System for automatic feeding and sorting goods shelf

An automatic feeding and racking technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of reducing the efficiency of sorting and distribution operations, unable to adapt to large-scale centralized distribution, and stopping from time to time, so as to improve accuracy and work efficiency. , The effect of improving operating efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

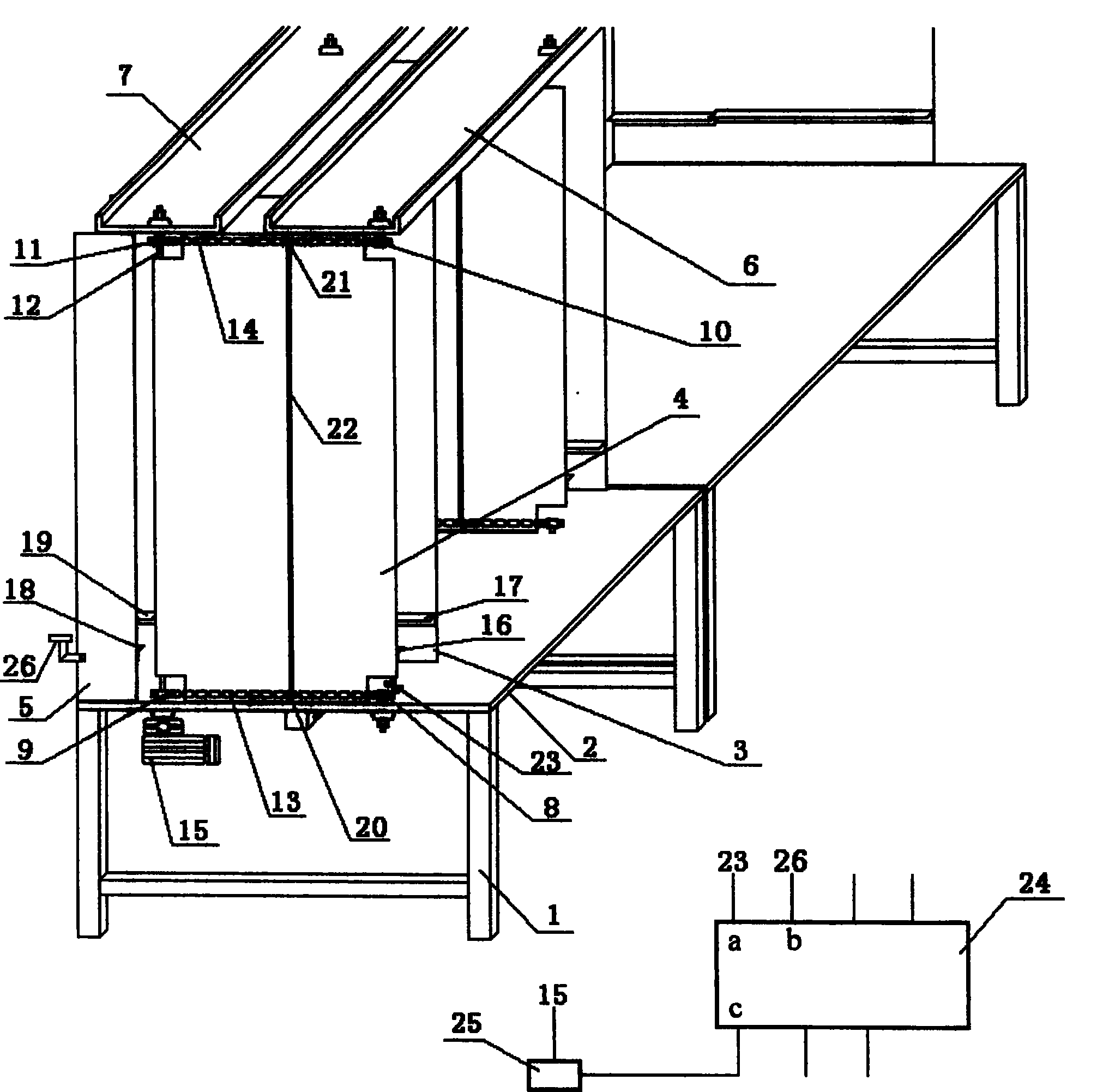

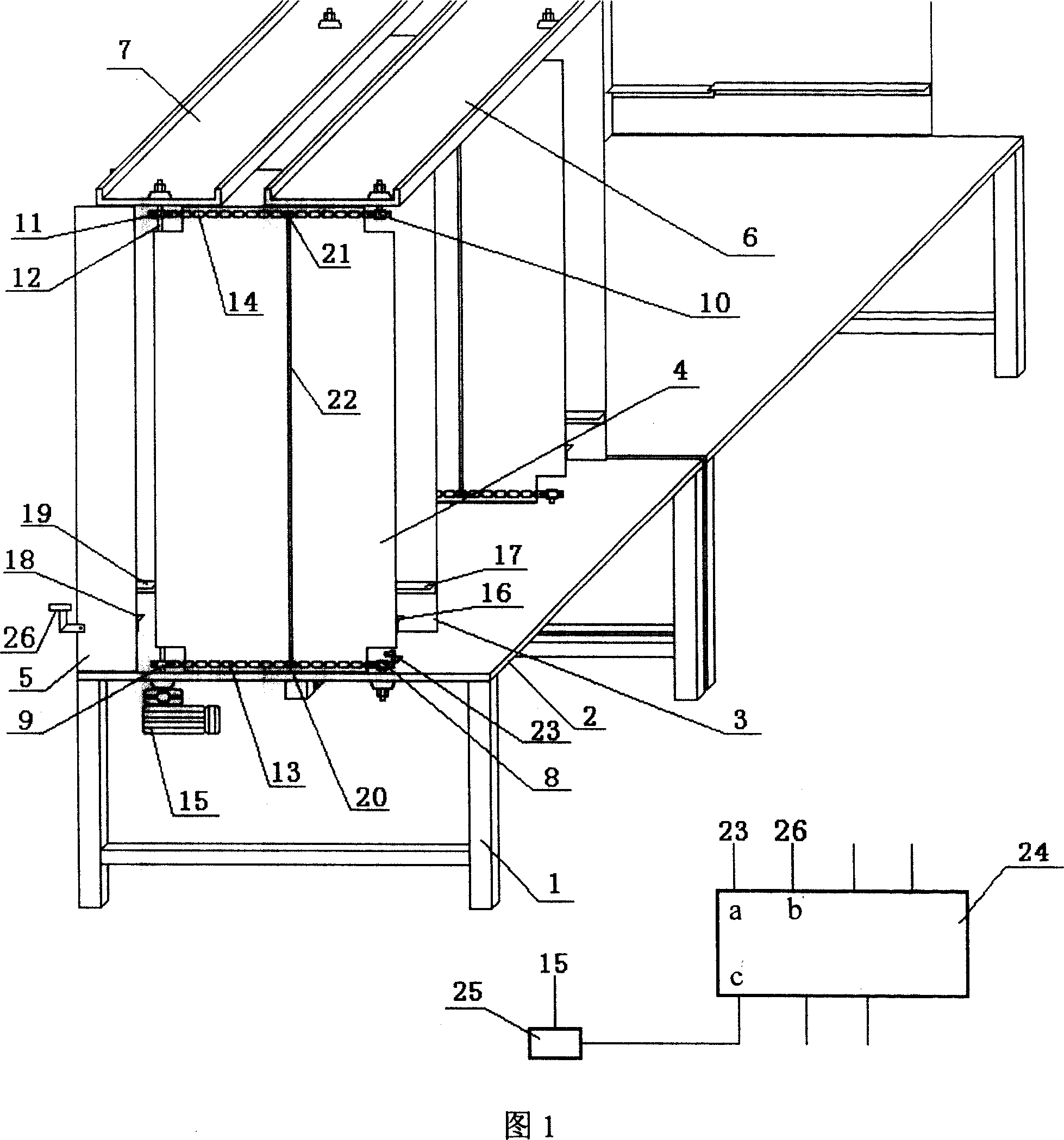

