Coal gasification chilling grey water high pressure flash evaporation decompression buffering device

A high-pressure flash evaporation and buffer device technology, which is applied in the direction of heating water/sewage treatment, etc., can solve the problems of frequent maintenance and short service life of the flash tower, achieve good economic and social benefits, alleviate wear, and reduce the flow rate smoothly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

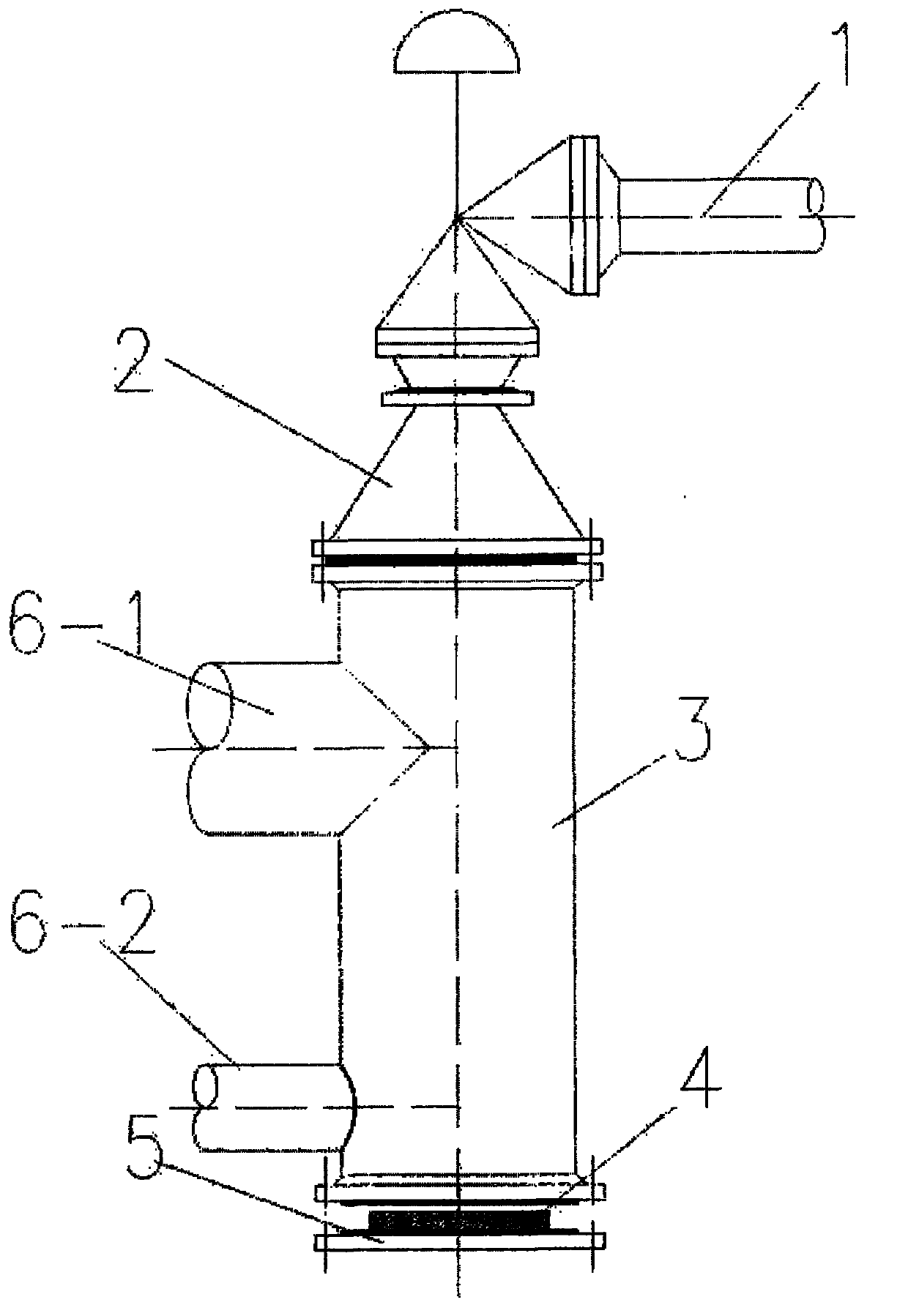

[0018] Example 1: Such as figure 1 As shown, the present invention includes: a water inlet pipe 1, a diffuser pipe 2, a tank body 3, a flushing table 4, a detachable sealing plate 5, a water outlet pipe 6-1, 6-2, and the water inlet pipe 1 is arranged on the tank body 3. The top of the water inlet pipe 1 is connected to the upper end of the trapezoidal cone-shaped diffuser 2, the lower end of the diffuser 2 is connected to the tank 3, the lower end of the tank 3 is provided with a flushing table 4, in the tank 3 Water outlet pipes 6-1 and 6-2 are arranged above the outer side walls. The high-temperature and high-pressure gray water enters the tank through the inlet pipe 1 and the angle valve, and the three-phase fluid of gas, liquid and solid of the gray water buffered by pressure relief flows out through the outlet pipes 6-1 and 6-2, and directly enters the subsequent flash evaporation unit. Due to the adoption of the high-pressure flash evaporation pressure relief buffer dev...

Embodiment 2

[0019] Example 2: The difference from Example 1 is that figure 1 As shown, the present invention also includes a flushing station 4 provided at the bottom of the tank 3, the flushing station 4 is located on the detachable sealing plate 5, and the detachable sealing plate 5 is fixed to the tank 3 by bolts. bottom of. Easy to replace.

Embodiment 3

[0020] Example 3: The difference from Example 1 is that figure 1 As shown, the flushing table 4 is made of 150mm-250mm high chromium cast iron or ceramic material. A high chromium cast iron or ceramic scouring table 4 is set at the bottom of the tank body 3 to receive strong erosion from the high temperature and high pressure gray water from the top of the tank body, which has a better buffer effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com