Surface mounted sensor

A surface mount, inductor technology, applied in the direction of inductors, fixed inductors, transformer/inductor coils/windings/connections, etc., can solve the problems of insulation coating damage, etc., and achieve the effect of high anti-drop impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

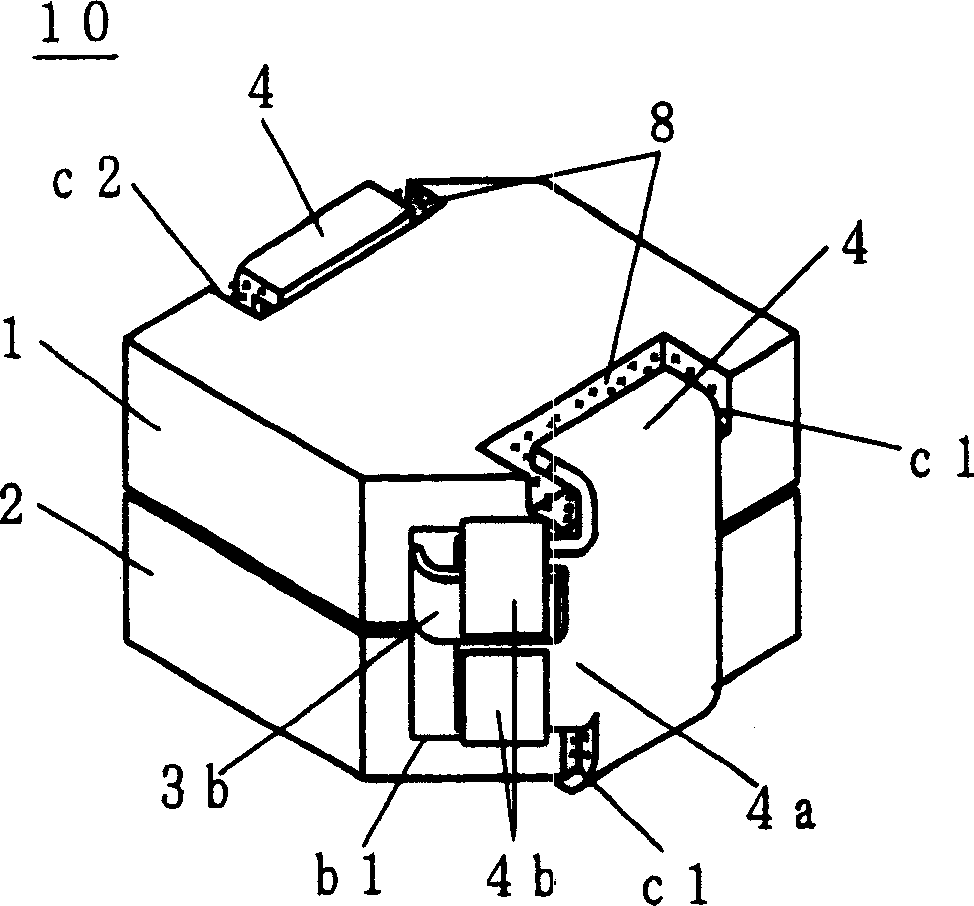

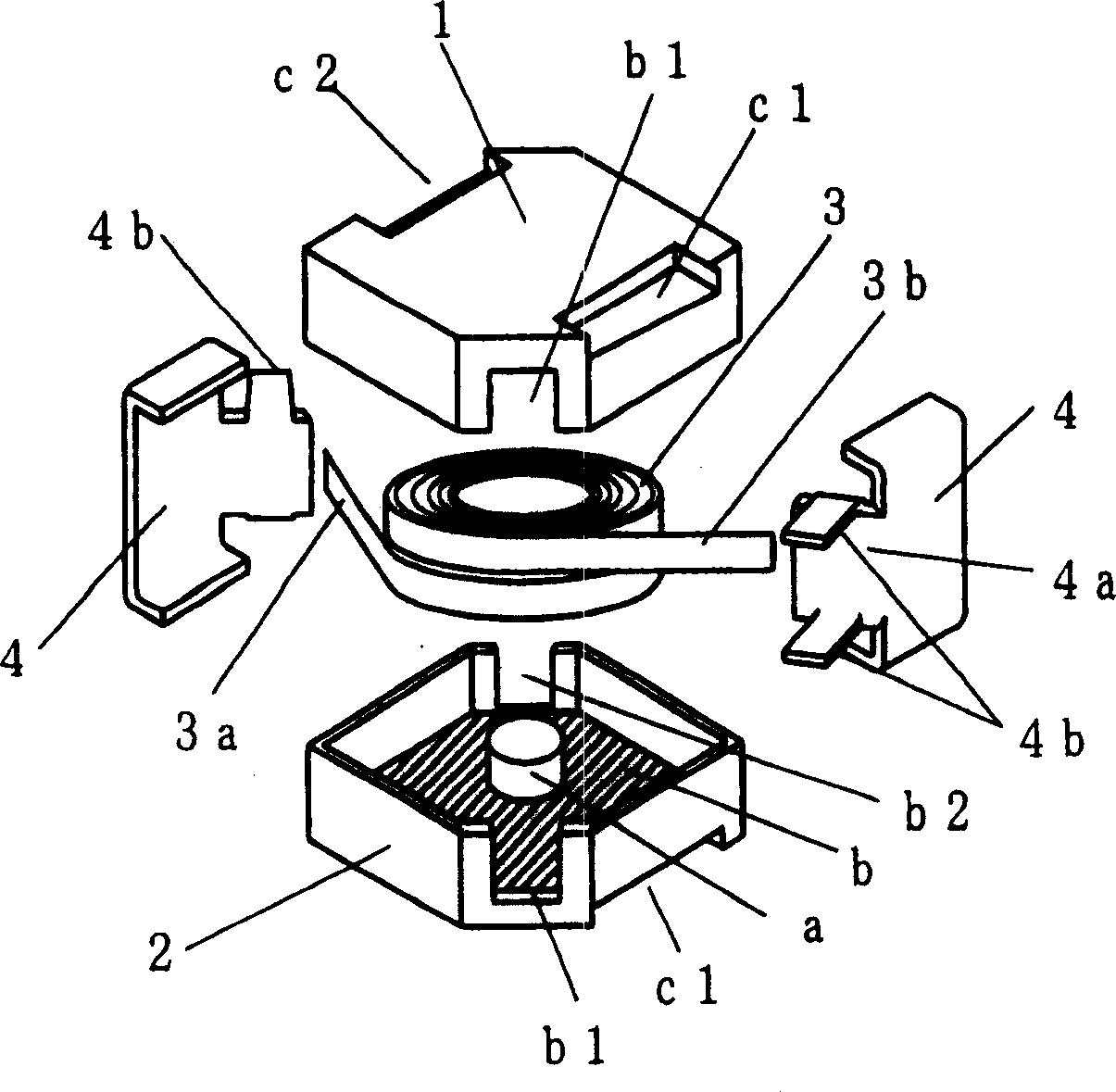

[0018] Refer below figure 1 and 2 An embodiment of the present invention is described.

[0019] figure 1 It is a perspective view of a surface mount sensor according to an embodiment of the present invention. figure 2 yes figure 1 An exploded perspective view of the surface mount sensor shown. Such as figure 1 and figure 2 As