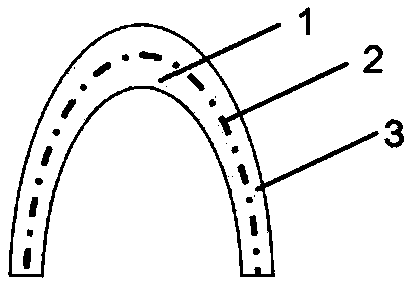

High-temperature-resistant frequency selective surface antenna cover and preparation method thereof

A frequency selective surface, radome technology, applied in antennas, radiation unit covers, electrical components and other directions, can solve the problems of unstable high and low temperature dielectric properties, cumbersome preparation process, affecting FSS performance, etc., to achieve stable FSS structure and process. The method is simple and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

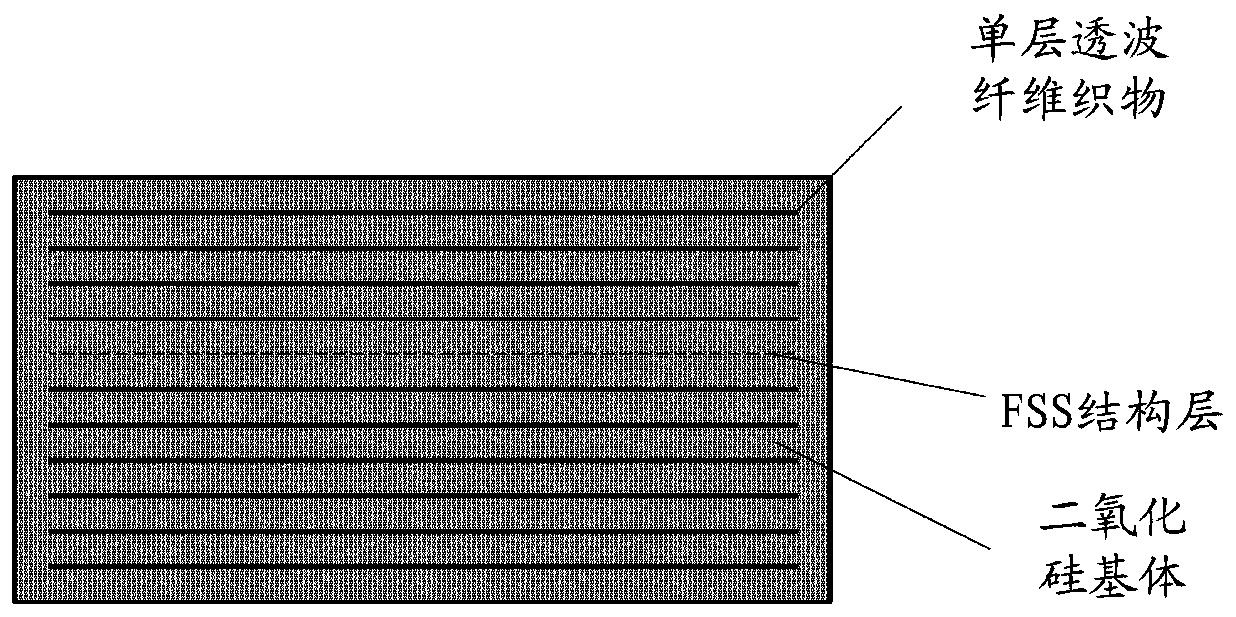

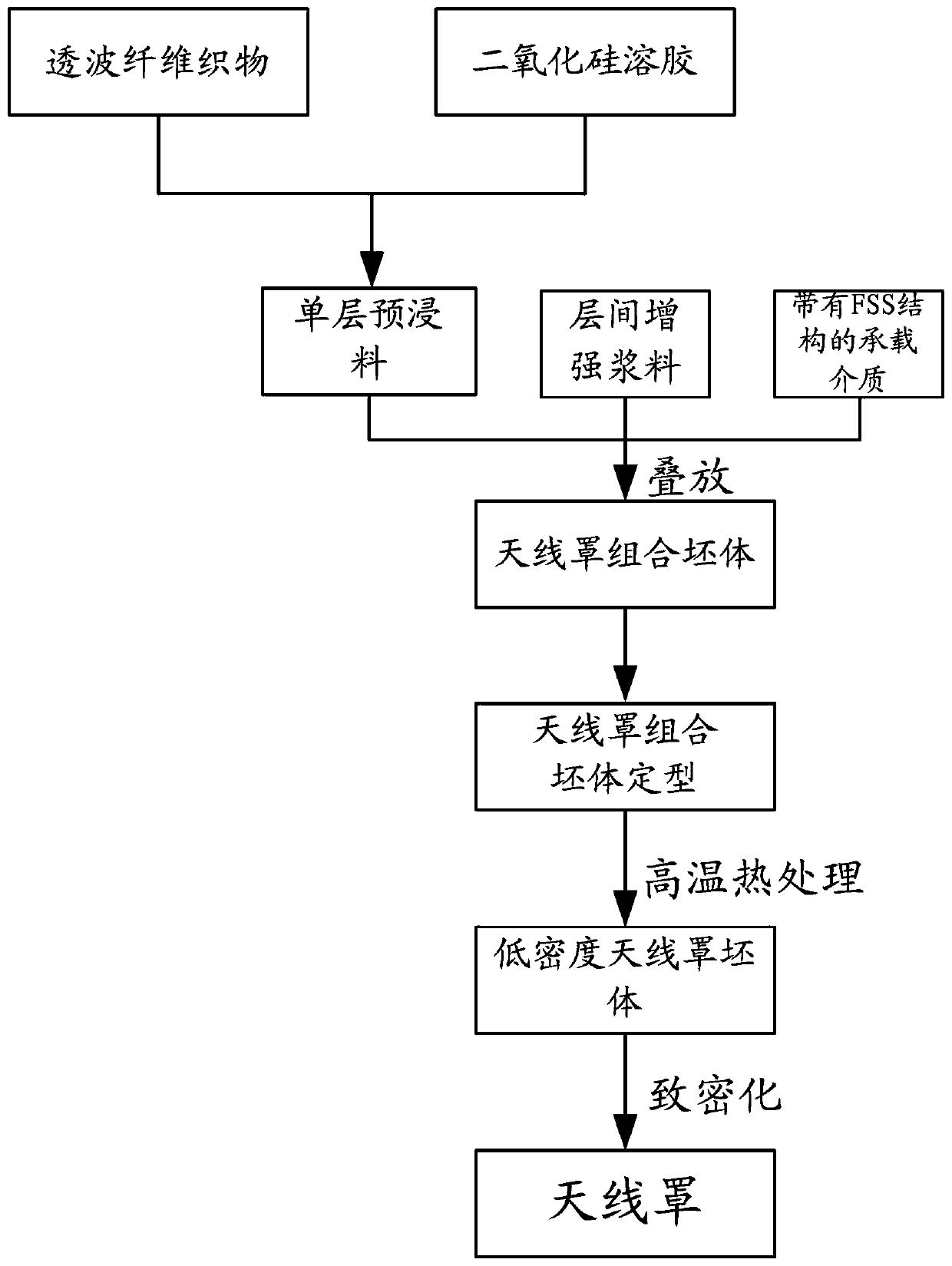

[0138] Preparation of Radome Containing Single FSS Layer Structure

[0139] 1. Raw material preparation

[0140] Mix commercially available low-temperature sintered alkali-free lead-free glass powder and fumed silica at a mass ratio of 10:90 to obtain reinforced powder. The glass powder includes the following components in mass percentage: B 2 o 3 : 30wt%; BiO 2 :35wt%; Al 2 o 3 : 10wt%; SiO 2 : 25wt%. Mix terpineol, ethyl cellulose, and the above-mentioned reinforcing powder at a mass ratio of 29:1:70, and grind to obtain an interlayer reinforcing slurry with a viscosity of 400-500 Pa.S.

[0141] The ceramic substrate is a domestic alumina-based HTCC ceramic chip with a thickness of 100 μm. The precious metal electronic paste is a sintered silver paste. The FSS periodic unit is printed on the alumina-based HTCC ceramic chip through the screen printing process of the sintered silver paste. , with a thickness of 10 μm and dried at 120°C for 1 hour, the unit structure is...

Embodiment 2

