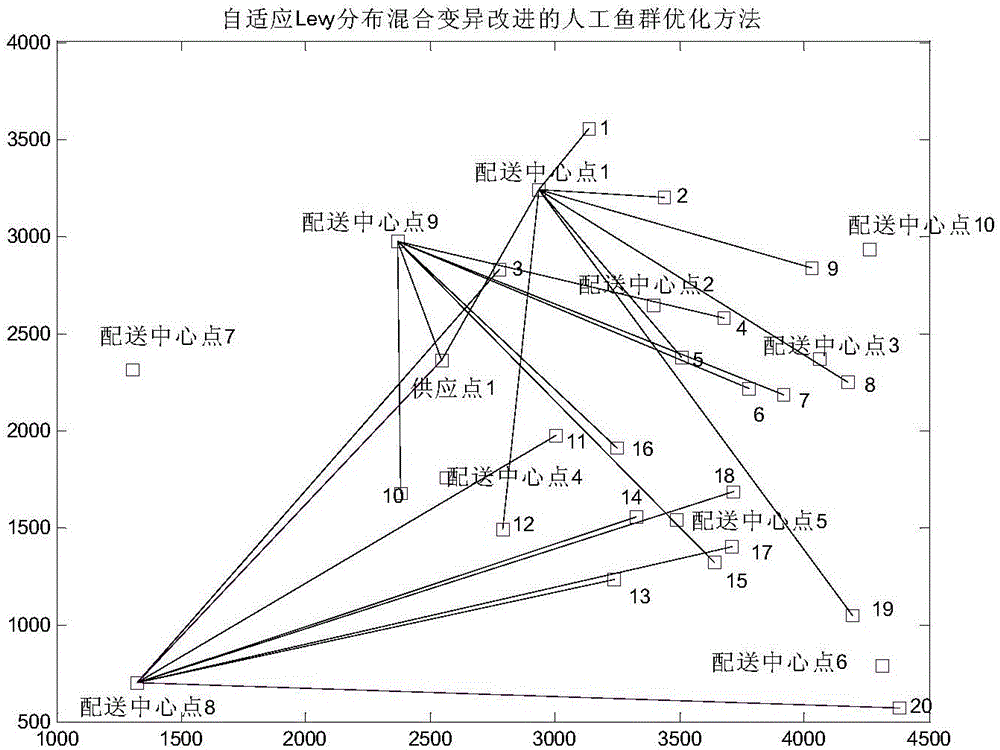

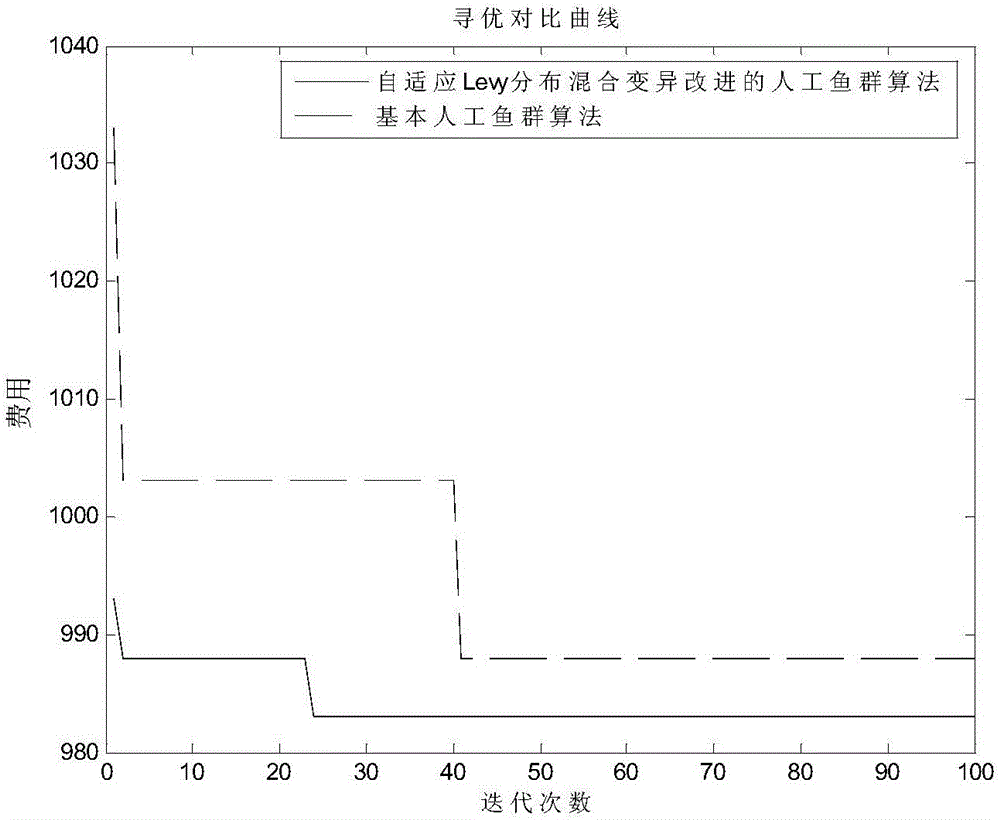

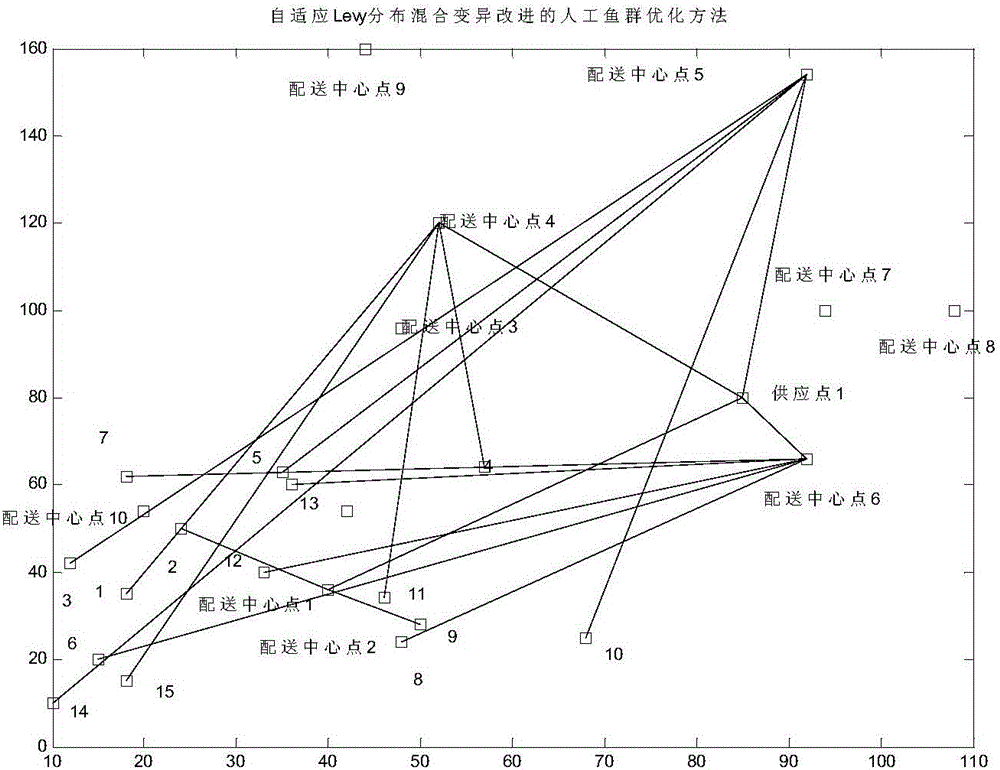

Adaptive Levy distribution hybrid mutation improved artificial fish swarm algorithm-based distribution center site selection optimization method

ActiveCN106339770ADiversity guaranteedReduce the possibility of getting stuck in a local optimumForecastingArtificial lifeLocal optimumLogistics management

The invention belongs to the logistics distribution site selection technical field and relates to an adaptive Levy distribution hybrid mutation improved artificial fish swarm algorithm-based distribution center site selection optimization method. The method includes the following steps that: (1) relevant parameters are initialized, and a distribution center site selection optimization model is established; (2) the distribution center site selection optimization model is solved through using the optimization method according to which adaptive Levy distribution hybrid mutation is utilized to improve an artificial fish swarm algorithm; and (3) a distribution center site selection result is compared with the result of using the adaptive Levy distribution hybrid mutation to improve the artificial fish swarm algorithm in solving a distribution center site selection problem. According to the method of the invention, Levy mutation and chaotic mutation are introduced into the basic fish swarm algorithm, so that the diversity of artificial fish states in the basic artificial fish swarm algorithm can be increased, the capability of the basic artificial fish swarm algorithm to jump out of local optimum can be improved, and the optimization of distribution center site selection can be enhanced.

