Hydraulically compressed molten steel flow control valve with side opening door

A technology of flow control valve and side door, which is used in manufacturing tools, casting melt containers, metal processing equipment, etc., can solve the problems of affecting the sliding of the sliding plate, complicated operation, unreasonable structure, etc., to improve safety performance and structural design. Simple, even pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

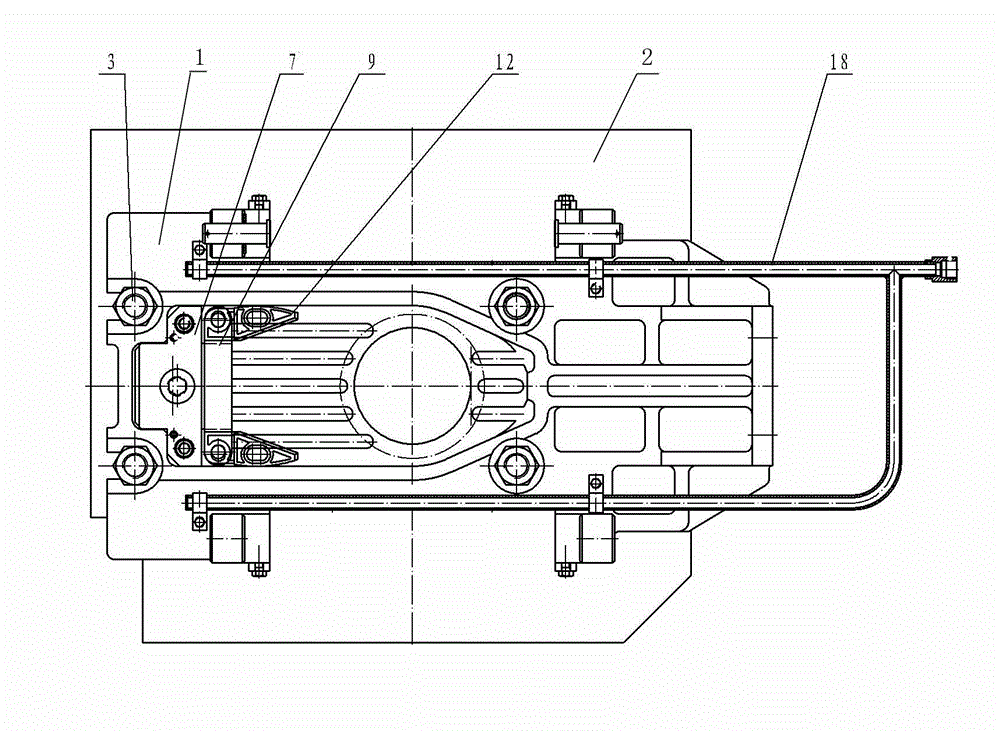

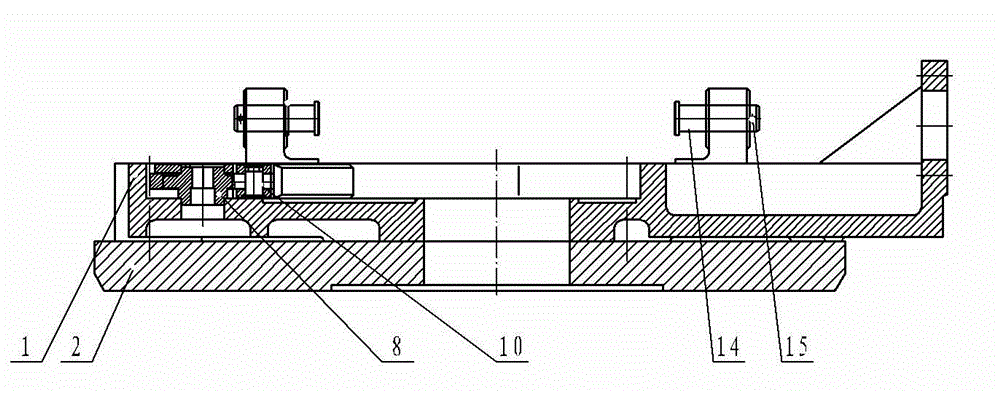

[0026] Embodiment one: see figure 1 , Figure 4 , Figure 7 , Figure 10 , Figure 12 , the liquid steel flow control valve of the hydraulic pressing side opening door of the present invention comprises a base 1, a moving frame 21, a pressing frame 30, and a combination of refractory materials. The sides are connected by a pivot 14, so that the compression frame and the motion frame can be centered on the connected side to form a side opening mode, which is convenient for refractory combination replacement. Base 1, motion frame 21 and compression frame 30 realize compression by spring combination, and described spring combination is made up of spring case 51, spiral spring 52, spring pull bar 53, spring pressing plate 54 and compression rod 55, and spring coil 52 and spring The pressing plate 54 is nested and installed in the spring box 51, and the spring box 51 and the pressing rod 55 are matched together by the spring pressing plate 54 and the spring pull rod 55. Both en...

Embodiment 2

