Husking device for processing and remaining rice germs

A technology of rice and germ, which is applied in grain husking, grain degerming, grain treatment, etc., and can solve the problem of low filling rate of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

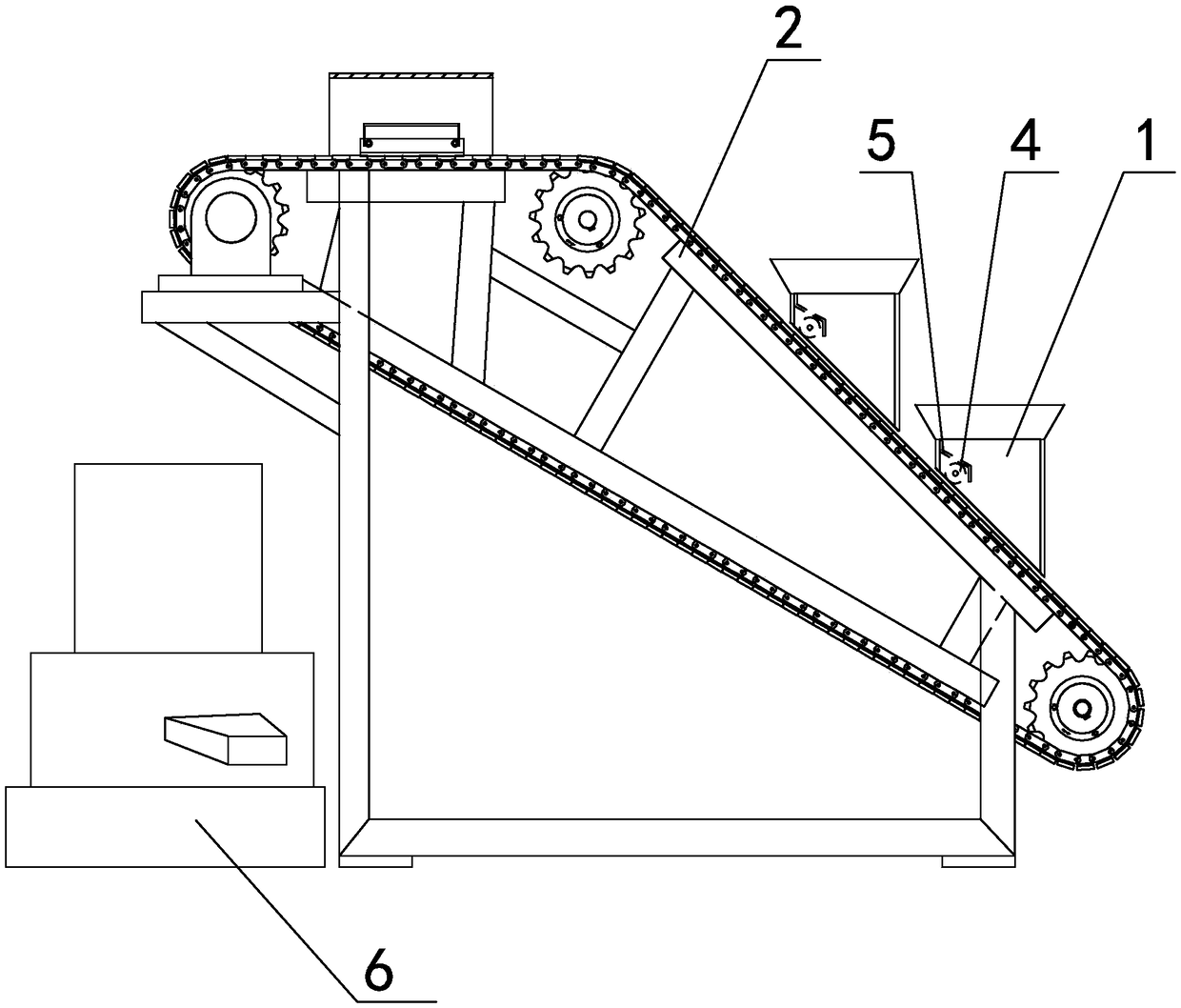

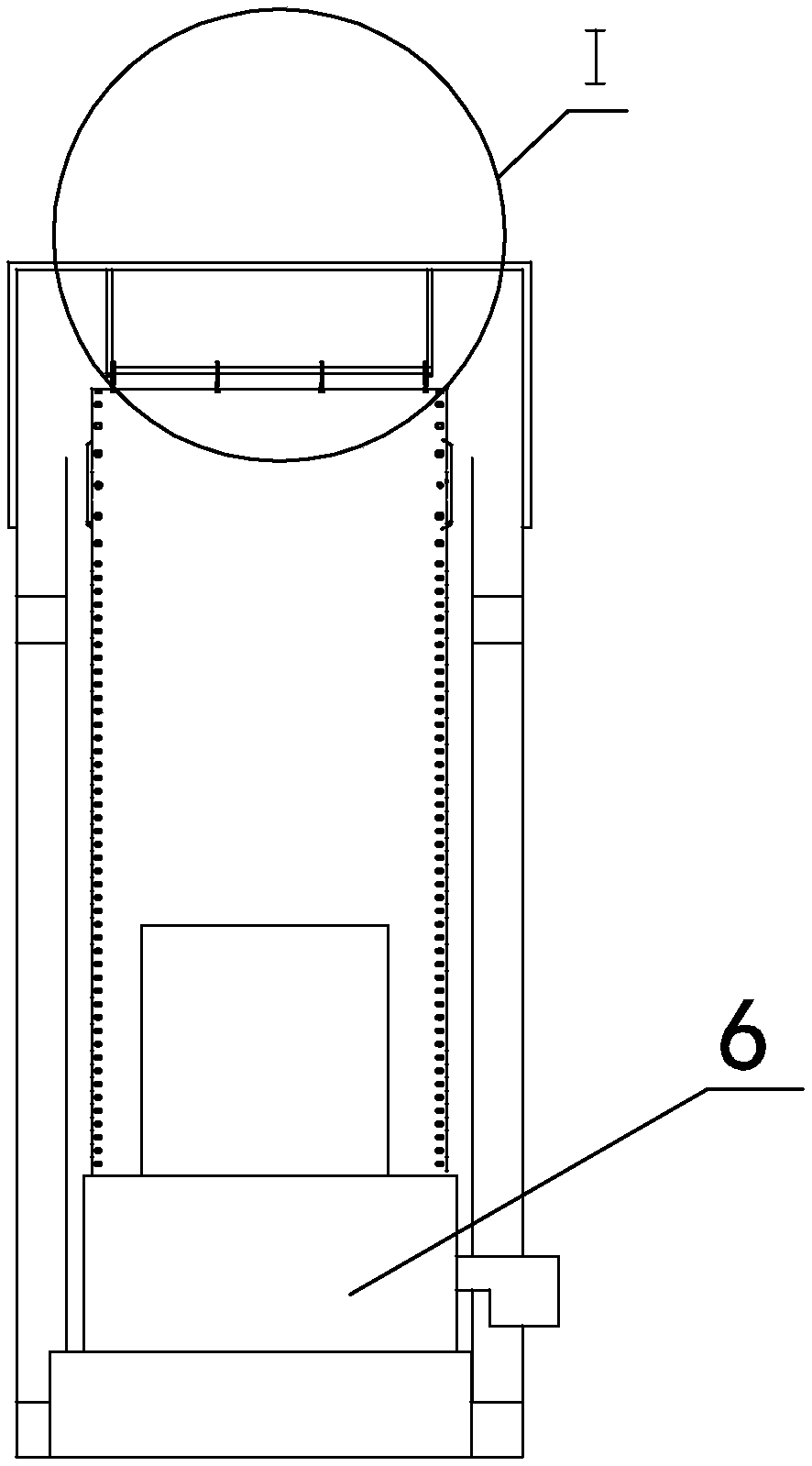

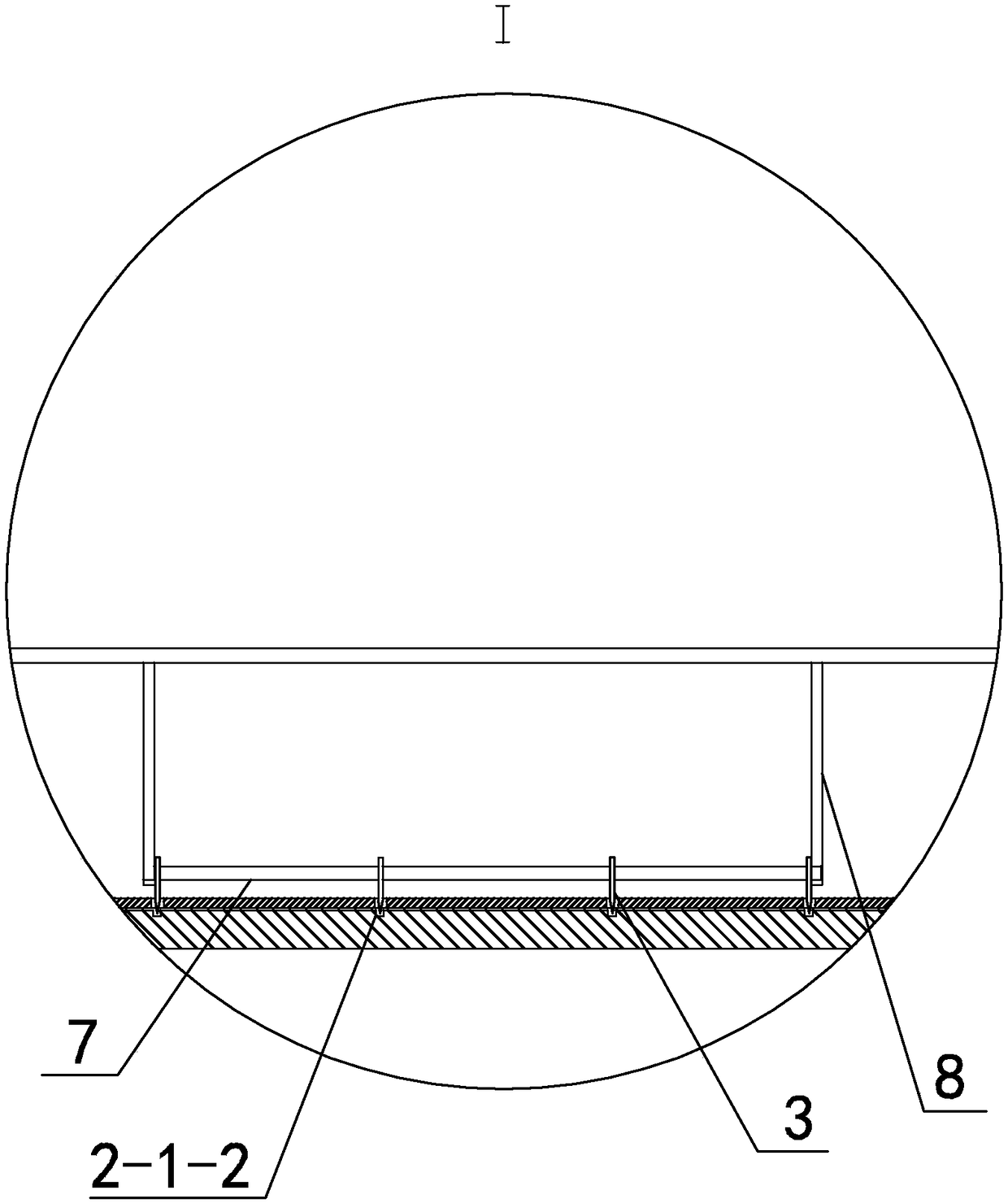

[0018] Specific implementation mode one: combine Figure 1 ~ Figure 4 To illustrate this embodiment, this embodiment includes a plurality of blades 3, conveyors, electric brushes 4 and a plurality of hoppers 1;

[0019] The conveyor is a chain-plate conveyor 2, the input end of the chain-plate conveyor 2 is arranged obliquely downward, the output end of the chain-plate conveyor 2 is arranged horizontally, and each chain plate 2-1 of the chain-plate conveyor 2 There are multiple rows and rows of rice grooves 2-1-1, and each rice groove 2-1-1 can only accommodate one grain of rice, and the center of the width direction of each row of rice grooves 2-1-1 is provided with a knife groove 2-1-2,

[0020] Electric hairbrush 4 and baffle plate 5 are all arranged in each hopper 1, and each hopper 1 is all arranged on the side of the input end of chain conveyor 2, and the mouth of each hopper 1 is connected with described chain plate 2-1. The gap can only accommodate the rice of the ri...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the bottom of the hopper 1 in this embodiment is a square tube, the top of the hopper 1 is a square cone tube, and the bottom of the square tube is an oblique opening; the hopper 1 is vertically arranged on the chain conveyor 2 side of the input.

[0026] Such setting increases the contact area between the feed opening of the hopper 1 and the chain conveyor 2, and increases the filling rate of the rice tank 2-1-1.

[0027] Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 4 To describe this embodiment, the depth of each sipe 2-1-2 in this embodiment is greater than the depth of each meter groove 2-1-1. Such setting is to ensure that the rice in each rice groove 2-1-1 is cut off from the middle.

[0029] Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com