Mechanical vegetable and vine plant chopping machine

A mechanical shredder technology, applied in metal processing, etc., can solve problems such as waste of labor, safety, hidden dangers, etc., and achieve the effect of improving shredding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

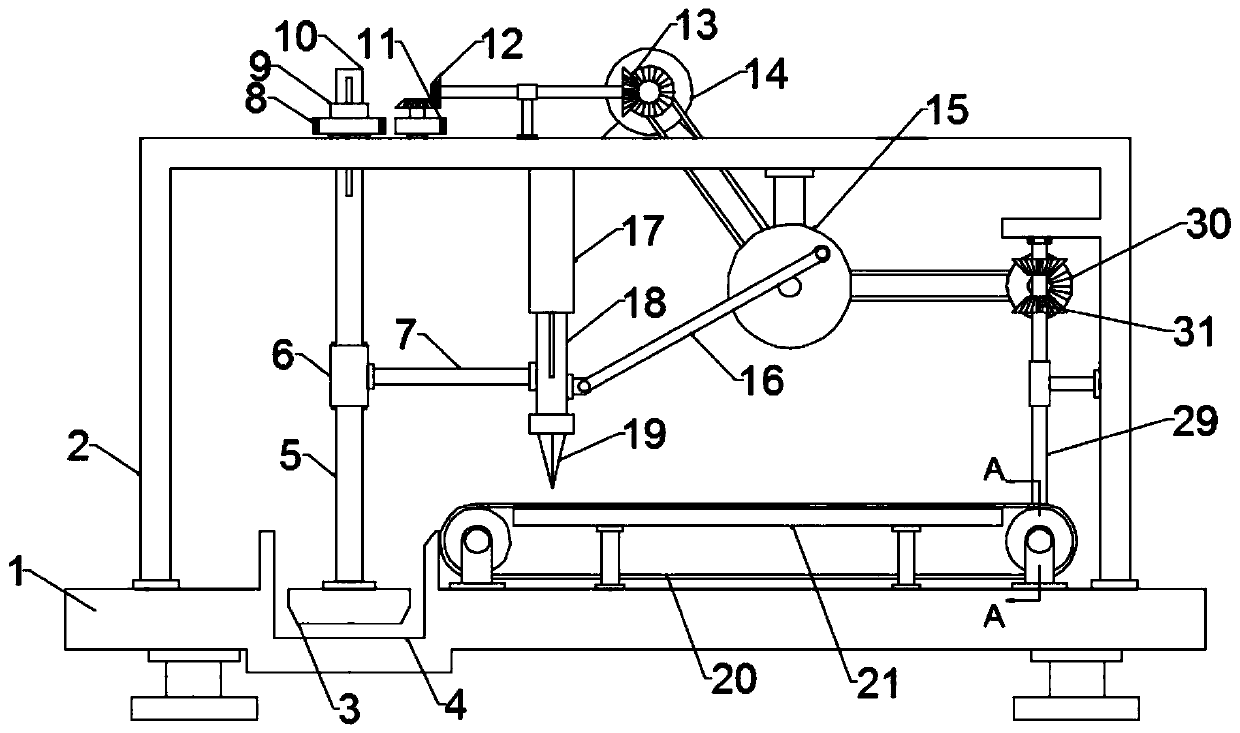

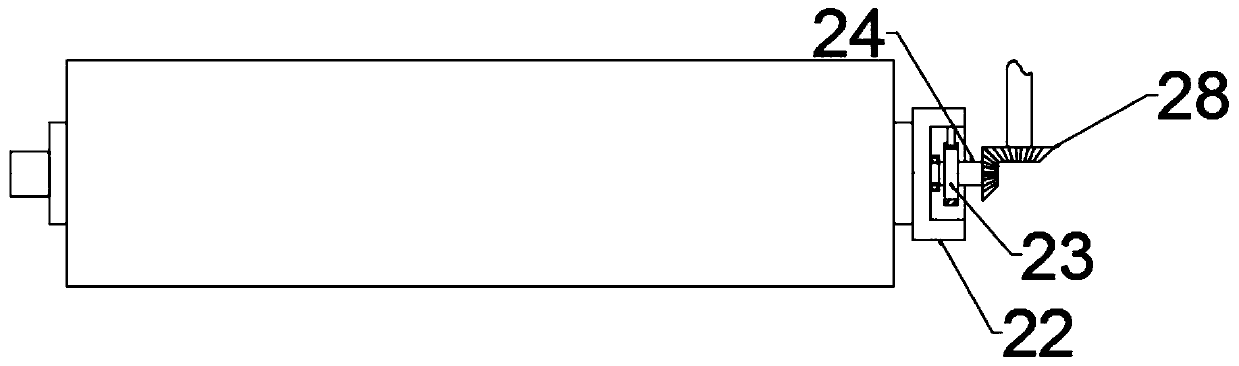

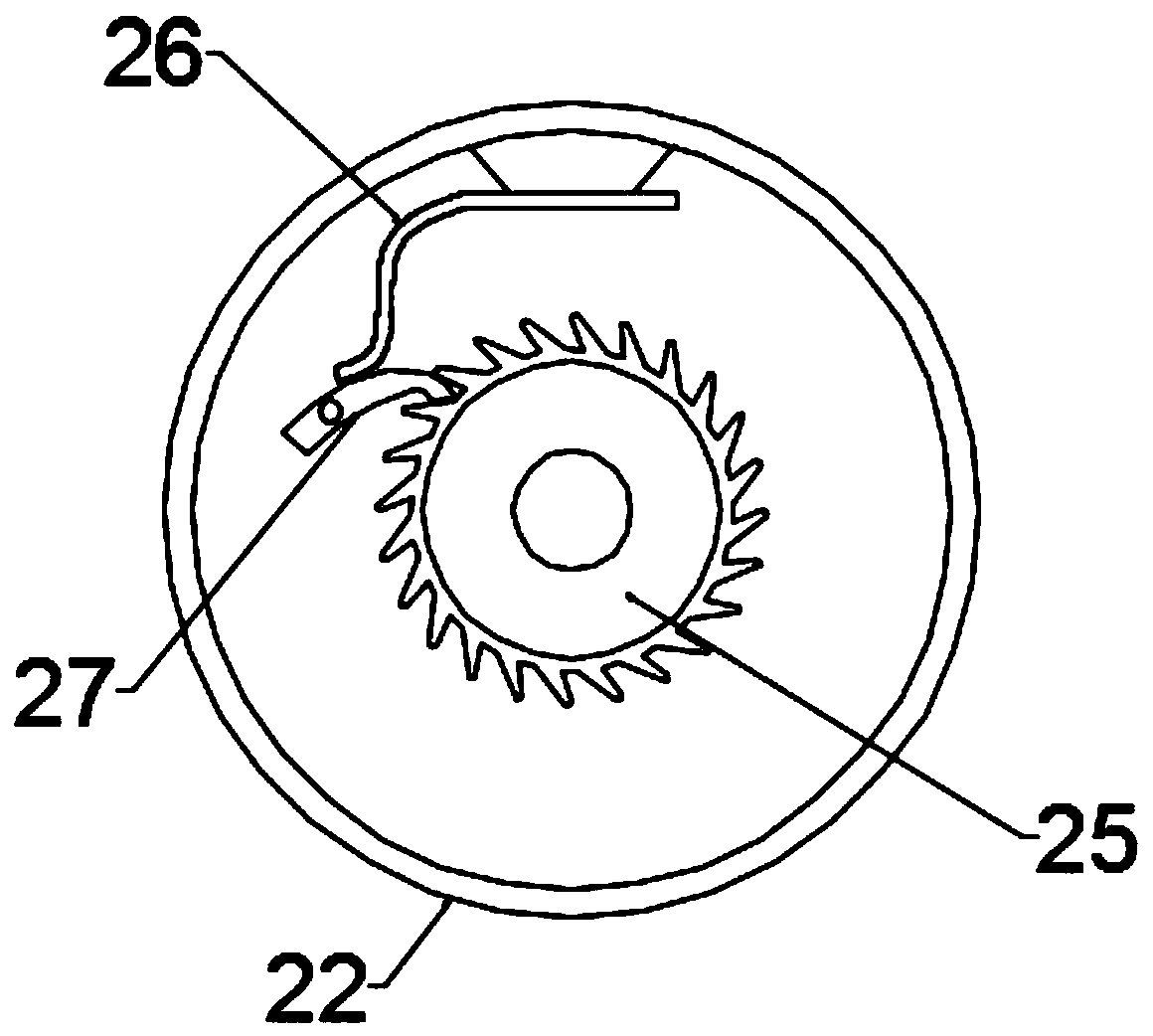

[0027] In the embodiment of the present invention, a mechanical vegetable and rattan plant shredder includes a workbench 1, a support 2, an up and down cutting mechanism, and a conveyor belt 20 for intermittently transporting vegetables or rattan plants; the support 2 is fixed on On the workbench 1, it is used for fixing the up and down cutting mechanism. The up and down cutting mechanism is arranged above the conveyor belt 20 on the workbench 1. The up and down cutting mechanism is driven by the motor 14 installed on the support 2. The motor 14 The output shaft is rotatably connected with the linkage mechanism of the intermittent drive mechanism installed on the belt pulley on one side of the conveyor belt 20 through a multi-section transmission belt. The inner side of the ratchet disc 22 is used to receive the first transmission rod 24 of the ratchet mechanism 23. The end of the first transmission rod 24 away from the ratchet disc 22 is rotationally connected with the transmi...

Embodiment 2

[0032] In the embodiment of the present invention, a mechanical vegetable and rattan plant shredder includes a workbench 1, a support 2, an up and down cutting mechanism, and a conveyor belt 20 for intermittently transporting vegetables or rattan plants; the support 2 is fixed on On the workbench 1, it is used for fixing the up and down cutting mechanism. The up and down cutting mechanism is arranged above the conveyor belt 20 on the workbench 1. The up and down cutting mechanism is driven by the motor 14 installed on the support 2. The motor 14 The output shaft is rotatably connected with the linkage mechanism of the intermittent drive mechanism installed on the belt pulley on one side of the conveyor belt 20 through a multi-section transmission belt. The inner side of the ratchet disc 22 is used to receive the first transmission rod 24 of the ratchet mechanism 23. The end of the first transmission rod 24 away from the ratchet disc 22 is rotationally connected with the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com