Microporous membrane, preparing method and use

A technology of microporous membrane and microporous structure, which is applied in the field of microporous membrane materials, can solve the problem that the air permeability, moisture permeability and tensile strength of water pressure resistance of membranes differ greatly, the size of pores in microporous products cannot be accurately controlled, and bacteria , poor virus protection and other problems, to achieve uniform air permeability and moisture permeability, light weight, and the effect of SARS virus protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

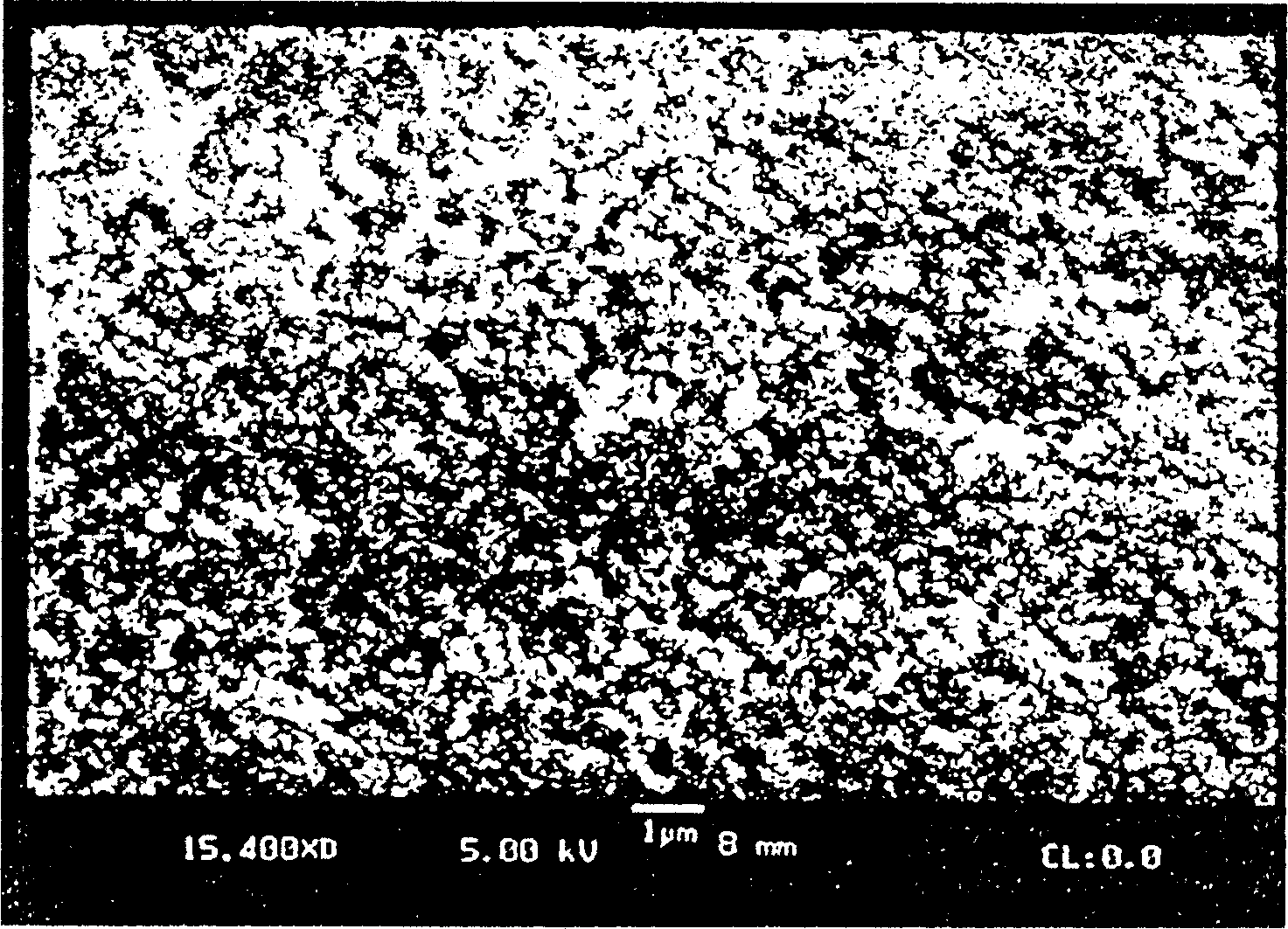

[0036] (1) Extrusion calendering method: Mix the components listed in Table 1 evenly in a high-speed mixer, then extrude and plasticize them at 180°C in an extruder (domestic, TP-35), and use a calender (three Roller calender) at 70 ° C to form a sheet-like coil with a thickness of 0.12 mm. Then, the film was washed with xylene at 70° C. for 25 minutes, finally dried, and wound up. A microporous membrane with a volume porosity of 55% and an average pore diameter of 30 nm was prepared. Its electron microscope photo is as figure 1 .

[0037] (2) Blow molding method Mix the components listed in the table evenly in a high-speed mixer, then use an extruder (domestic, TP-35) to extrude and plasticize at 200°C, and then use a blow molding machine for blow molding , the thickness is controlled at 0.05mm, then, wash with xylene at 70°C for 8 minutes, and finally dry and roll. A microporous membrane with a volume porosity of 85% and an average pore diameter of 80 nm was prepared. I...

