Graded peanut huller

A shelling machine, peanut technology, applied in the direction of shelling, solid separation, separation of solids from solids by air flow, etc. The effect of breakage rate and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

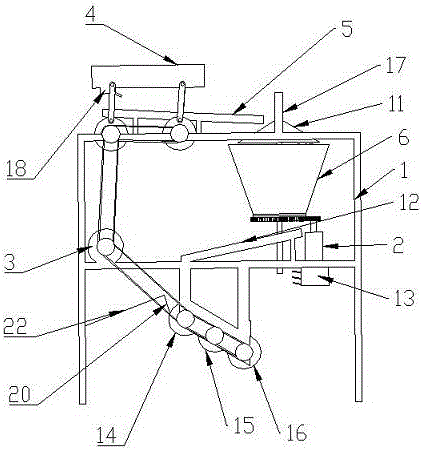

[0019] The present invention will be further described below in conjunction with accompanying drawings and examples.

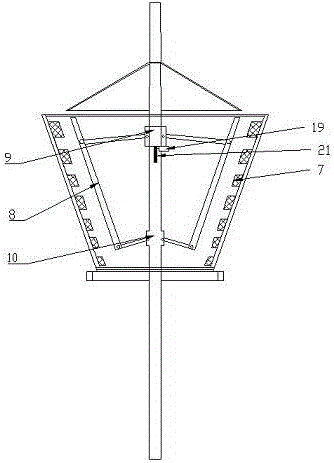

[0020] A peanut grading and shelling machine includes a frame and a control device, a screening device, a power device, a shelling device, a collecting device and the like arranged on the frame. The power device is connected with the screening device, the shelling device and the collecting device respectively. The control device is K51 single-chip microcomputer and stepping motor. The collecting device is arranged below the outlet of the shelling device, including belts, baffles and three cylindrical drums with small, medium and large apertures respectively, and is arranged directly below the outlet of the shelling device, so as to realize one machine for different Size, different varieties of peanuts are collected; the shelling device includes a feeding trough and a shelling drum, and the shelling drum includes two parts, the inner and the outer, and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com