Preparation method of alginate and silk fibroin composite sponge

A technology of silk fibroin and composite sponge, which is applied in the field of materials, can solve the problems that the mechanical strength of alginate-based sponges cannot meet the application requirements, reduce the biocompatibility and degradation of sponges, etc., achieve excellent moisture absorption and moisturizing properties, and improve product quality. Effect of adding value and expanding development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of silk fibroin solution:

[0029] (1) Cut silkworm cocoons into pieces of 0.5cm 2 The pieces were dried in an oven for later use. Prepare 5g / L of Na 2 CO 3 solution, take a certain amount of silkworm cocoon fragments and put them in it, degumming for 30min under heating in a water bath at 100°C. Take it out, wring it dry, and wash it 2 to 3 times. The obtained product was dried in an oven.

[0030] (2) Prepare a mixed solution of calcium chloride, ethanol and water, put it in a flask, and add the above dried silk fibroin into it. Dissolve and stand at a certain temperature, cool in the air, and then pour the solution into a dialysis bag, and immerse the dialysis bag in deionized water for dialysis. After the dialysis, pour out the solution, put it into a centrifuge for centrifugation, and take the supernatant after centrifugation.

Embodiment 1

[0032] This example discloses a method for preparing a sponge blended with alginate and silk fibroin, which is prepared by the following method:

