High-temperature-resistant and high thermal conductive adhesive and preparation method thereof

A technology with high thermal conductivity and high temperature resistance, which can be used in adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc., and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

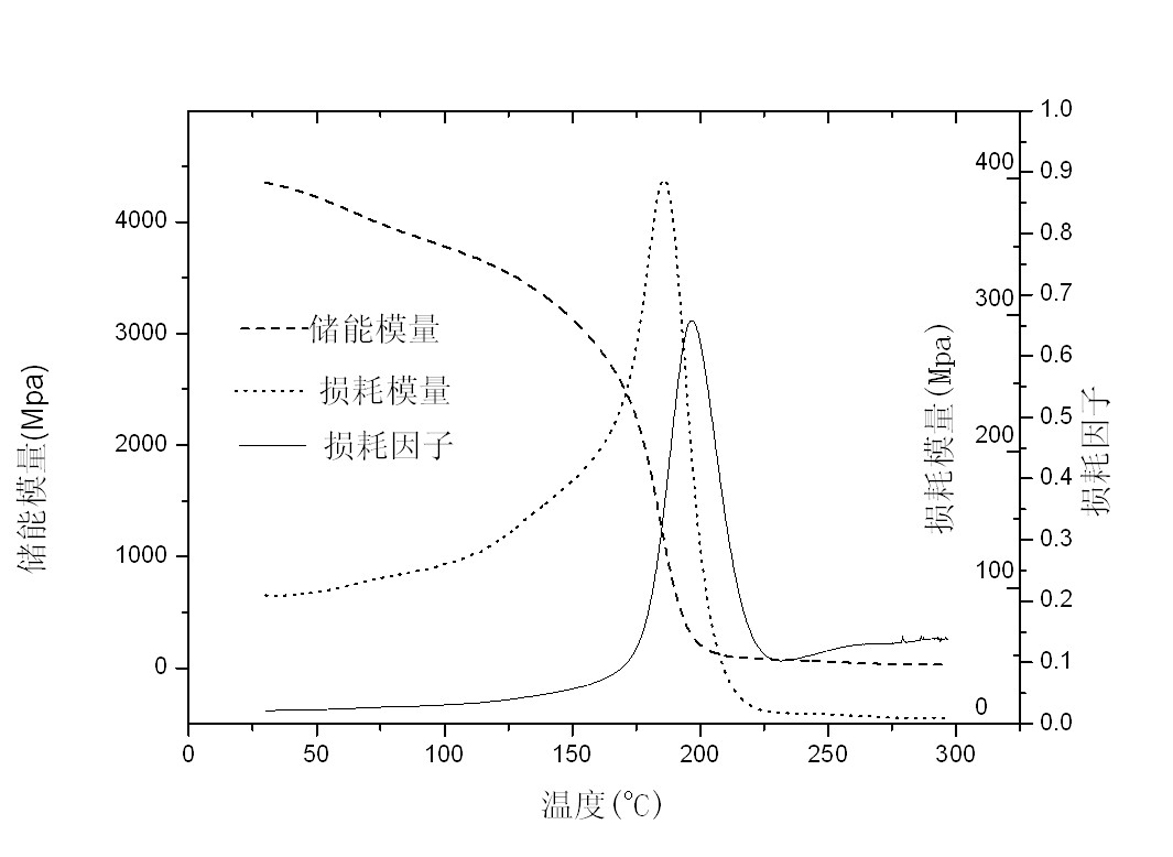

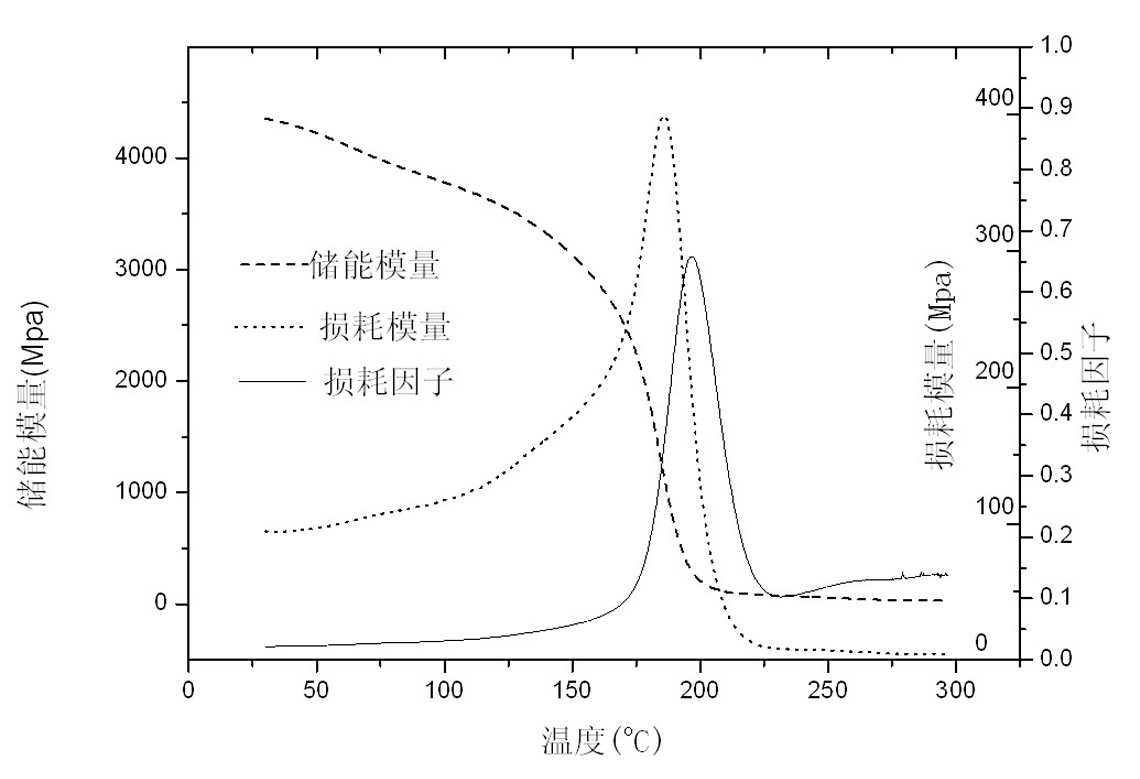

Image

Examples

preparation example Construction

[0013] The present invention also provides a preparation method of the high-temperature-resistant and high-thermal-conductivity adhesive. The method comprises: uniformly dispersing the curing agent and the curing accelerator in the epoxy resin, mixing them with high-thermal-conductivity fillers, and grinding them evenly with a grinder.

[0014] Its components and contents are:

[0015] The epoxy resin is an alicyclic epoxy resin, its epoxy value is 7.0-7.9 (Eq / Kg), and its mass percentage is 15-30%.

[0016] The curing agent is hexahydrophthalic anhydride, and its mass percentage is 10-25%.

[0017] The curing accelerator is a modified amine accelerator, and its mass percentage is 0.15-0.5%.

[0018] The high thermal conductivity filler is nano-aluminum nitride (AlN) whisker, nano-boron nitride (BN) powder or nano-aluminum nitride powder, and its mass percentage is 40-70%.

[0019] The ratio of described epoxy resin and curing agent is: [0018] The ratio of the epoxy resin ...

Embodiment 1

[0024] Proportion of high temperature resistant and high thermal conductivity adhesive (percentage by weight):

[0025] Epoxy resin ERL4221: 30%;