Embodiment 2

[0041] Mix the components listed in the table evenly in a high-speed mixer, then use an extruder (domestic, TP-35) to extrude and plasticize at 180°C, and use a calender (three-roll calender) to compress at 150°C to form Sheet-like coils with a thickness of 0.2 mm. Then, wash with n-hexane at 50° C. for 10 minutes, and finally dry and wind up. A microporous membrane with a volume porosity of 40% and an average pore diameter of 30 nm was prepared. Next, the above-mentioned microporous membrane was biaxially stretched with a stretching machine, and the stretching ratio was 5 times to obtain a microporous membrane with a thickness of 0.07 mm, a volume porosity of 80%, and a pore diameter of 150 nm.

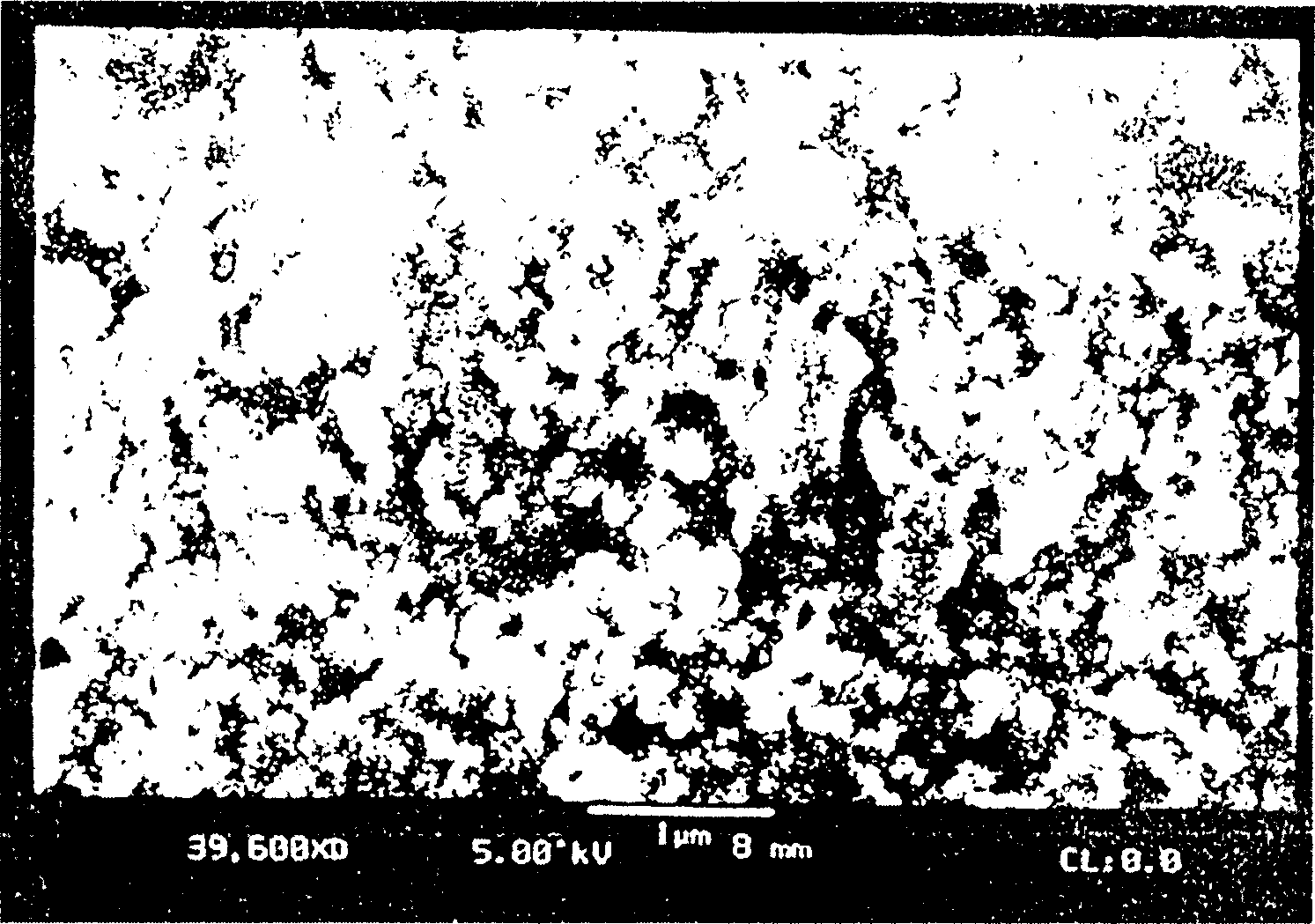

[0042] The above-mentioned microporous membrane has excellent antibacterial properties, the membrane has good flexibility, high elasticity, smooth hand feeling, and the moisture permeability is greater than 5000g / m 2 · d, water pressure resistance 6m water column; observed by elect...

Embodiment 3

[0045] (1) Casting method Mix the components listed in the table evenly in a high-speed mixer, then plasticize at 230°C, cast into a film with a thickness of 0.07mm through a casting machine, wash with toluene at 60°C for 20 minutes, Finally, it is dried and rolled. A microporous membrane with a volume porosity of 80% and an average pore diameter of 60 nm was prepared.

[0046] (2) Casting stretching method Mix the components listed in Table 1 uniformly in a high-speed mixer, then plasticize at 220°C, cast into a film with a thickness of 0.15mm through a casting machine, and wash with toluene at 60°C 20 minutes, finally dry and roll. A microporous membrane with a volume porosity of 50% and an average pore diameter of 50 nm was prepared. Next, the above-mentioned microporous membrane was biaxially stretched with a stretching machine, and the stretching ratio was 7 times to obtain a microporous membrane with a thickness of 0.06 mm, a volume porosity of 80%, and a pore diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com