Production method of linseed oil as well as vacuum low-temperature pressing device of linseed oil

A technology of linseed oil and production method, which is applied in the directions of fat oil/fat production, press, and fat production, can solve the problems of reducing the nutrition and physiological activity of linseed oil, high maintenance cost of extraction technology and equipment, and destroying oil cells, etc. Achieve the effect of shortening the pressing process, high shelling efficiency, and reducing bitter substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

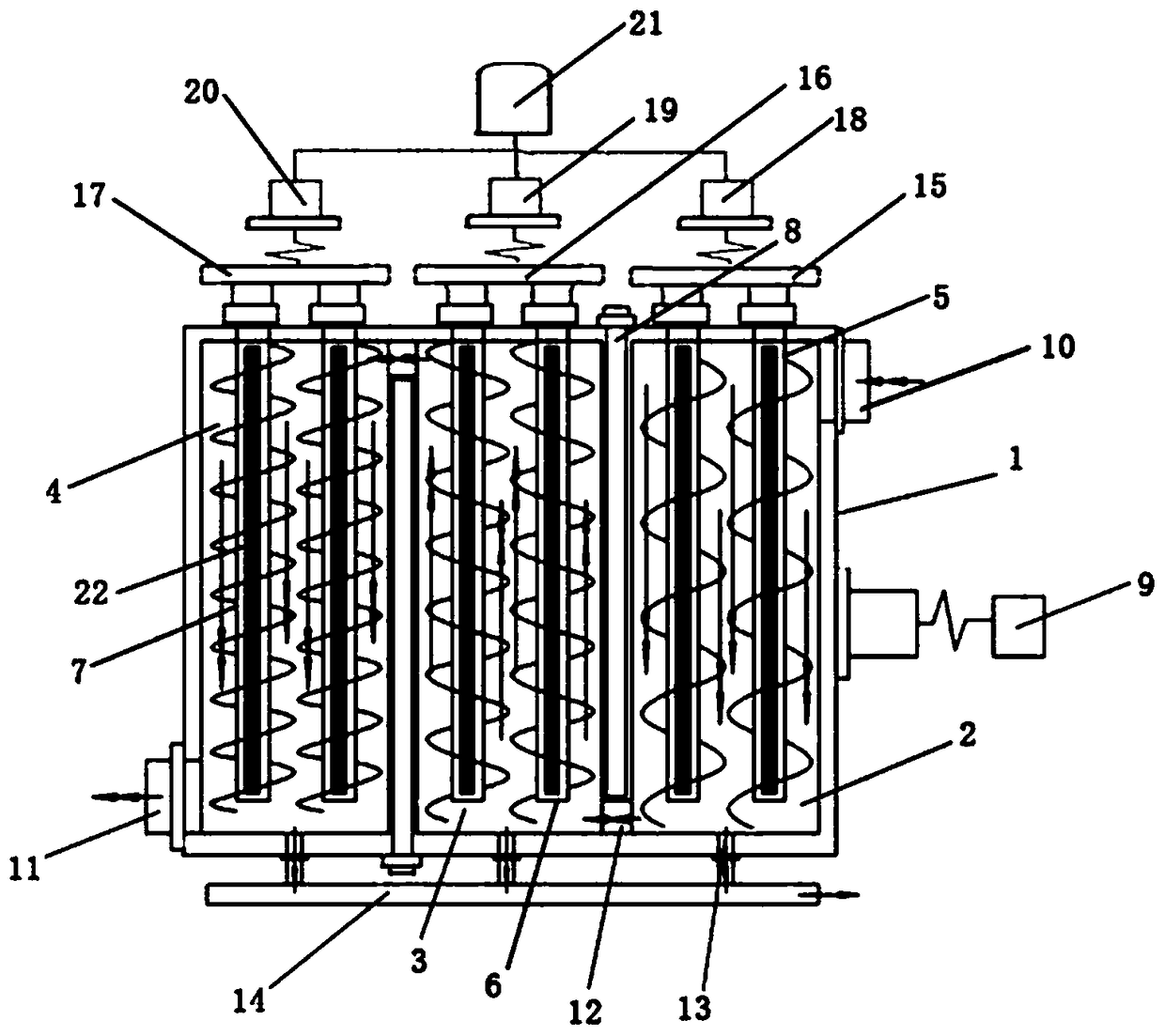

Image

Examples

Embodiment 3

[0058] Screening Example 3: The processing parameters of the treatment process of Preferred Screening Example 1 and Screening Example 2 are combined with linseed through high-voltage pulsed electric field and ultrasonic waves to prepare linseed oil:

[0059] Put 2.5kg of linseed into a high-voltage pulsed electric field for pretreatment. The pulsed electric field intensity is 26kV / cm, the pulse width is 20μs, the temperature is 38°C, and the treatment time is 4min to obtain matured linseed; then the matured linseed is Transport to the crusher for crushing to obtain coarse-grained linseeds with a particle size of 0.8-1mm; then transport the coarse-grained linseeds to an ultrasonic chamber for ultrasonic treatment, the ultrasonic frequency is 18kHz, the temperature is 33°C, and the processing time is 8 minutes to obtain the pressed raw material; then the pressed raw material was subjected to vacuum low-temperature pressing to extract oil, the vacuum degree was 0.06MPa, the temper...

preparation Embodiment 1

[0063] The production method of this preparation example linseed oil may further comprise the steps:

[0064] A. Hulling and kernel shell separation: Screen high-quality clean flaxseeds without damage, mildew, and dryness, put the high-quality flaxseeds into bags, put them into ultra-high pressure equipment, seal, pressurize to 358MPa, and hold the pressure for 4 minutes , carry out shelling, and then the linseed and flax husk mixture is separated by a high-speed rotating fan to obtain linseed and set aside;

[0065] B. High-voltage pulse electric field pretreatment: put 35kg of flaxseed into a high-voltage pulse electric field for pretreatment, the pulse electric field strength is 22kV / cm, the pulse width is 17μs, the temperature is 36°C, and the treatment time is 3min, and the mature flaxseed is obtained ;

[0066] C. Crushing: transport the matured linseed to a crusher for crushing to obtain coarse-grained linseed with a particle size of 0.8 to 1 mm;

[0067] D. Ultrasoni...

preparation Embodiment 2

[0075] The production method of this preparation example linseed oil may further comprise the steps:

[0076] A. Hulling and kernel shell separation: Screen high-quality clean flaxseeds without damage, mildew, and dryness, put high-quality flaxseeds into bags, put them into ultra-high pressure equipment, seal, pressurize to 482MPa, and hold the pressure for 5 minutes , carry out shelling, and then the linseed and flax husk mixture is separated by a high-speed rotating fan to obtain linseed and set aside;

[0077] B. High-voltage pulse electric field pretreatment: put 35kg of flaxseed into high-voltage pulse electric field for pretreatment, the pulse electric field strength is 25kV / cm, the pulse width is 18μs, the temperature is 37°C, and the processing time is 4min to obtain matured flaxseed ;

[0078] C. Crushing: transport the matured linseed to a crusher for crushing to obtain coarse-grained linseed with a particle size of 0.8 to 1 mm;

[0079] D. Ultrasonic reprocessing:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com