Coix seed huller

A barley husking machine and the technology of the husking machine, which are applied in grain husking, grain processing, application, etc., can solve the problems of high damage rate of grain kernel edges and waste of effective ingredients in grain kernels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

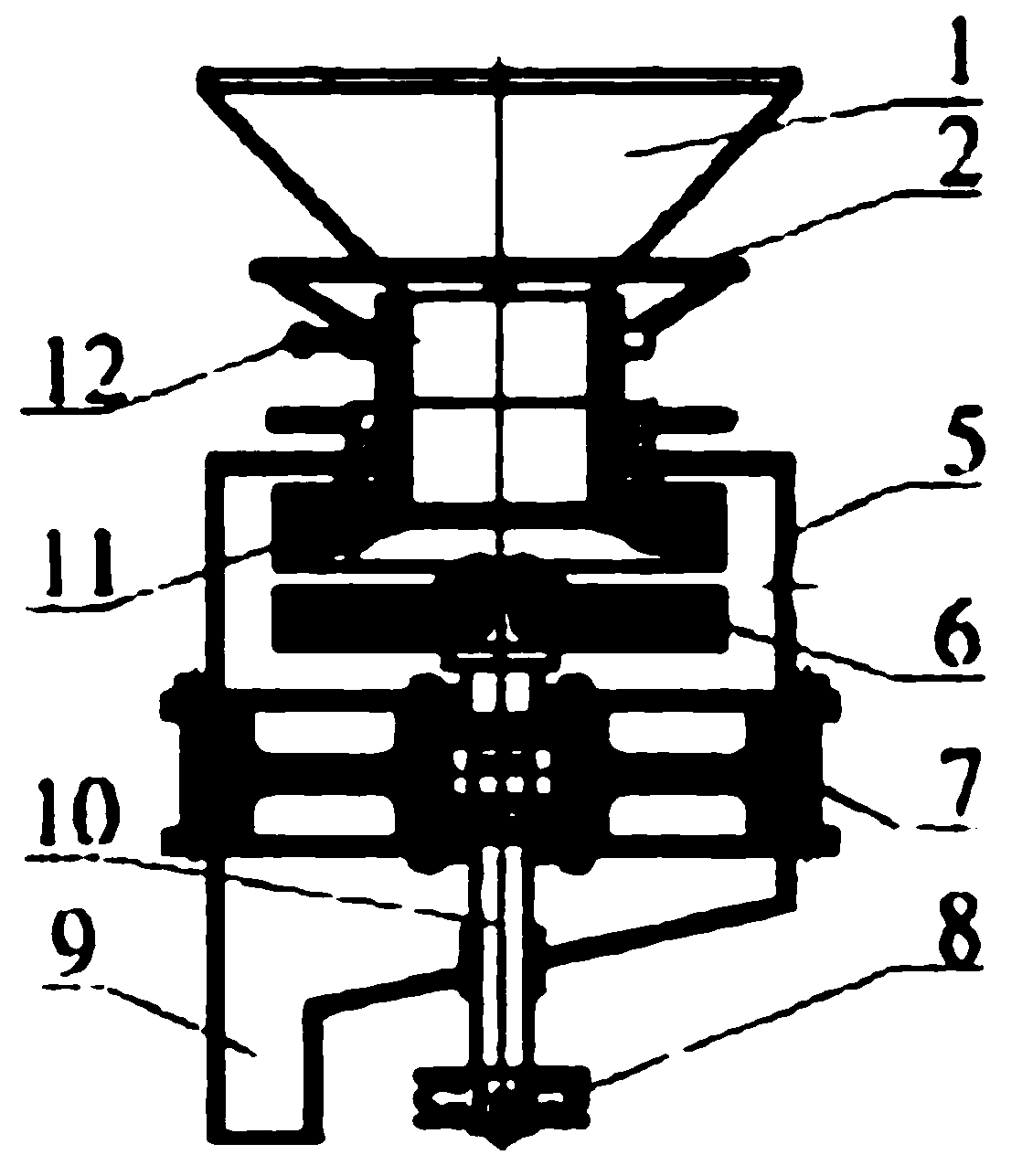

[0016] The barley dehulling machine of the present invention includes a feeding hopper 1 and a fixed grinding disc 6, characterized in that the feeding hopper 1 is connected with an upper casing 5 through a base, and a feeding channel is arranged at the center of the fixed grinding disc 6, and The feed channel is communicated with the feed hopper 1;

[0017] A main shaft 10 is connected to the upper casing 5 through a bearing seat 7, and the bearing seat 7 is fixedly connected to the upper casing 5. One end of the main shaft 10 is fixedly connected with a rotating grinding disc 11, and the other end is connected with a belt pulley 8, the rotating grinding disc 11 It is on the same straight line as the central axis of the fixed grinding disc 6, and the rotating grinding disc 11 and the fixed grinding disc 6 are arranged parallel to each other;

[0018] A discharge bin is connected to the bottom of the upper casing 5, and a discharge port 9 is arranged on the discharge bin. One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com