Owner:TIANJIN UNIV OF COMMERCE

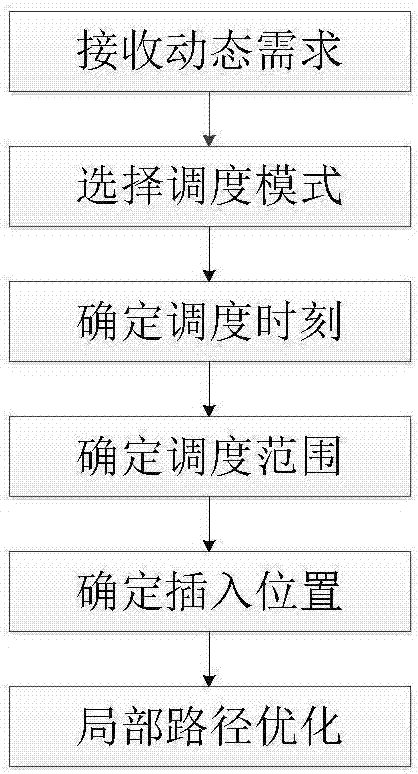

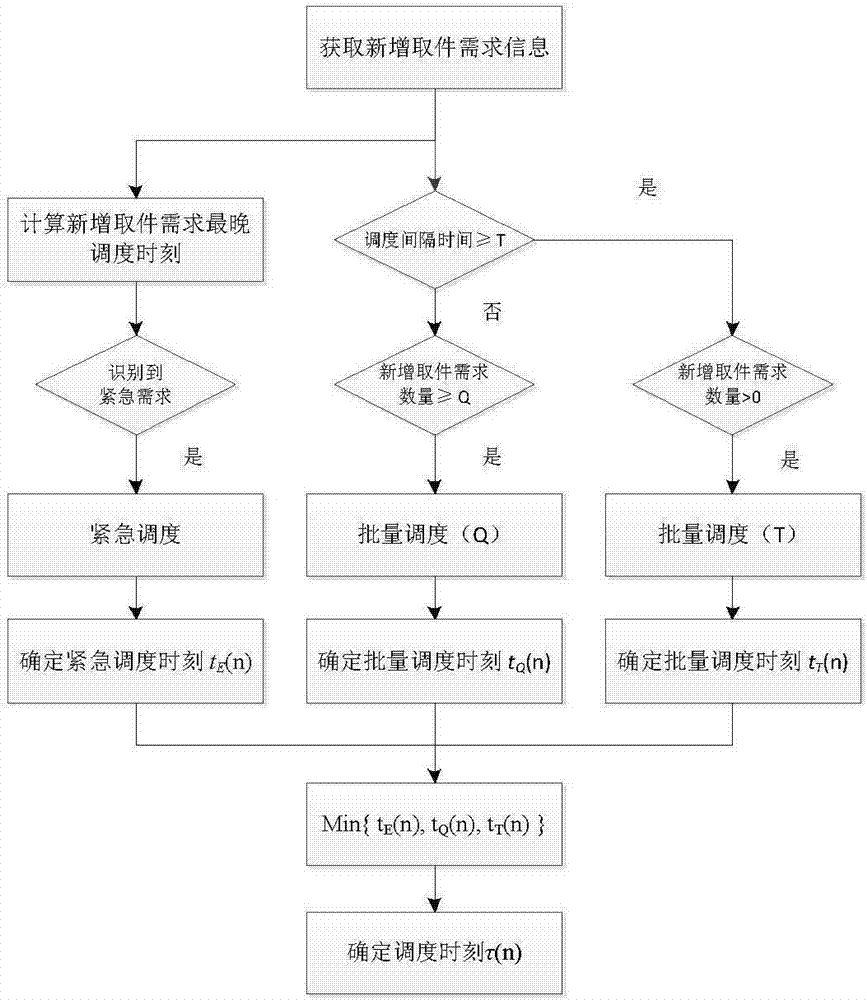

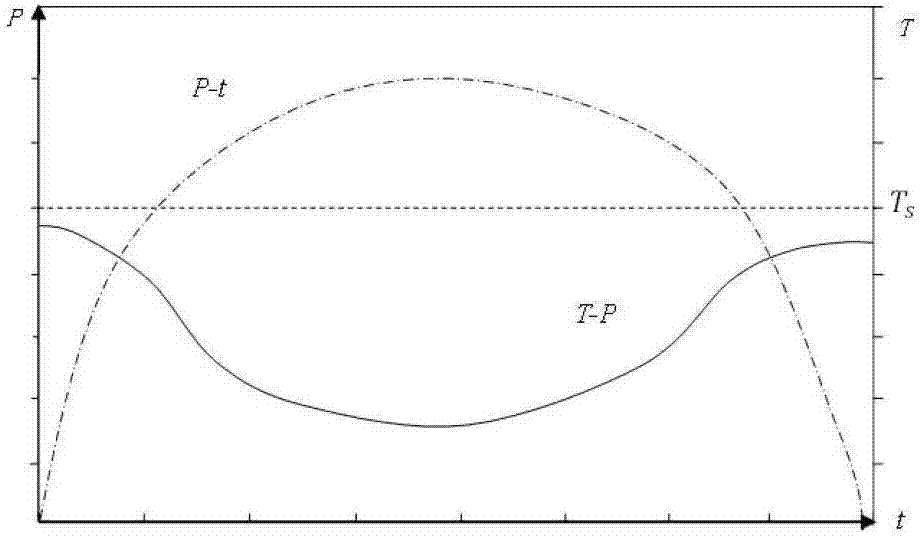

Dynamic scheduling method for processing newly-added express pickup demands during express distribution process

InactiveCN107194576AReduce logistics costsQuick responseResourcesLogisticsLoad ratioComputer science

The invention provides a dynamic scheduling method for processing newly-added express pickup demands during an express distribution process, which belongs to the technical field of intelligent and optimal vehicle scheduling. In order to solve the problems that the current express company distribution vehicles are high in no-load ratio and newly-added express pickup demands can not be met timely, the invention provides a dynamic scheduling method for simultaneous express pickup and delivery with batch scheduling and emergency scheduling combined. The method particularly comprises steps: 1, a distribution center receives newly-added express pickup demands; 2, a scheduling mode is selected; 3, the scheduling time is determined; 4, a scheduling range is determined; 5, the newly-added express pickup demand insertion positions are determined, and newly-added express pickup demands which can not be inserted to the current line are completed by vehicles assigned by the distribution center; and 6, local path optimization in the scheduling range is carried out.

Owner:CHONGQING UNIV

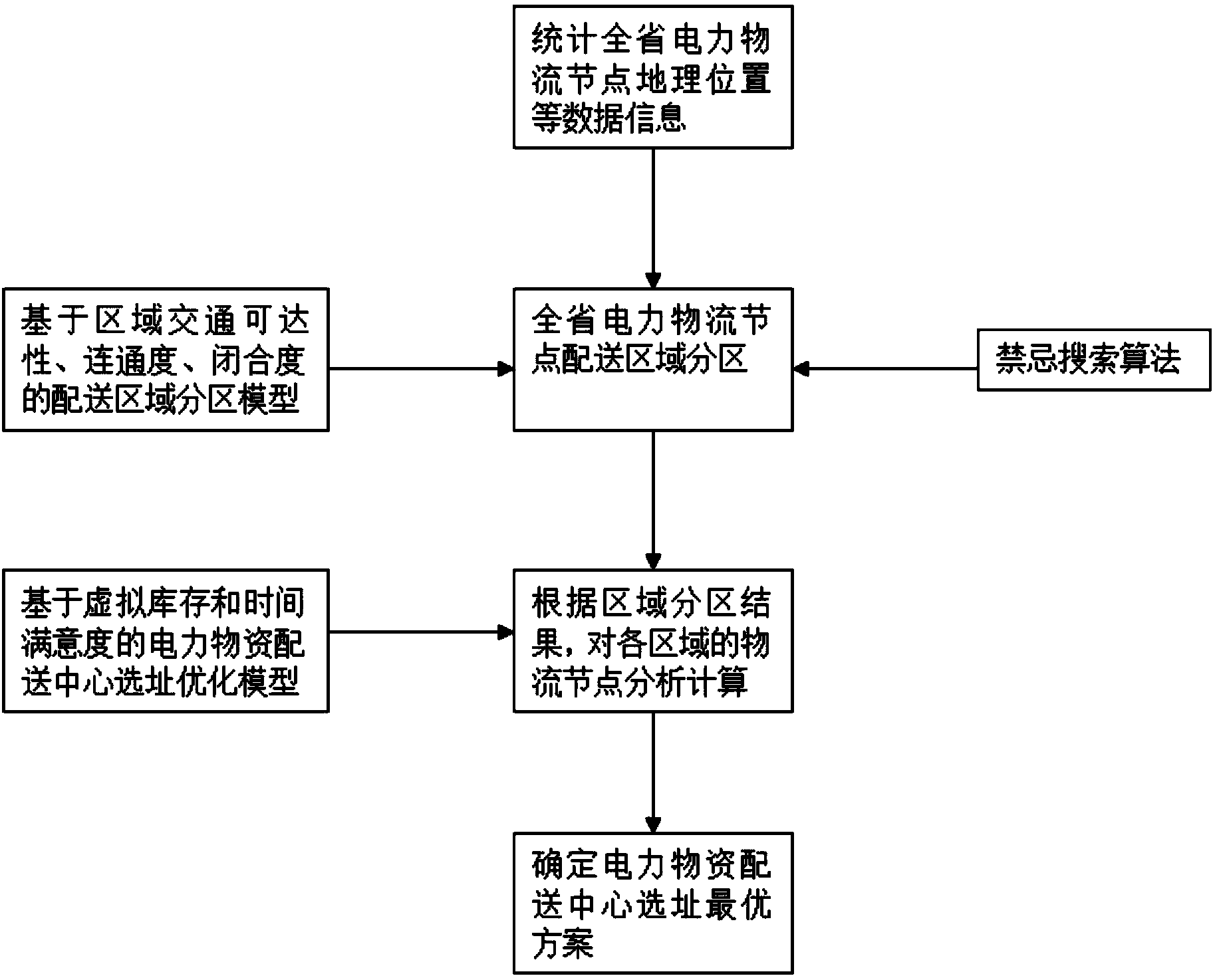

Electric power material distribution center location selection method

InactiveCN104268705AMeet complex power distribution system requirementsResource optimizationResourcesLogisticsSystem requirementsSimulation

The invention provides an electric power material distribution center location selection method. The method comprises the following steps that A, a destination region is divided into sub-regions; B, distribution centers are arranged at different logistics nodes in each sub-region, and the sum of weighted distances from suppliers and the distribution centers at different positions in the sub-regions to a demand point is determined; C, the position of the distribution center corresponding to the minimum weighted distance in each sub-region is determined as the position of the distribution center of the sub-region. By the adoption of the electric power material distribution center location selection method, the characteristics of a supplier inventory management pattern and a joint inventory management pattern can be considered, and a proper location of an electric power material distribution center is determined based on the virtual inventory technology and the time satisfaction degree; therefore, complex electric power distribution system requirements are met, resources are optimized, and the service quality is improved.

Owner:STATE GRID CORP OF CHINA +2

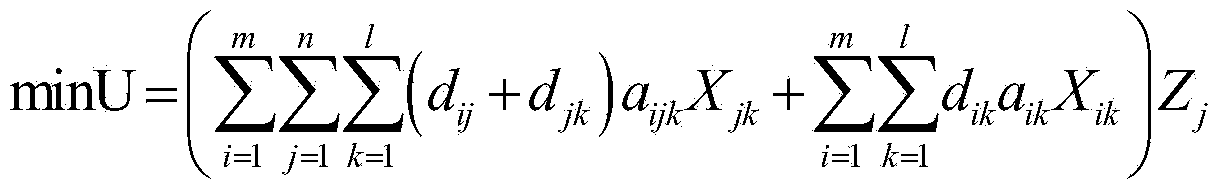

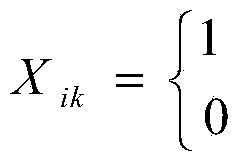

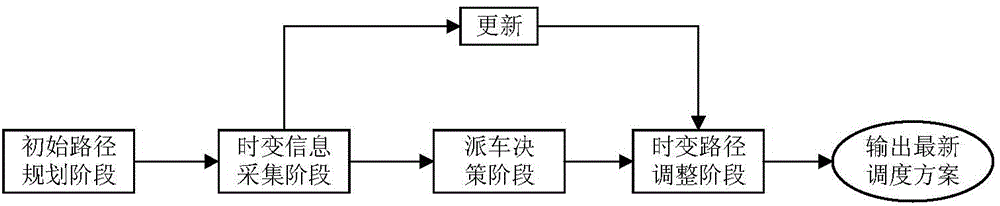

Associated logistics transportation optimized dispatching method with time-varying demand

InactiveCN104463379AMeet needsFast convergenceForecastingArtificial lifeLogistics managementComputer science

The invention relates to a time-varying demand associated logistics transportation optimized dispatching method based on a bee colony algorithm. The method comprises the specific implementation steps that (1) a distribution center acquires known demand information of a client; (2) an initial solution is constructed; (3) optimization is performed on the initial solution through an artificial bee colony algorithm based on taboo table thought; (4) a pre-loop passing through all the vertexes of a complete undirected graph G is obtained; (5) the distribution center collects time-varying information and acquires demand information of the time-varying client; (6) the pre-loop is adjusted according to a certain rule, and constraint conditions are satisfied; (7) the process is ended. According to the method, a final dispatching scheme based on time-varying demand associated with transportation dispatching is obtained.