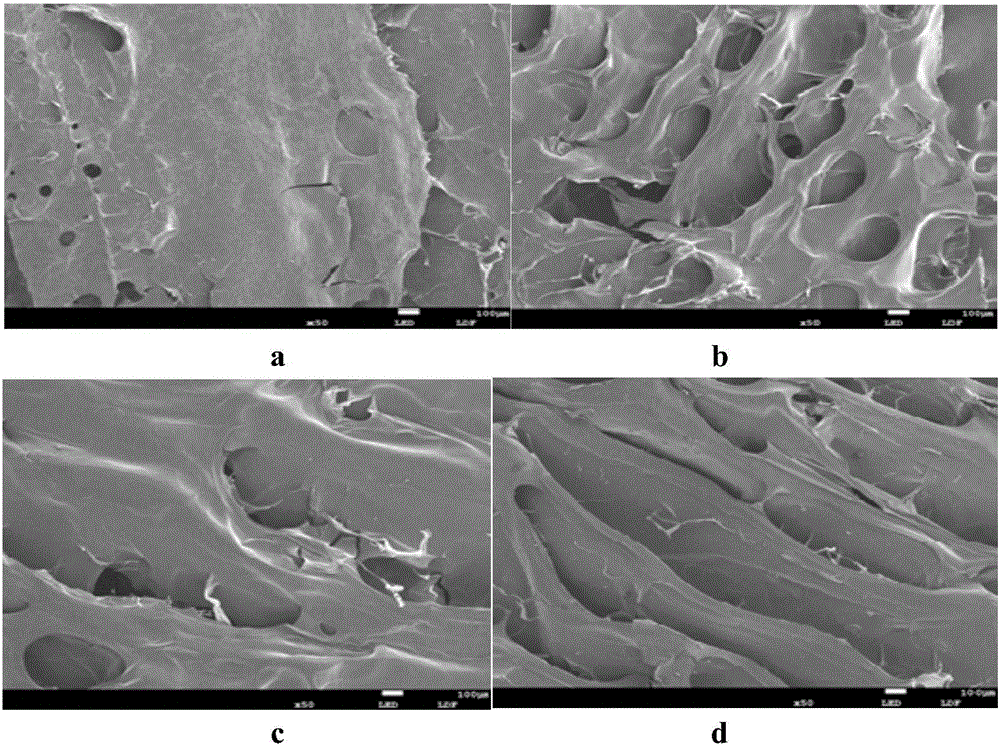

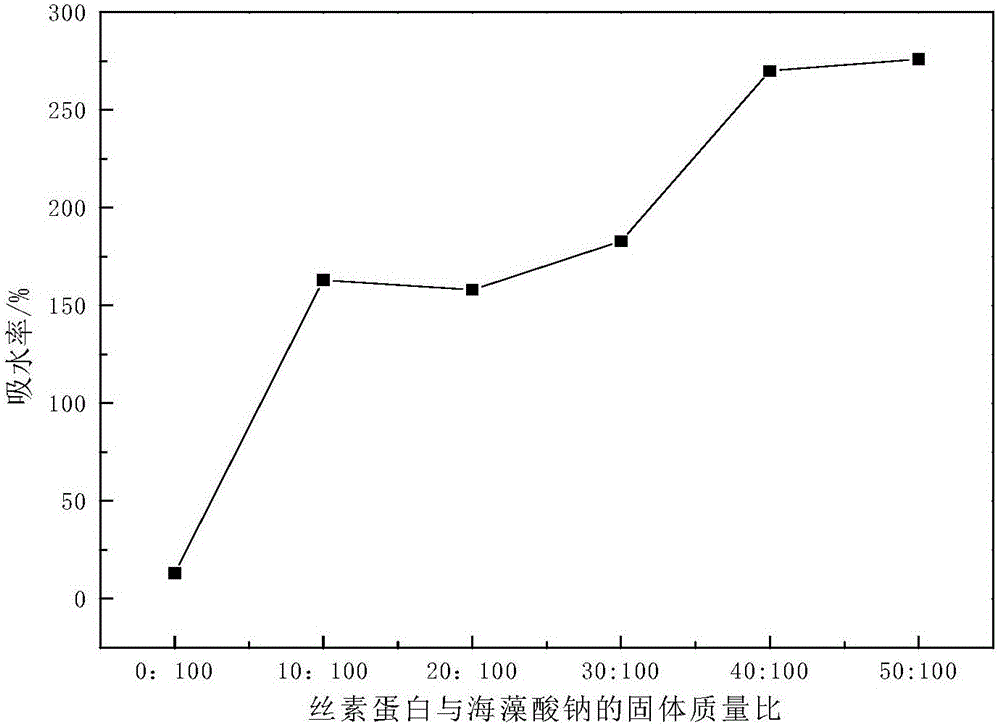

[0033] 0.2g (solid weight) silk fibroin and 2g sodium alginate were prepared into 100mL blending solution. When preparing, first add water to dissolve sodium alginate, then add silk fibroin solution, and mechanically stir to make the solution evenly mixed. Put the prepared mixed solution into a freeze dryer to dry and remove water, and the freeze dryer to dry and remove water for 6 to 8 hours to form a pore structure.

[0034] Immerse the product into the prepared solution, the solution is calcium chloride, glycerol and ethanol solution with a mass ratio of 7:3:90, and the soaking time is 15 minutes. After a period of time, it is taken out and dried to obtain a composite sponge product. Composite sponge products have a water absorption rate of 170%, a moisture absorption rate of 79%, and a moisture retention rate of 76%.

[0035]...

Embodiment 2

[0037] This example discloses a method for preparing a sponge by blending alginate and silk fibroin, which is prepared by the following method:

[0038] 0.6g (solid weight) silk fibroin and 2g sodium alginate were prepared into 100mL blending solution. When preparing, first add water to dissolve sodium alginate, then add silk fibroin solution, and mechanically stir to make the solution evenly mixed. Put the prepared mixed solution into a freeze dryer to dry and remove water, and the freeze dryer to dry and remove water for 6 to 8 hours to form a pore structure.

[0039] Immerse the product into the prepared solution, the solution is calcium chloride, glycerol and ethanol solution with a mass ratio of 7:3:90, and the soaking time is 15 minutes. After a period of time, it is taken out and dried to obtain a composite sponge product. Composite sponge products have a water absorption rate of 180%, a moisture absorption rate of 88%, and a moisture retention rate of 82%.

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com