Composite cathode material of lithium ion battery and preparation method thereof

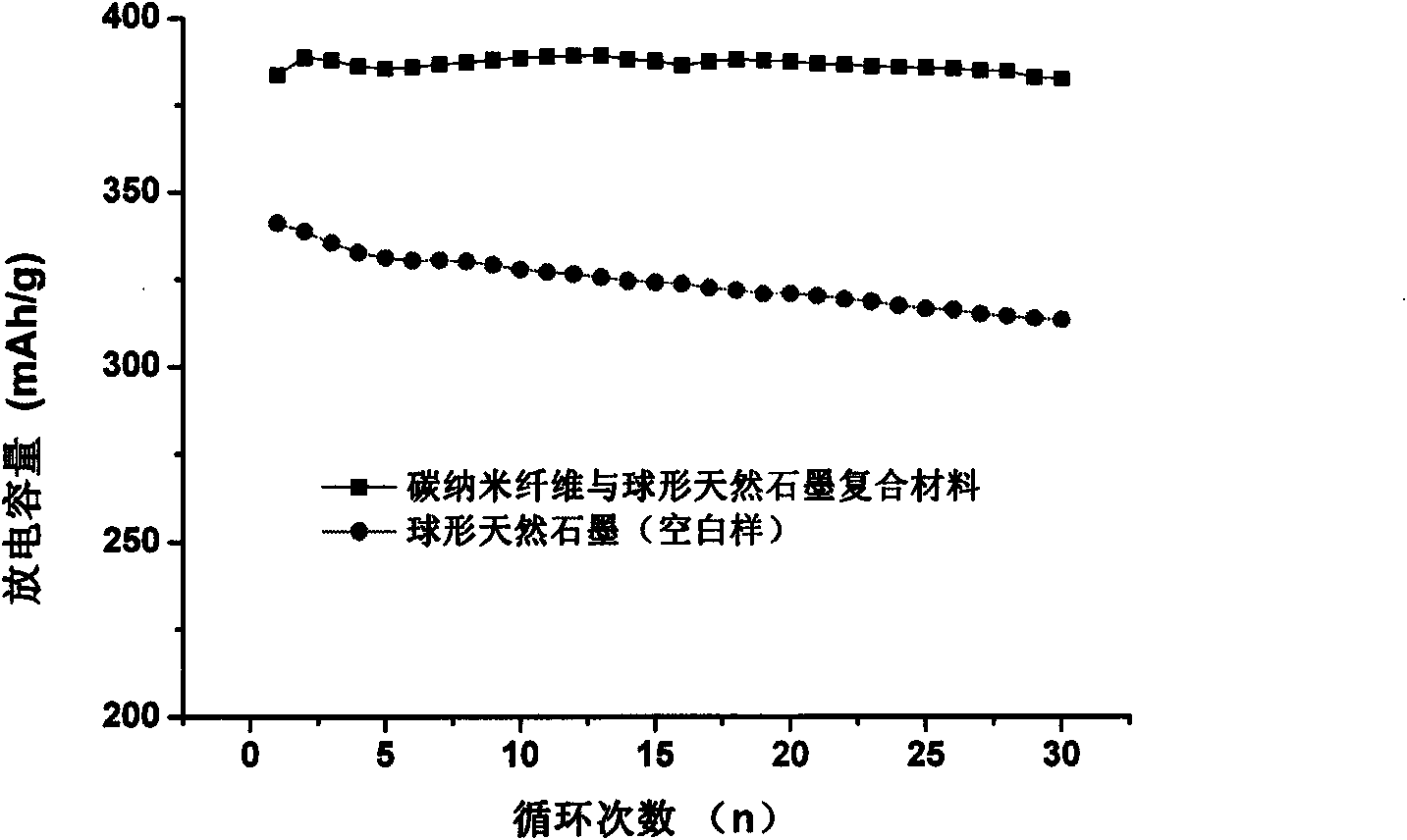

A technology of lithium-ion batteries and negative electrode materials, applied in the field of nanomaterials and chemical power sources, can solve the problem of reducing the first cycle efficiency and cycle stability of negative electrode materials, high power characteristics of negative electrode materials and poor rapid charge and discharge capabilities, uniform distribution and dense The degree can not be effectively controlled and other problems, to achieve the effect of improving distribution uniformity and density, improving high-power characteristics, and facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Components and mass percentages thereof of a lithium-ion battery negative electrode composite material are:

[0032] Negative electrode material 90wt.%

[0033] Carbon Nanofiber 10wt%

[0034] Wherein: the negative electrode material is spherical natural graphite with an average particle size of 20 microns.

[0035] The concrete steps of a kind of preparation method of negative electrode composite material of lithium ion battery are as follows:

[0036] (1) Prepare the mixed solution of negative electrode material and catalyst

[0037] According to negative electrode material spherical natural graphite: the mass ratio of catalyst nickel nitrate is the ratio of 100:0.1, and the average particle diameter of spherical natural graphite is 20 microns, and spherical natural graphite and nickel nitrate are mixed and added in the water solvent and mixed and stirred evenly to prepare into a mixed solution with a concentration of 0.01g / ml;

[0038](2) Remove the solvent

[0...

Embodiment 2

[0043] Components and mass percentages thereof of a lithium-ion battery negative electrode composite material are:

[0044] Carbon anode material 95wt.%

[0045] Multi-walled carbon nanotubes 5wt%

[0046] Wherein: the carbon negative electrode material is graphitized mesophase carbon microspheres with an average particle size of 15 microns.

[0047] The concrete steps of a kind of preparation method of negative electrode composite material of lithium ion battery are as follows:

[0048] (1) Prepare the mixed solution of negative electrode material and catalyst

[0049] With embodiment 1, feature is: negative electrode material graphitization mesophase carbon microsphere: the mass ratio of catalyst ferrocene is 100: 1, and the average particle diameter of graphitization mesophase carbon microsphere is 15 microns, and graphitization mesophase Carbon microspheres and ferrocene are mixed in acetone solvent to prepare a mixed solution with a concentration of 1g / ml;

[0050] (2...

Embodiment 3

[0055] Components and mass percentages thereof of a lithium-ion battery negative electrode composite material are:

[0056] Negative material 85wt.%

[0057] SWNT 15wt%

[0058] Among them, the negative electrode material is LiTi 2 o 4 , with an average particle size of 0.1 microns.

[0059] The concrete steps of a kind of preparation method of negative electrode composite material of lithium ion battery are as follows:

[0060] (1), prepare the mixed solution of negative electrode material and catalyst

[0061] With embodiment 1, feature is: LiTi 2 o 4 : The mass ratio of catalyst ferrocene is 100:10, LiTi 2 o 4 The average particle size of LiTi is 0.1 μm, and the LiTi 2 o 4 Mix with ferrocene in solvent acetone to make a mixed solution with a concentration of 5g / ml;

[0062] (2), remove the solvent

[0063] With embodiment 2;

[0064] (3), chemical vapor deposition

[0065] Same as embodiment 1, the feature is: first pass into high-purity helium, after the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com