Sea cucumber pretreatment technology for mechanically processing and corresponding equipment thereof

A mechanical processing and sea cucumber technology, which is applied in the sea cucumber pretreatment process improvement method and its corresponding equipment field, can solve the problems that affect the normal progress of the follow-up process, the ginseng body is soft and easy to damage, and the sea cucumber waits for a long period of cooking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

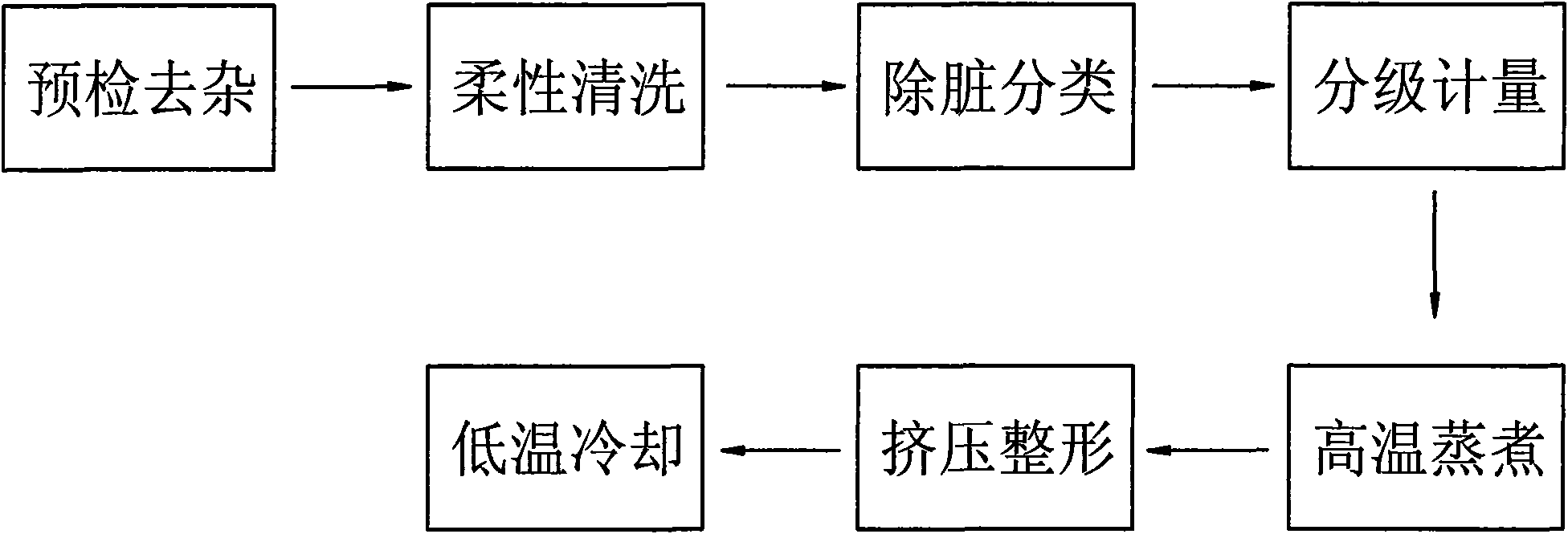

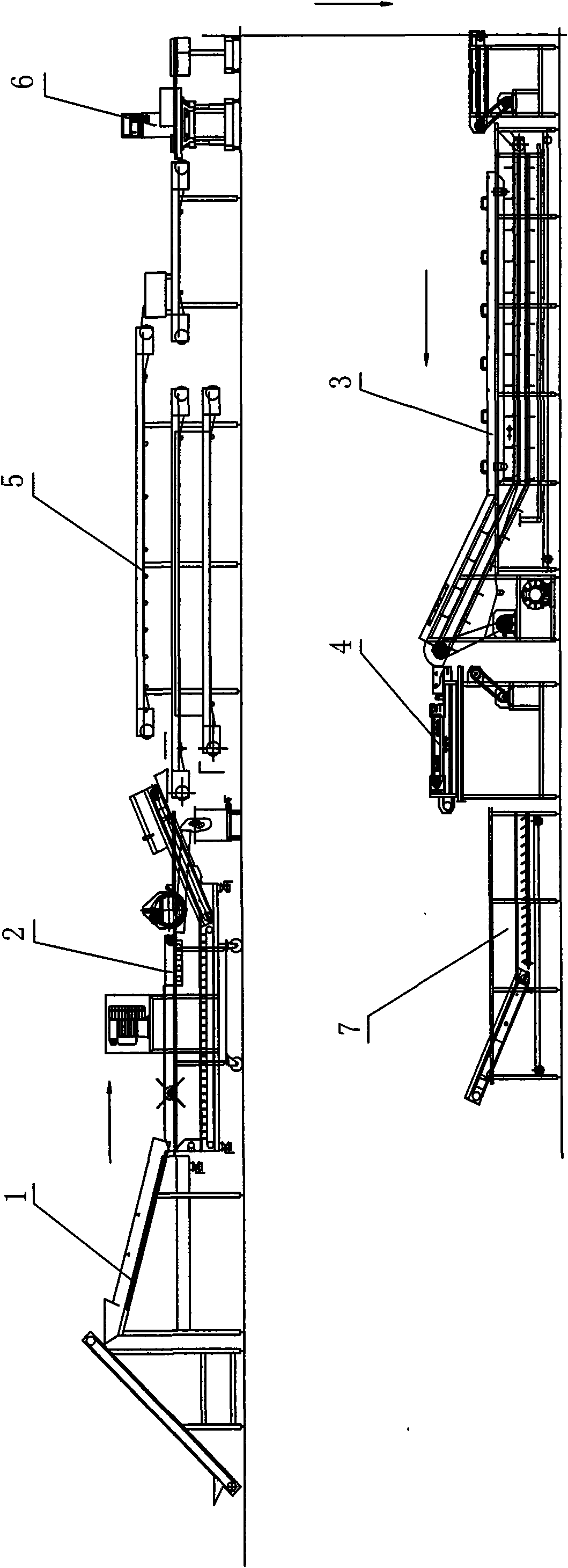

[0059] The method and equipment structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

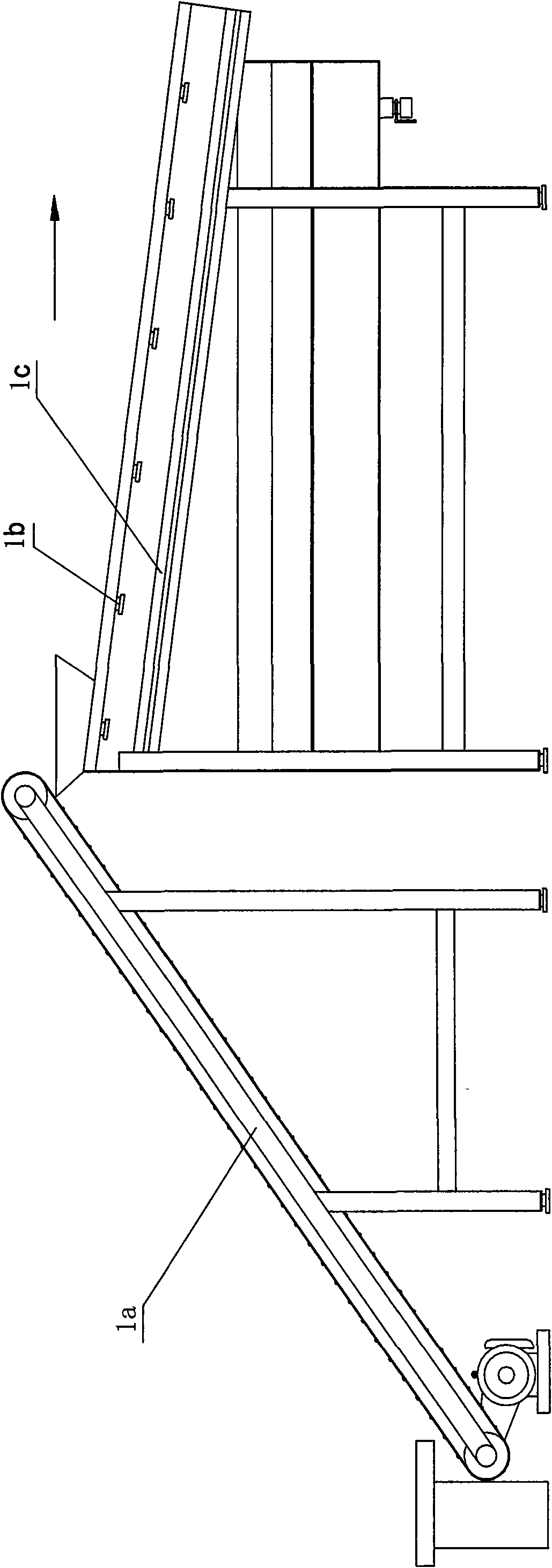

[0060] A pre-inspection and impurity removal device completed according to the sea cucumber pre-treatment machining process according to claim 1, the pre-inspection device 1 includes two parts: an automatic feeding mechanism and a screening mechanism connected successively;

[0061] The automatic feeding mechanism is a roller conveyor belt 1a structure powered by a motor;

[0062] The screening mechanism is that a screening slideway 1c is composed of pipes with high entrance, high outlet and low inclination, a spraying system 1b is set above the screening slideway 1c, and a sundry tank is arranged below the screening slideway 1c; The screening chute 1c is made of stainless steel pipes with a diameter of 30 to 50 mm and a pipe wall spacing of 7 to 20 mm.

[0063] A flexible cleaning device completed according to the sea c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com