Seedling sending, taking and delivering device for pressing type seedling taking full-automatic seed tray seedling transplanter

A technology for plug seedlings and transplanting machines, applied in the directions of transplanting machinery, planting methods, applications, etc., can solve the problems of restricting the development of the vegetable industry, mismatching planting methods, and high control system requirements, and achieves low cost and seedling retrieval. The effect of high efficiency and low seedling injury rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

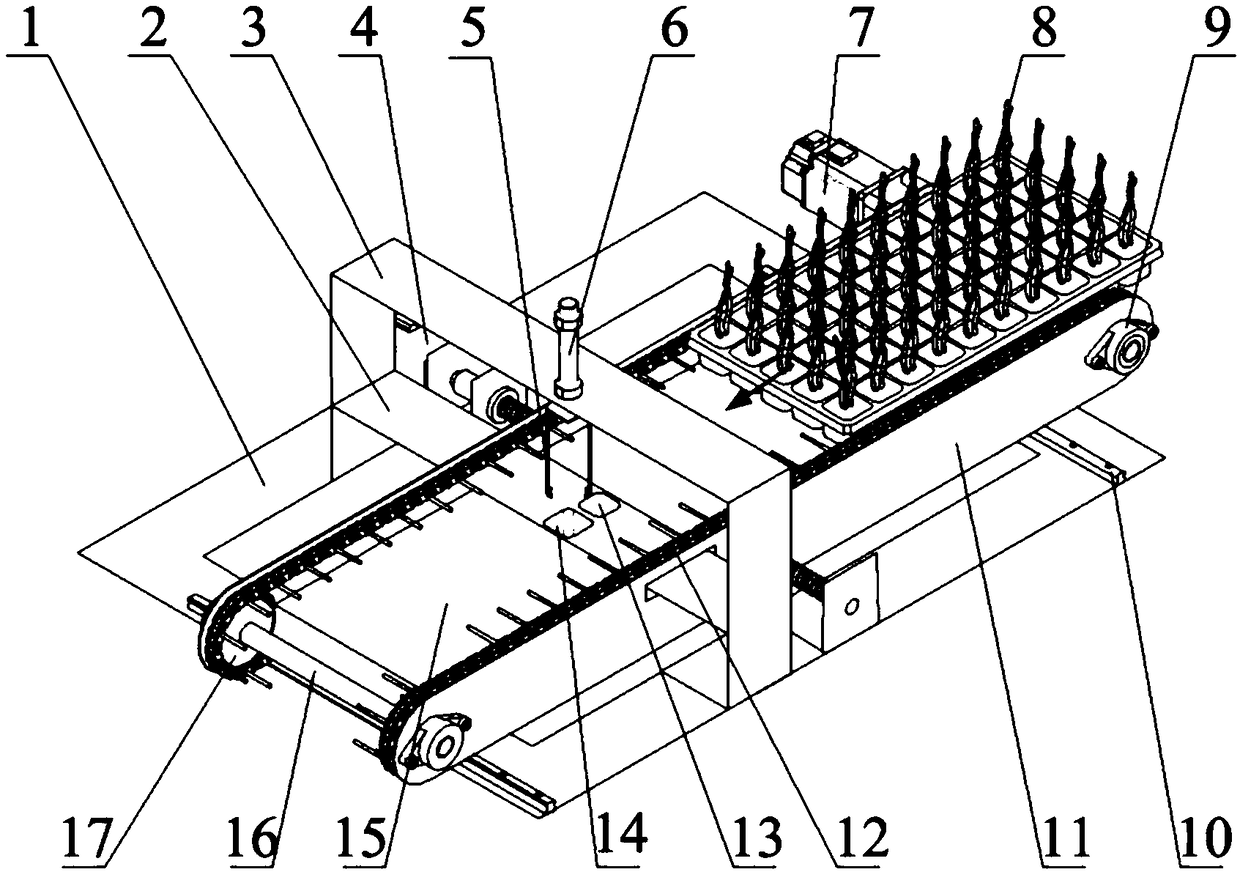

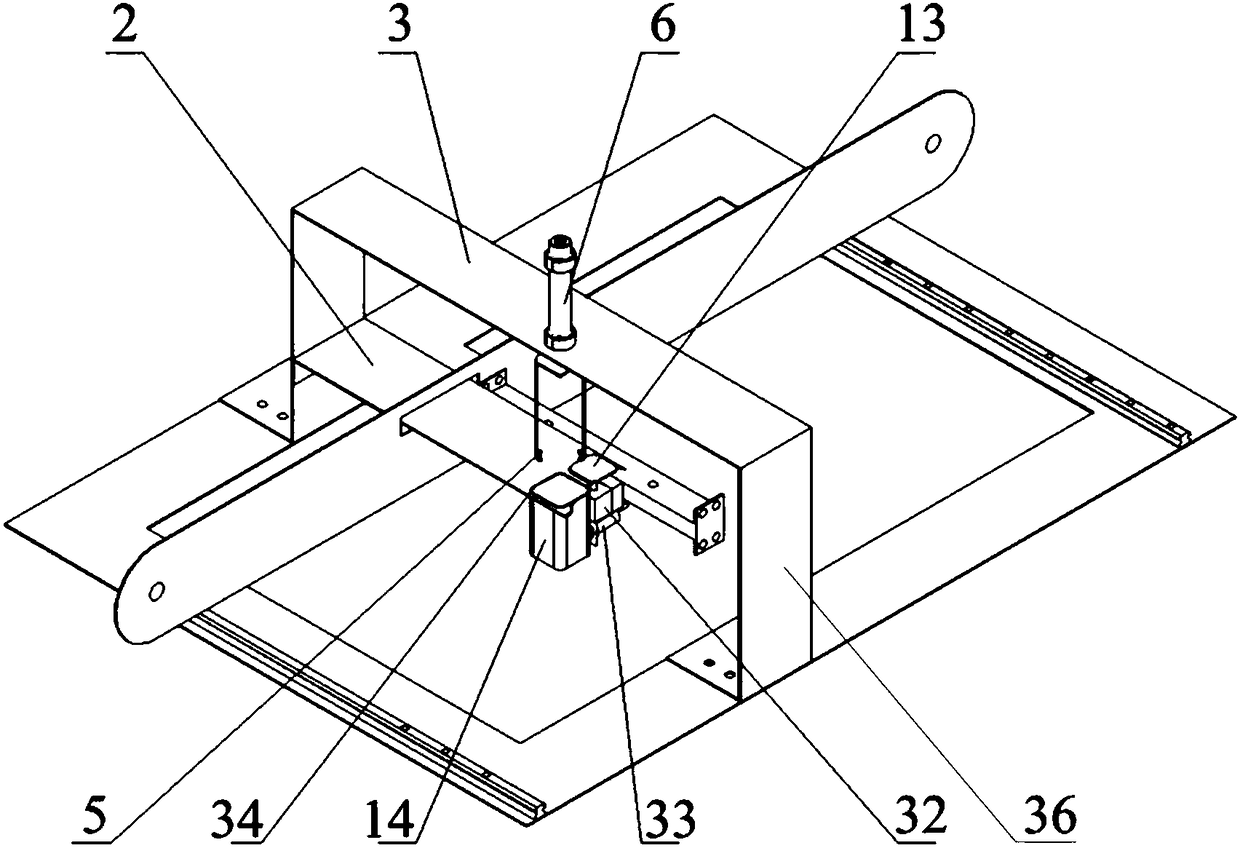

[0056] Such as figure 1 As shown, a seedling-feeding and seedling-feeding device of a fully automatic plug-in tray seedling transplanter of a down-pressing type includes a frame 1, a seedling-feeding mechanism and a seedling-feeding and seedling throwing mechanism. The pot seedling 35 in the matrix type hole seedling dish 8 of row is thrown in the planting mechanism of transplanting machine.

