Bagged material car-loading system and method

A material and cargo technology, applied in the field of automatic control, can solve the problems of insecurity and low loading efficiency of bagged materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

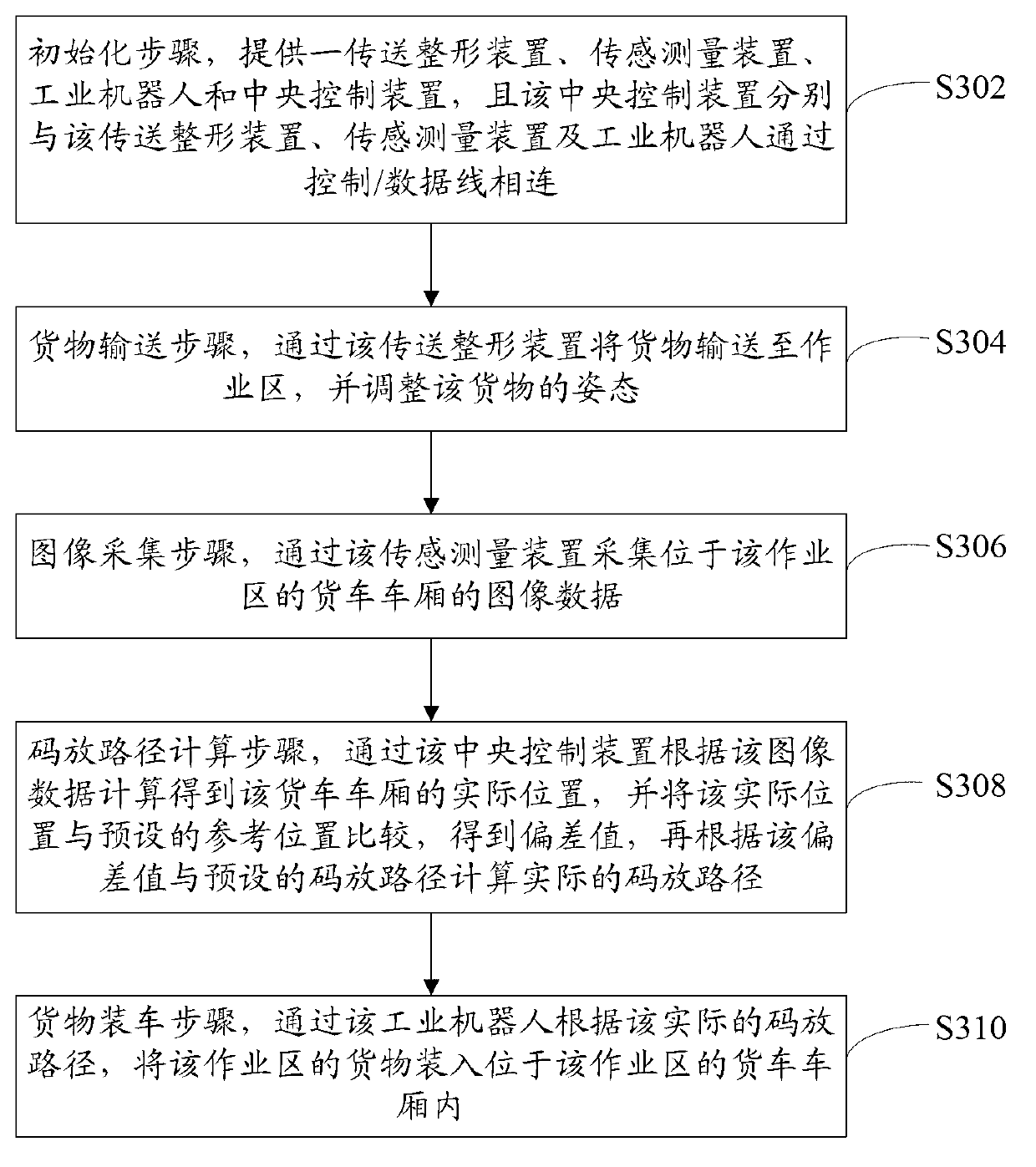

[0048] The technical solution of the bagged material loading system and method will be described in detail below in conjunction with specific embodiments and accompanying drawings, so as to make it more clear.

