Automatic goods supplying system of goods allocation line of allocation center

A distribution center and replenishment system technology, applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as errors, time-consuming and laborious, and inability to adapt to large-scale centralized distribution, so as to enhance distribution capabilities and reduce labor intensity , Improve accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

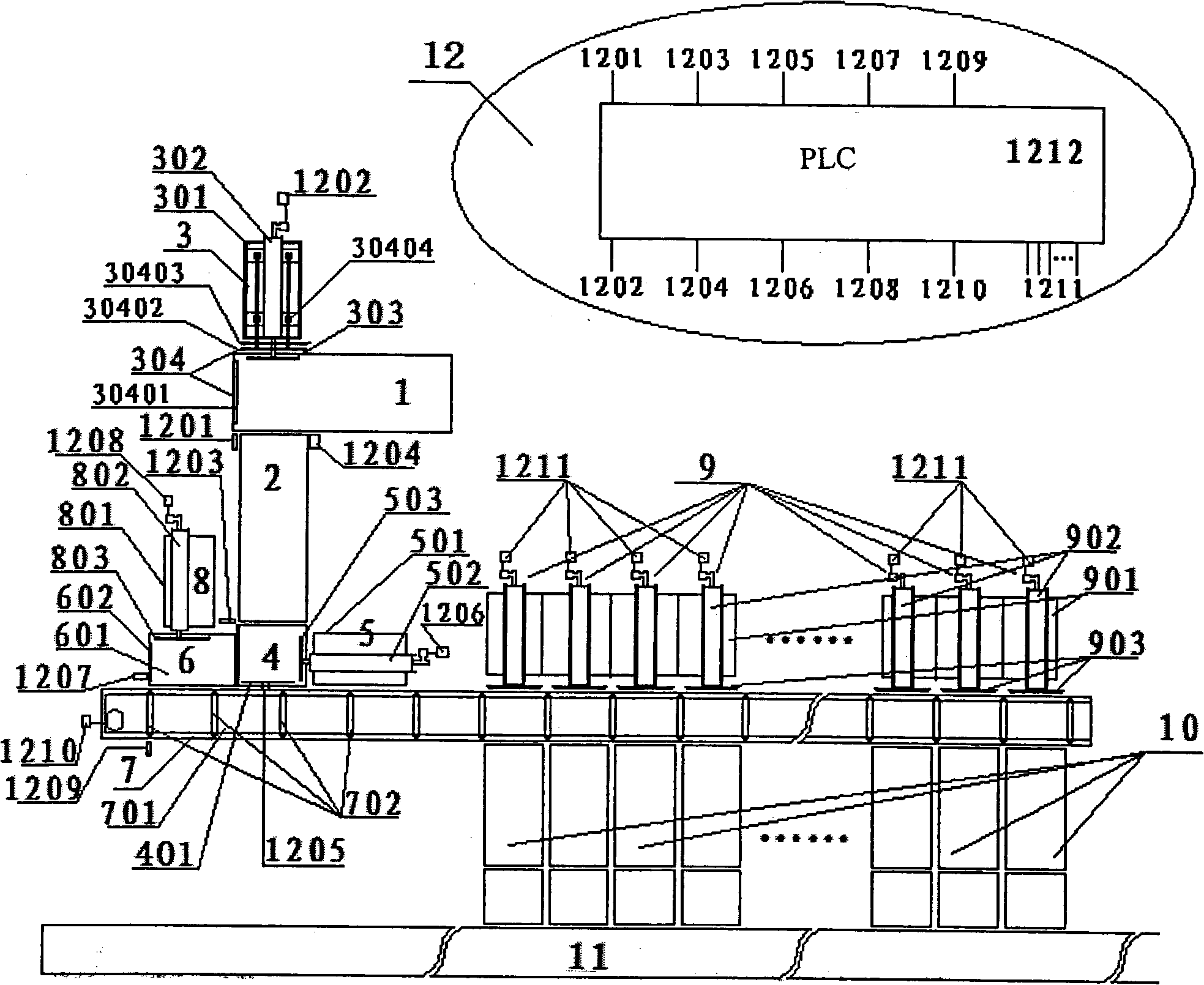

