Graphene aerogel hollow fiber, and preparation method and application thereof

A technology of graphene airgel and graphene sheet, applied in the direction of hollow filament manufacturing, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problem of affecting the multifunctional application of hollow fibers, restricting the application of hollow fibers, and restricting hollow fibers Application expansion and other issues to achieve excellent fluid transport performance, high-efficiency light-to-heat conversion performance, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned graphene airgel hollow fiber, which includes:

[0077] 1) Using coaxial needle-assisted sol-gel technology to prepare graphene hydrogel hollow fibers;

[0078] 2) Carry out supercritical fluid drying and / or freeze-drying treatment to described graphene hydrogel hollow fiber, while keeping gel network from being destroyed, remove solvent molecule in gel, obtain graphene airgel hollow fiber fiber.

[0079] In some preferred embodiments, the step 1) specifically includes:

[0080] A graphene oxide liquid crystal is provided, wherein the graphene oxide liquid crystal is concentrated from a graphene oxide aqueous solution, the graphene oxide aqueous solution is subjected to high-speed centrifugation, and the lower layer dispersion is collected to obtain the graphene oxide liquid crystal;

[0081] Inject the graphene oxide liquid crystal into the coagulation ba...

Embodiment 1

[0115] (a) 5mg / mL graphene oxide liquid crystal and 0.001wt% HCl solution were injected into 0.1wt% HCl solution at the same time through a coaxial needle at an injection speed of 10 μL / min to obtain a continuous graphene oxide hydrogel hollow fiber.

[0116] (b) soaking the graphene oxide hydrogel hollow fiber in step a) in an aqueous ascorbic acid solution, and standing at 5° C. for 72 hours to obtain a graphene hydrogel fiber.

[0117] (c) replacing the graphene hydrogel hollow fiber in step b) with an ethanol solvent, and supercritically drying at 33° C. for 24 hours to obtain a graphene airgel hollow fiber.

[0118] (d) uniaxially weaving the graphene airgel hollow fiber into a fabric in step c), and then crimping it to obtain a graphene airgel hollow fiber reel. Then the reel is soaked in the silica gel pre-solidified solution and cured to obtain the silica gel-graphene airgel hollow fiber reel composite. Test water evaporation performance under 1.0 sun.

[0119] The ...

Embodiment 2

[0122] (a) 15mg / mL graphene oxide liquid crystal and 6wt% calcium chloride solution are simultaneously injected into 3wt% cetyltrimethylammonium bromide aqueous solution at an injection speed of 50 μL / min through a coaxial needle to obtain continuous graphene oxide hydrogel hollow fibers.

[0123] (b) soaking the graphene oxide hydrogel hollow fiber in step a) in an aqueous solution of hydroiodic acid, and standing at 100°C for 0.5h to obtain a graphene hydrogel fiber.

[0124] (c) Freeze-drying the graphene hydrogel hollow fiber in step b) at -50° C. for 24 hours to obtain a graphene airgel hollow fiber.

[0125] (d) Integrating and winding the graphene airgel hollow fibers in step c) into bundles, then immersing the graphene airgel hollow fiber bundles in the ethylene oxide pre-solidified liquid, curing to obtain ethylene oxide - Graphene airgel hollow fiber bundle composite. Test water evaporation performance under 1.0 sun.

