Oil tea fruit shelling and screening processing method and equipment

A processing method and technology of camellia oleifera fruit, applied in chemical instruments and methods, filtering, shelling, etc., can solve the problems of small difference in size and specific gravity, complicated processing process, poor screening effect of seed shells, etc., to prevent damage , The process is simple and the screening effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

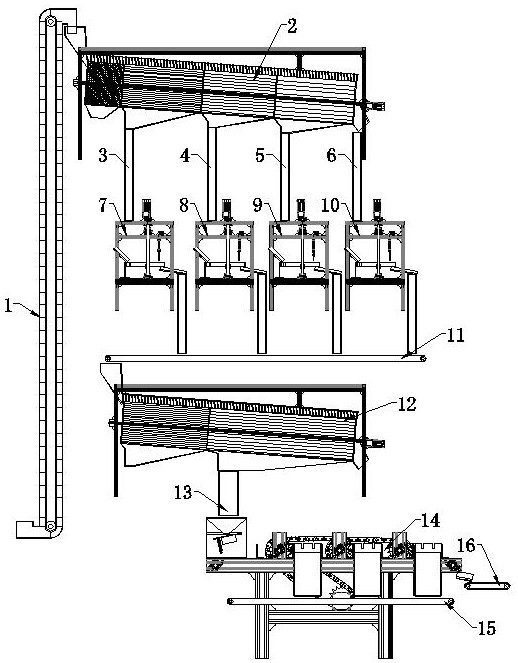

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

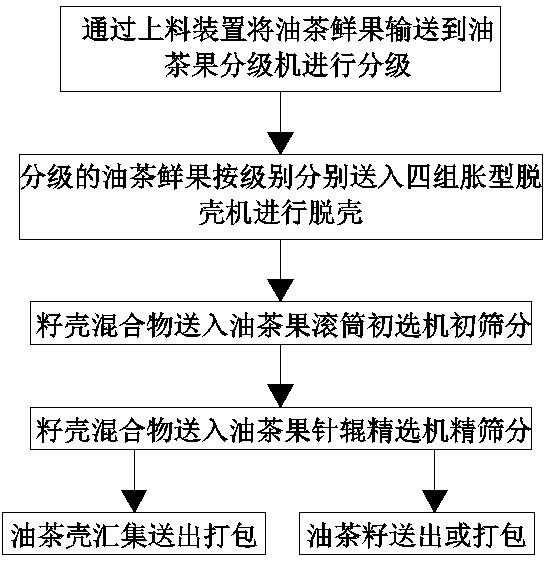

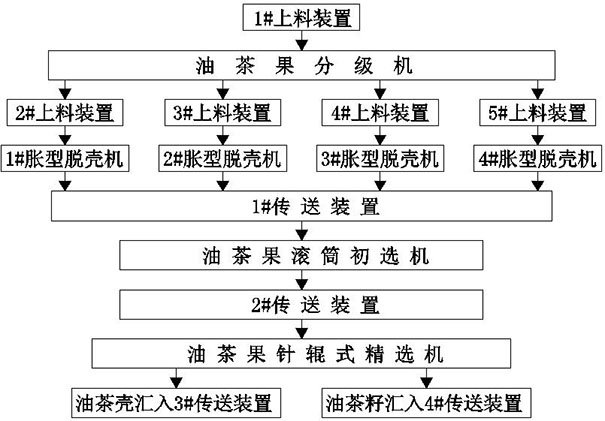

[0034] Examples refer to the attached Figure 1-6 Shown, a kind of Camellia oleifera shelling and screening processing method comprises the following steps:

[0035] Step 1. Grading treatment: through the 1# feeding device (1), the picked fresh camellia oleifera fruit is sent to the camellia oleifera fruit classifier (2) for grading treatment, and the classified fresh camellia oleifera fruit is divided into grade I, grade II and grade according to the diameter Ⅲ, grade Ⅳ four kinds of Camellia oleifera;

[0036] Step 2, shelling treatment: send the grade I Camellia oleifera fruit described in step 1 to the 1# expansion shelling machine (7) through the 2# feeding device (3) for shelling treatment, and obtain the 1# camellia seed shell mixture; Send the grade II camellia fruit described in step 1 to the 2# expansion sheller (8) throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com