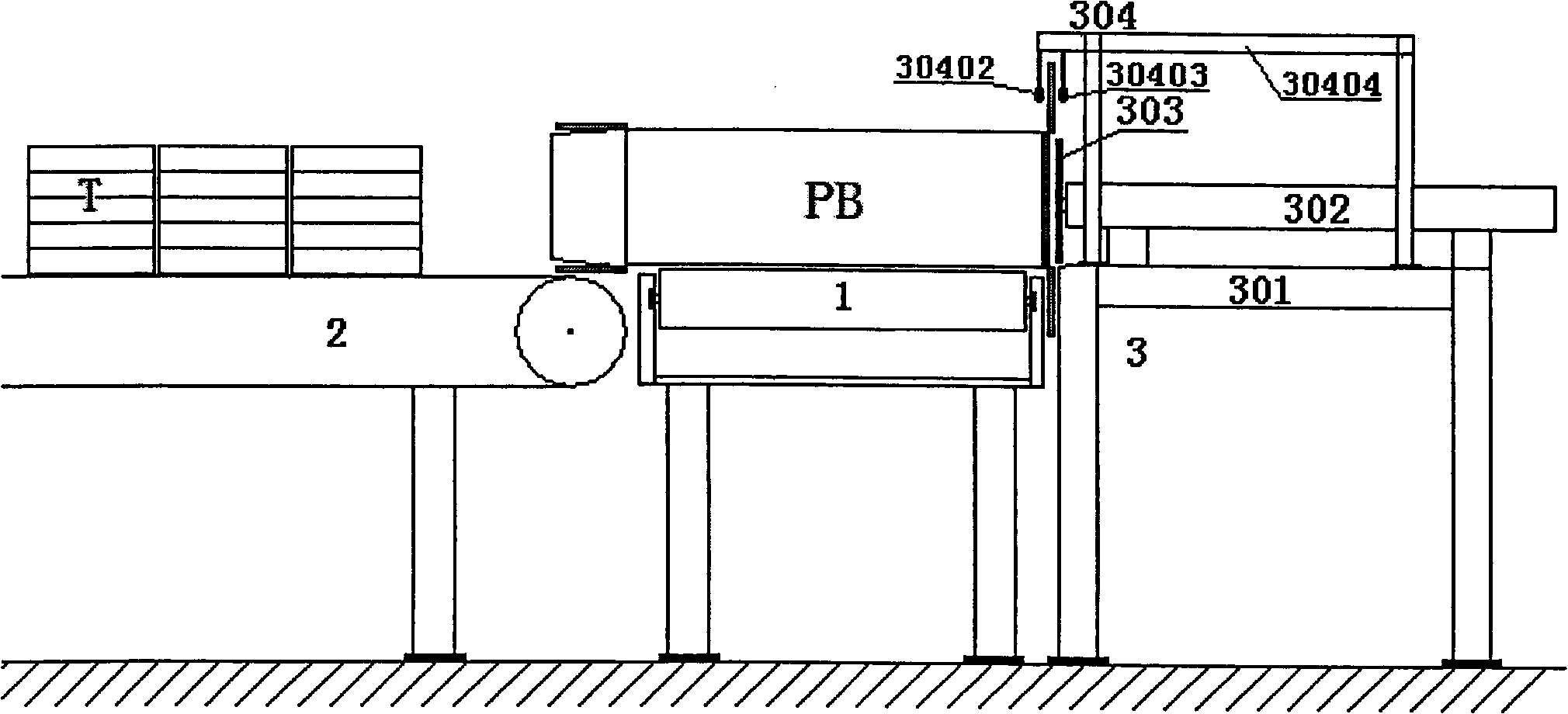

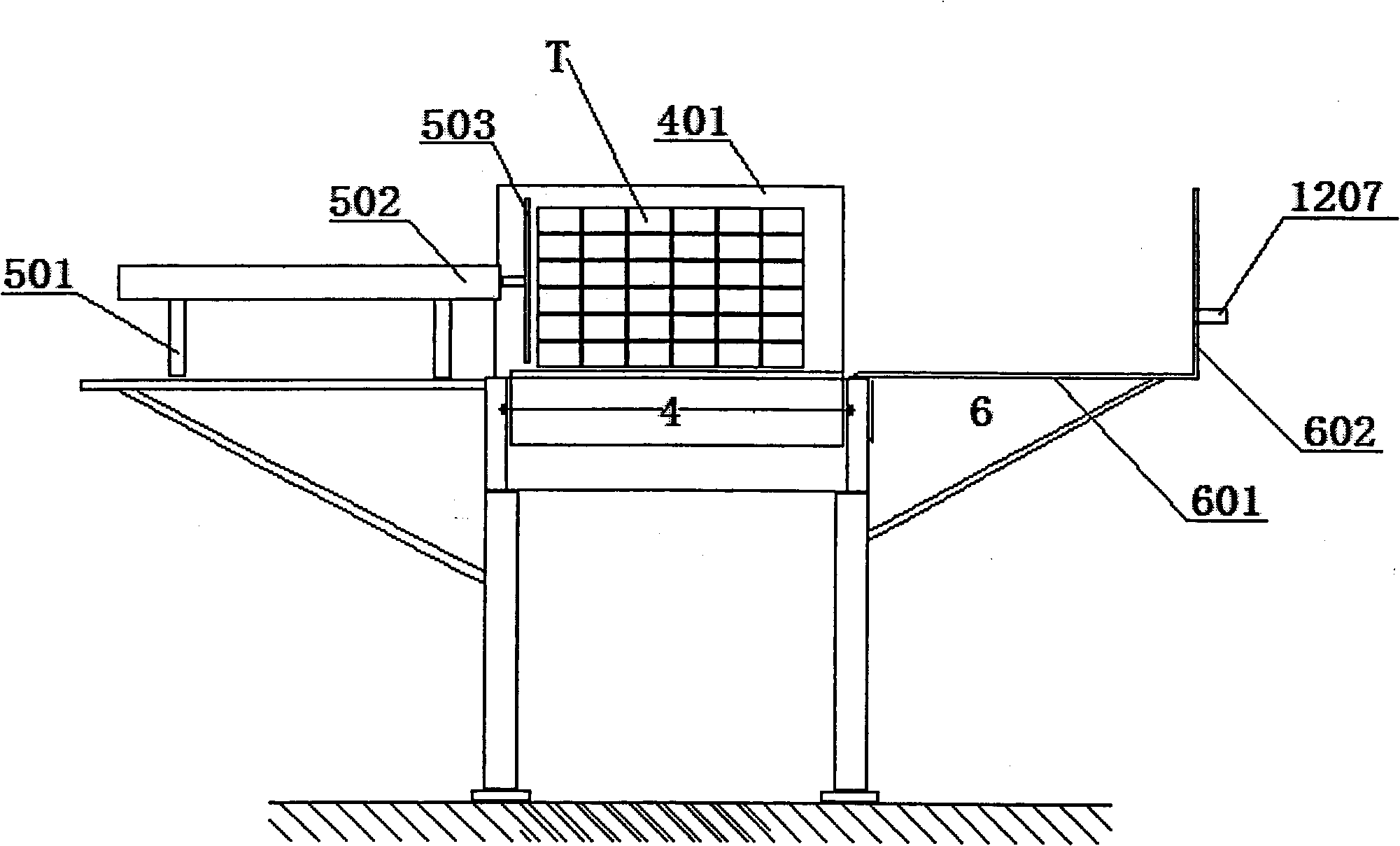

[0021] Such as figure 1 As shown, the present invention is on both sides of one end of the roller conveyor 1 and is on the same horizontal plane with the roller conveyor 1 and perpendicular to the running direction of the roller conveyor 1, and the belt conveyors for the articles in the conveying box are respectively fixedly installed. 2 and the item push-out device 3 in the box, one end of the first section belt conveyor 2 away from the side of the roller conveyor 1 is connected to the second section belt conveyor 4, and the two sides of the second section belt conveyor 4 are respectively installed with Item side push-out device 5 and item buffering platform 6 in the box, at the end of the second belt conveyor 4 and the item buffering platform 6 in the box and perpendicular to the direction of movement of the second belt conveyor 4, a grid with a grid is installed. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com