Peanut sheller

A technology for shelling machine and peanuts, applied in the field of shelling machines, can solve the problems that peanuts remain in manual work, poor cleaning rate, high crushing rate, and achieve high shelling and sorting efficiency, maintaining cleanliness, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

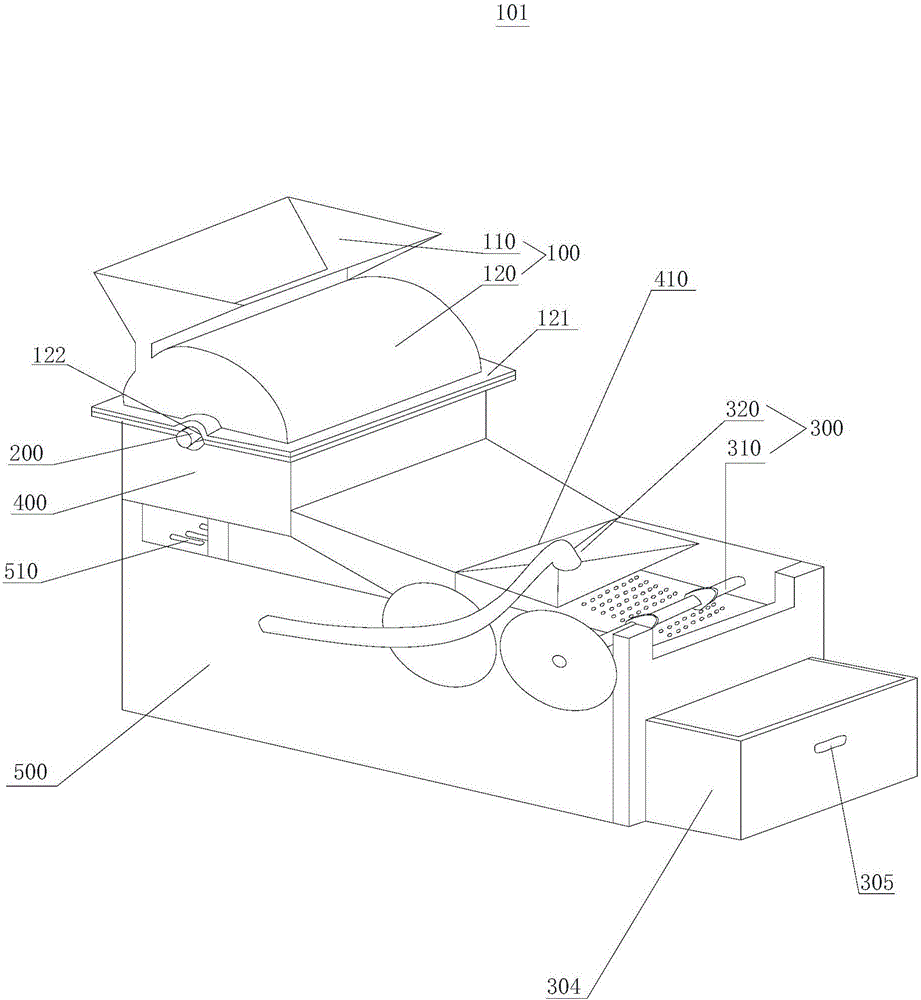

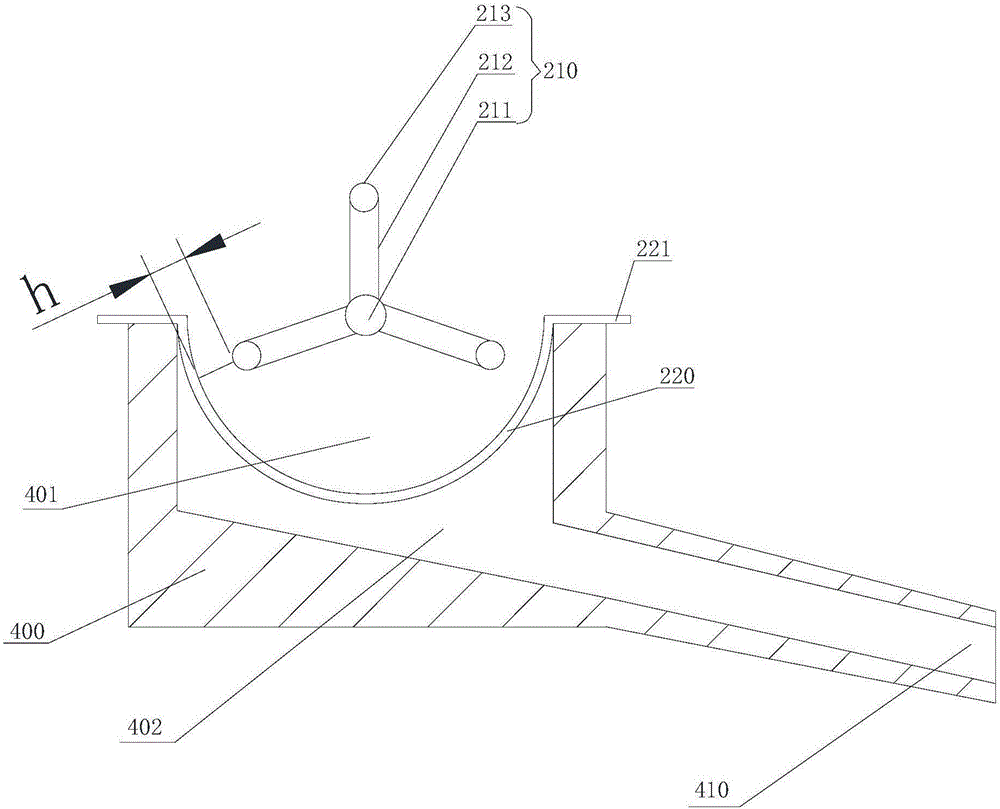

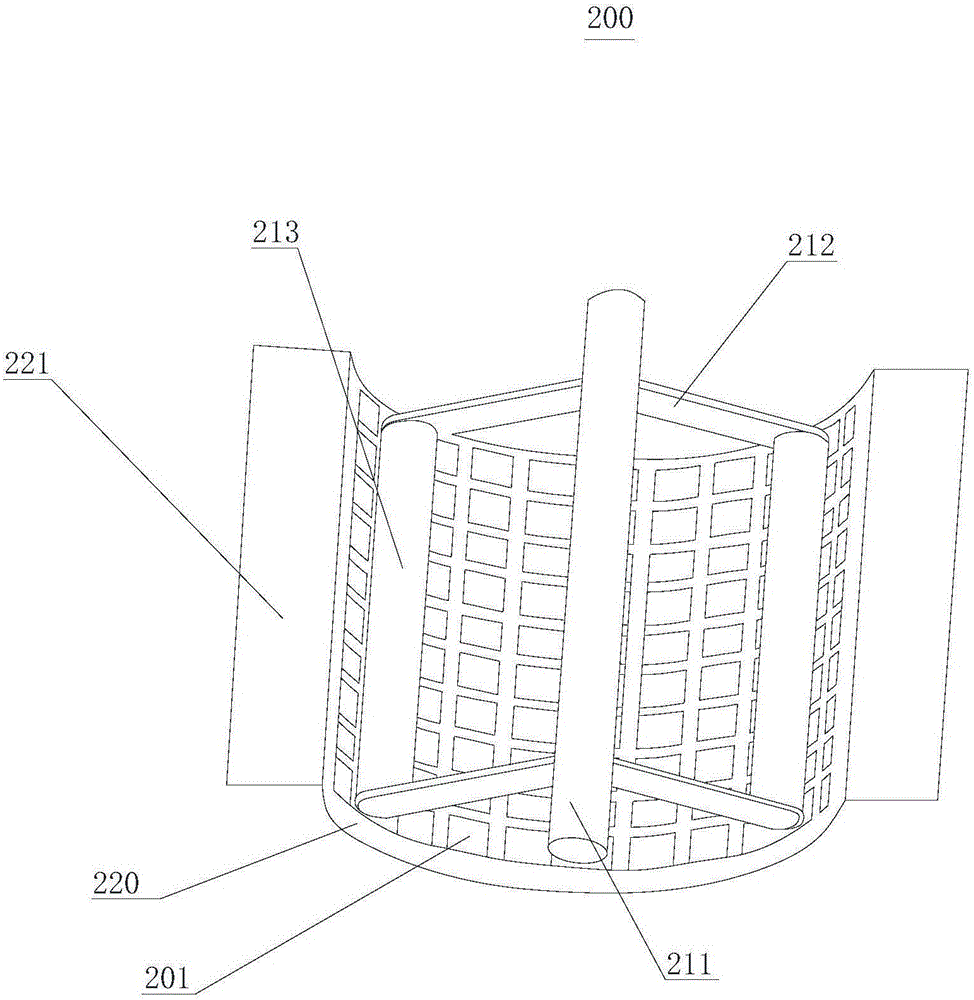

[0030] See attached figure 1 , a peanut sheller 101 provided in an embodiment of the present invention includes a feed hopper 100, a shelling mechanism 200, a shell-kernel separation mechanism 300, and a first box 400 with an open upper end.

[0031]The feeding hopper 100 is a feeding device for peanuts, which can improve the convenience of using the peanut sheller 101 to a certain extent, and further improve the efficiency. Specifically, in this embodiment, the feeding hopper 100 includes a funnel 110 and a cover plate 120 , the upper and lower sides of the funnel 110 are open, and the upper side is larger and the lower side is smaller. The funnel 110 is surrounded by two inclined plates and two vertical plates. The two vertical plates and the two inclined plates are set opposite to each other. The inner walls of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com