Owner:GUANGDONG YIFU NETWORK TECH

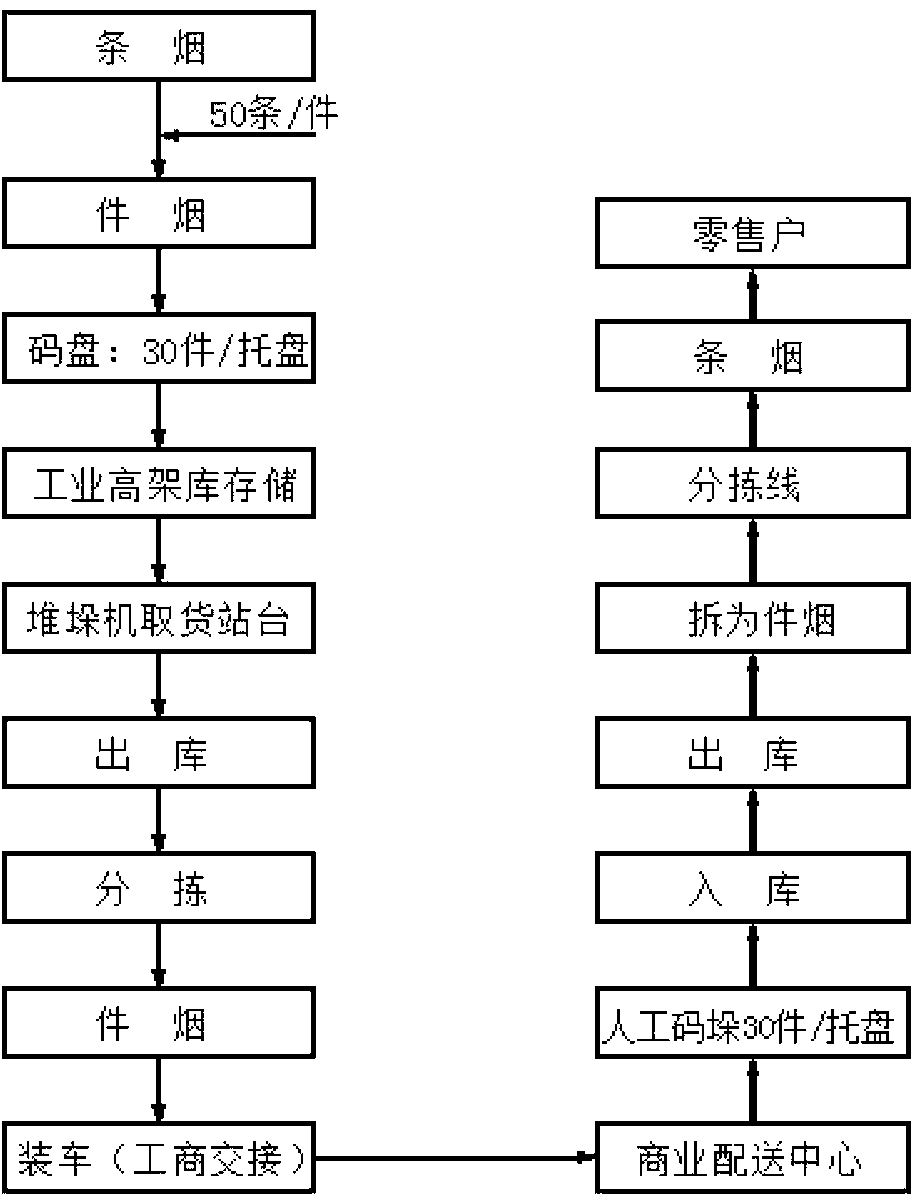

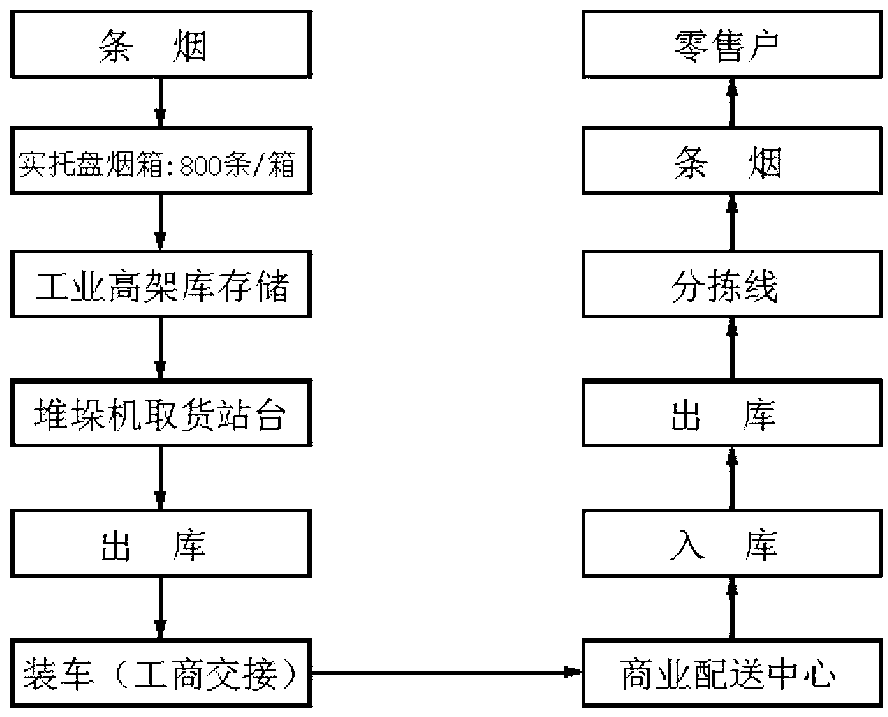

Industrial and commercial cooperation cigarette packaging, storage and transportation logistics system and method

InactiveCN103318653AAvoid wastingSimplify the work processStorage devicesComputer control systemLogistics management

The invention relates to a cigarette logistics system, in particular to an industrial and commercial cooperation cigarette packaging, storage and transportation logistics system. The logistics system comprises a computer control system, an industrial cigarette plant area and a commercial distribution center area. The industrial cigarette plant area comprises an encasement area, a warehouse inlet area, an elevated warehouse area and a warehouse outlet area. The commercial distribution center area comprises a warehouse inlet area, an elevated warehouse area, a warehouse outlet area and a sorting area. A packaging and transportation mode between industrial finished product cigarettes and commercial distribution is converted from an original industrial and commercial separation mode to an industrial and commercial cooperation mode, and a system operation process is simplified; mechanical hands and conveyors replace encasement sealing machine sets, turnover cigarette boxes are changed from cartons to wood cigarette boxes, resource waste caused by carton abandonment is avoided, and production cost is reduced; a cigarette barcode recognition mode is changed into a tray radio frequency identification (RFID) recognition mode, the problem of system errors caused by barcode pollution and the like is solved, and working efficiency is improved.