[0026] Curing agent: 29.7% (hexahydrophthalic anhydride);

[0027] Curing accelerator: 0.3% (modified amine accelerator);

[0028] Thermally conductive filler: 40% (nano-aluminum nitride powder);

[0029] Mix and stir the above ingredients, grind them evenly with a three-roller mill, and cure at 150°C for 30 minutes. After testing, the glass transition temperature of the cured product of high temperature resistance and high thermal conductivity is higher than 150°C, and it can be used at 260°C for more than 10 minutes; its bond strength is 24.7MPa, and the bond strength will not decrease by more than 5% after baking at 260°C for 10 minutes ; The thermal conductivity is 1.2W / m·K.

[0030]

Embodiment 2

[0032] Proportion of high temperature resistant and high thermal conductivity adhesive (percentage by weight):

[0033] Epoxy resin ERL4221: 25%;

[0034] Curing agent: 23% (hexahydrophthalic anhydride);

[0035] Curing accelerator: 0.5% (modified amine accelerator);

[0036] Thermally conductive filler: 51.5% (nano-aluminum nitride powder);

[0037] Mix and stir the above ingredients, grind them evenly with a three-roller mill, and cure at 150°C for 30 minutes. After testing, the glass transition temperature of the cured product of high temperature resistance and high thermal conductivity is higher than 150°C, and it can be used at 260°C for more than 10 minutes; its bond strength is 21.6MPa, and the bond strength will not decrease by more than 5% after baking at 260°C for 10 minutes ; The thermal conductivity is 1.8W / m·K.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com