Method for processing foul gas through using biological combined technology

A odorous gas, combined process technology, applied in separation methods, chemical instruments and methods, air quality improvement and other directions, can solve the problems of high system energy consumption, complex operation, complex process, etc., and achieve the effect of stable system operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

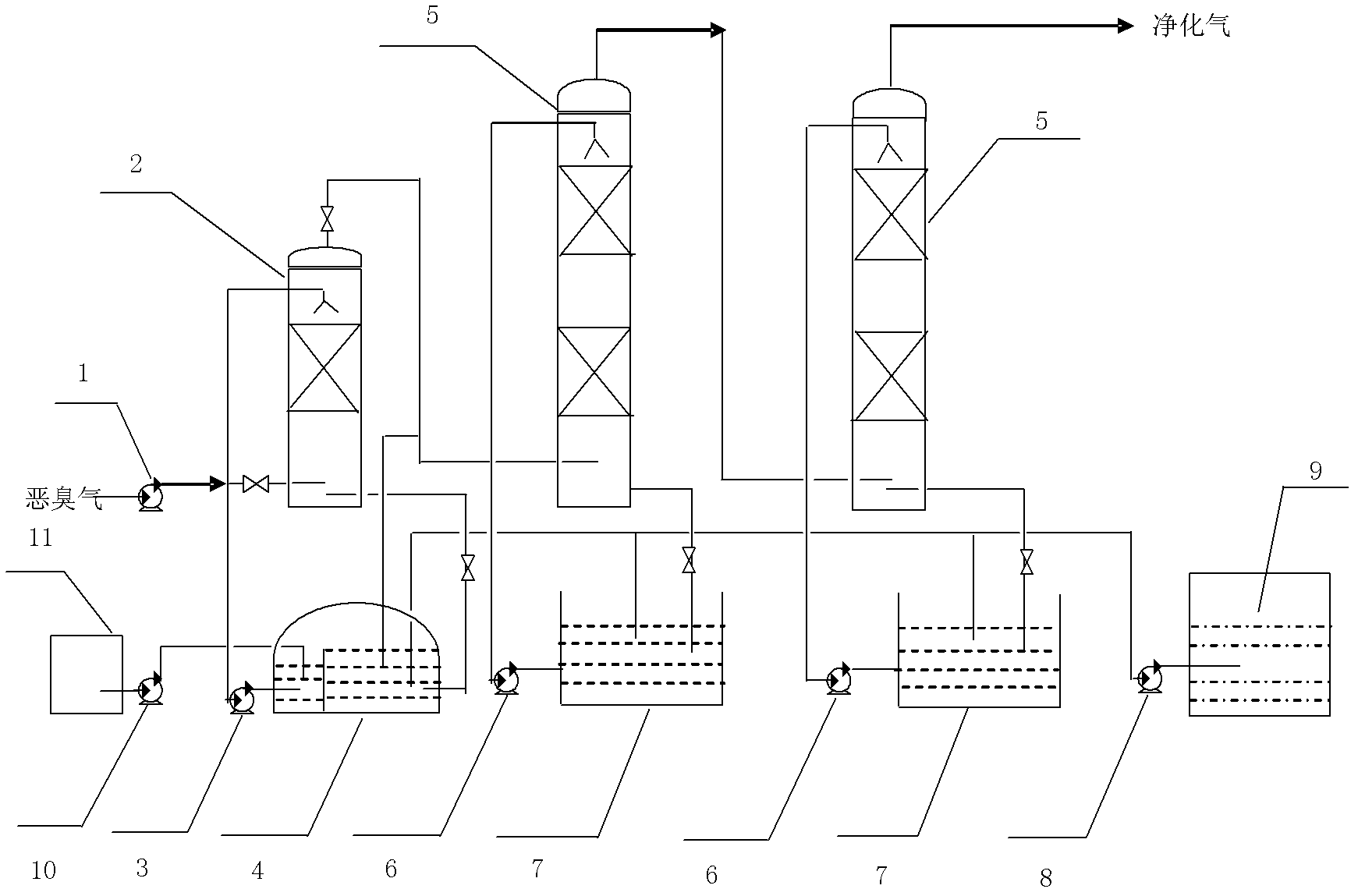

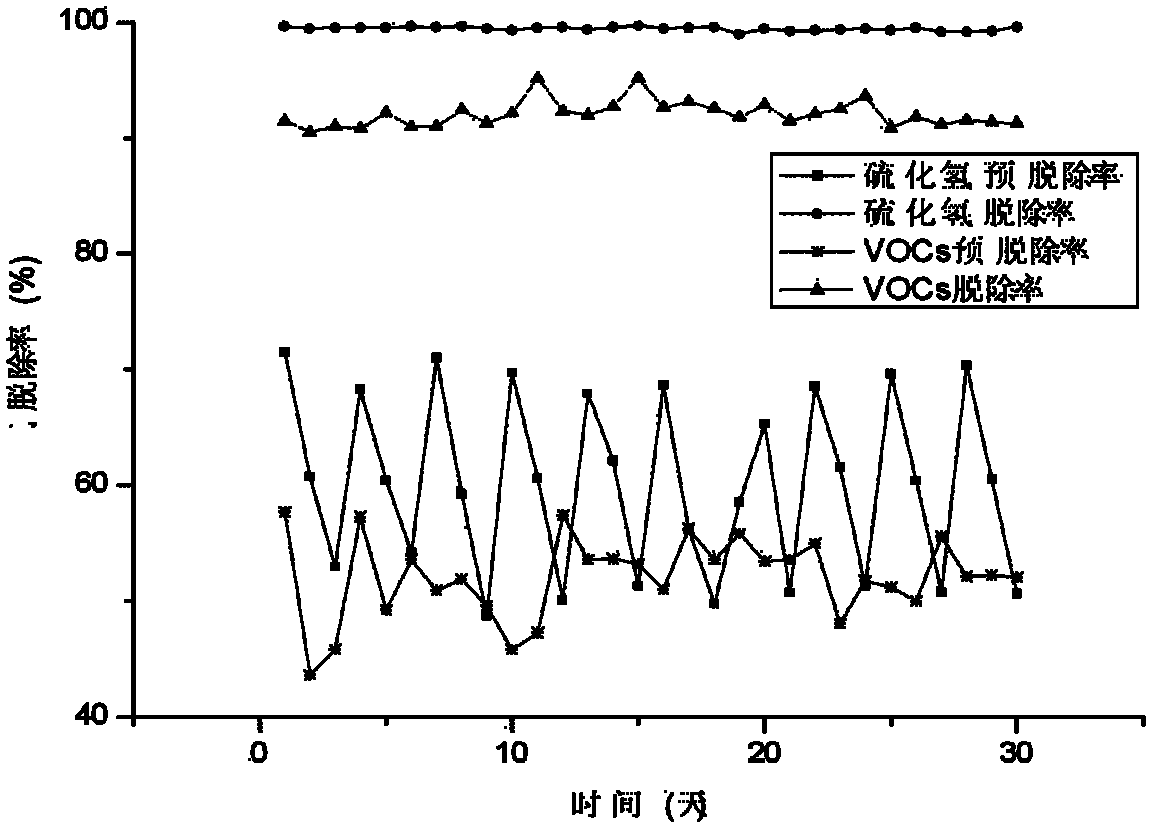

[0027] The method for treating malodorous gas by the biological combination process of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] Hydrogen sulfide, methyl mercaptan, ammonia, volatile organic gas and oil gas enter the biological scrubber 2 through the induced draft fan 1, and in the biological scrubber 2, oil and insoluble organic pollutants are biologically scrubbed by the biological scrubber pump 3 Liquid absorption and adsorption, some easily soluble organic pollutants and malodorous gases are dissolved in the biological washing liquid and then directly oxidized and decomposed by microorganisms in the biological scrubber 3. After being treated by the biological trickling filter tower, it is directly discharged up to the standard.