Owner:北京达特集成技术有限责任公司

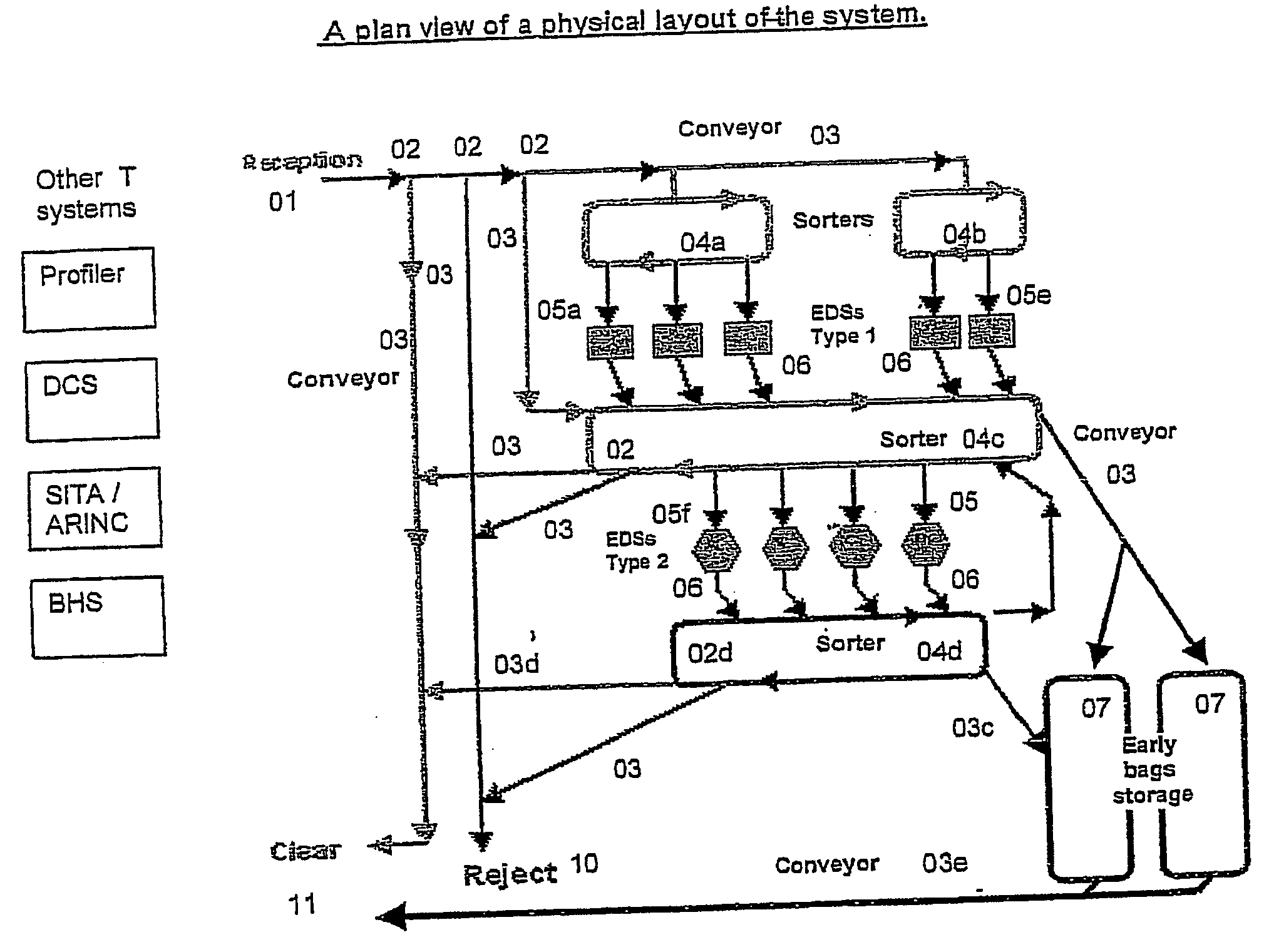

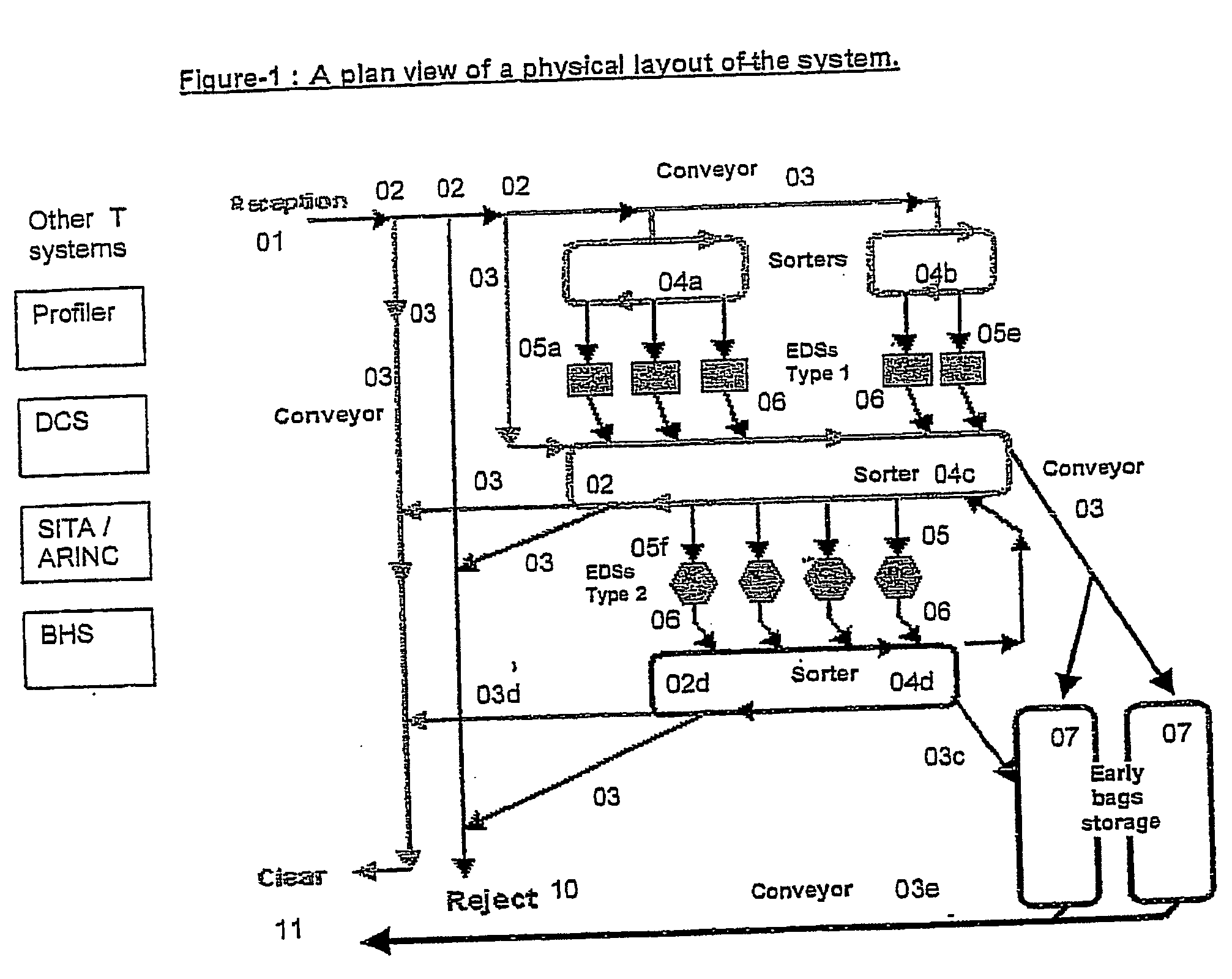

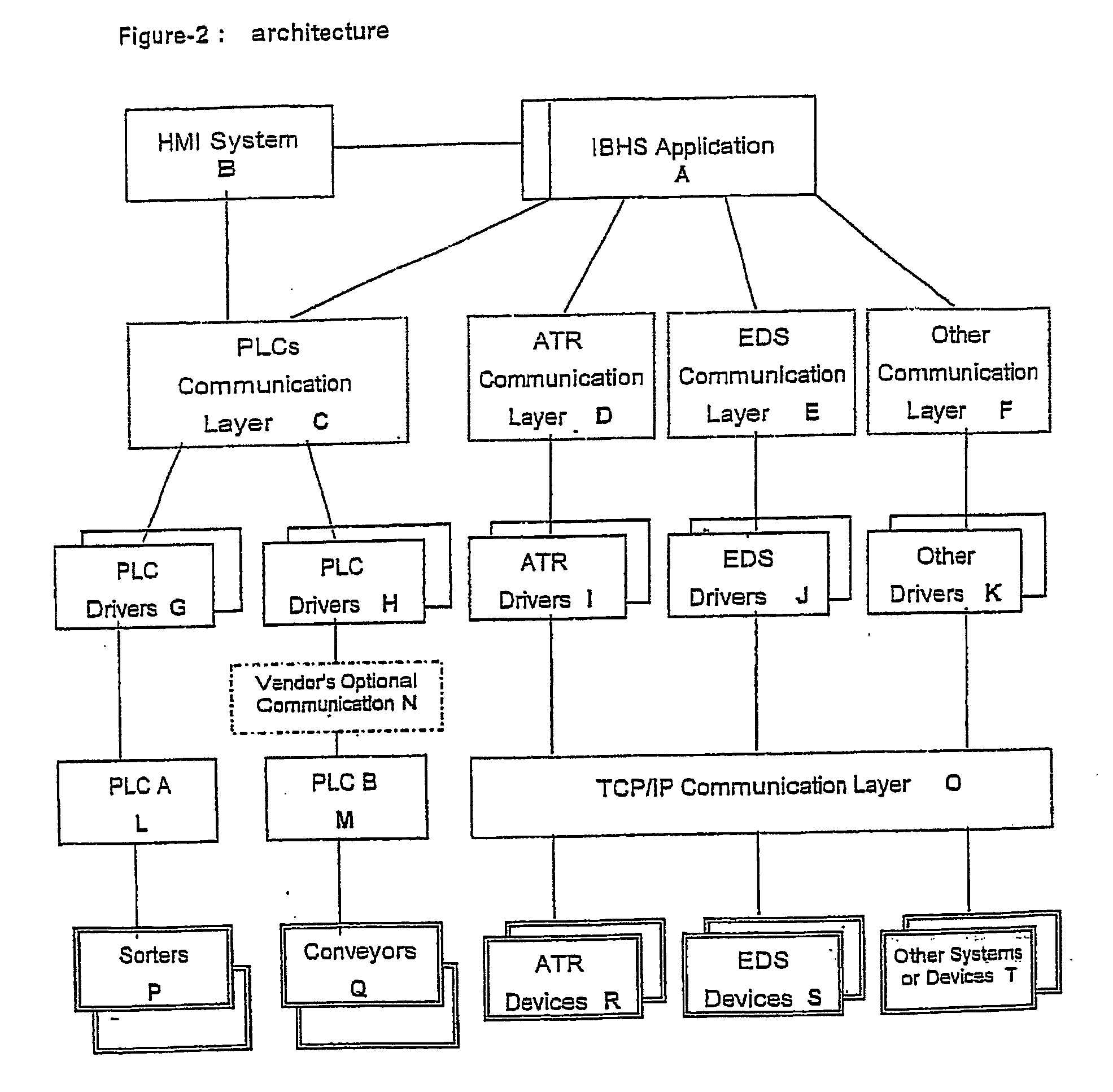

Screening system for objects in transit

InactiveUS20050177271A1Improve the detection rateMinimal labor costDigital data processing detailsFreight handling installationsBorder crossingControl system

The present invention relates to the screening of objects in-transit and materials, for security purposes (i.e. explosives detection). The invention provides an adjustable computerized system suitable for use at airports, seaports, land terminals, distribution centers, railway terminals, border crossings or other transit terminals, in order to achieve maximal efficiency and detection reliability, by adjustment of the screening process of any specific object to its risk factor in conjunction with the characteristics of the available in-line detection equipment. The invention provides an automated security inspection and conveying system for in-transit objects, comprising means for identifying the sender of each package and to profile and import the security status data relevant to the object into the system, and a plurality of various security screening machines in combination with conveying and sorting components. The system tracks each package from a reception point through the conveyors and screening machines to reach a sorting junction, via a user-adjustable screening process, the conveying and sorting components being interfaced with the security status data for assigning a risk assessment factor to the object and the sender. Each package is routed via an appropriate number of screening devices, the output of the screening devices being processed and the risk assessment factor being adjusted accordingly, the new risk assessment factor being sent to a control system of the conveying and sorting components.

