Self-propelled replenish truck system of cargo allocation line of distribution center

A distribution center, self-propelled technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of not being able to adapt to large-scale centralized distribution, errors, time-consuming and labor-intensive, etc., to improve accuracy and work efficiency, strengthen Delivery capacity and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

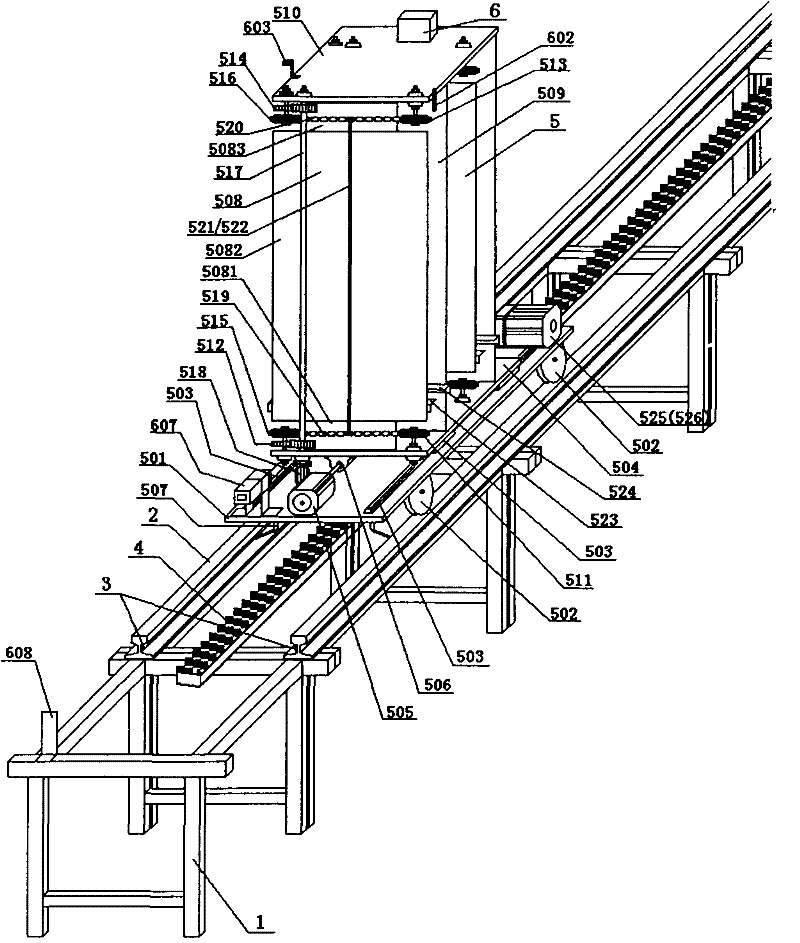

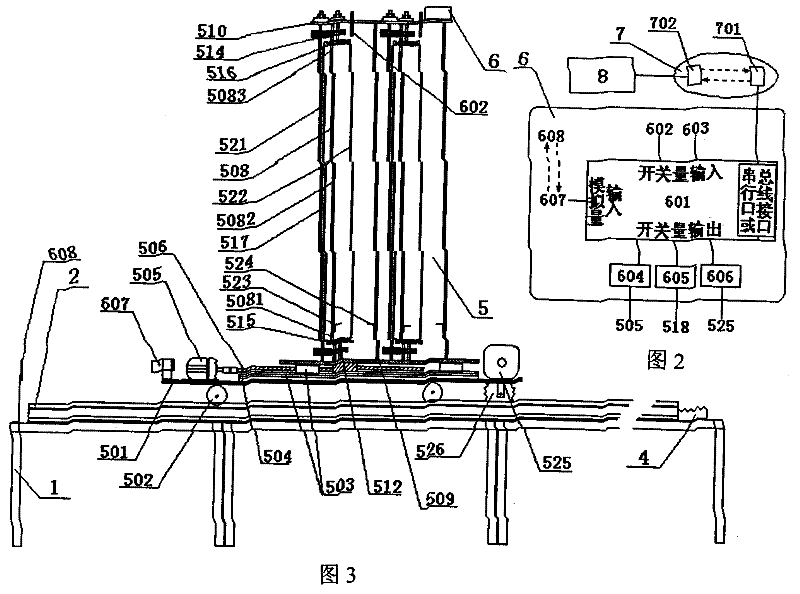

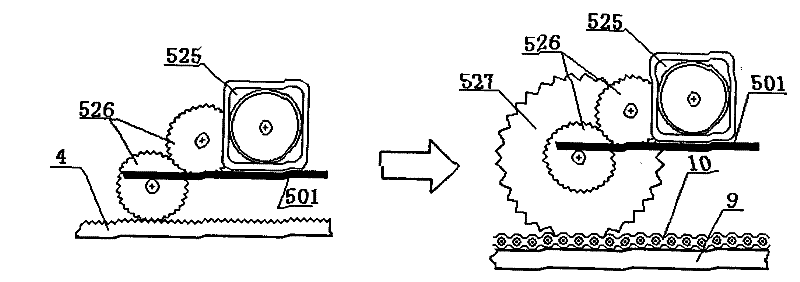

[0017] Such as figure 1 , figure 2 with image 3 As shown, the present invention is horizontally fixedly installed with two rails 2 and two power supply copper strips 3 that are insulated from the bracket 1 and the rails 2 on the bracket 1, and a rack 4 is installed between the two rails 2 on the bracket 1, Replenishment car 5 is placed on track 2, below the main chassis 501 of replenishment car 5, track roller 502 is fixedly installed, and a pair of parallel linear guide rails 503 are fixedly installed on the main chassis 501, and linear guide rail 503 and track 2 Parallel, the movable bottom plate 504 is fixedly installed on the slider of the linear guide rail 503, and the first motor 505 with a reducer is fixedly installed on the main chassis 501, and the first motor 505 is connected to the lead screw of the ball screw 506 through the reducer drive. Part, the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com