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

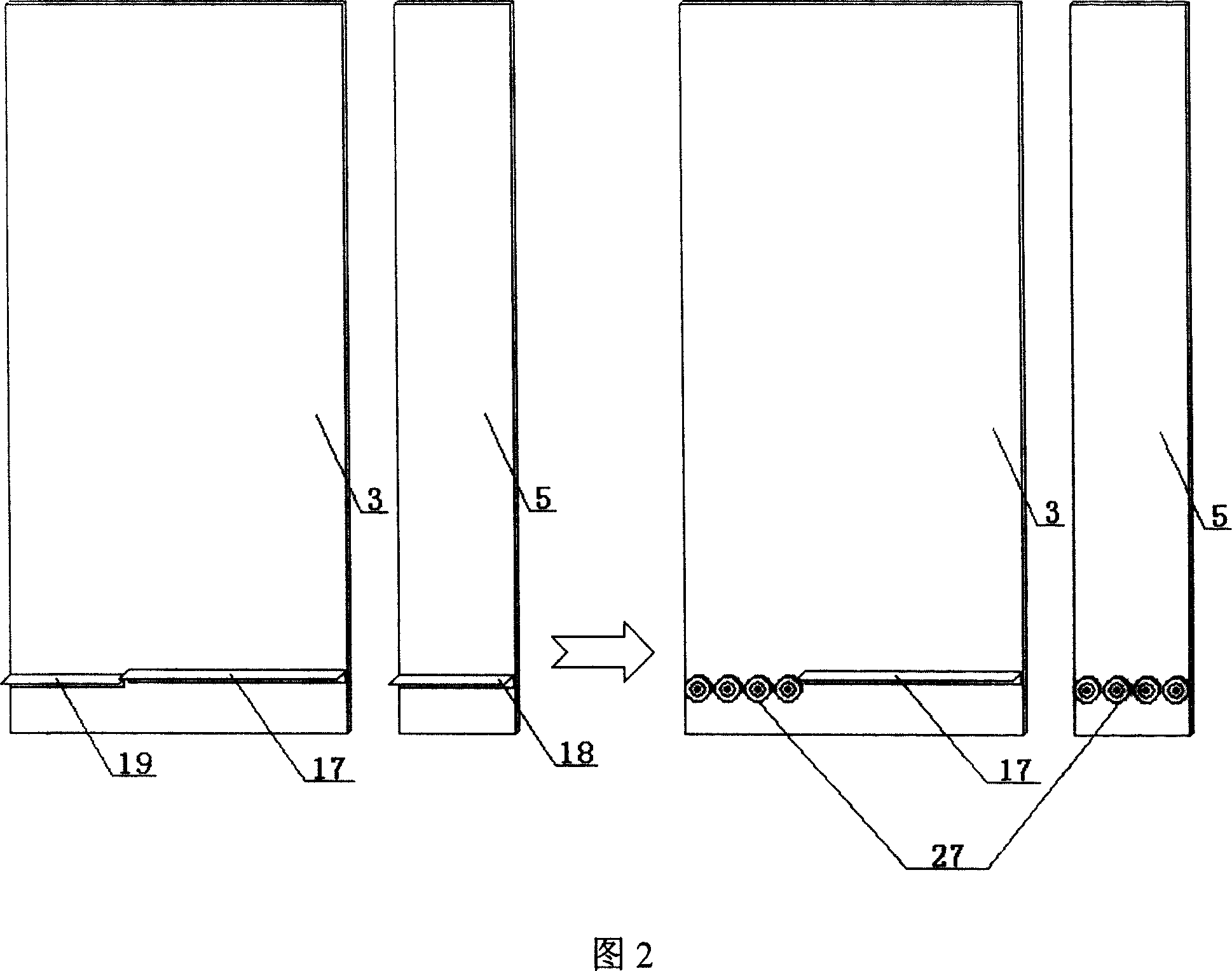

[0014] As shown in Figure 1, the present invention is installed vertically on the bottom plate 2 of support 1 with several dividing plate groups with the same structure and distributed side by side, and each dividing plate group has a No. 1 dividing plate 3 perpendicular to the base plate 2, and No. 1 partition 3 parallel distance and width less than No. 2 partition 4 of No. 1 partition 3, and No. 2 partition 4 is equipped with No. 3 partition 5 whose width is smaller than No. 2 partition 4 on one side of the same vertical plane , there is a slit between No. 2 partition 4 and No. 3 partition 5, and the width of No. 2 partition 4 and No. 3 partition 5 plus the width of the slit is equal to the width of No. 1 partition 3; There is a No. 1 top plate 6 above the partition 3 and the No. 2 partition 4, a No. 2 top plate 7 is arranged above the No. 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com