Method for synthesizing taurine

A synthetic method, the technology of taurine, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems of harsh production environment, difficult to accurately measure pH, difficult to control, etc., and achieve the effect of friendly production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

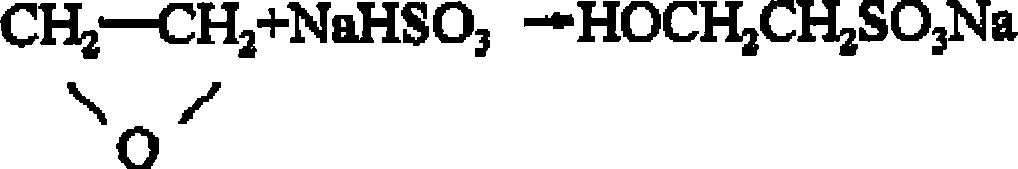

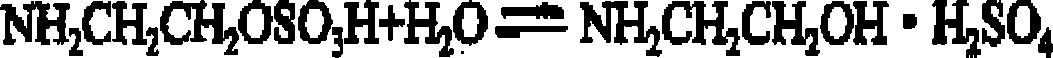

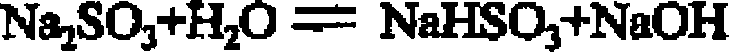

Method used

Image

Examples

Embodiment 1

[0058] Put ammonium bisulfite (50%) 588kg (2.97×10 3 mol), add ammonium bicarbonate 138kg (1.74×10 3 mol), until no carbon dioxide gas is released, add ethanolamine sulfate 352.5kg (2.5×10 3 mol), heating and stirring to 75°C, and maintaining the pressure in the kettle at -0.08MPa, after continuing to react for 60h, cooling down to 10°C while stirring, and centrifugal separation to obtain 360kg of crude taurine.

[0059] Put 360kg of the above-mentioned crude product taurine into a 1000L reactor, add 500L of water and 0.5kg of active carbon, dissolve the crude product taurine under heating and stirring, filter and remove the active carbon to obtain a colorless transparent liquid, and cool down to 5 ℃, centrifuged and washed to obtain 220kg of high-quality taurine, and dried to obtain 201kg of finished product taurine (1.61×10 3 mol), after testing, all the indicators are in line with the Japanese Pharmacopoeia JP8 edition and the United States Pharmacopoeia USP26 edition.

Embodiment 2

[0061] Add liquid ammonium bisulfite (50%) 650kg (3.29×10 3 mol), add equimolar ammonium bicarbonate, react under stirring to produce ammonium sulfite, and add ethanolamine hydrochloride 391kg (4.93×10 3 mol), heated and stirred to 90°C, and continued to react under normal pressure for 50h, then cooled down to 10°C under stirring, and centrifuged to obtain 430kg of crude taurine.

[0062] Put 430kg of the above crude taurine into a 1000L reaction kettle, add 500L of water and 1kg of activated carbon, dissolve the crude taurine under heating and stirring, filter out the activated carbon to obtain a colorless transparent liquid, and cool down to 10°C while stirring , centrifuged and washed to obtain 243kg of high-quality taurine, and dried to obtain 210kg of finished product taurine (1.68×10 3 mol), after testing, all indicators are in line with JP8 and USP26.

Embodiment 3

[0064] Add liquid ammonium bisulfite (50%) 645kg (3.29×10 3 mol), and added 450kg of ethanolamine phosphate (3.19×10 3 mol), pressurized to 0.4MPa, heated to 115°C and kept for 50h, cooled down to 10°C under stirring, and centrifuged to obtain 400kg of crude taurine.

[0065] Put 400kg of the above crude taurine into a 1000L reaction kettle, add 500L of water and 1kg of activated carbon, dissolve the crude taurine under heating and stirring, filter out the activated carbon to obtain a colorless transparent liquid, and cool down to 10°C while stirring , centrifuged and washed to obtain fine-quality taurine 225kg (1.8×10 3 mol), dried to obtain 200kg of finished taurine (1.6×10 3 mol), after testing, all indicators are in line with JP8 and USP26.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com