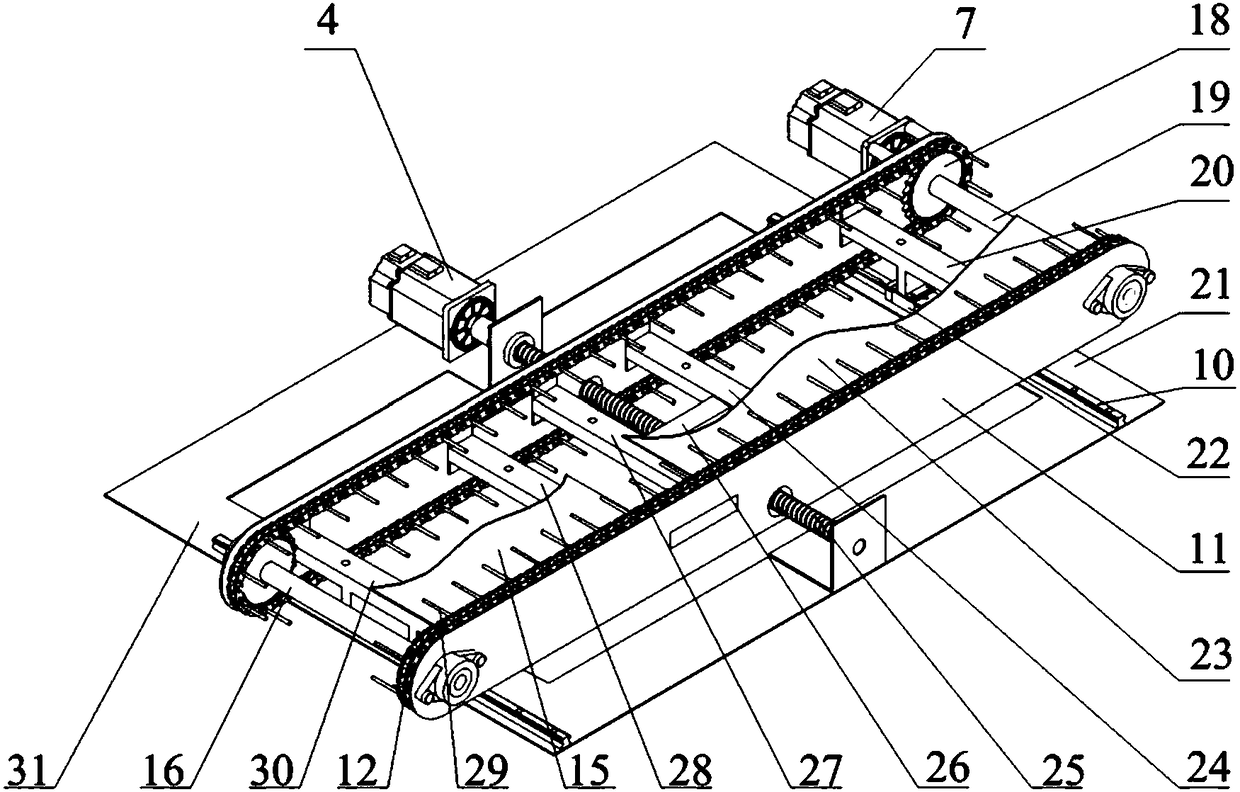

[0057] Such as figure 2 As shown, the frame 1 includes a frame rear beam 21, a frame front beam 31, and left and right longitudinal beams.

[0058] Described seedling sending mechanism comprises screw drive motor 4, chain drive motor 7, slide rail 10, side plate 11, chain 12, front bottom plate 15, driven shaft 16, drive shaft 19, rear slide rail support 20, slide rail slide Block 22, rear bottom plate 23, first connecting beam 24, ball screw 25, lead screw sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com