Peanut huller

A shelling machine and peanut technology, applied in the field of agricultural machinery, can solve the problems of poor applicability, small effective working area and increased damage probability of peanut shelling, so as to improve the cleaning rate and shelling efficiency, high effective use area, Effect of improving shelling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

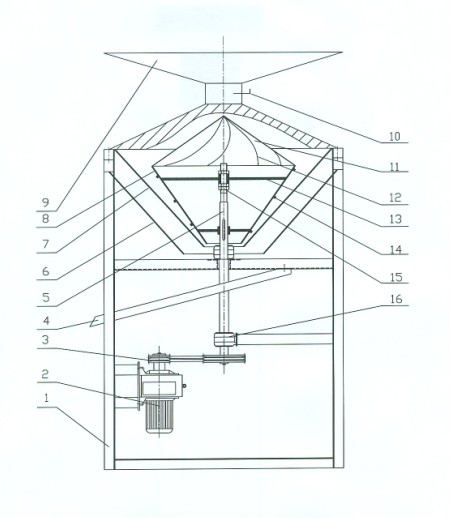

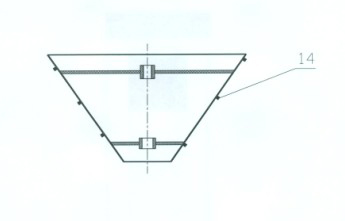

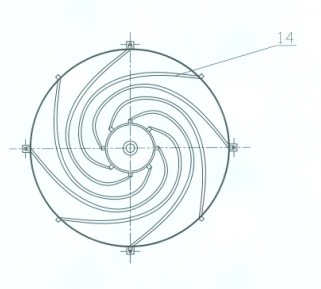

[0019] See Figure 1-4 , the specific structure is as follows: a bearing seat 16 is set on the frame 1, and the roller shaft 5 is rotated and assembled on the bearing seat 16; the roller shaft 5 is connected to the motor 2 through the belt transmission device 3. Assemble the collecting tube 6 on the frame 1, and set the inclined receiving plate 4 under the collecting tube 6; set the feeding hopper 9 on the upper end of the frame 1, and set the pull-type flow control plate 10 on the feeding hopper 9. The drum 8 is arranged below the feeding hopper 9, and the drum 8 is an inverted conical vertical hollow cylinder, and its outer surface is welded with a plurality of evenly distributed spiral raised ribs 14, and the upper end of the drum 8 is provided with a cone-shaped uniform distributor 11, uniform Eight spiral ribs 12 are evenly distributed on the device 11 to play a role of diversion, so that the falling peanuts can evenly enter the shelling section. Disc 13 is welded up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com