[0031] Embodiment two: see Figure 1 to Figure 12 , the liquid steel flow control valve with hydraulic pressure side opening in this embodiment is provided with a slide plate positioning point and a top-tight assembly respectively in the base and the longitudinal ends of the motion frame. (not shown), top clamping plate 9 and top clamping block 12, 10 in the figure is the hinge shaft of the top clamping block, 7 is the cam cover plate, when the upper slide plate is put into the base, turn the cam 8 with a special tool to make the spring act on force On the clamping block 12, the clamping block is moved longitudinally and pressed against the upper slide plate arranged in the base from the direction of the wedge angle; Figure 4 ~ Figure 6Among them, the lower plate jacking assembly in the motion frame includes a cam 26, a spring, a jacking plate 25 and a jacking block 23. In the figure, 24 is the hinge shaft of the jacking block, 29 is a cam cover plate, 20 is a guard plate, an...

Embodiment 3

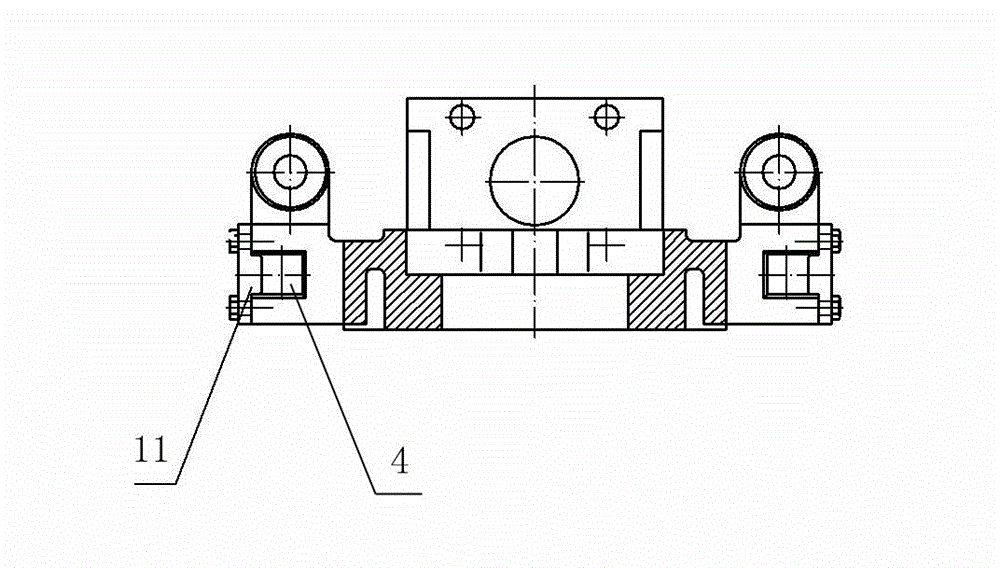

[0033] Embodiment three: see Figure 10 , Figure 11 The difference between the liquid steel flow control valve of this embodiment and the previous embodiments is that a convenient force application structure 58 for supporting the pressing rod is provided on the pressing rod 55 in cooperation with the bottom plate of the spring box 51, so that The force applying mechanism is designed as a stepped hole with a variable diameter. After the hydraulic gun is placed in the stepped hole, its movable part and fixed part can respectively press against the bottom plate of the spring box 51 or block the compression rod 55, so that the compression rod and The spring box is separated and the axles at both ends of the spring box are placed in the groove 4. At the same time, the coil spring produces the contraction force of the compression base and the compression frame, so that the upper and lower plates Create a steady pressure. The installation is quick, the pressure is constant after p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com