Slim type backlight unit

a backlight unit and slim technology, applied in lighting support devices, lighting and heating apparatus, instruments, etc., can solve the problems of increasing the manufacturing cost of the backlight unit, affecting the efficiency of the product, so as to reduce the thickness and weight, reduce the cost of mcpcb b>20/b>, and reduce the manufacturing cost. cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

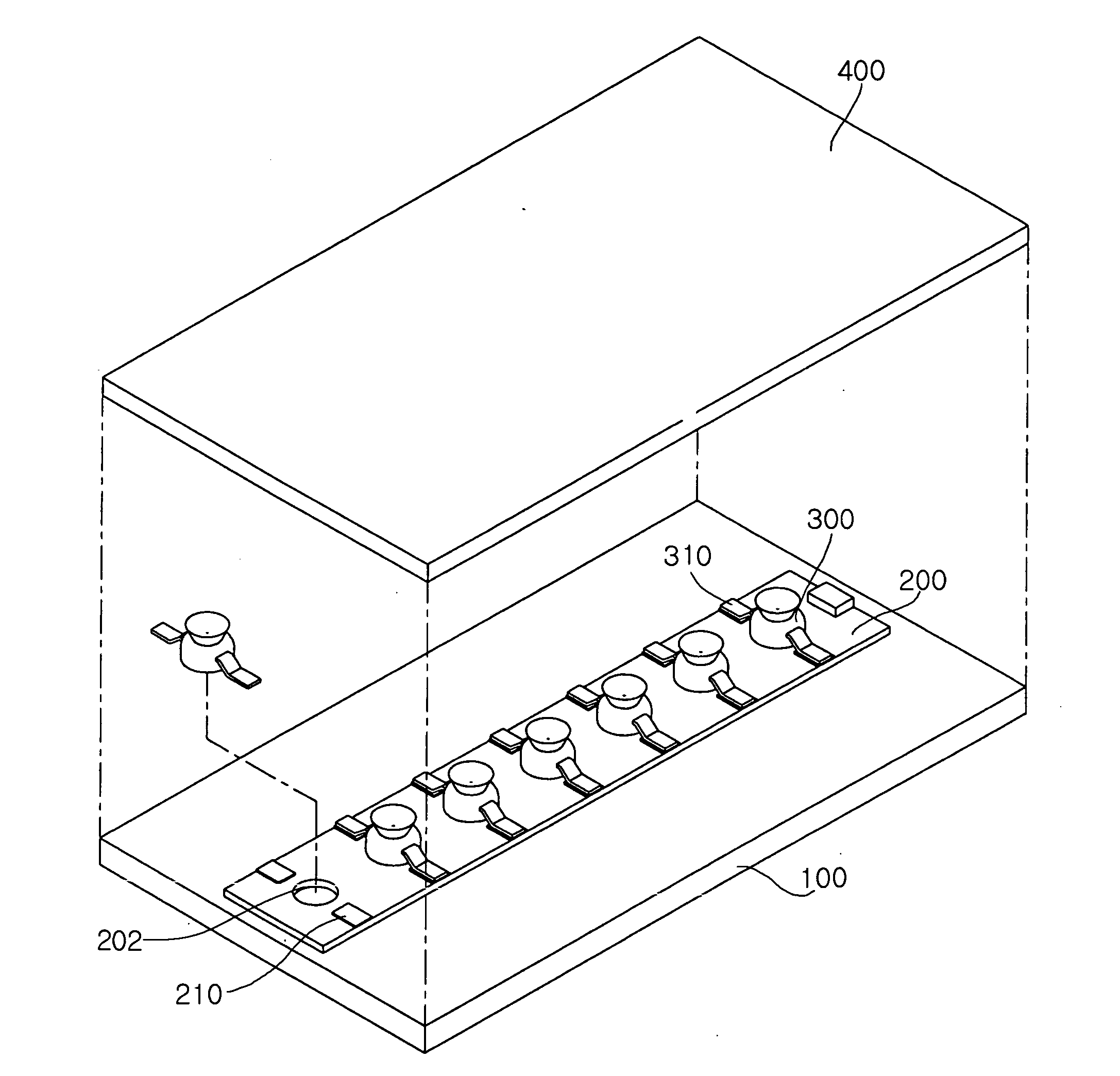

[0029]FIG. 3 is an exploded perspective view illustrating a backlight unit of the invention.

