System and method for treating industrial water by induced crystallization process

A technology of inducing crystallization and industrial water, which is applied in the direction of sedimentation treatment, special treatment targets, water/sewage treatment, etc., can solve problems such as heat exchanger blockage, low thermal efficiency, chemical pollution, etc., and achieve the effect of reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

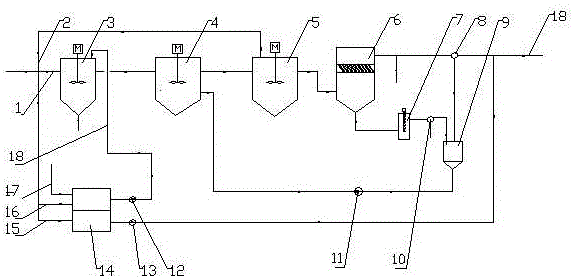

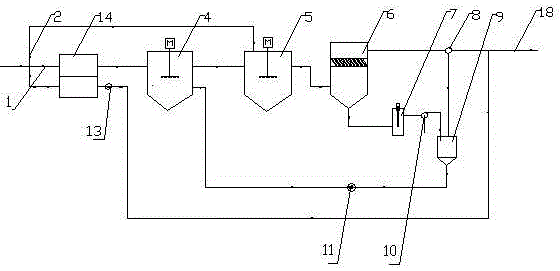

[0019] The specific implementation of the present invention is given below in conjunction with the drawings.

[0020] Such as Figure one Shown:

[0021] Raw water 1 with higher hardness and alkalinity enters the conditioning tank 3 and is mixed with the lye produced by the electrochemical processor 14, and the following reactions occur in the conditioning tank 3:

[0022] HCO 3 - + OH - → H 2 O + CO 3 2-

[0023] Ca 2+ +CO 3 2- → CaCO 3 ↓

[0024] Mg 2+ +CO 3 2- → MgCO 3 ↓

[0025] CaCO in conditioning tank 3 after reaction 3 , MgCO 3 Exist in a saturated state, the PH value rises above 9.5; CaCO 3 And MgCO 3 The seed crystal in crystallizer I4 is crystal nucleus, and gradually grows up, the PH value is basically unchanged.

[0026] Seed, CaCO 3 And MgCO 3 Crystals and incomplete reaction lye enter crystallizer Ⅱ5, HCO in raw water 3 - , Ca 2 + , Mg 2+ The following reactions continue to occur in the crystallizer II5:

[0027] HCO 3 - + OH - → H 2 O + CO 3 2-

[0028] Ca 2+ +CO 3 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com