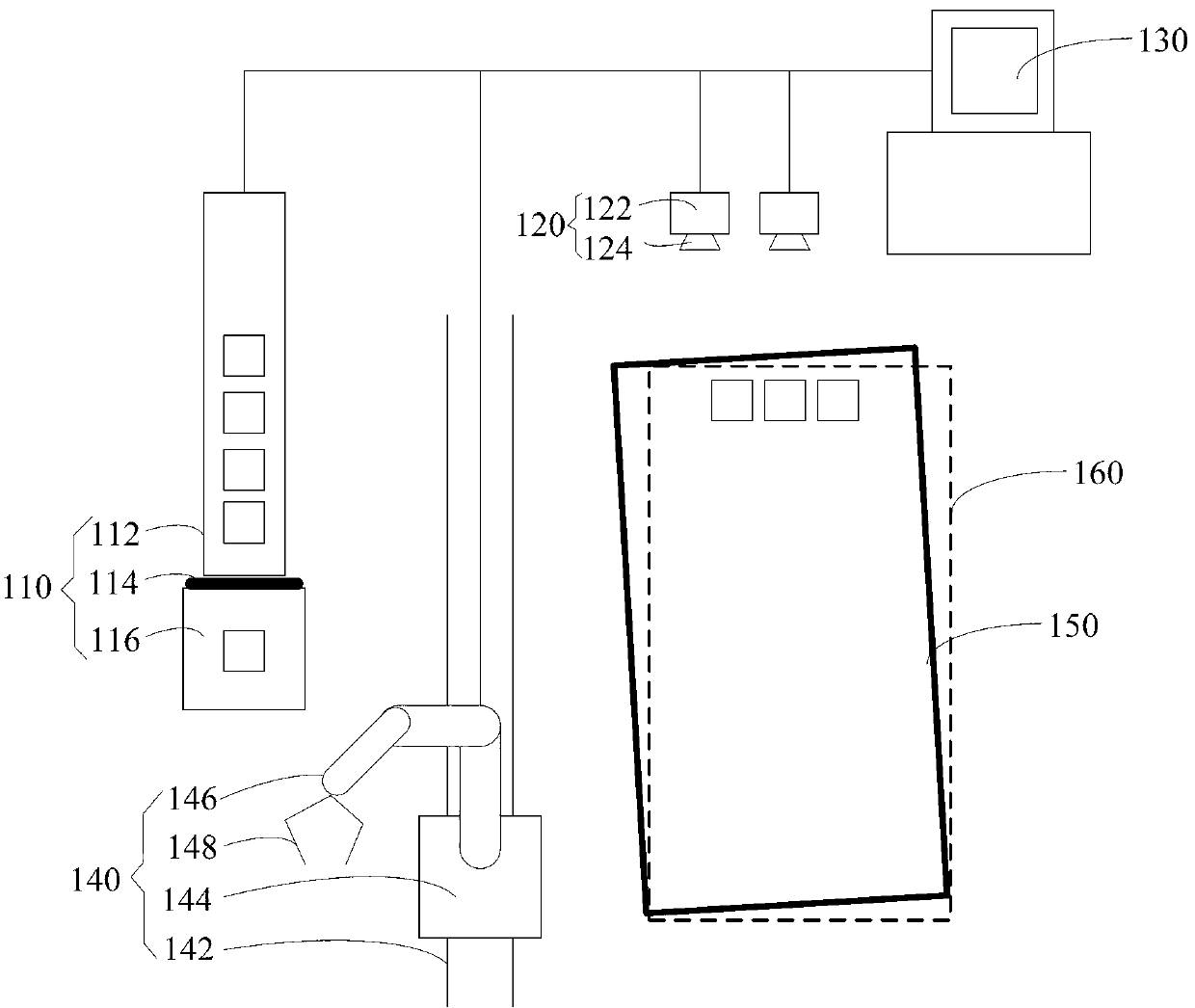

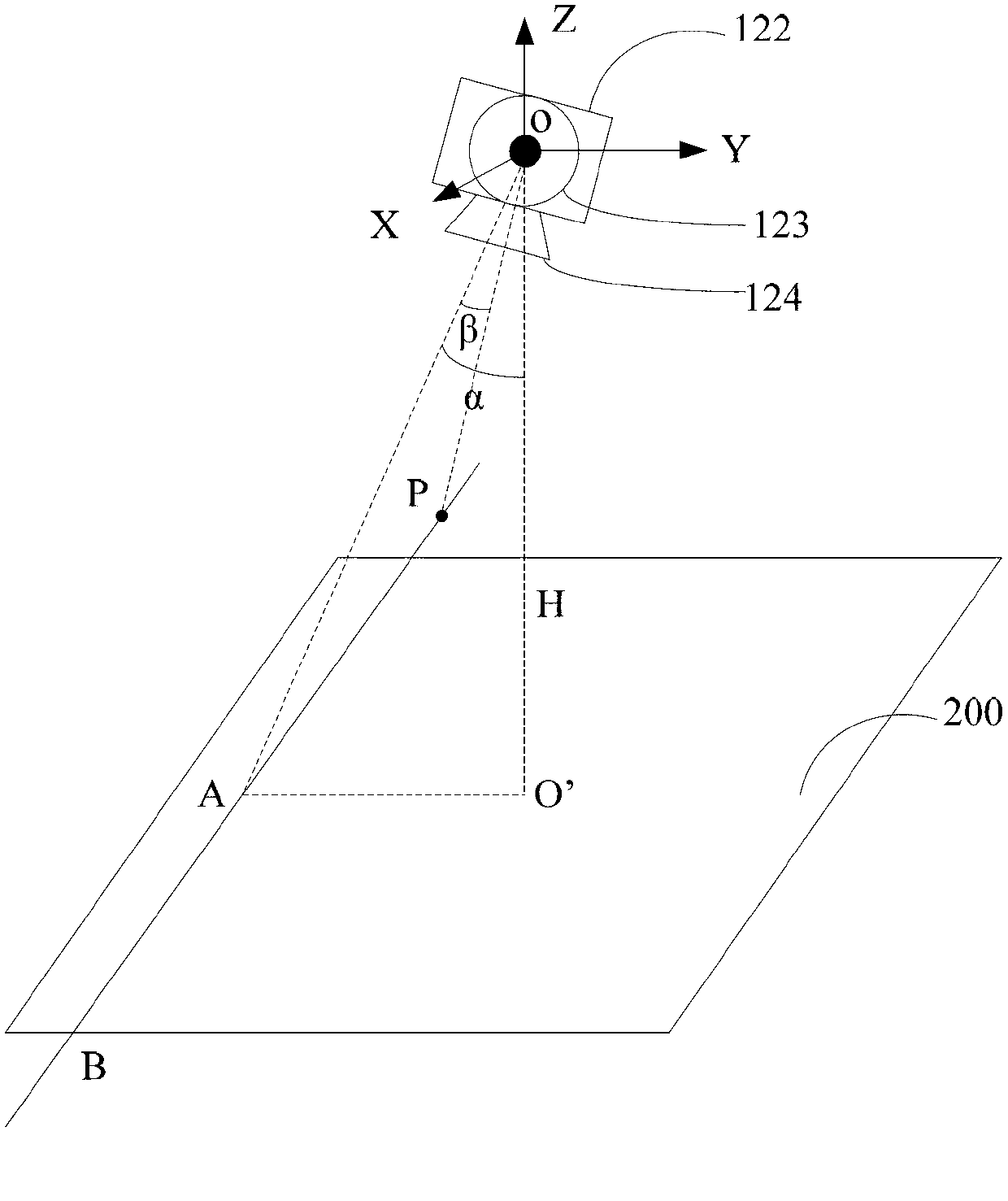

[0049] Such as figure 1 As shown, it is a schematic structural diagram of a bagged material loading system in an embodiment. The bagged material loading system includes a conveying and shaping device 110 , a sensing and measuring device 120 , a central control device 130 and an industrial robot 140 . The central control device 130 is respectively connected with the transmission shaping device 110 , the sensing and measuring device 120 and the industrial robot 140 through control / data lines.

[0050] Wherein, the conveying and shaping device 110 is used to transport the goods to the work area and adjust the attitude of the goods.

[0051] In this embodiment, the conveying and shaping device 110 includes a conveyor belt device 112 , shaping rollers (not shown in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com