Vehicle window sealing strip

A technology for sealing strips and car windows, which is applied in the direction of sealing devices, engine seals, vehicle parts, etc. It can solve the problems of variation, the sealing lip of the window cannot adapt to sheet metal solder joints, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

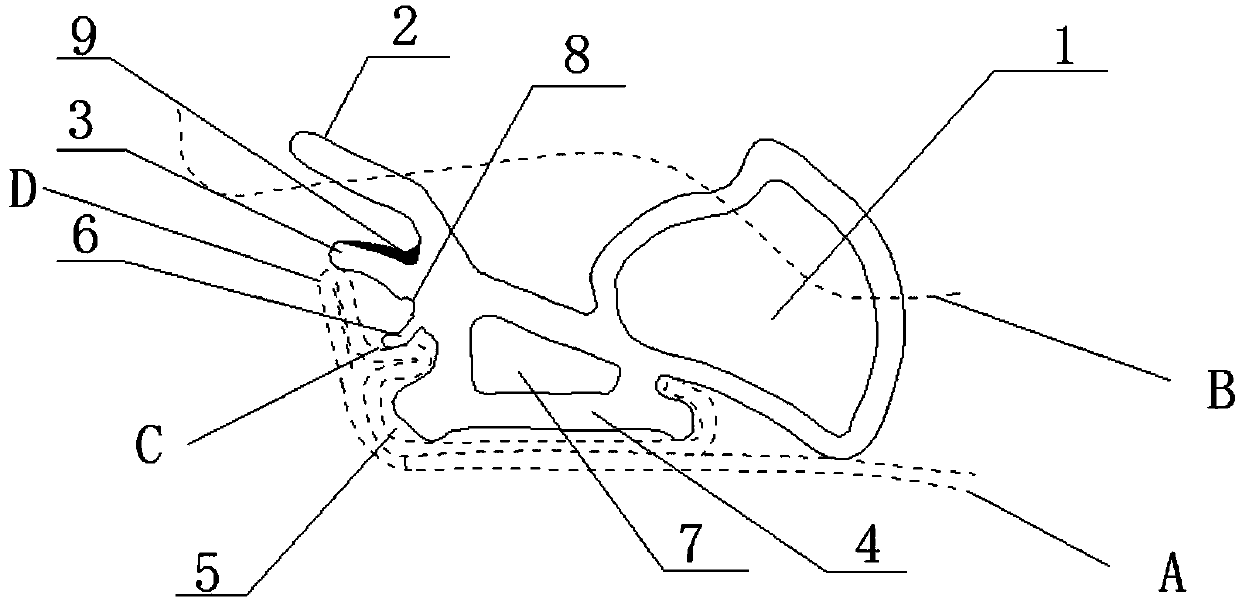

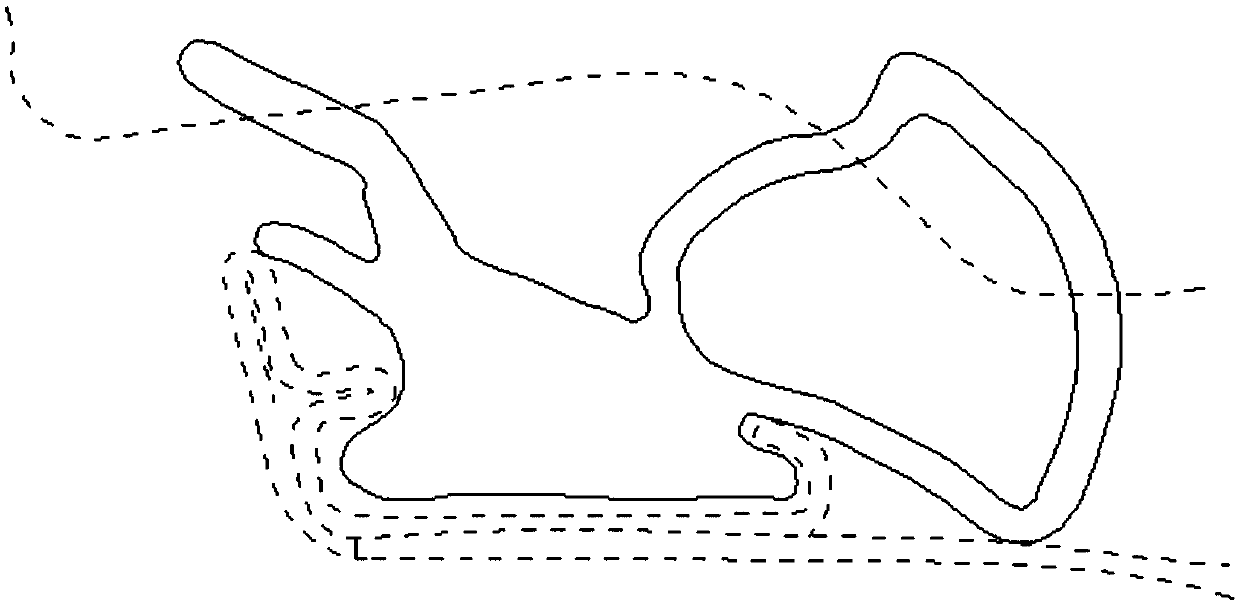

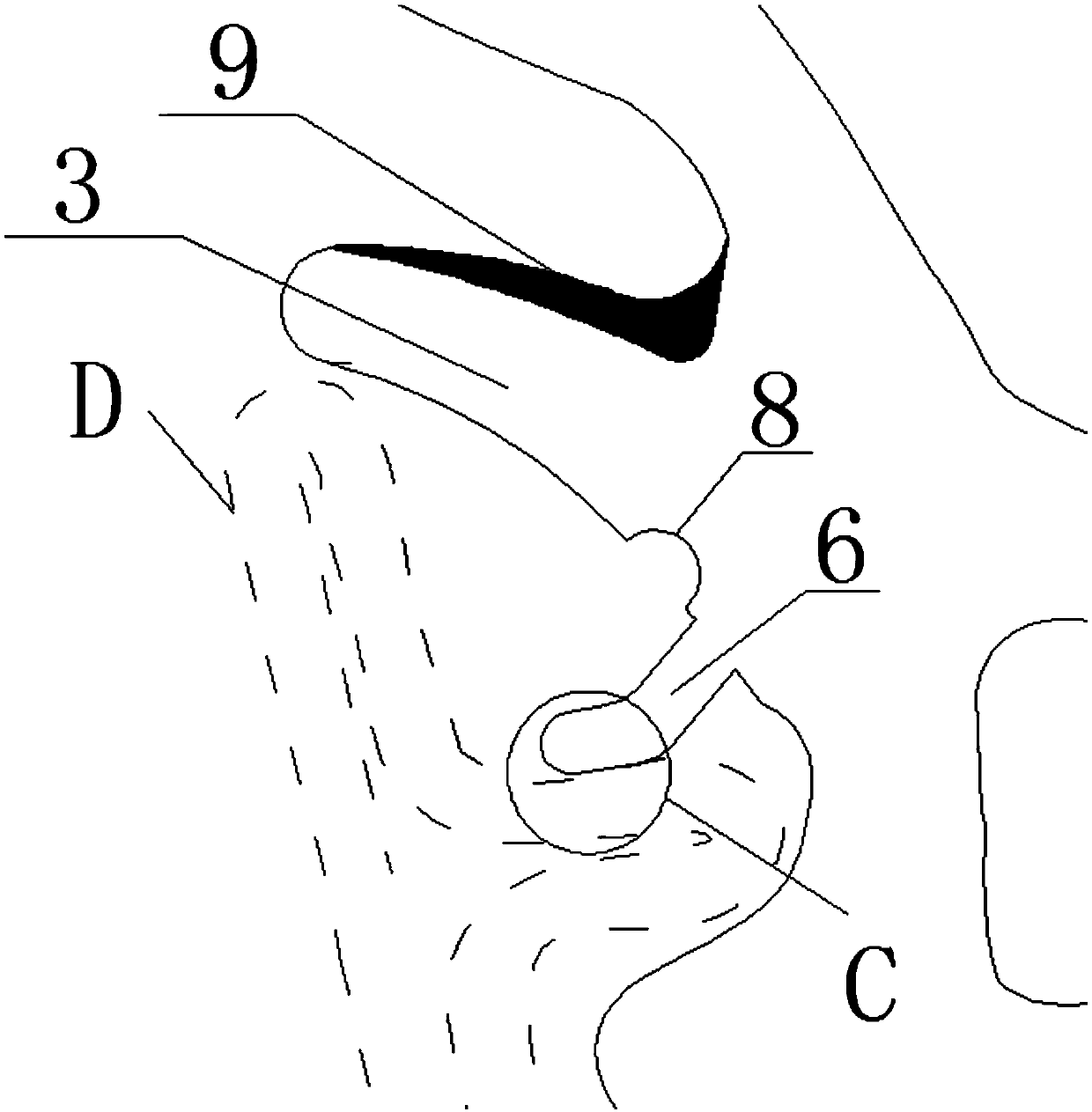

[0015] Such as figure 1 As shown, the dotted line A represents the window sheet metal, and the dotted line B represents the side panel metal of the vehicle body when the door is closed. Deformation capsule 1, snap-in portion 4 snapped to the upper slot 5 of the window sheet metal, first lip 2 that contacts and seals with the side wall sheet metal, and second lip 3 that contacts and seals with the upper part of the window guide rail. compared to figure 2 , A third lip 6 which contacts and seals with the window sheet metal is provided between the second lip 3 and the clamping portion 4 , and the thickness of the third lip 6 is smaller than that of the second lip 3 .

[0016] Since there is no need to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com