shown, in the surface-mounted inductor 10 of the present invention, 1 and 2 represent pot-shaped magnetic cores with dimples, 3 represents an air-core coil, and 4 represents the structure of connecting terminals.

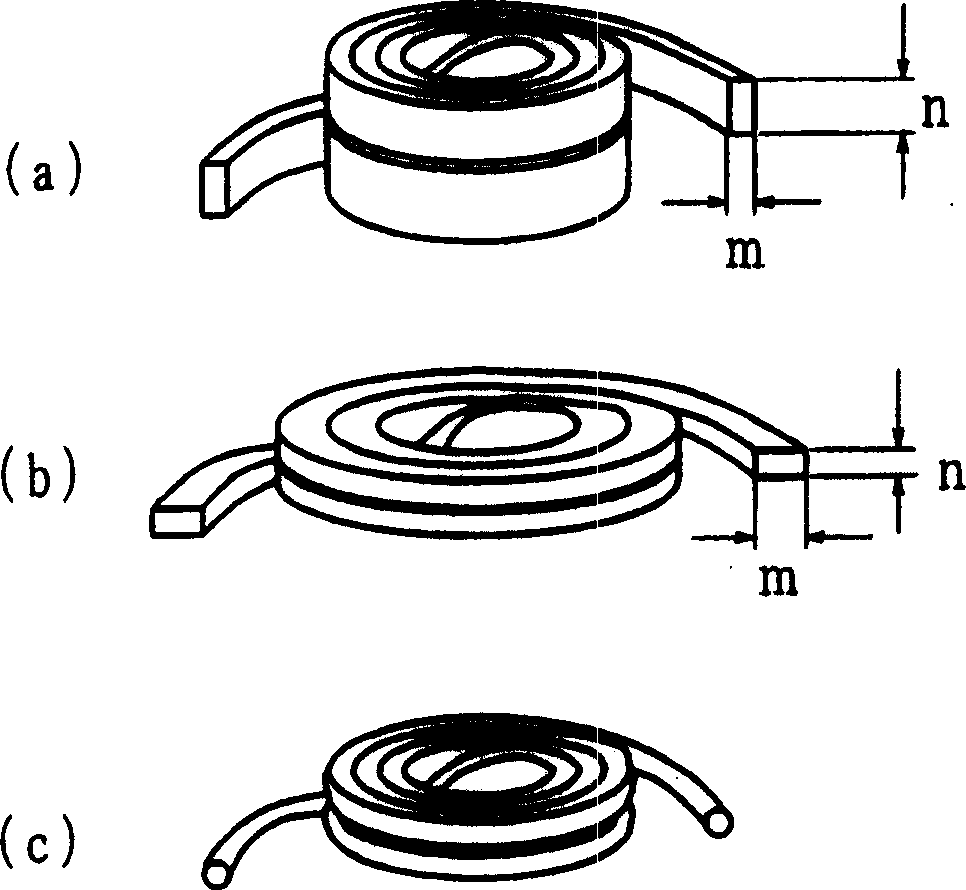

[0020] The air-core coil 3 uses an insulated coated wire with a thermal adhesive layer on the surface and a wide quadrilateral cross section, that is, a flat wire. The initial end and terminal end 3a, 3b of the two-layer winding are drawn out to the outer circumference, that is, the α winding .

[0021] The dimpled pot cores 1 and 2 are formed by molding and sintering ferrite magnetic materials into a roughly square shape, and are equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com