Rotary lotus seed peeling machine

A peeling machine and rotary technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of slow manual peeling of lotus seeds, achieve the effect of less parts, low manufacturing cost, and convenient maintenance of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

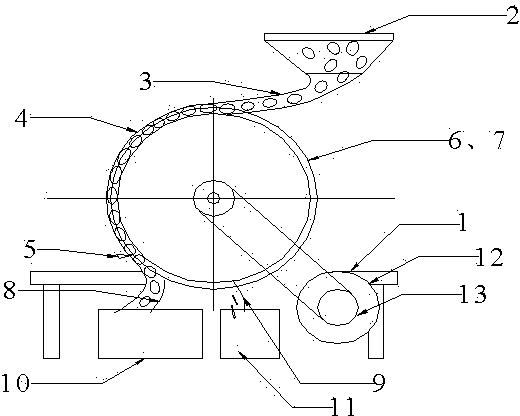

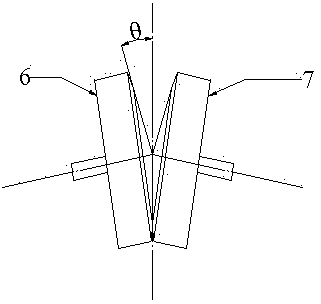

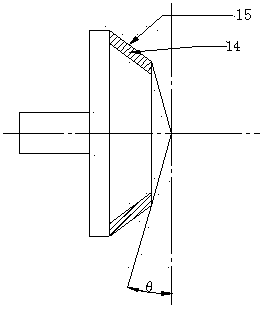

[0012] Such as Figure 1 ~ Figure 3 As shown, the rotary lotus seed peeling machine of the present invention, a kind of rotary lotus seed peeling machine, comprises frame 1, feeding device 2, material guide groove 3, processing groove 4, processing cutter head 5, extruding opposite wheel, lotus seed Seed separator 8, lotus skin separator 9, lotus seed trough 10, lotus skin trough 11, motor 12, power transmission parts 13, etc.

[0013] The motor 12 is connected with the extrusion counter wheel through the power transmission part 13, and transmits the power to the extrusion counter wheel; a processing groove 4 is provided on one side of the extrusion counter wheel, and the upper end of the processing groove 4 is connected with the feeding device 2 through the material guide groove 3 , the lotus seeds are transported to the processing tank 4 through the material guide groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com