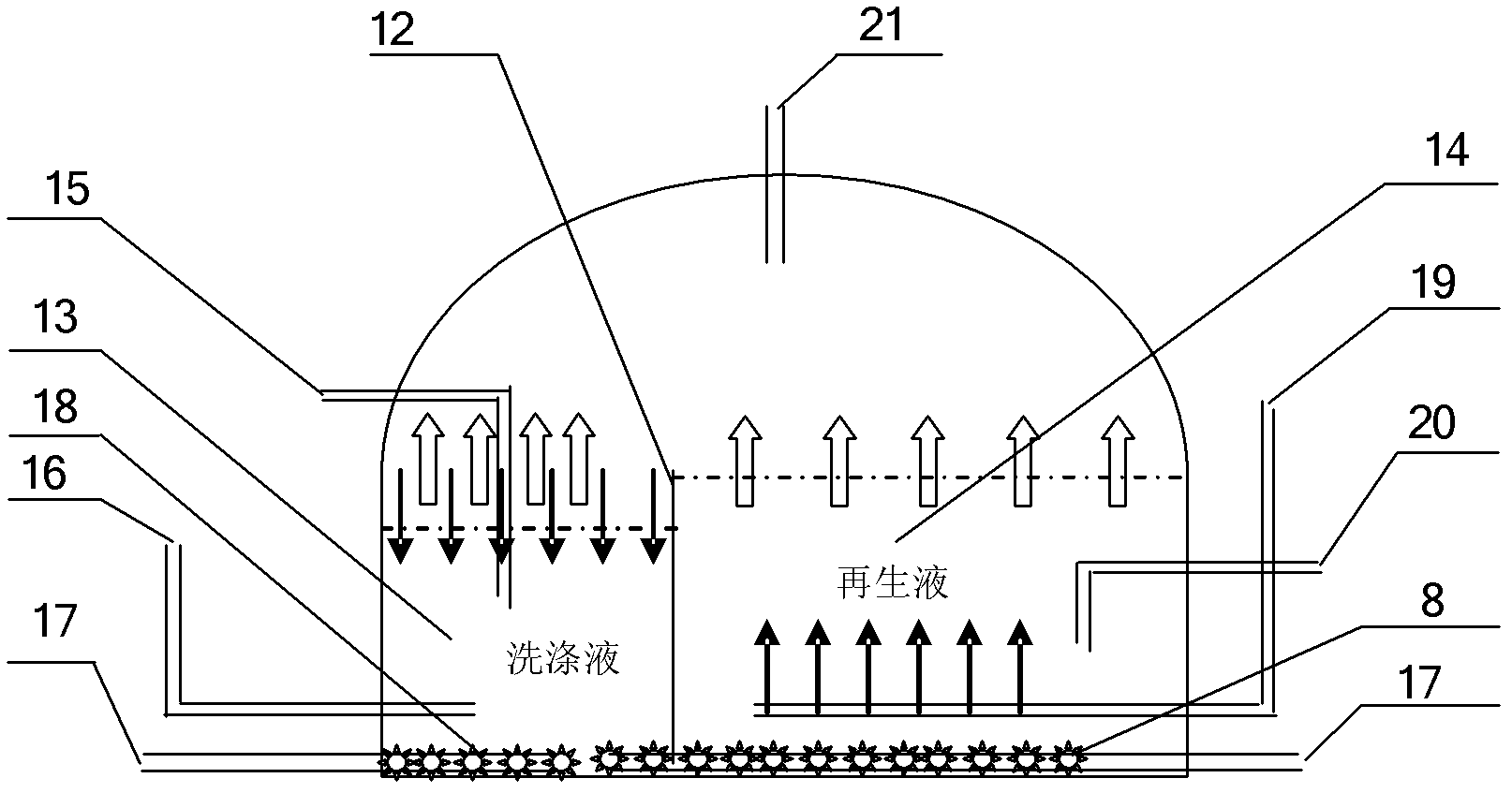

[0029] The biological cleaning solution used in the present invention is the return activated sludge in the secondary sedimentation tank of the sewage plant. After the activated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com