Owner:SECURELOGIC

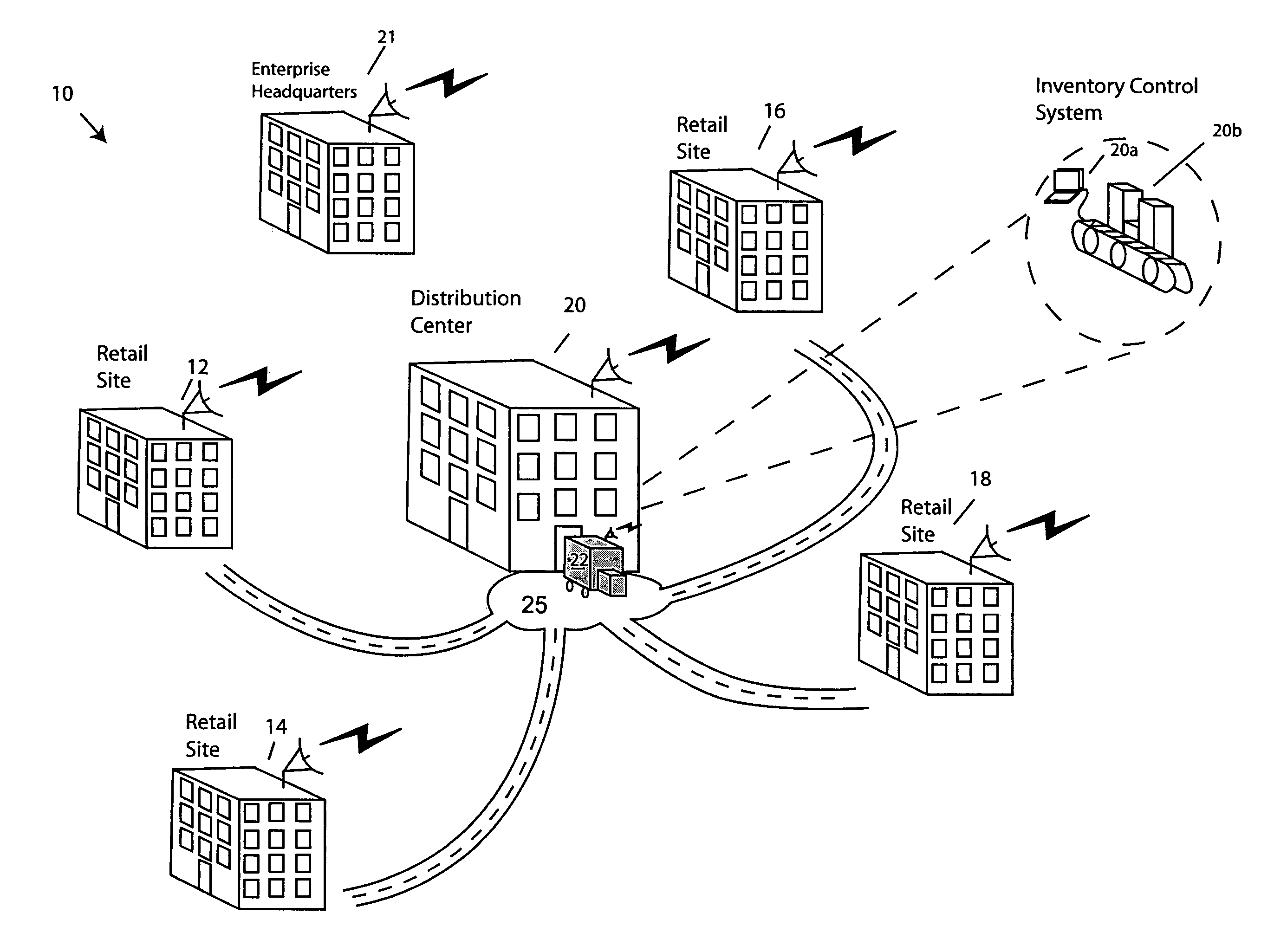

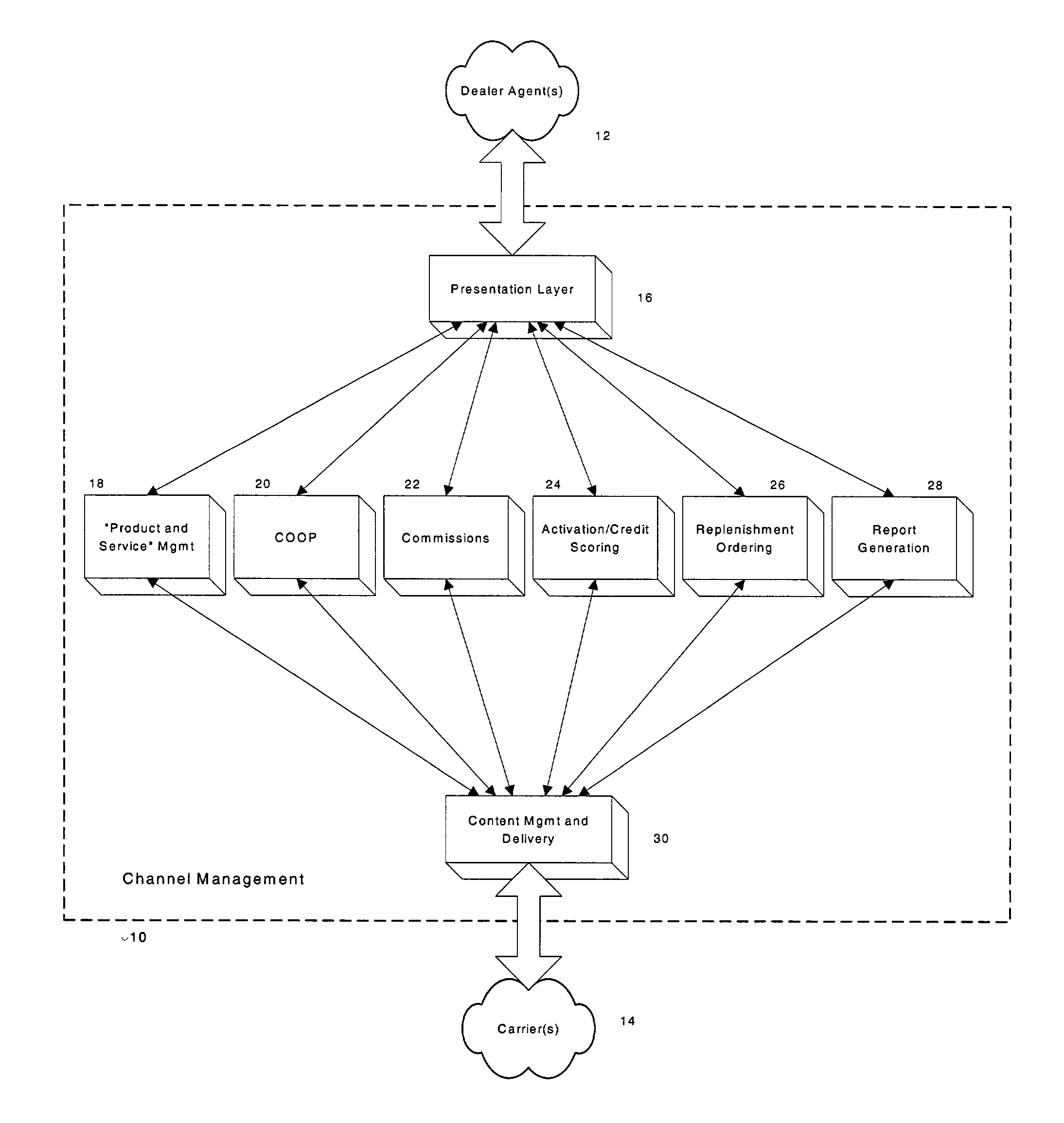

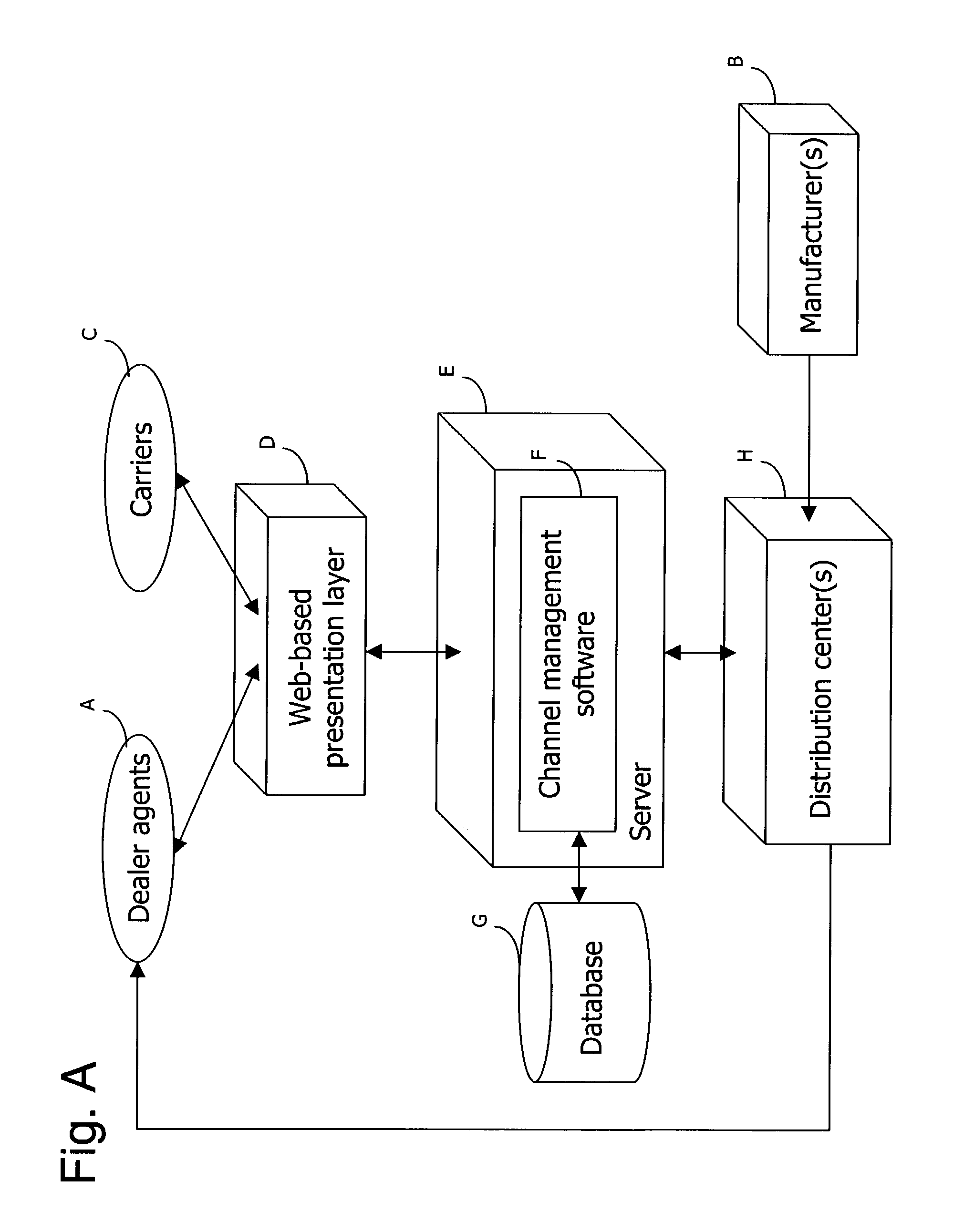

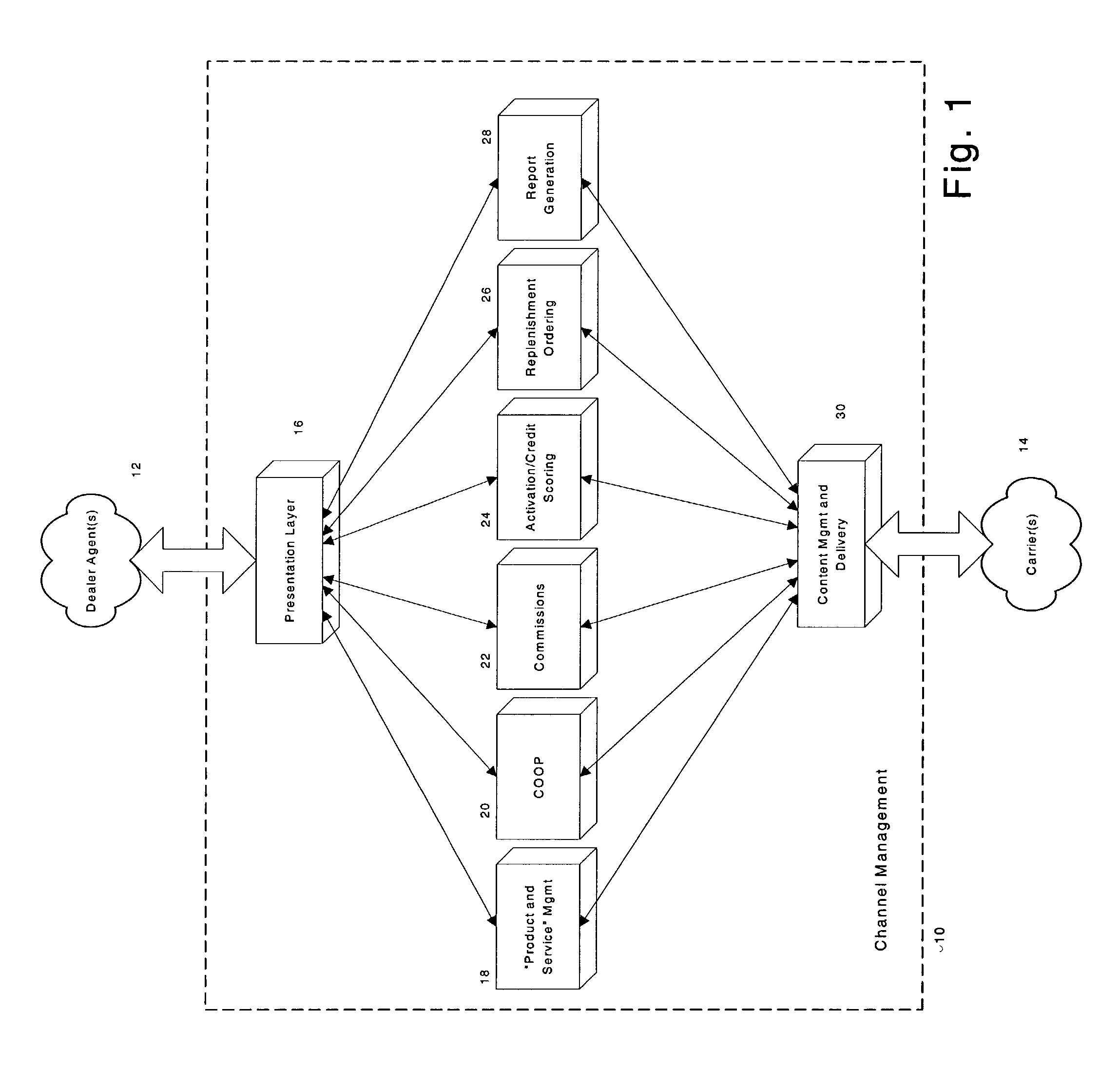

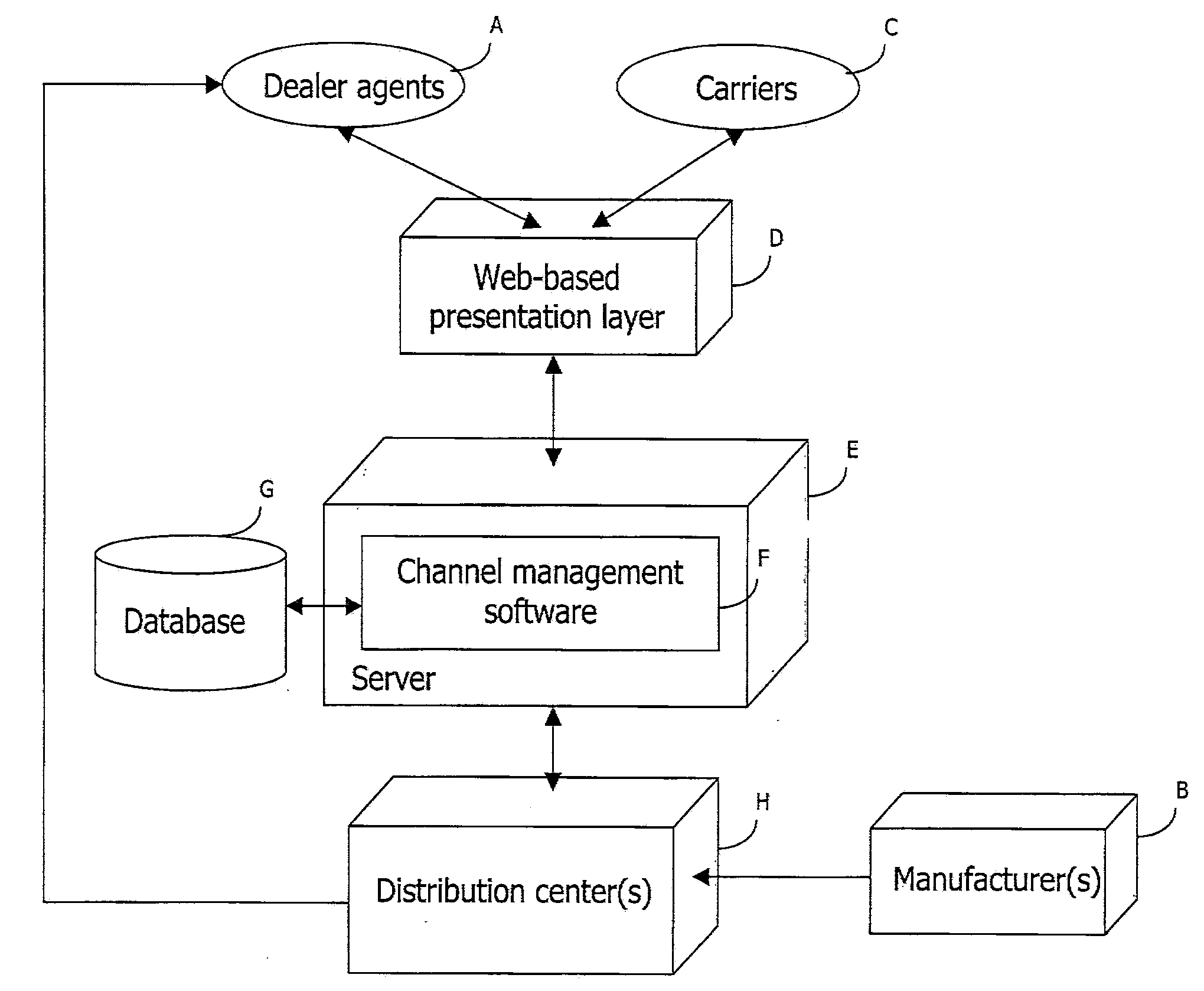

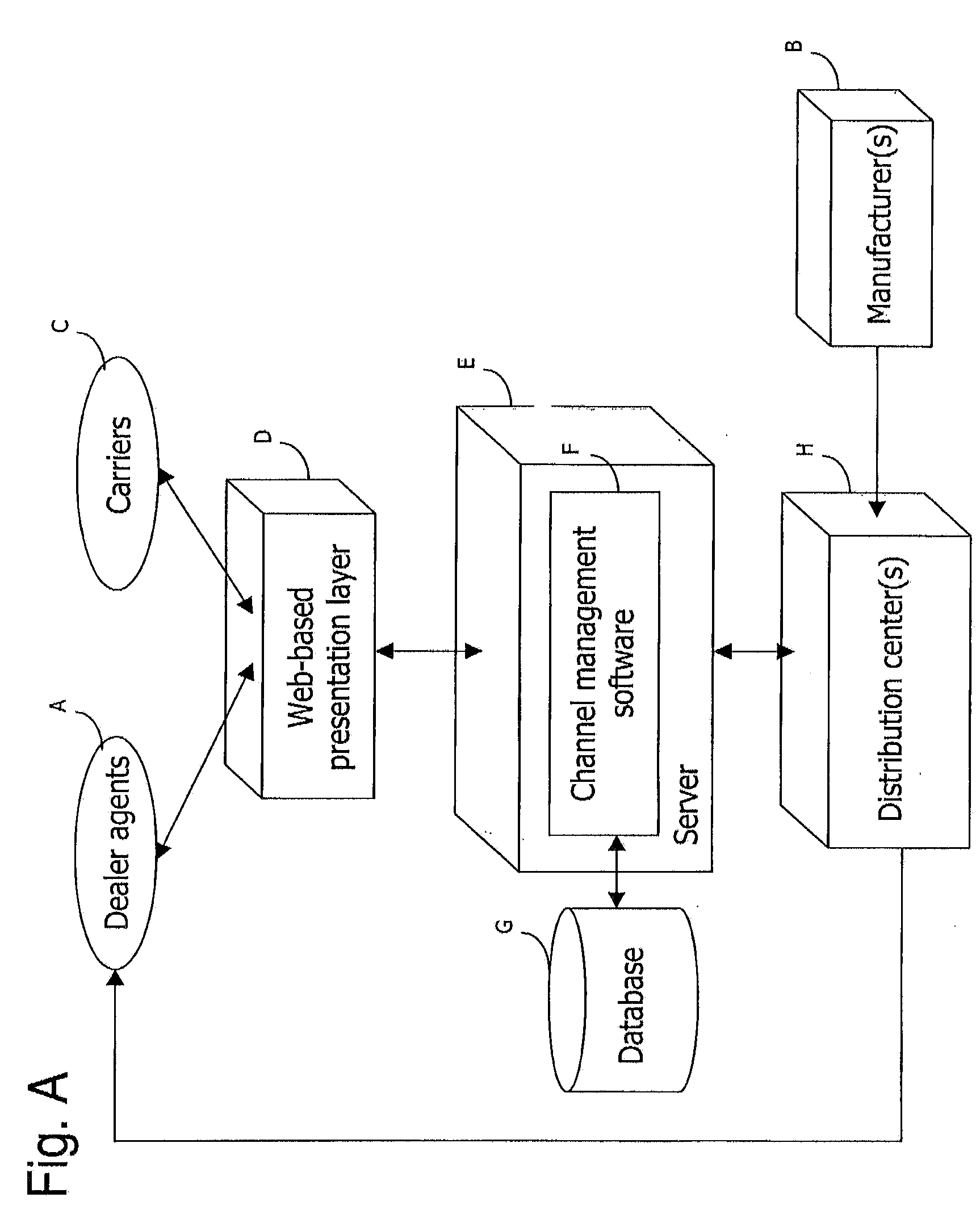

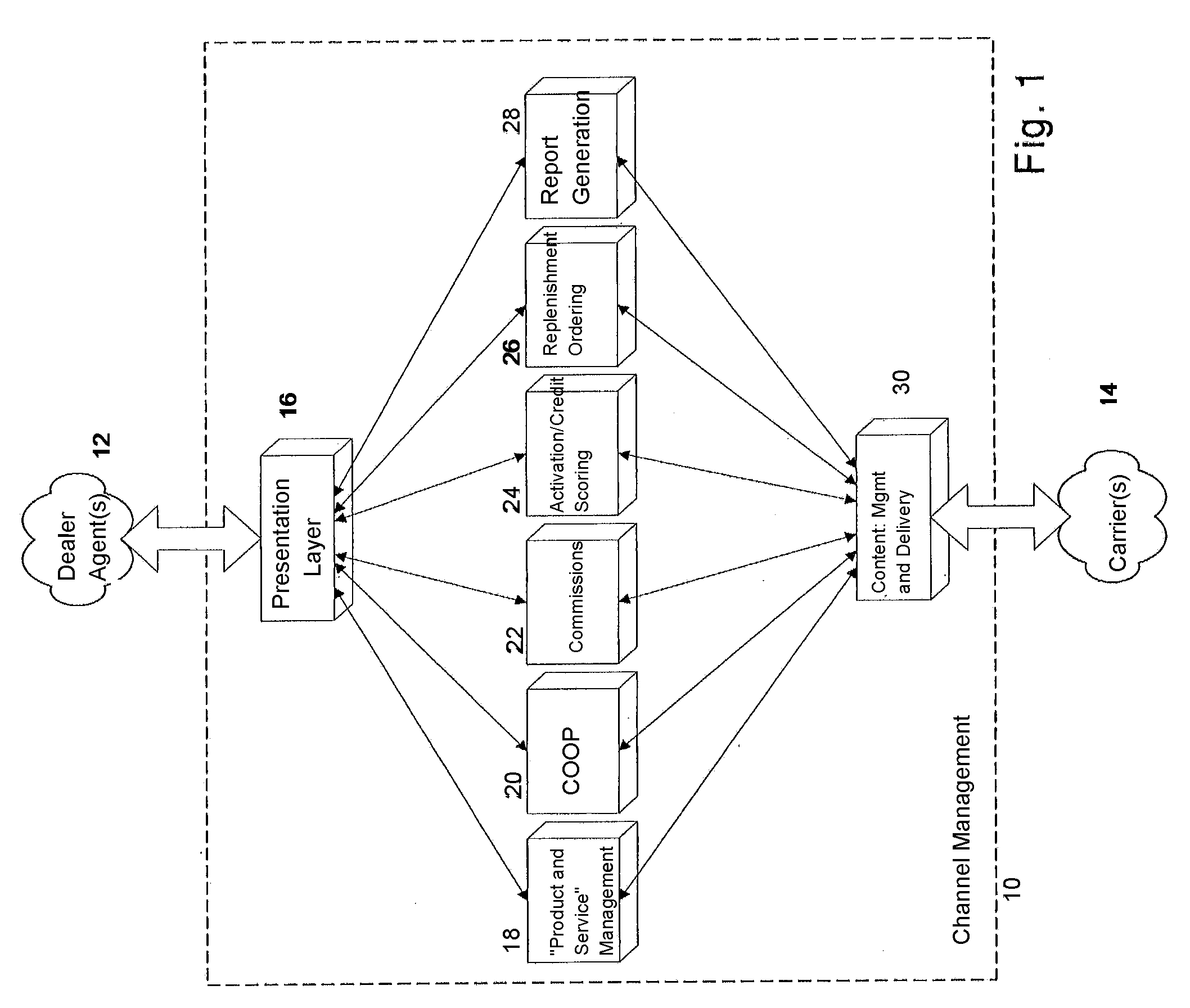

Distribution channel management for wireless devices and services

A system and method for distribution channel management for devices and services in the wireless telecommunications industry are disclosed. A product ordering software module is integrated with an activation and credit scoring software module, a commissions management software module, and a coop management software module, wherein the software modules are optionally integrated with additional software modules for product and service management, and report generation. A plurality of geographically distributed dealer agents who operate retail interfaces with customers use a web-based interface with the software modules and a data link with one or more distribution centers for delivery of wireless devices from a plurality of wireless device manufacturers, and with one or more carriers providing the subscription services activated for the customers via the activation and credit scoring software module.

