Directional yarn guide mechanism of computer flat knitting machine

A yarn guiding mechanism and technology of flat knitting machine, which are applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of increasing the resistance of yarn traveling, unfavorable yarn guiding smoothly, and yarn breakage, etc., and achieve smooth guiding. Lead, good orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

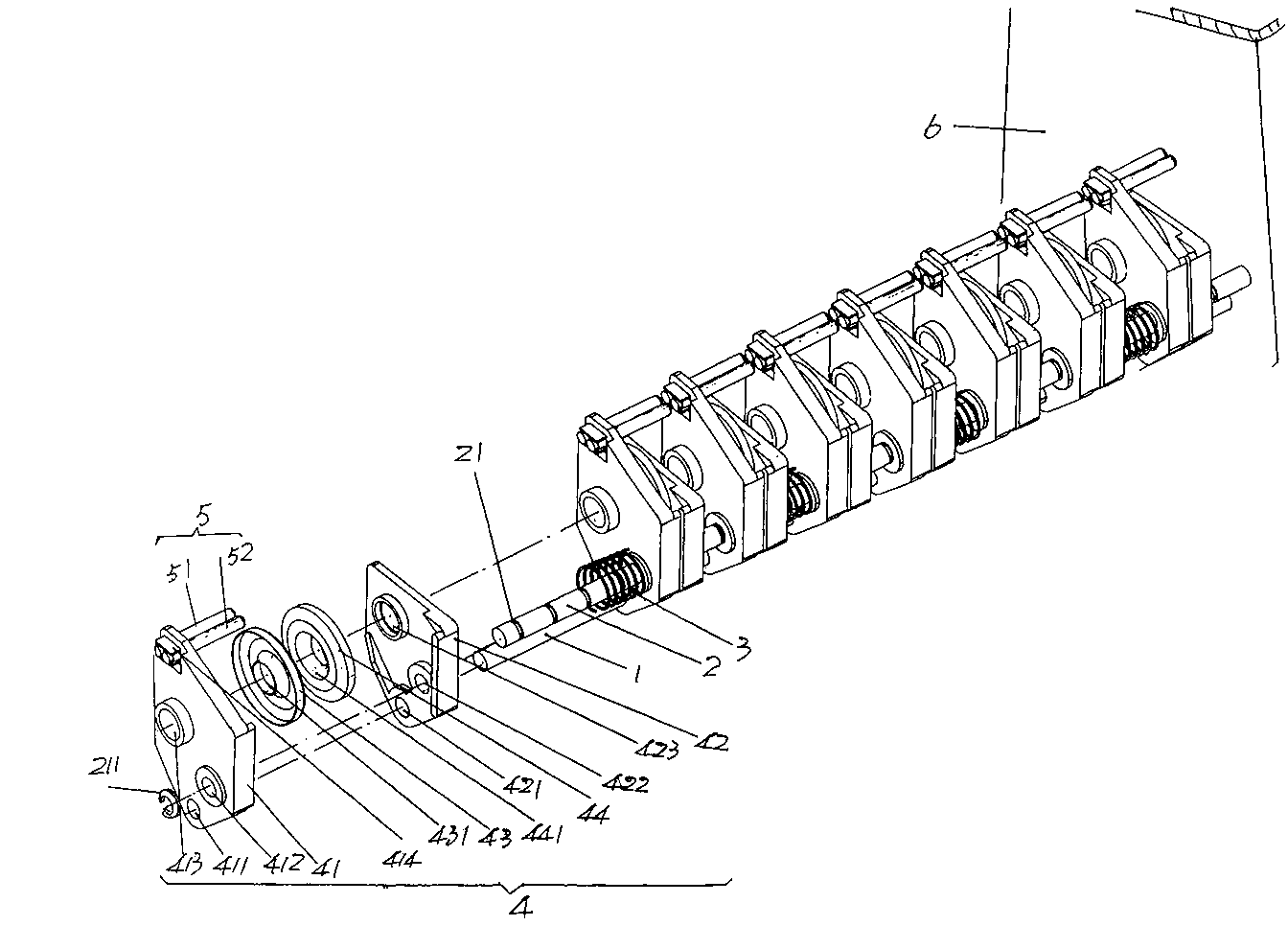

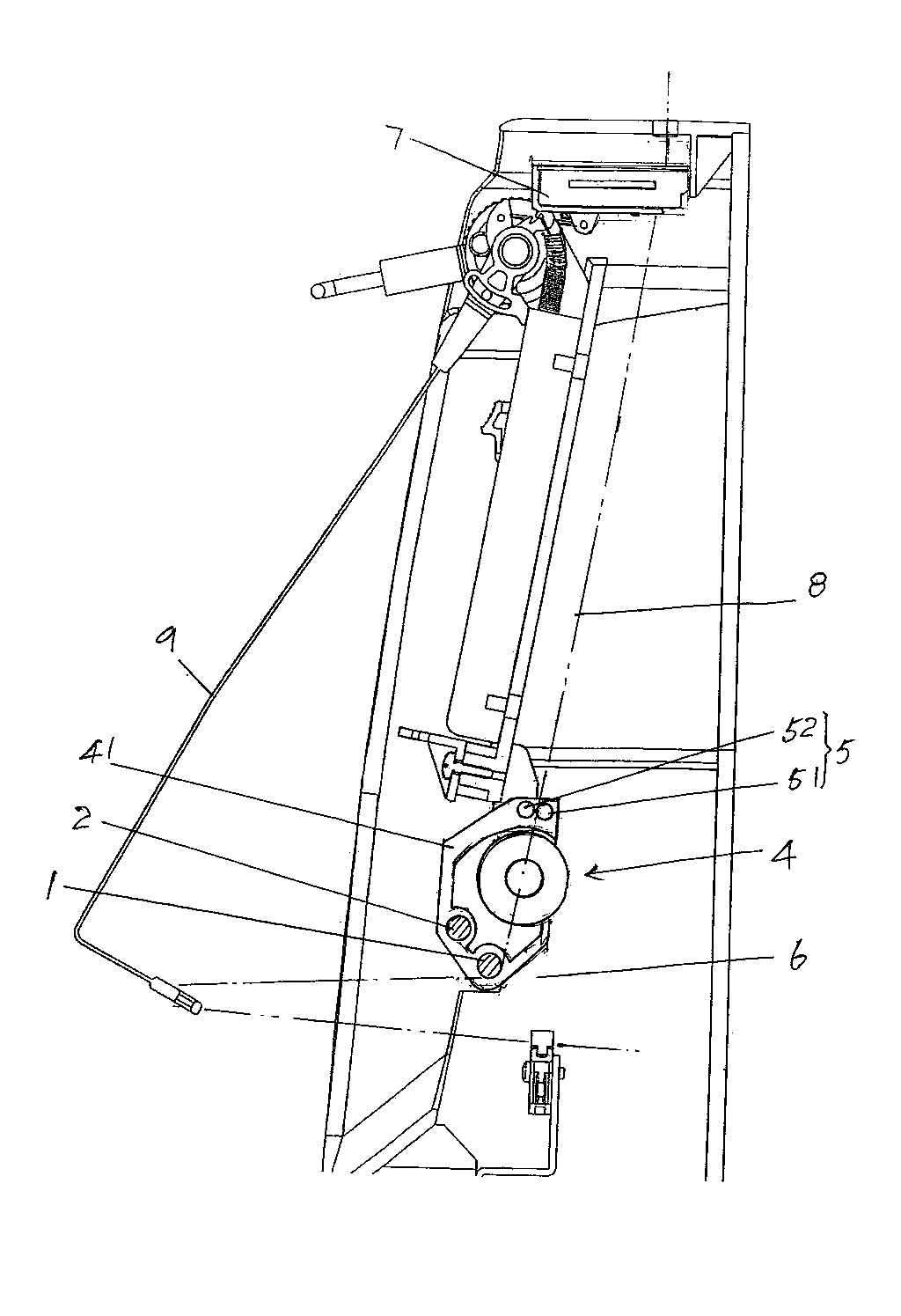

[0017] See figure 1 , a guide roller 1 and a spring bar 2 are given, the guide roller 1 and the spring bar 2 are obliquely parallel, and the guide roller 1 is located obliquely below the spring bar 2 in the state of use ( figure 2 Show). A set of limit snap ring grooves 21 are provided at intervals on the spring rod 2 , and a limit snap ring 211 is clamped in each limit snap ring groove 21 . There are two yarn clamping devices 4 in a group of yarn clamping devices 4 of the present invention corresponding to each two adjacent limit clips 211, and a chuck is allocated between every two adjacent yarn clamping devices 4 Seat spring 3 and two yarn guides 5.

[0018] The aforementioned chuck seat spring 3 is sleeved on the spring bar 2. In this embodiment, since the number of clamping devices 4 is eight, the number of chuck seat springs 3 is four, and the number of the yarn guide 5 is four. Quantity is equal to the quantity of clamping device 4 namely eight.

[0019] Sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com