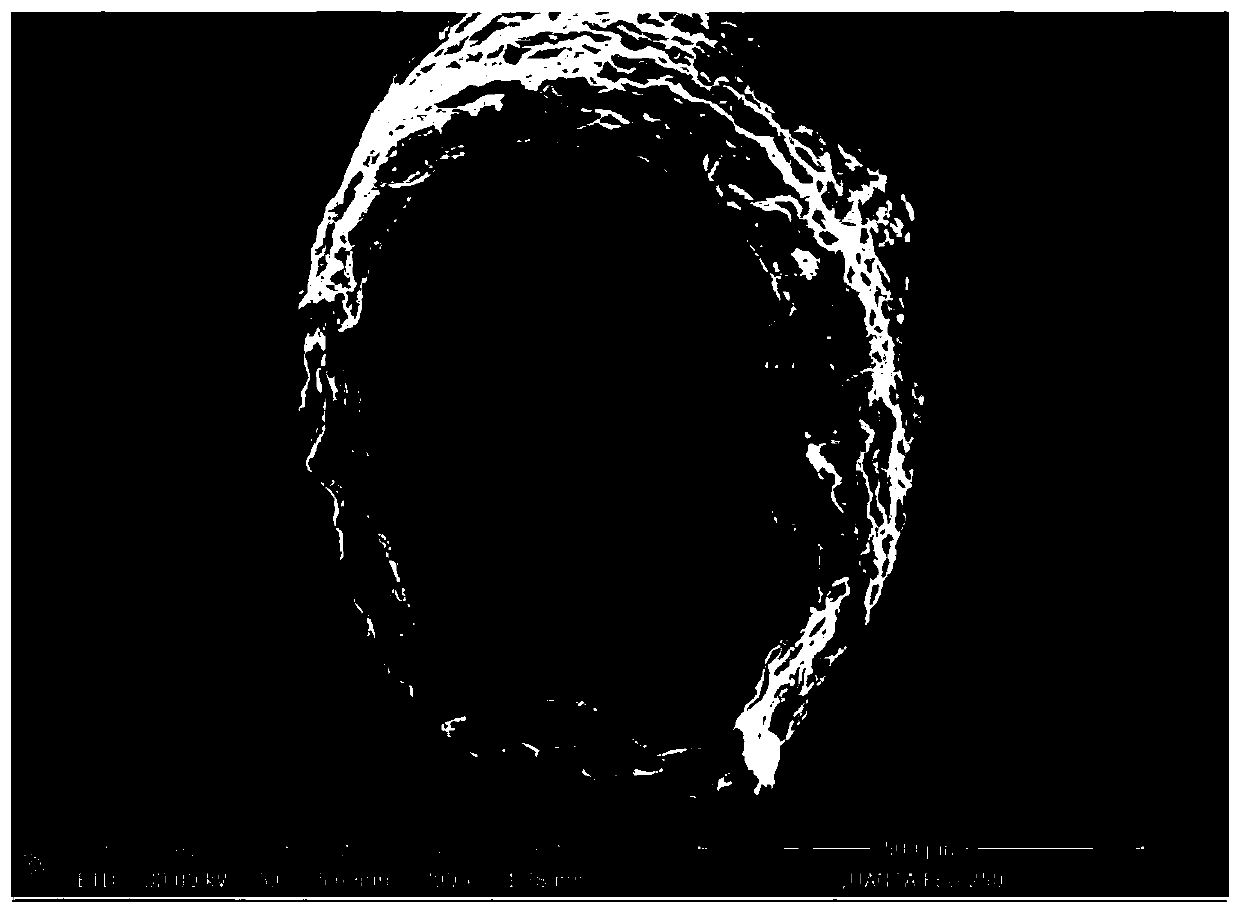

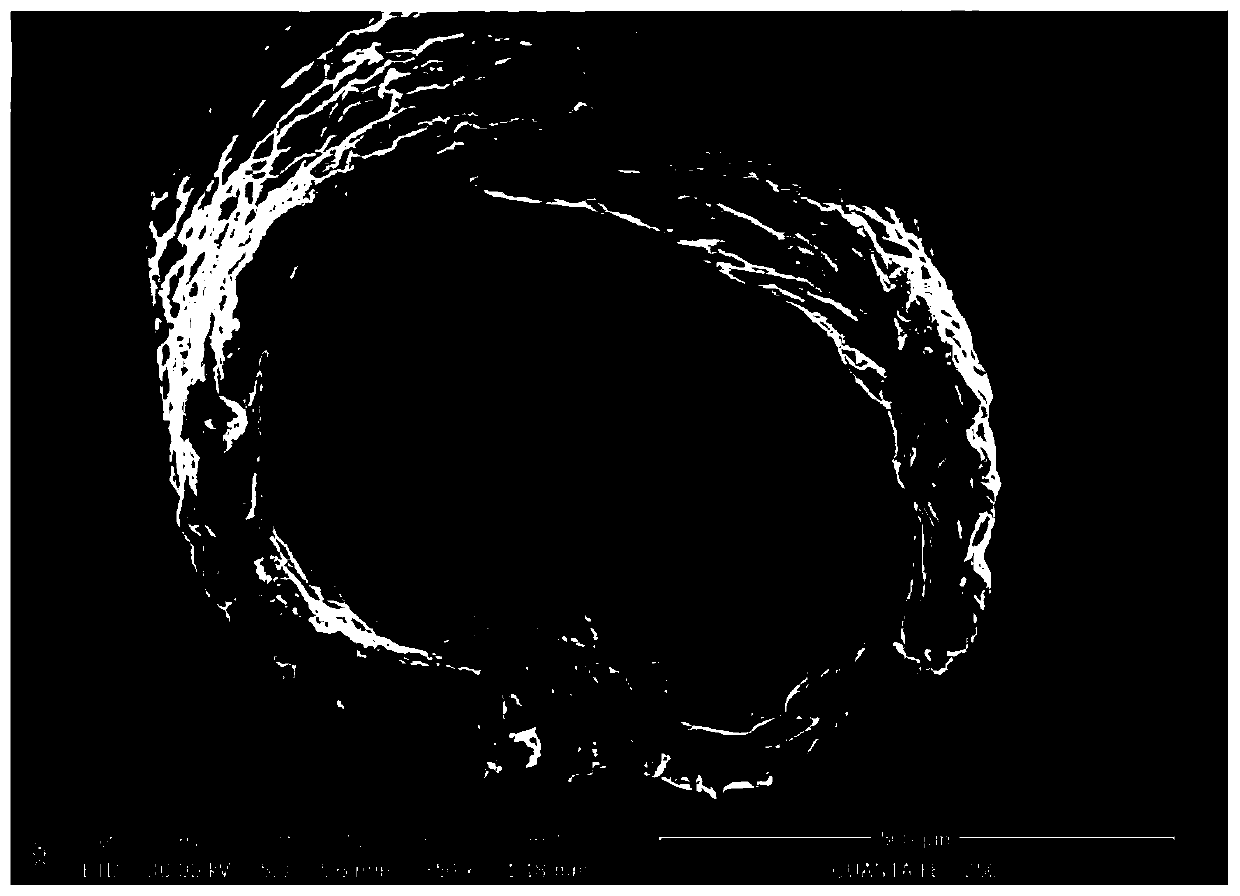

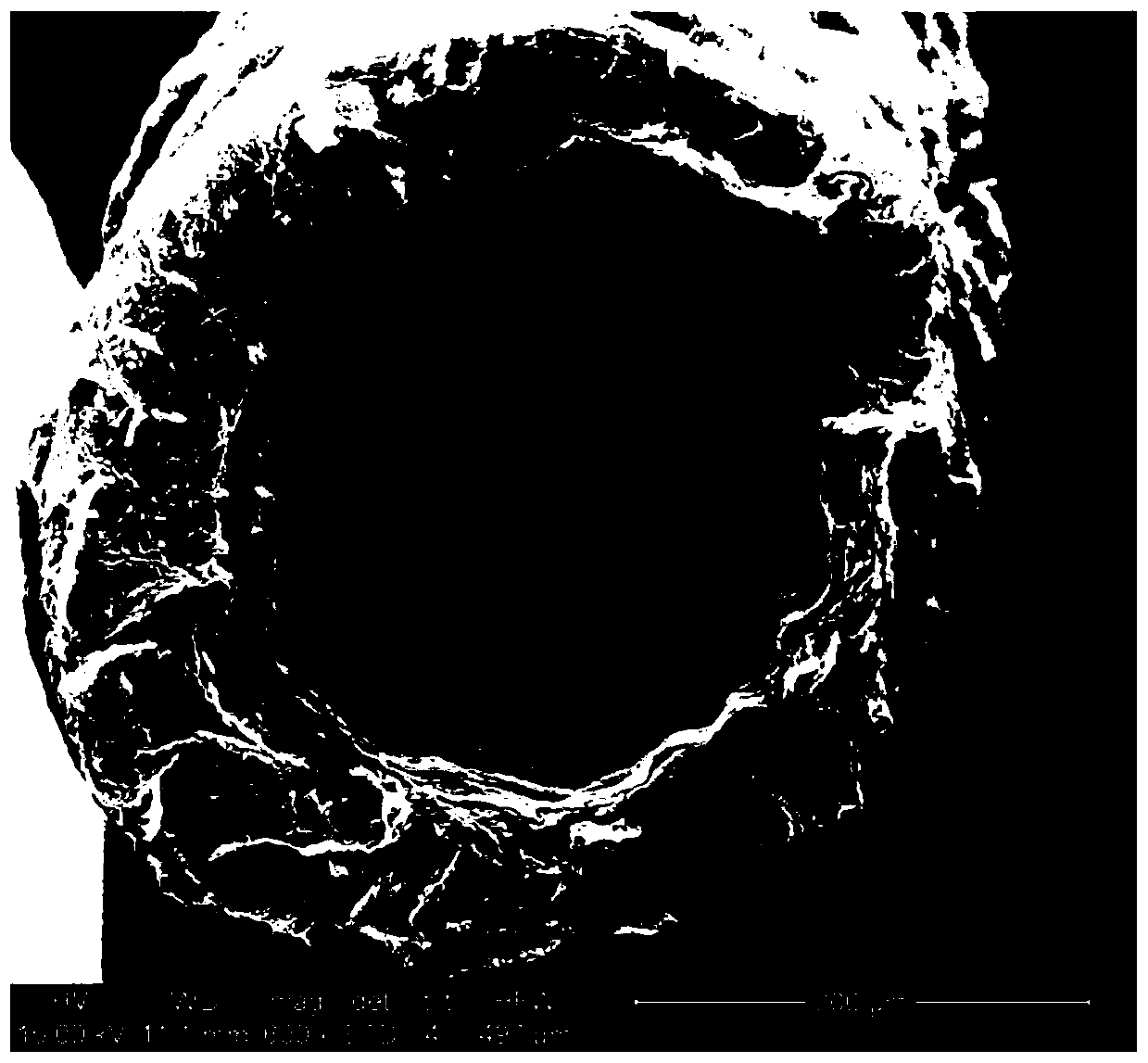

[0126] The scanning electron microscope photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com