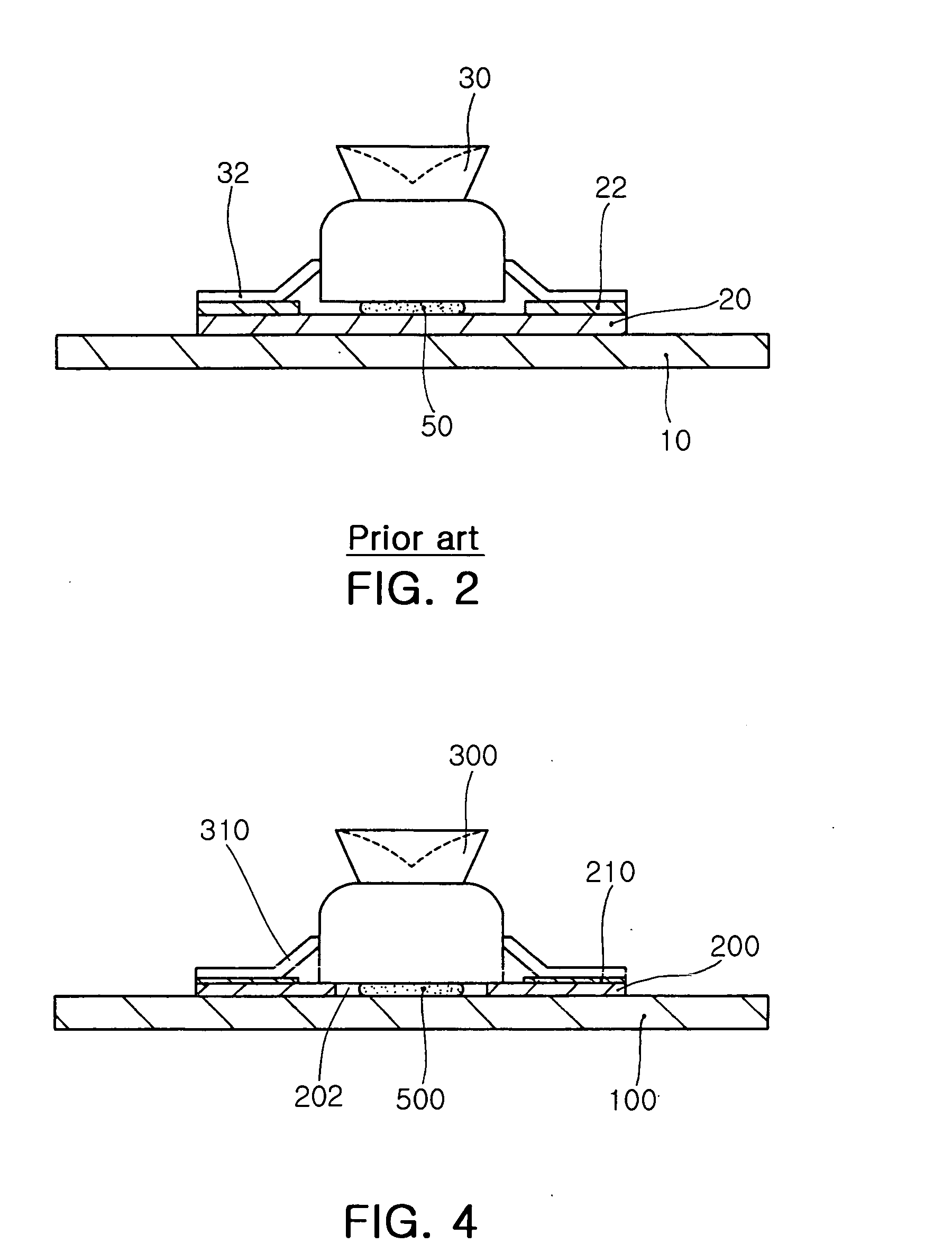

[0030]As show in FIG. 3, the backlight unit of the invention includes a bottom plate 100, a flexible printed circuit board 200, an LED package 300 and an optical sheet 400. The bottom plate 100 has each part mounted thereon. The flexible printed circuit board 200 has an electrically-conducting pattern formed on a top surface thereof and through holes 202 perforated therein. The flexible printed circuit board 200 is provided on the bottom plate 100. The LED package 300 is disposed on a top portion of the flexible printed circuit board corresponding to the through holes 202. The optical sheet 400 is disposed over the LED package 300 to evenly mix light generated from the LED package 300.

[0031]The LED package 300 includes lead frames 310 each having one portion connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com