Chinese chestnut and hazelnut dual-purpose huller

A peeling machine, the technology of hazelnuts, applied in the direction of application, shelling, pod removal, etc., can solve the problems of difficult shelling and peeling, and achieve the effect of high peeling efficiency, good quality, and high shelling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

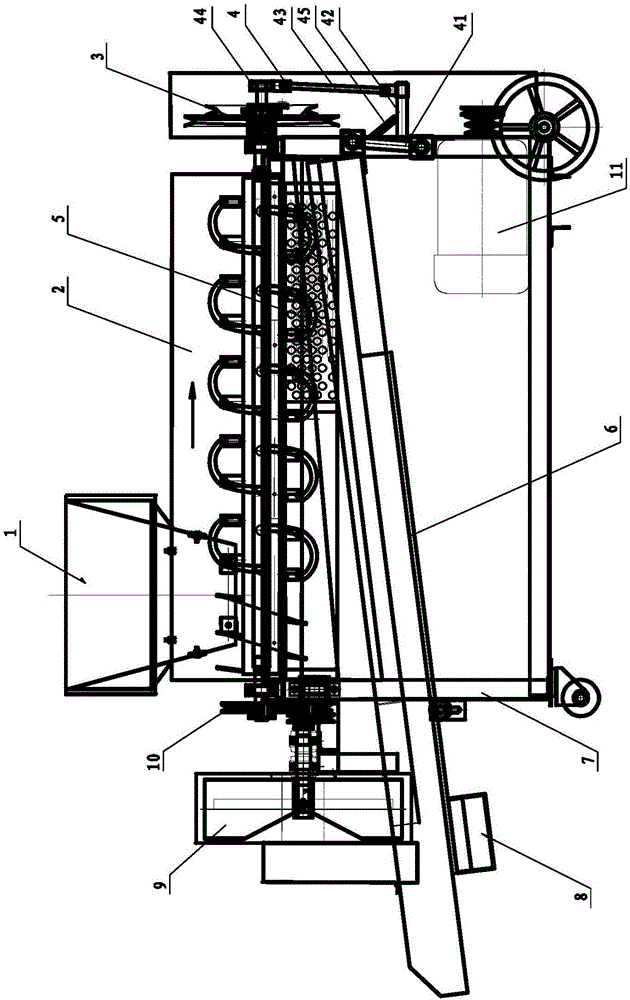

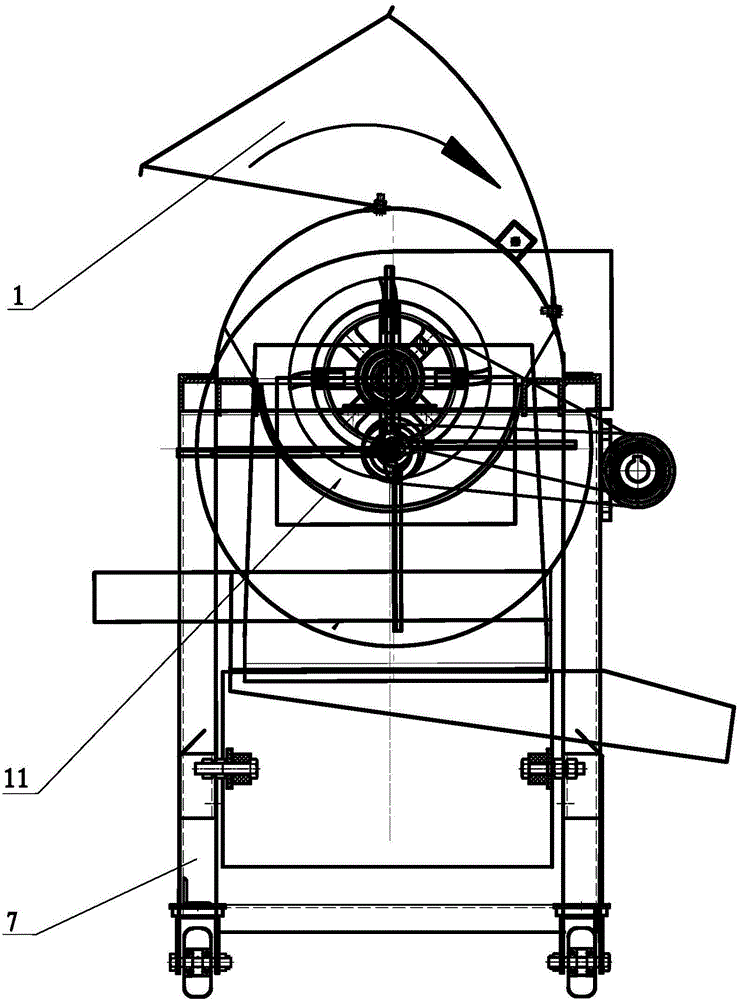

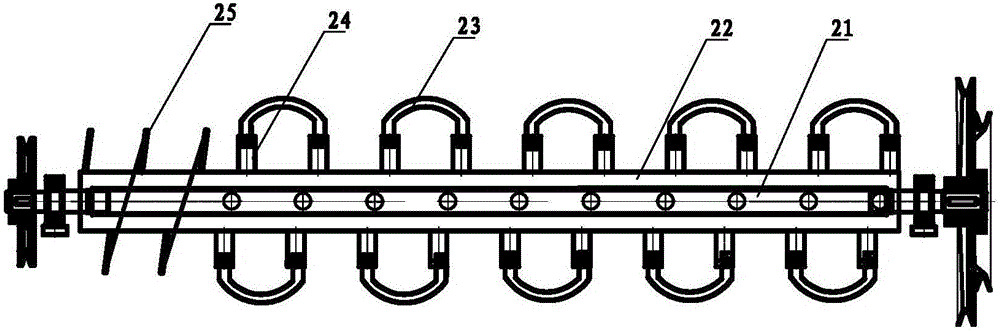

[0031] Embodiment 1: as Figure 1-Figure 3 As shown, a dual-purpose peeling machine for chestnuts and hazelnuts of the present invention includes a frame 7, a motor 11, a transmission mechanism, a main shaft roller 2, a semicircular sieve 5, a vibrating screen 6 and a fan 9, and the top of the frame 7 is provided with a main shaft Roller 2, one side on the main shaft roller 2 is provided with material inlet 1, the two ends of the main shaft 21 of the main shaft drum 2 are installed on the frame 7, and the main shaft 21 in the main shaft roller 2 is equipped with a driving roller 22, A semicircular screen 5 is installed at the material pushing end below the driving roller 22 of the main shaft roller 2, and a vibrating screen 6 is installed obliquely below the semicircular screen 5. One end of the main shaft 21 is connected to the output shaft of the motor 11 through the transmission mechanism I, and the other end is connected to the output shaft of the motor 11 through the trans...

Embodiment 2

[0040] Embodiment 2: The difference between this example and Example 1 is that this example is used for peeling hazelnuts, the axial length of the semicircular sieve 5 is 2 / 5-3 / 5 of the driving roller 22, and this example selects 2 / 5, semicircular There are a plurality of long holes on the sieve, and the width of the long holes is 15-25mm; multiple steel pipes are arranged at equal intervals on the vibrating screen, and the distance between adjacent steel pipes is 15-25mm. There is a long-hole screen, and the width of the strip holes on the long-hole screen is 15-25mm.

Embodiment 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the axial length of the semicircular screen 5 in this embodiment is 3 / 5 of the drive roller 22 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com