[0164] The FSS periodic unit is printed on the polyimide film by screen printing process with sintered silver paste, the thickness is 30 μm, and the unit structure is circular hole. The high-temperature heat treatment system is as follows: the temperature is raised from room temperature to 350°C in 60 minutes, then raised to 650°C in 240 minutes (polyimide film decomposition stage), then raised to 750°C in 30 minutes, and kept for 15 minutes (slurry sintering stage). ). Others are the same as in Embodiment 1, and the performance of the radome obtained is similar to that of Embodiment 1.

Embodiment 3

[0166] The sintered silver paste is used to print the FSS periodic unit on the cold-melt PVA film by the screen printing process, the thickness is 10 μm, and the unit structure is a circular hole.

[0167] Take out the prepreg with reinforcing slurry, and stack the dried single-layer prepreg compounded with interlayer reinforcing slurry and the PVA film with FSS structure on the radome mold according to the design requirements of the combined body. Lay the PVA film on the prepreg. When paving, the side of the water-soluble film with the FSS structure is attached to the prepreg, and then lay the prepreg on the PVA film, and repeatedly brush the silicon on the surface of the prepreg. Sol, on the one hand, makes the coated prepreg more compliant, and removes air bubbles and wrinkles; on the other hand, it allows the glue to penetrate into the impregnated body, dissolves the water-soluble film and leaves the FSS periodic unit. According to the impregnation composite molding techno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com