Owner:CELLSTAR CORP +1

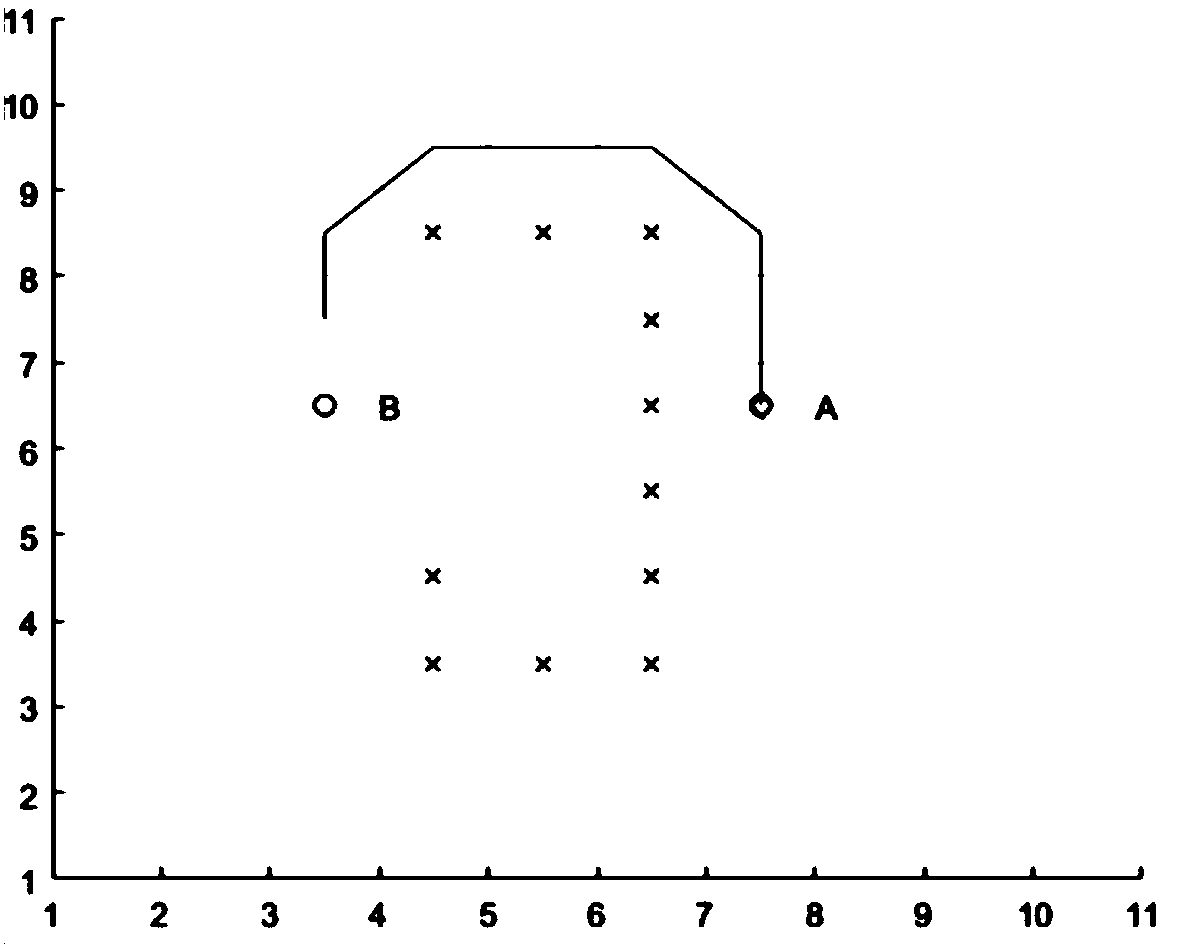

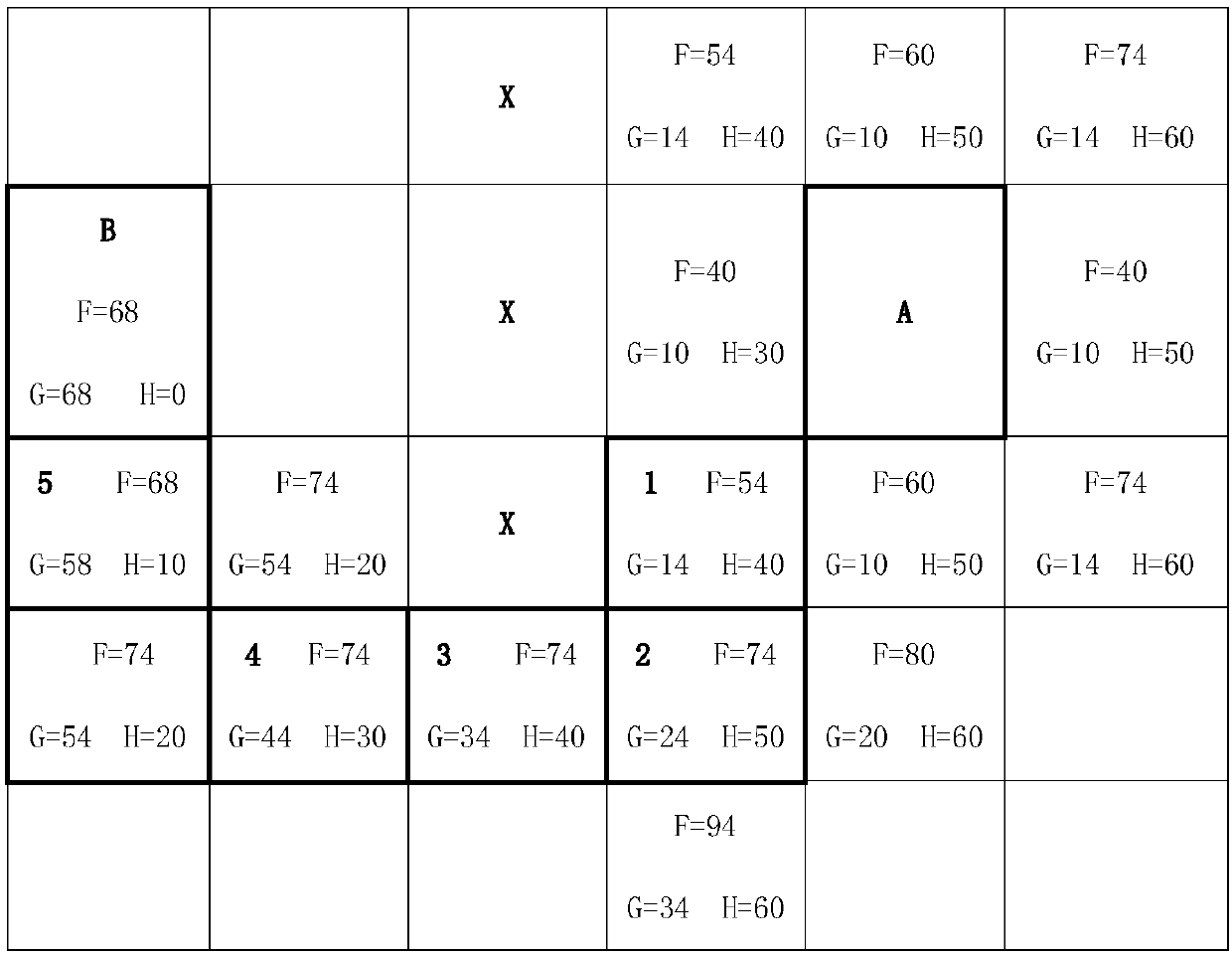

Logistics distribution vehicle scheduling method based on improved A* algorithm

The invention relates to a logistics distribution vehicle scheduling method based on an improved A* algorithm, and proposes a plan for vehicle scheduling, route selection and route planning in logistics distribution including two parts: an improved A* algorithm and a logistics distribution algorithm. The improved A* algorithm is used to quickly search for the optimal path between two points, including: meshing the distribution area, preferably selecting the appropriate evaluation distance, and recursively searching for the shortest distance. The logistics distribution algorithm is used to generate vehicle information sent from the distribution center to each customer node, the vehicle information includes vehicle numbers, passing customer nodes, vehicle routes, load capacities, and total distances of the routes, and the logistics distribution algorithm includes two parts of calculating distances and routes from the customer nodes to the logistics center, and generating the distributionplane with the improved weighted graph algorithm. This scheduling method considers the constraints in the vehicle path, reduces the total transportation distance, enhances the overall control and management of the logistics distribution process, and achieves a more economical distribution line.

