Fruit shelling device and shell and seed separator comprising the shelling device

An equipment and fruit technology, applied in the direction of solid separation, shelling, sieving, etc., can solve the problems of difficulty in finding the rubbing structure, affecting the oil yield, and the uniformity of the fruit size, etc., to improve the efficiency and effect, and improve the extraction rate. , to ensure a uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

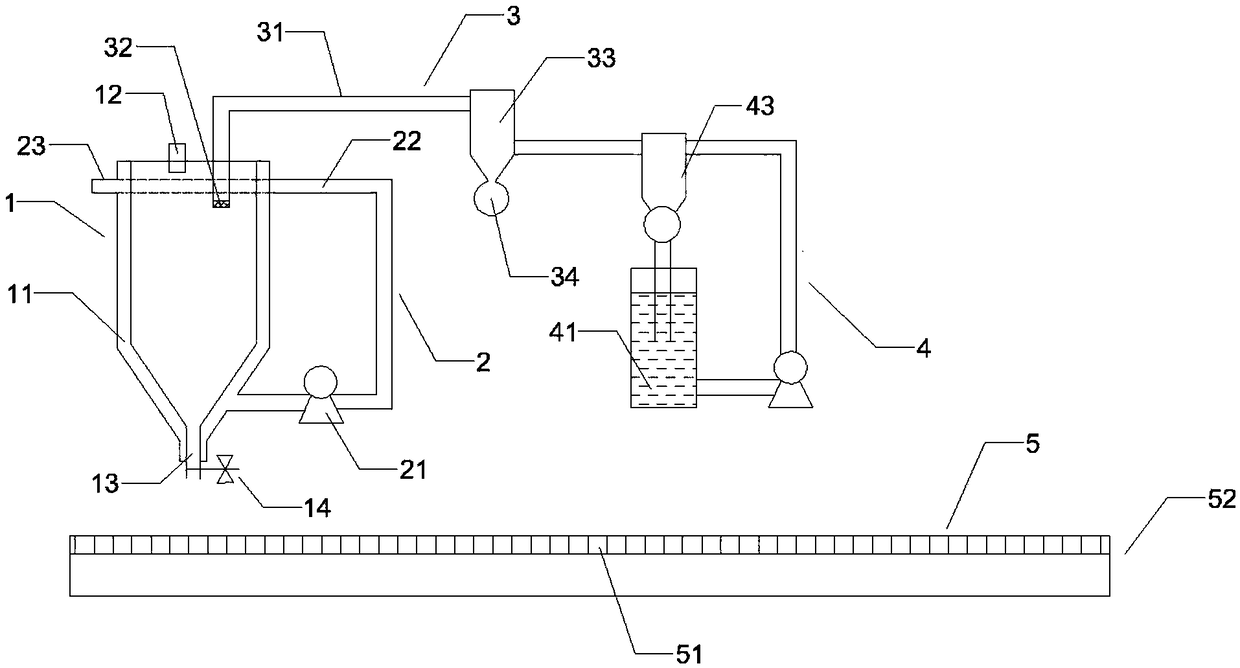

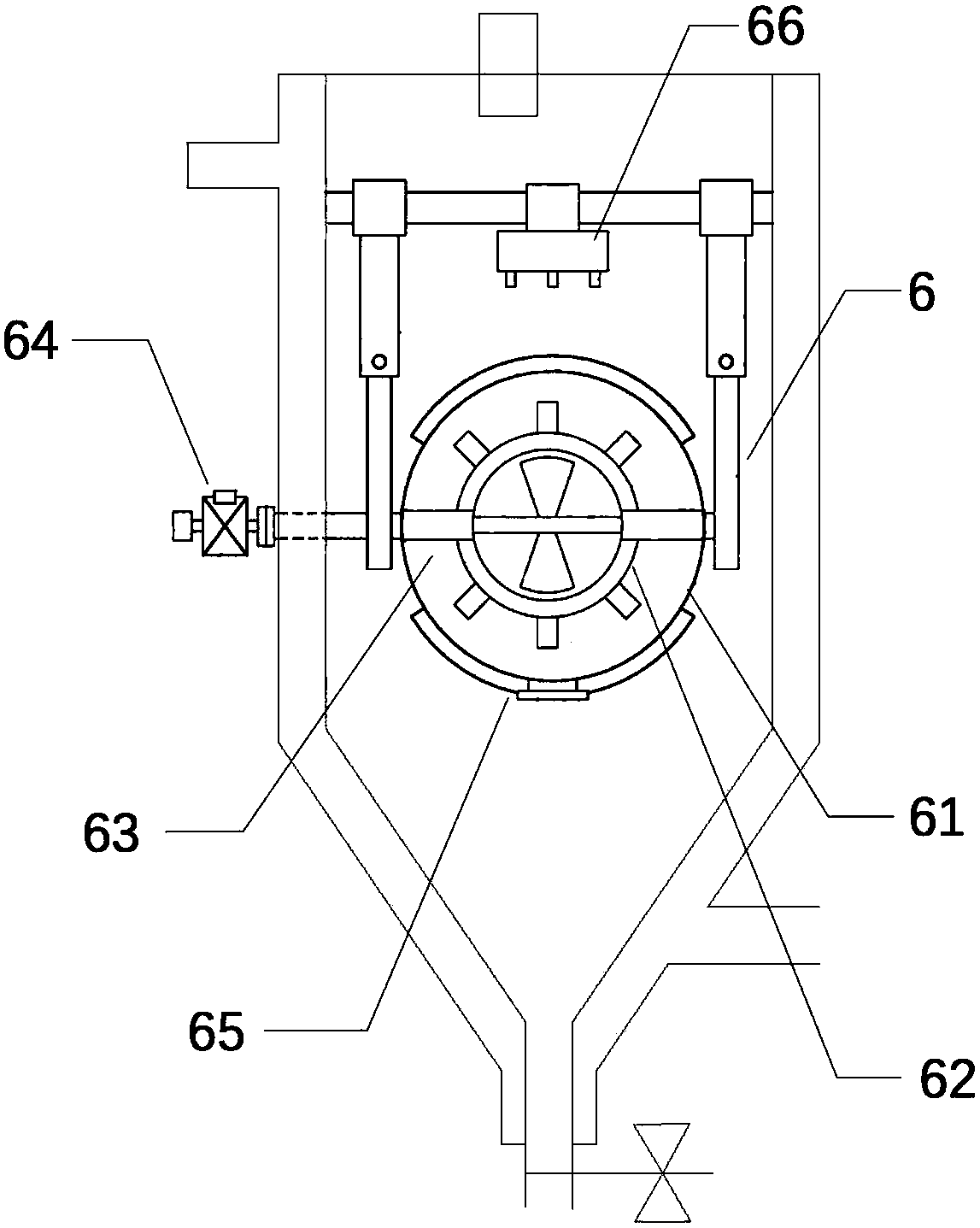

[0041] Such as Figure 1 to Figure 2 As shown, a kind of fruit shelling equipment includes a closed and internally accommodating shelling chamber 1, the outer wall of the shelling chamber 1 includes an interlayer 11 for setting a heat-conducting fluid, and the shelling chamber 1 is made of a heat-conducting material Such as stainless steel, the outer surface of the interlayer 11 can also be provided with an insulating material layer, and the insulating material layer can further help the temperature in the chamber of the drying chamber 1 to reduce diffusion, so that the constant temperature can be maintained in the chamber; shelling chamber 1 top There is a material inlet 12, and the material inlet 12 is equipped with a sealing assembly to ensure the internal airtightness of the shelling chamber 1; the bottom of the shelling chamber 1 is provided with a material outlet 13, and the shelling of the contents is completed. Finally, the opening and closing of the discharge port 13 ...

Embodiment 2

[0049] A shell and seed separator, comprising a fruit shelling device disclosed in Example 1, a vibrating separation screen 5 is arranged at the lower part of the fruit shelling device, and the vibrating separation screen 5 is provided with a seed separation outlet 51 and a shell separation outlet 52 .

Embodiment 3

[0051] The fruit shelling equipment and shell seed separator disclosed in embodiment 1 and embodiment 2 are used to realize shelling and shell seed separation of camellia oleifera green fruit.

[0052] Put the fresh camellia oil green fruit into the inside of the drying chamber 1 through the feed port 12, close the feed port 12 and the bottom valve 14, and the inside of the whole device is airtight. Turn on the water balance circulation pump 43, and the circulation system is opened, so that the air in the drying chamber 1 is taken out through the water circulation, forming a negative pressure with a pressure of 200bar, and forming a stream of water from the lower chamber in the chamber of the drying chamber 1. Airflow from chamber to chamber. Turn on the heat source 2, and turn on the oil pump 21, the heat transfer fluid in the interlayer 11 is driven by the oil pump 21 to circulate in the interlayer 11 and the heat source 2, the heat transfer fluid is heated when passing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com