Task scheduling method of multilayer shuttle vehicle automatic warehousing system

A technology of task scheduling and warehousing system, applied in the field of logistics, can solve the problems of ignoring the advantages and characteristics of parallel pickup of multi-storey shuttle automatic warehousing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solution of the invention includes the following methods:

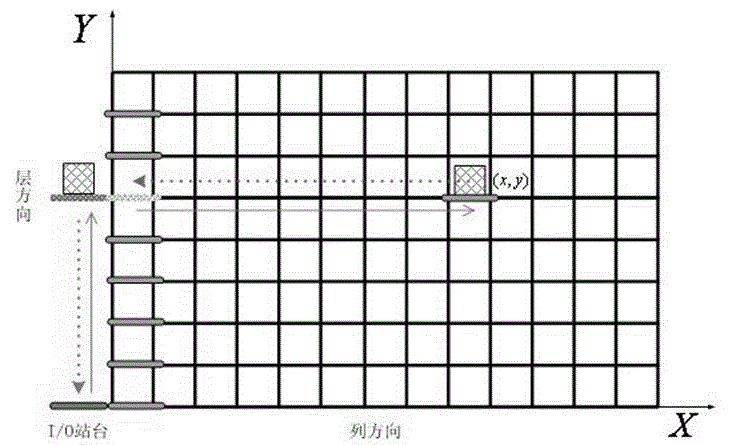

[0060] 1. Based on the characteristics of the parallel operation of the shuttle cars and the serial operation of the hoists, a time model for the out-of-warehouse operation of the multi-storey shuttle cars is established;

[0061] 2. Analyze the hoist and shuttle car separately, so as to establish a task scheduling model with the goal of the shortest total out-of-warehouse operation time, the minimum idle time of the hoist, and the minimum waiting time of the shuttle car;

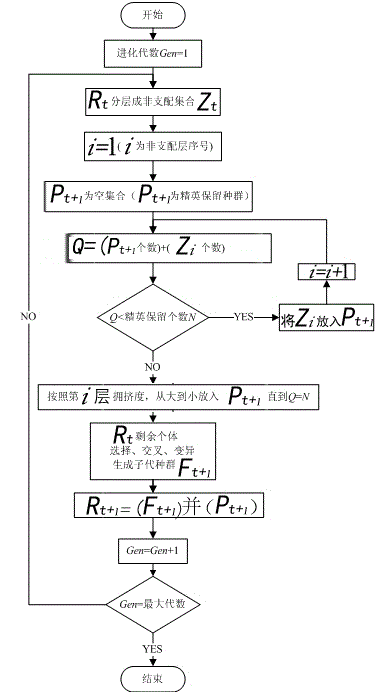

[0062] 3. Improve the elite-preserving non-inferior sorting genetic algorithm based on Pareto optimal solution to solve the model.

[0063] Further technical solutions are: In the step 1, the multi-storey shuttle car out of the warehouse operation time model includes:

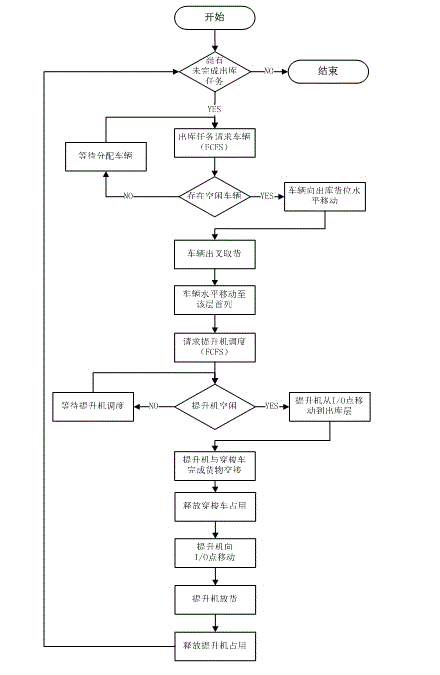

[0064] 1) From the outbound job task flow (such as figure 2 As shown in ), it can be seen that the shuttle vehicles on each floor perform a batch of outbou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com