Owner:上海锦觅网络科技有限公司

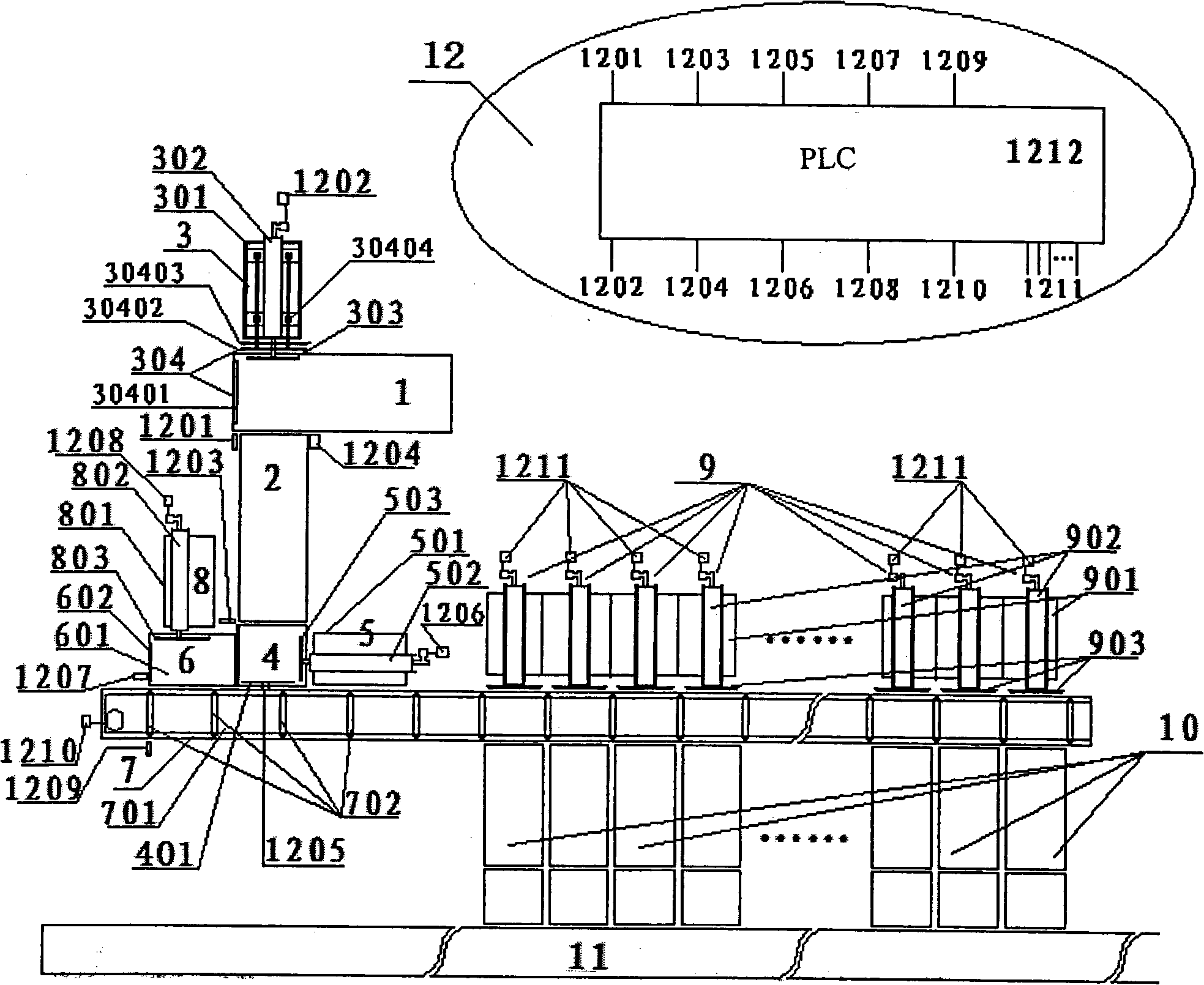

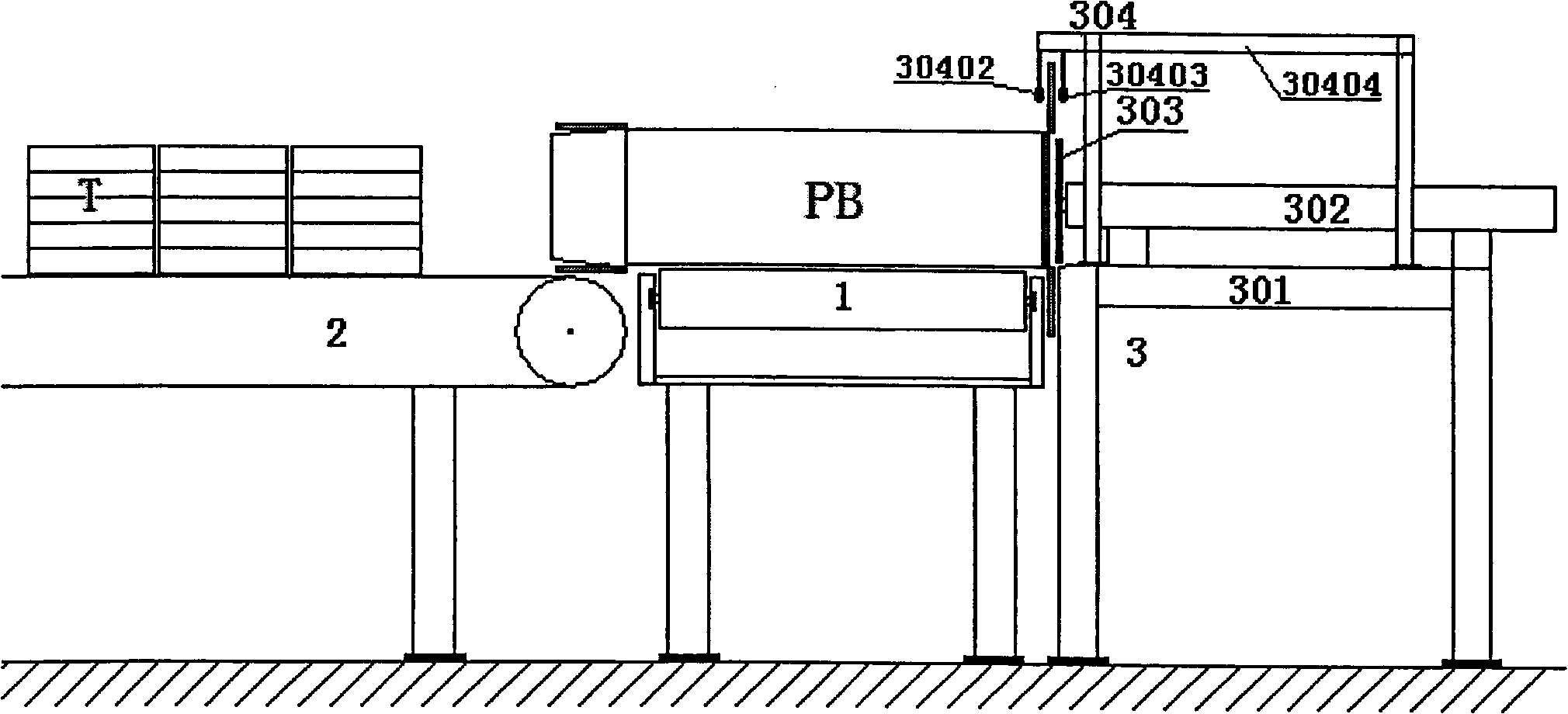

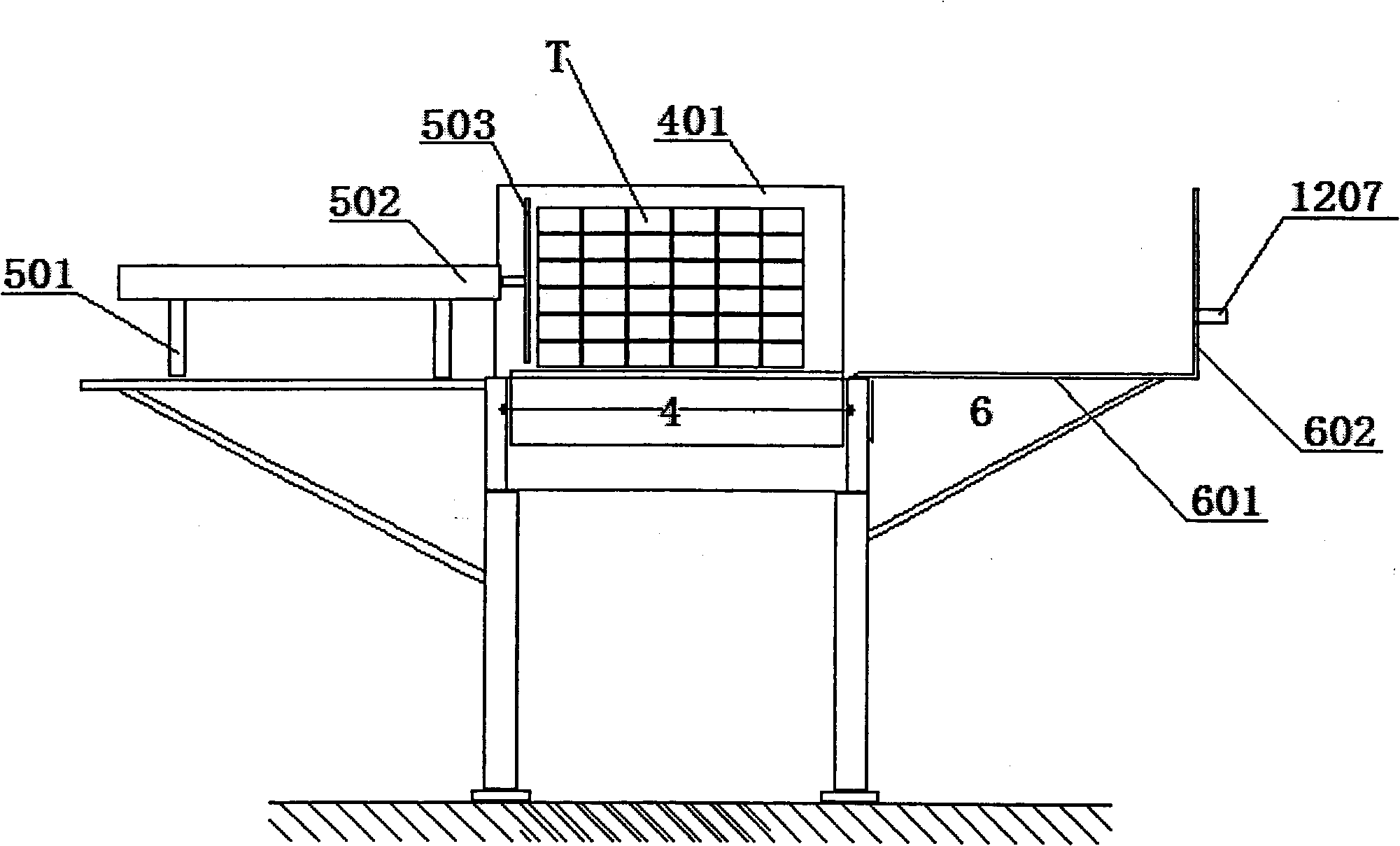

Automatic goods supplying system of goods allocation line of allocation center

InactiveCN101357716AStrengthen distribution capacityImprove operational efficiencyControl devices for conveyorsArticle unpackingAutomatic controlEngineering

The invention discloses an automatic cargo supplementing system used for a cargo distributing line of a distribution center. Two sides of one end of a roller conveying machine are respectively provided with a belt conveying machine which is used for conveying cargos inside the box and a cargo pushing out device; one end of the belt conveying machine which is far away from one side the roller conveying machine is connected with another belt conveying machine; two side surfaces of another belt conveying machine are respectively provided with a cargo lateral pushing-out device and a cargo storage platform; a stepping-typed cargo conveying machine with grids is arranged along the conveying motion direction of another belt conveying machine; a cargo push-in device is arranged at the other side of the cargo storage platform correspondingly to the stepping-typed cargo conveying machine; two sides of the stepping-typed cargo conveying machine are respectively and correspondingly provided with a group of cargo supplementing push-out devices and cargo distributing storage conveying machines; a cargo motion sensor and a controller inside an automatic control device are respectively arranged on the devices of the invention. The automatic cargo supplementing system improves the running efficiency of the sorting and distributing line, lightens the labor intensity, and improves the exactness of the distribution operation, the working efficiency and the distributing capability.

Owner:ZHEJIANG UNIV CITY COLLEGE

Distribution channel management for wireless devices and services

A system and method for distribution channel management for devices and services in the wireless telecommunications industry are disclosed. A product ordering software module is integrated with an activation and credit scoring software module, a commissions management software module, and a coop management software module, wherein the software modules are optionally integrated with additional software modules for product and service management, and report generation. A plurality of geographically distributed dealer agents who operate retail interfaces with customers use a web-based interface with the software modules and a data link with one or more distribution centers for delivery of wireless devices from a plurality of wireless device manufacturers, and with one or more carriers providing the subscription services activated for the customers via the activation and credit scoring software module.

Owner:BURGER PHILIP G +3

Systems and methods for integrated global shipping and visibility

ActiveUS20090281857A1Promote sportsEasy to managePackaging vehiclesContainers for machinesDelivery systemIndustrial engineering

Disclosed is an integrated global shipment system that provides end-to-end visibility of the movement of a package. The integrated global shipment system employs a shipment consolidating application for integrating one or more freight tracking systems with one or more end-delivery systems. As a result, shippers are provided with complete visibility of the movement of their shipments of goods from an origin country to a destination country and till the final consignees. In addition, the integrated shipment system significantly decreases the cost of managing inventories by providing a virtual inventory solution. Under this virtual inventory solution, suppliers are able to bypass distribution centers and delay allocation of goods until after the importation of goods into a destination country.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com